Abstract

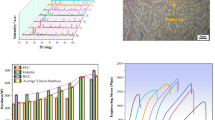

Using thermochemical treatments, boronized layers were successfully prepared on Al0.25CoCrFeNi high-entropy alloys (HEAs). The thickness of the boronized layers ranged widely from 20 to 50 µm, depending on the heat treatment time. Boronizing remarkably improved the surface hardness from HV 188 to HV 1265 after treating at 900°C for 9 h. Moreover, boronizing enhanced the yield strength of HEAs from 195 to 265 MPa but deteriorated the tensile ductility. Multiple crackings in the boride layers significantly decreased the plasticity. The insufficient work-hardening capacity essentially facilitated the plastic instability of the boronized HEAs. With decreasing substrate thickness, the fracture modes gradually transformed from dimples to quasi-cleavage and eventually to cleavage.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Jin, J.Y. Gan, T.S. Chen, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured high-entropy alloy with multiple principal element: Novel alloy design concepts and outcomes, Adv. Eng. Mater., 6(2004), No. 5, p. 299.

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Micro-structural development in equiatomic multicomponent alloys, Mater. Sci. Eng. A, 375–377(2004), p. 213.

Y. Zhang, J.W. Qiao, and P.K. Liaw, A brief review of high entropy alloys and serration behavior and flow units, J. Iron Steel Res. Int., 23(2016), No. 1, p. 2.

D.B. Miracle and O.N. Senkov, A critical review of high entropy alloys and related concepts, Acta Mater., 122(2017), p. 448.

M.C. Gao, J.W. Yeh, P.K. Liaw, and Y. Zhang, High-Entropy Alloys: Fundamentals and Applications, Springer, Cham, 2016.

L.J. Zhang, Z.K. Jiang, M.D. Zhang, J.T. Fan, D.J. Liu, P.F. Yu, G. Li, and R.P. Liu, Effect of solid carburization on the surface microstructure and mechanical properties of the equiatomic CoCrFeNi high-entropy alloy, J. Alloys Compd., 769(2018), p. 27.

A. Nishimoto, T. Fukube, and T. Maruyama, Microstructural, mechanical, and corrosion properties of plasma-nitrided CoCrFeMnNi high-entropy alloys, Surf. Coat. Technol., 376(2019), p. 52.

Z.H. Xia, M. Zhang, Y. Zhang, Y. Zhao, P.K. Liaw, and J.W. Qiao, Effects of Ni-P amorphous films on mechanical and corrosion properties of Al0.3CoCrFeNi high-entropy alloys, Intermetallics, 94(2018), p. 65.

J.X. Hou, M. Zhang, H.J. Yang, J.W. Qiao, and Y.C. Wu, Surface strengthening in Al0.25CoCrFeNi high-entropy alloy by boronizing, Mater. Lett., 238(2019), p. 258.

B.B. Straumal, A.S. Gornakova, O.A. Kogtenkova, S.G. Protasova, V.G. Sursaeva, and B. Baretzky, Continuous and discontinuous grain-boundary wetting in ZnxAl1−x, Phys. Rev. B: Condens. Matter., 78(2008), No. 5, art. No. 054204.

C. Meriç, S. Sahin, and S.S. Yilmaz, Investigation of the effect on boride layer of powder particle size used in boronizing with solid boron-yielding substances, Mater. Res. Bull., 35(2000), No. 13, p. 2165.

H.J. Hunger and G. Trute, Boronizing to produce wear-resistant surface layers, Heat Treat. Met., 21(1994), No. 2, p. 31.

Y. Soydan, S. Köksal, A. Demirer and V. Çelik, Sliding friction and wear behavior of pack-boronized AISI 1050. 4140, and 8620 steels, Tribol. Trans., 51(2008), No. 1, p. 74.

T. Takasugi and O. Izumi, Surface strengthening in aluminium single crystals coated with evaporated films, Acta Metall., 24(1976), No. 12, p. 1107.

T. Takasugi and O. Izumi, Surface strengthening in aluminium single crystals coated with electro-deposited nickel film, Acta Metall., 23(1975), No. 9, p. 1111.

J.X. Hou, M. Zhang, S.G. Ma, P.K. Liaw, Y. Zhang, and J.W. Qiao, Strengthening in A10.25CoCrFeNi high-entropy alloys by cold rolling, Mater. Sci. Eng. A, 707(2017), p. 593.

Z.F. Zhang and J. Eckert, Unified tensile fracture criterion, Phys. Rev. Lett., 94(2005), No. 9, art. No. 094301.

F. Ahmed, K. Bayerlein, S.M. Rosiwal, M. Göken, and K. Durst, Stress evolution and cracking of crystalline diamond thin films on ductile titanium substrate: Analysis by micro-Raman spectroscopy and analytical modelling, Acta Mater., 59(2011), No. 14, p. 5422.

S. Frank, U.A. Handge, S. Olliges, and R. Spolenak, The relationship between thin film fragmentation and buckle formation: Synchrotron-based in situ studies and two-dimensional stress analysis, Acta Mater., 57(2009), No. 5, p. 1442.

T. Guo, Y.M. Chen, R.H. Cao, X.L. Pang, J.Y. He, and L.J. Qiao, Cleavage cracking of ductile-metal substrates induced by brittle coating fracture, Acta Mater., 152(2018), p. 77.

Y. Leterrier, J. Waller, J.A.E. Månson, and J.A. Nairn, Models for saturation damage state and interfacial shear strengths in multilayer coatings, Mech. Mater., 42(2010), No. 3, p. 326.

T. Cramer, A. Wanner, and P. Gumbsch, Energy dissipation and path instabilities in dynamic fracture of silicon single crystals, Phys. Rev. Lett., 85(2000), No. 4, p. 788.

J.R. Garcia, J.E. Fernández, J.M. Cuetos, and F.G. Costales, Fatigue effect of WC coatings thermal sprayed by HVOF and laser treated, on medium carbon steel, Eng. Fail. Anal., 18(2011), No. 7, p. 1750.

L.B. Freund, Crack propagation in an elastic solid subjected to general loading—III. Stress wave loading, J. Mech. Phys. Solids, 21(1973), No. 2, p. 47.

T. Guo, L.J. Qiao, X.L. Pang, and A.A. Volinsky, Brittle film-induced cracking of ductile substrates, Acta Mater., 99(2015), p. 273.

A. Seeger, J. Diehl, S. Mader, and H. Rebstock, Work hardening and work softening of face centred cubic metal crystals, Philos. Mag., 2(1957), No. 15, p. 323.

D.A. Hughes and N. Hansen, The microstructural origin of work hardening stages, Acta Mater., 148(2018), p. 374.

S.W. Wu, G. Wang, J. Yi, Y.D. Jia, I. Hussain, Q.J. Zhai, and P.K. Liaw, Strong grain-size effect on deformation twinning of an Al0.1CoCrFeNi high-entropy alloy, Mater. Res. Lett., 5(2017), No. 4, p. 276.

I. Gutierrez-Urrutia and D. Raabe, Grain size effect on strain hardening in twinning-induced plasticity steels, Scripta Mater., 66(2012), No. 12, p. 992.

A. Rohatgi, K.S. Vecchio, and G.T. Gray, The influence of stacking fault energy on the mechanical behavior of Cu and Cu-Al alloys: Deformation twinning work hardening and dynamic recovery, Metall. Mater. Trans. A, 32(2001), No. 1, p. 135.

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, and C.T. Liu, Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases, Acta Mater., 116(2016), p. 332.

I. Baker, F.L. Meng, M. Wu, and A. Brandenberg, Recrystallization of a novel two-phase FeNiMnAlCr high entropy alloy, J. Alloys Compd., 656(2016), p. 458.

Acknowledgements

Jun-wei Qiao would like to acknowledge the financial support from National Key Laboratory for Remanufacturing, Academy of Armored Forces Engineering (No. 61420050204) and the Transformation of Scientific and Technological Achievements Programs of Higher Education Institutions in Shanxi, China (No. 2019BY044), and Jinxiong Hou would like to acknowledge the financial support from the Graduate Science and Technology Innovation Fund Project of Shanxi, China (No. 2019BY044).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou, Jx., Fan, J., Yang, Hj. et al. Deformation behavior and plastic instability of boronized Al0.25CoCrFeNi high-entropy alloys. Int J Miner Metall Mater 27, 1363–1370 (2020). https://doi.org/10.1007/s12613-020-1967-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-1967-6