Abstract

Thick coatings, up to few microns, of the active material are necessary for the preparation and commercialization of electrode materials for energy storage applications, as thin layers of active material drains out of the current collector after a few cycles. Moreover, larger mass loading of the active material is required for high energy density pseudocapacitor applications as more active material involves more redox reactions to store large amount of charge. This study reports thick electrodeposits of vanadium pentoxide (V2O5) on nickel foam substrate and its evaluation as supercapacitor electrode material. Vanadium pentoxide with thickness of 3–5 μm were successfully electrodeposited (potentiostatically and galvanostatically) on metallic nickel foam to obtain potentiostatically electrodeposited V2O5 on nickel foam (PE-V2O5Ni) and galvanostatically electrodeposited V2O5 on nickel foam (GE-V2O5Ni), respectively. The PE-V2O5Ni electrode with layered morphologies exhibits more charge storage and discharge capability than spherically dense morphologies of GE-V2O5Ni electrodes. The synthesized electrode materials were structurally, morphologically and chemically characterized through X-ray diffractometer, X-ray photoelectron spectroscopy, scanning electron microscopy and energy dispersive X-ray spectroscopy. The PE-V2O5Ni and GE-V2O5Ni exhibited gravimetric capacitance of 657 and 421 F g−1 with tremendous stability in the polypropylene carbonate electrolyte.

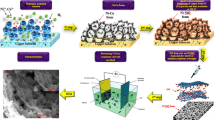

Graphic abstract

Similar content being viewed by others

References

Sathiya M, Prakash A, Ramesha K, Tarascon J M and Shukla A K 2011 J. Am. Chem. Soc. 133 16291

Simon P and Gogotsi Y 2008 Nat. Mater. 7 845

Chen Z, Augustyn V, Wen J, Zhang Y, Shen M et al 2011 Adv. Mater. 23 791

Yang L, Cheng S, Ding Y, Zhu X, Wang L and Liu M 2011 Nano Lett. 12 321

Omar S, Numan A, Duraisamy N, Ramly M M and Ramesh S 2017 Electrochim. Acta 227 41

Trasatti S and Kurzweil P 1994 Platin. Met. Rev. 38 46

Xiao J, Wan L, Yang S, Xiao F and Shuai W 2014 Nano Lett. 14 831

Wang H, Yi H, Chen X et al 2014 J. Mater. Chem. A 2 1165

Li Y, Xie H, Wang J et al 2011 Mater. Lett. 65 403

Kuo L and Wu L 2003 Electrochem. Solid-State Lett. 6 85

Wu L, Wang Y, Han Y, Wu S et al 2003 J. Power Sources 113 173

Liu C, Pell G et al 1999 Electrochim. Acta 44 2829

Li N, Chen Z, Ren W, Li F et al 2012 Proc. Natl. Acad. Sci. USA 109 17360

Liu L, Yao T, Tan X, Li Q, Wang Z et al 2012 Small 8 3752

Cao A M, Hu J S, Liang H P et al 2005 Angew. Chemie Int. Ed. 44 4391

Nagaraju H, Wang Q, Beaujuge P et al 2014 J. Mater. Chem. A 2 17146

Sahu V, Goel S, Tomar A K, Singh G et al 2017 Electrochim. Acta 230 255

Vernardou D, Pemble M E, Sheel D W et al 2006 Chem. Vap. Depos. 12 263

Vernardou D, Spanakis E, Kenanakis G, Koudoumas E et al 2010 Mater. Chem. Phys. 124 319

El Mandouh Z S and Selim M S 2000 Thin Solid Films 371 259

Lee J W and Pyun S I 2003 J. Power Sources 119 760

Hu C C, Huang C M et al 2008 J. Power Sources 185 1594

Lee J K, Kim G P, Song I K et al 2009 Electrochem. Commun. 11 1571

Li J M, Chang K H and Hu C C 2010 Electrochem. Commun. 12 1800

Ghosh A, Ra E J, Jin M, Jeong H K et al 2011 Adv. Funct. Mater. 21 2541

Ye S, Feng J and Wu P 2013 ACS Appl. Mater. Interfaces 5 7122

Gujar T P, Kim W Y, Puspitasari I, Jung K D and Joo O S 2007 Int. J. Electrochem. Sci. 2 666

Liang K, Tang X, Hu W, Yang Y et al 2016 ChemElectroChem 3 704

Huang C M, Hu C C, Chang K H, Li J M and Li Y F 2009 J. Electrochem. Soc. 156 667

Bai M H, Liu T Y, Luan F, Li Y et al 2014 J. Mater. Chem. A 2 10882

Scherer M R, Li L, Cunha P M et al 2012 Adv. Mater. 24 1217

Ingole R S and Lokhande B J 2017 J. Mater. Sci.: Mater. Electron. 28 10951

Vernardou D, Spanakis E, Katsarakis N, et al 2014 Adv. Mater. Lett. 5 569

Gu L, Wang Y, Lu R et al 2014 J. Mater. Chem. A 2 7161

Lang X, Hirata A, Fujita T and Chen M 2011 Nat. Nanotechnol. 6 232

Lindström H, Södergren S, Solbrand A and Rensmo H 1997 J. Phys. Chem. B 101 7717

Kuwabata S, Masui S, Tomiyori H et al 2000 Electrochim. Acta 46 91

Saravanakumar B, Purushothaman K K and Muralidharan G 2012 ACS Appl. Mater. Interfaces 4 4484

Purushothaman K K, Saravanakumar B, Muralidharan G et al 2017 Mater. Technol. 32 584

Huang G, Li C, Sun X et al 2017 New J. Chem. 41 8977

Shao L, Wu K, Lin X, Shui M, et al 2014 Ceram. Int. 40 6115

Armer C F, Lübke M, Reddy M V, Darr J A et al 2017 J. Power Sources 353 40

Zhai T, Liu H, Li H, Fang X et al 2010 Adv. Mater. 22 2547

Acknowledgment

We acknowledge the Higher Education Commission of Pakistan for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

AAMIR, A., AHMAD, A., KHAN, Y. et al. Electrodeposited thick coatings of V2O5 on Ni foam as binder free electrodes for supercapacitors. Bull Mater Sci 43, 273 (2020). https://doi.org/10.1007/s12034-020-02249-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-02249-6