Abstract

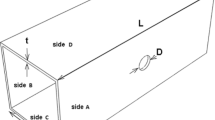

In many industries, it is necessary to use structures that exhibit a proper stability against the design loads and depreciate the energy in a controlled manner. In this study, the energy absorption characteristics of thin-walled structures with rectangular cross sections are investigated under the quasi-static loading. The section of structures has a different aspect ratio, and in all of them, an elliptical cutout with a different diameter ratio exists on the larger side. In all instances, the area of the cross section and cutout is constant. Hence, an experimental design with two design parameters consisting of the shell aspect ratio and the diameter ratio of the cutout was conducted by applying the central composite design method. Energy absorption parameters were modeled using the artificial neural network and the response surface method. A systematic crashworthiness study was carried out with a multi-objective optimization design using the genetic algorithm. The results showed that the optimal amount of the specific energy absorption was 14.48 kJ/kg and the optimal amount of the peak crushing load was 37.77 kN which was obtained in the aspect ratio of 1 and the diameter ratio of 0.7. The validity of the results was confirmed by empirical experiments.

Similar content being viewed by others

References

Sun G, Pang T, Xu C, Zheng G, Song J (2017) Energy absorption mechanics for variable thickness thin-walled structures. Thin Walled Struct 118:214–228. https://doi.org/10.1016/j.tws.2017.04.004

Dadrasi A, Beynaghi M, Fooladpanjeh S (2019) Crashworthiness of thin-walled square steel columns reinforced based on fractal geometries. Trans Indian Inst Met 72:215–225. https://doi.org/10.1007/s12666-018-1475-9

Chen C, Zhao S, Cui M, Han X, Fan S, Zhao X (2018) Comparative investigation of auxiliary processes for increasing the strength of clinched joints. Proc Inst Mech Eng Part E J Process Mech Eng 232:165–172. https://doi.org/10.1177/0954408916686998

Xiao Y, Yin H, Fang H, Wen G (2016) Crashworthiness design of horsetail-bionic thin-walled structures under axial dynamic loading. Int J Mech Mater Des 12:563–576. https://doi.org/10.1007/s10999-016-9341-6

Ha NS, Lu G, Xiang X (2018) High energy absorption efficiency of thin-walled conical corrugation tubes mimicking coconut tree configuration. Int J Mech Sci 148:409–421. https://doi.org/10.1016/j.ijmecsci.2018.08.041

Firouzi M, Niknejad A, Ziaee S, Rahim M (2018) Optimization of H-shaped thin-walled energy absorber by Taguchi method and a new theoretical estimation for its energy absorption. Thin Walled Struct 131:33–44. https://doi.org/10.1016/j.tws.2018.06.027

Hong W, Fan H, Xia Z, Jin F, Zhou Q, Fang D (2014) Axial crushing behaviors of multi-cell tubes with triangular lattices. Int J Impact Eng 63:106–117. https://doi.org/10.1016/j.ijimpeng.2013.08.007

Song J, Chen Y, Lu G (2013) Light-weight thin-walled structures with patterned windows under axial crushing. Int J Mech Sci 66:239–248. https://doi.org/10.1016/j.ijmecsci.2012.11.014

Nagel GM, Thambiratnam DP (2004) Dynamic simulation and energy absorption of tapered tubes under impact loading. Int J Crashworthiness 9:389–399. https://doi.org/10.1533/ijcr.2004.0298

Ming S, Zhou C, Li T, Song Z, Wang B (2019) Energy absorption of thin-walled square tubes designed by kirigami approach. Int J Mech Sci 157–158:150–164. https://doi.org/10.1016/j.ijmecsci.2019.04.032

Sun G, Pang T, Fang J, Li G, Li Q (2017) Parameterization of criss-cross configurations for multiobjective crashworthiness optimization. Int J Mech Sci 124–125:145–157. https://doi.org/10.1016/j.ijmecsci.2017.02.027

Bigdeli A, Nouri MD (2019) A crushing analysis and multi-objective optimization of thin-walled five-cell structures. Thin Walled Struct 137:1–18. https://doi.org/10.1016/j.tws.2018.12.033

Baroutaji A, Gilchrist MD, Smyth D, Olabi AG (2015) Crush analysis and multi-objective optimization design for circular tube under quasi-static lateral loading. Thin Walled Struct 86:121–131. https://doi.org/10.1016/j.tws.2014.08.018

Fang J, Gao Y, Sun G, Zheng G, Li Q (2015) Dynamic crashing behavior of new extrudable multi-cell tubes with a functionally graded thickness. Int J Mech Sci 103:63–73. https://doi.org/10.1016/j.ijmecsci.2015.08.029

Saxena R, Siddique S, Gupta T, Sharma RK, Chaudhary S (2018) Impact resistance and energy absorption capacity of concrete containing plastic waste. Constr Build Mater 176:415–421. https://doi.org/10.1016/j.conbuildmat.2018.05.019

Akhondizadeh M, Rezaeizadeh M (2019) Effect of specimen size and ball size on breakage throughput in the drop-weight test. Proc Inst Mech Eng Part E J Process Mech Eng 233:202–210. https://doi.org/10.1177/0954408918765293

Hosseini SM, Shariati M (2018) Experimental analysis of energy absorption capability of thin-walled composite cylindrical shells by quasi-static axial crushing test. Thin Walled Struct 125:259–268. https://doi.org/10.1016/j.tws.2018.01.026

Dadrasi A, Alavi Gharebagh A, Fooladpanjeh S (2016) Modeling the energy absorption characteristics of free and top- constrained frusta under axial impact loading. In: 4th International conference on science and engineering

Kumar V, Iqbal MA, Mittal AK (2018) Study of induced prestress on deformation and energy absorption characteristics of concrete slabs under drop impact loading. Constr Build Mater 188:656–675. https://doi.org/10.1016/j.conbuildmat.2018.08.113

Chen J, Fang H, Liu W, Zhu L, Zhuang Y, Wang J, Han J (2018) Energy absorption of foam-filled multi-cell composite panels under quasi-static compression. Compos B Eng 153:295–305. https://doi.org/10.1016/j.compositesb.2018.08.122

Deng X, Liu W (2019) Experimental and numerical investigation of a novel sandwich sinusoidal lateral corrugated tubular structure under axial compression. Int J Mech Sci 151:274–287. https://doi.org/10.1016/j.ijmecsci.2018.11.010

Wang Y, Zhai X, Yan J, Ying W, Wang W (2018) Experimental, numerical and analytical studies on the aluminum foam filled energy absorption connectors under impact loading. Thin Walled Struct 131:566–576. https://doi.org/10.1016/j.tws.2018.07.056

Ledford N, May M (2020) Modeling of multimaterial hybrid joints under high-rate loading. Proc Inst Mech Eng Part E J Process Mech Eng. https://doi.org/10.1177/0954408920919012

Gan N, Yao S, Dong H, Xiong Y, Liu D, Pu D (2018) Energy absorption characteristics of multi-frusta configurations under axial impact loading. Thin Walled Struct 122:147–157. https://doi.org/10.1016/j.tws.2017.10.011

Fang J, Gao Y, Sun G, Qiu N, Li Q (2015) On design of multi-cell tubes under axial and oblique impact loads. Thin Walled Struct 95:115–126. https://doi.org/10.1016/j.tws.2015.07.002

Meng Z, Can-Gang W, Jian-Qiao L, Shu-Cai X, Xiong Z (2015) The energy absorption of bamboo under dynamic axial loading. Thin Walled Struct 95:255–261. https://doi.org/10.1016/j.tws.2015.06.017

Pol MH, Golshan NR (2019) Experimental investigation of parameters affected on behavior of composite tubes under quasi static and dynamic axial loading. Compos B Eng 163:471–486. https://doi.org/10.1016/j.compositesb.2019.01.011

Montazeri S, Elyasi M, Moradpour A (2018) Investigating the energy absorption, SEA and crushing performance of holed and grooved thin-walled tubes under axial loading with different materials. Thin Walled Struct 131:646–653. https://doi.org/10.1016/j.tws.2018.07.024

Shariati M, Farzi G, Dadrasi A (2015) Mechanical properties and energy absorption capability of thin-walled square columns of silica/epoxy nanocomposite. Constr Build Mater 78:362–368. https://doi.org/10.1016/j.conbuildmat.2015.01.031

Alavi Nia A, Fallah Nejad K, Badnava H, Farhoudi HR (2012) Effects of buckling initiators on mechanical behavior of thin-walled square tubes subjected to oblique loading. Thin Walled Struct 59:87–96. https://doi.org/10.1016/j.tws.2012.03.002

Yang K, Xu S, Shen J, Zhou S, Xie YM (2016) Energy absorption of thin-walled tubes with pre-folded origami patterns: numerical simulation and experimental verification. Thin Walled Struct 103:33–44. https://doi.org/10.1016/j.tws.2016.02.007

ASTM E8 (2010) ASTM E8/E8M standard test methods for tension testing of metallic materials 1. Ann Book of ASTM Stand 4:1–27. https://doi.org/10.1520/E0008

Dadrasi A, Farzi GA, Shariati M, Fooladpanjeh S, Parvaneh V (2020) Experimental study and optimization of fracture properties of epoxy-based nano-composites: effect of using nano-silica by GEP, RSM, DTM and PSO. Eng Fract Mech 232:107047. https://doi.org/10.1016/j.engfracmech.2020.107047

Baranitharan P, Ramesh K, Sakthivel R (2019) Measurement of performance and emission distinctiveness of Aegle marmelos seed cake pyrolysis oil/diesel/TBHQ opus powered in a DI diesel engine using ANN and RSM. Meas J Int Meas Confed 144:366–380. https://doi.org/10.1016/j.measurement.2019.05.037

Dadrasi A, Gharebagh AA, Fooladpanjeh S (2016) Optimization of mechanical properties of rubber/silica/epoxy nanocomposites by RSM. Int J Innov Res Sci Eng Technol 5(6):11677–11688. https://doi.org/10.15680/IJIRSET.2015.0506281

Yu C, Chen J, Zeng M, Gao B (2019) Numerical study on turbulent heat transfer performance of a new parallel-flow shell and tube heat exchanger with sinusoidal wavy tapes using RSM analysis. Appl Therm Eng 150:875–887. https://doi.org/10.1016/j.applthermaleng.2019.01.043

Bahrami M, Akbari M, Bagherzadeh SA, Karimipour A, Afrand M, Goodarzi M (2019) Develop 24 dissimilar ANNs by suitable architectures and training algorithms via sensitivity analysis to better statistical presentation: measure MSEs between targets and ANN for Fe–CuO/Eg–Water nanofluid. Phys A 519:159–168. https://doi.org/10.1016/j.physa.2018.12.031

Dadrasi A, Alavi Gharahbag A, Fooladpanjeh S (2016) Modeling the mechanical properties of composites reinforced by Silica nanoparticles through response surface method and regression tree method. In: 3rd International conference on science and engineering

Dadrasi A, Gharebagh AA, Fooladpanjeh S (2016) Prediction and optimization of fracture properties of nano-silica/epoxy composites using ANN, regression tree and RSM. In: International conference on mechanical engineering

Ismail HY, Shirazian S, Skoretska I, Mynko O, Ghanim B, Leahy JJ, Walker GM, Kwapinski W (2019) ANN-Kriging hybrid model for predicting carbon and inorganic phosphorus recovery in hydrothermal carbonization. Waste Manag 85:242–252. https://doi.org/10.1016/j.wasman.2018.12.044

Xiang Y, Gou L, He L, Xia S, Wang W (2018) A SVR–ANN combined model based on ensemble EMD for rainfall prediction. Appl Soft Comput J 73:874–883. https://doi.org/10.1016/j.asoc.2018.09.018

Dadrasi A, Fooladpanjeh S, Alavi Gharahbagh A (2019) Interactions between HA/GO/epoxy resin nanocomposites: optimization, modeling and mechanical performance using central composite design and genetic algorithm. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-019-1564-7

Zhang J, Zhao L, Deng S, Xu W, Zhang Y (2017) A critical review of the models used to estimate solar radiation. Renew Sustain Energy Rev 70:314–329. https://doi.org/10.1016/j.rser.2016.11.124

Zare Naghadehi M, Samaei M, Ranjbarnia M, Nourani V (2018) State-of-the-art predictive modeling of TBM performance in changing geological conditions through gene expression programming. Meas J Int Meas Confed 126:46–57. https://doi.org/10.1016/j.measurement.2018.05.049

Dadrasi A, Alavi-Gharebagh A, Fooladpanjeh S (2014) Prediction and optimization of fracture properties of nano-silica/epoxy composites using response surface method abstract. Am J Oil Chem Technol 2:1–10

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dadrasi, A., Albooyeh, A.R., Fooladpanjeh, S. et al. RSM and ANN modeling of the energy absorption behavior of steel thin-walled columns: a multi-objective optimization using the genetic algorithm. J Braz. Soc. Mech. Sci. Eng. 42, 563 (2020). https://doi.org/10.1007/s40430-020-02643-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02643-5