Abstract

Manufacturing remains one of the most energy intensive sectors, additionally, the energy used within buildings for heating, ventilation and air conditioning (HVAC) is responsible for almost half of the UK’s energy demand. Commonly, these are analysed in isolation from one another. Use of machine learning is gaining popularity due to its ability to solve non-linear problems with large data sets and little knowledge about relationships between parameters. Such models use relationships between inputs and outputs to make further predictions on unseen data, without requiring any understanding regarding the system, making them highly suited to dealing with the stochastic data sets found in a manufacturing environment. This has been seen in literature for determining electrical energy demand for residential or commercial buildings, rather than manufacturing environments. This study proposes a novel method of coupling simulation with machine learning to predict indoor workshop conditions and building energy demand, in response to production schedules, outdoor conditions, building behaviour and use. Such predictions can subsequently allow for more efficient management of HVAC systems. Based upon predicted energy consumption, potential spikes were identified and manufacturing schedules subsequently optimised to reduce peak energy demand. Coupling simulation techniques with machine learning algorithms eliminates the requirement for costly and intrusive methods of data collection, providing a method of predicting and optimising building energy consumption in the manufacturing sector.

Similar content being viewed by others

1 Introduction

With increased industrial demand, rising material and energy prices, along with need to ensure product quality and productivity, manufacturing companies are required to develop strategies to reduce the energy consumption of their facility, or face potential penalties from governments for C02 emissions as well as consequences on company image. Facilities also have complex high energy consuming heating, ventilation and air conditioning (HVAC) systems to regulate workshop conditions as well as the high-powered machining equipment. Buildings and the manufacturing industry are responsible for 40% and 42% of the world’s energy consumption respectively (Harish and Kumar 2016; Agency IE 2017).

HVAC systems have a reactive based control system, based upon CO2 levels and air temperature, aiming to provide thermal comfort to occupants. Such systems react to combat changes in environmental conditions as and when they occur, and are ideal for office and domestic environments.

Manufacturing facility environmental conditions however, are heavily influenced by fluctuating heat and moisture gains from machinery, impacting thermal comfort of occupants and influencing quality control of condition sensitive production. HVAC control can therefore be vital for production quality control, and manufacturing processes should be considered in control of HVAC systems.

Quantification and prediction of waste heat within a facility poses the opportunity for heat recovery, however in the case of highly fluctuating and stochastic thermal energy flows within manufacturing facilities, such heat recovery is difficult and the resulting waste heat is distributed to the surrounding environment, affecting indoor climatic conditions.

Heat gain from equipment is dependent upon production demand, and how this influences indoor conditions is dependent upon facility operation and design. Indoor climatic conditions are influenced by thermal emissions from machinery, radiation from windows in the facility, solar gains on the surrounding walls of the facility, HVAC operation and occupant behaviour, as well as required optimal HVAC set points. Furthermore, building standards and regulations such as ASHRAE 55 do not give climate sensitive guidelines or recommendations for HVAC set points (ASHRAE 2017) in manufacturing facilities.

This study aims to provide a method of predicting indoor climatic conditions, such as air temperature and relative humidity, as well as building energy demand, in response to production schedules, outdoor conditions, building behaviour and use, to allow for more efficient management of HVAC systems. Predicted energy consumption and indoor conditions were used to optimise a manufacturing schedule in order to reduce spikes in energy consumption.

Prediction of building energy demand allows shift managers to understand the impact of machining on facility energy consumption and the surrounding production environment, and allow for better decision-making and shift pattern management in order to reduce spikes in energy consumption, of which can make up 30% of the monthly utility cost in manufacturing facilities (Gazprom 2017). Furthermore, increased efficiency in the management of HVAC systems ensures production conditions are constantly met for optimum product quality.

1.1 Artificial neural networks

Due to the increased size of data sets requiring analysis, the convergence of simulation and machine learning is gaining popularity due to its potential for improved data consolidation and ability to identify and observe new theories and connections between parameters.

Manufacturing and energy management systems can generate a large amount of data, of which is often stochastic, noisy and difficult to analyse and understand without suitable data management systems or algorithms. Such data is therefore highly suited to further analysis with Artificial Neural Networks (ANN’s). ANN’s are a common tool in the energy sector due to their ability to handle large datasets and determine complex relationships between variables.

There is an increase in the use of data simulators and simulation models together with ANN’s due to the increase in size of data sets. Tolk (2015) discusses the potential for improvements in data evaluation and analysis in both life and engineering sciences that the collaboration of modelling and simulation with big data and deep neural networks can bring (Fig. 1).

Collaboration of Big Data, Deep Learning and simulation (Tolk 2015)

The use of simulation can provide a methodology of generating datasets for ANN model training, avoiding the use of costly sensor system implementation, as well as providing a more flexible method of data collection. Parameters and data streams can be grouped to reduce parameters numbers, with the ability to specify data collection intervals based upon the problem specification.

This study couples machine learning with simulation of manufacturing facilities to determine impacts of production schedules on workshop environmental conditions, along with the prediction of HVAC and building energy consumption. With this energy and indoor environmental condition prediction, there is the potential to operate HVAC systems in a more efficient manner with a ‘soft start’ approach to heating and cooling systems, based on production demand, occupant behaviour and outdoor weather conditions, all of which will impact the thermal energy flows within the building.

2 Previous related work

Machine learning techniques, most commonly ANN’s, are being adopted in the building sector for prediction of electrical energy consumption (Nasr et al. 2001; González and Zamarreño 2005). These studies have focused primarily on using variables such as weather and occupancy as input variables to determine energy consumption and to ensure thermal comfort.

The first found study using ANN’s in the building sector for forecasting energy demand was by in NIzami and Al-Garni (1995), who used ANN’s to forecast electrical energy consumption based on weather data and population. The study used 7 years’ worth of data for model training and validation, and was considered adequate for energy forecasting based on the Chi square statistic. Authors also highlighted the ability of ANN’s to provide predictions with little information on relationships between input variables.

Studies found focus predominantly on energy analysis of office and residential spaces with only two studies found which forecast electricity energy use of an industrial location, one of which uses ANN’s.

Azadeh and Sohrabkhani (2006) adopted an ANN model for long term energy prediction, using a feed forward model approach along with back propagation. Metered energy data was used to both train and test the model for a period of 2 and 3 years respectively. The study highlighted the advantage of using ANN models over conventional regression techniques. A study was found in the area of un-supervised machine learning by Cupek et al. (2017) who used a k-means clustering algorithm for energy monitoring and fault detection of compressed air systems within a manufacturing environment. Using energy consumption measurements and machine behaviour observations, system state specific energy profiles were determined. No research was found on the use of machine learning for HVAC control within industrial facilities.

The convergence of simulation and machine learning is gaining popularity due to its potential for improved data consolidation and ability to identify and observe new theories and connections between parameters. This method is not widely adopted in the field of manufacturing facility energy analysis due to required implementation of sensors and actuators for constant monitoring and data collection, which may not be available for all building infrastructure. A large number of input variables are also often required.

Petri et al. (2014) looked at maintaining thermal comfort whilst reducing energy consumption though the coupling of an ANN based optimisation module with simulation. The optimisation module functions both independently and embedded within generic algorithm optimisation based modules (Fig. 2).

Energy optimisation module workflow (reproduced from (Petri et al. 2014))

The module was able to generate optimised values to specified outputs according to which set points within the building were altered. The method achieved a reduction in electrical and thermal energy consumption, along with additional system control over a 42-day period.

With enough training and based upon constant monitoring, data collection and sensor implementation, the ANN module was able to replace the simulation module in order to reduce computation time.

Neto and Fiorelli (2008) also coupled an energy simulation with a ANN model, comparing results from the analysis of a university building when forecasting building energy consumption due to external weather conditions. External dry bulb temperature, humidity and solar radiation were specified as input parameters to the ANN.

For a simulation period of 7 months, it was found that the simulation model produced a higher error of 13%, in comparison to the 10% error of the ANN. However a large number of assumptions were made in model development due to a lack of data, and is therefore a pilot study and the method is to be developed further.

Nakayama et al. (2002) utilised simulation as an optimisation tool, using radial basis function networks to predict objective functions, with genetic algorithms used to search for the optimal value of the predicted objective function.

Peak energy demand shaving is a common theme in literature, with studies adopting the concept of energy storage, (Baeten et al. 2017), use of renewable technology, (Jurasz and Campana 2019), and use reducing energy intensive equipment start up times (Voet et al. 2018). Where electricity prices are uncertain or variable, optimisation tools have been adopted in order to maximise profits (Zhang and Ponnambalam 2006).

Very few found studies address the coupling of manufacturing production requirements with the HVAC system, with no studies found adopting the use of predictive techniques to determine energy requirements of the facility and improve HVAC system efficiency and control.

This paper discusses the prediction of facility energy requirements based on production environmental condition and thermal comfort requirements, manufacturing scheduling and weather conditions, allowing for more effective energy management of production environments and HVAC systems.

3 Proposed method

In this study, a dynamic time-based thermal and building energy modelling software, IES-VE (2018), was used to build a manufacturing facility environment in order to obtain energy profiles and workshop conditions. The modelling software accounted for occupant and lighting schedules, production schedules, weather data, HVAC and building regulations.

Heat sources can be simulated, defined by heat gain or surface temperature, which allows for the modelling of manufacturing equipment and their heat gain profiles. Thus IES-VE allows for modelling of manufacturing equipment alongside the HVAC system and building. This model was validated using a DES (discrete event simulation) model and metered data from the manufacturing facility prior to generating data required to train the ANN. Based upon predicted energy consumption, spikes in energy consumption were identified. Thus, manufacturing schedules were optimised in order to reduce such spikes in energy consumption and provide a levelized energy profile for the facility.

Figure 3 displays the modelling method.

3.1 Artificial neural network for energy predictions

In order to predict future building environment conditions and energy consumption, an ANN was built, using results from the simulation study as training data.

Inputs to the model included outdoor conditions, such as air temperature, wind speed, cloud cover and humidity, which will all influence the thermal profile of the building. Machine use for all equipment on the shop floor were also provided as an input, with data intervals of 30 min.

This latter input was provided through the use of machine power profiles, with specific energy consumption in kilowatts at 30-minute intervals used to create the profiles.

Outputs from the models were predictions on building energy consumption, as well as predictions on internal conditions in order to provide the data required to make decisions regarding HVAC control. The main outputs of interest were internal humidity of the workshop environment, air temperature and electricity consumption. Waste heat from manufacturing processes was also predicted.

The neural network models were written in Python, adopting the use of libraries such as scikit-learn (2020) which provided machine learning tools and frameworks.

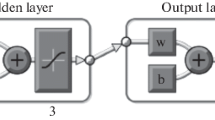

Feed forward multi-layer perceptron regression model were created, as this supervised model can learn a non-linear approximator given a set of x features, and a target y.

The models used in this study featured one hidden layer. A study on energy forecasting models reviewed the use of ANN’s for forecasted electrical load, renewable energy use and energy demand and highlighted that out of the 194 models reviewed, 83% of these utilised one hidden layer in the model, with 17% using 2 hidden layers (Debnath and Mourshed 2018). The number of neurons in the input layer was equal to that of the number of inputs, the number in the output layer equal to the number of target variables, however the number of neurons in the hidden layer used a trial and error approach.

The hyperbolic tan function (tanh), logistic and rectified linear unit function (ReLu) activation functions were tested for suitability. The ReLu function (1) was chosen as the best activation function for the models purpose, based on accuracy results, and the applicability of the function to the model.

The ReLu model is non-linear and can easily back propagate the errors as well as holding the advantage of not activating all the neurons at the same time, allowing for quicker computation. Furthermore, ReLu does not activate negative inputs.

The data required standardisation in order to ensure model convergence. The aim of data standardisation and scaling is to ensure features more or less represent normally distributed data. Data before and after standardisation were visually analysed in order to determine the distribution of the data and therefore the most appropriate method for the model.

Parameters utilised in the neural network model can be found in Appendix A.

4 Case study

A thermal energy simulation of a 6400 sq.m manufacturing facility in Yorkshire, UK, which focuses machining research, was run in IES-VE, utilising the manufacturing view component tool to account for energy as well as heat and moisture gains to the environment due to manufacturing processes. For this facility, manufacturing equipment is predominantly manually controlled with production schedules varying according to customer demand. The model was split into 59 thermal zones corresponding to rooms within the building. Individual thermal profiles and internal gains were specified for each room dependant on use and required thermal comfort thresholds. Machining schedules, worker schedules and facility usage patterns were also specified in the model.

4.1 Data acquisition

Data for the simulation was obtained through interviews and discussions with facility staff, machine bookings, schedule databases and manufacturing data booklets. Data regarding facility use was obtained through observation and interviews with staff. Historical electricity consumption data was obtained from a pre-installed sensor system. Data was available at 30 min intervals.

Building floor plans were obtained from management, and energy use for the building was obtained from pre-installed sensor systems. Weather data was obtained from the Met Office as part of the IES VE ApLocate weather and location module.

Construction material properties and building fabrics can be found in Appendix B. Boundary conditions such as HVAC system control and schedules, occupancy density and internal gains are displayed in Appendix C. Model assumptions follow manager guidelines at the site, as well as industry guidelines (CIBSE 2016).

The facility location and orientation was specified in order to determine solar gains and weather conditions.

4.2 Building model validation

The IES-VE software used to build the simulation model is predominantly used for building analysis rather than manufacturing process analysis. The tool has the ability to model equipment and respective heat flows, as well as specify machine position and schedule, however it was unknown if machining schedules and power profiles could model behaviour to the same level of accuracy as DES software. Therefore, a feasibility manufacturing energy study was run in DES software to validate the IES-VE model, which was also compared with metered data from the case study facility. Lanners WITNESS (2017) software was utilised to build the DES model of the manufacturing processes. All machining equipment with respective scheduling profiles were simulated, with data regarding idle time, standby, busy and fixed machining use specified.

The IES-VE model was found to underestimate manufacturing energy consumption by 17% in comparison to the WITNESS DES model. Trends in energy consumption from manufacturing processes for individual machines were consistent between the IES-VE and WITNESS manufacturing process models.

Due to the focus on integration of manufacturing energy flows with that of the building, rather than analysis of machining power, the manufacturing equipment modelling tool in IES-VE was used to model the machines on the shop floor. Furthermore, the DES tool did not provide detail on thermal energy flows and waste heat from equipment of which is a key variable in this study.

The second part of model validation involved a simulation of the facility with and without manufacturing equipment, and comparison of these models with metered data. Metered data was not available at component level, and therefore the total energy consumption of the facility was used for model comparison.

The building energy analysis in IES-VE, both with and without manufacturing equipment, was compared with the metered data (with equipment present) for a period of 1 year (Table 1).

The IES-VE model underestimated energy consumption by 6%, when compared to the metered data. From the validation study, it was concluded that the model was sufficient for further use, and as a training tool for neural networks.

5 Results

Thermal calculations of the building and workshop were calculated at 30-min intervals for a period of 2 months. During this time of manufacturing production, significant heat and moisture gains entered the surrounding environment, resulting in spikes in humidity, temperature and therefore energy consumption from HVAC systems due to the requirement of fans and pumps to remove moisture and heat from the air during times of high machining activity. Indoor conditions such as temperature and humidity were monitored, as well as energy consumption from all manufacturing processes (Fig. 4).

Manufacturing facilities are often charged for their spike in consumption, rather than the energy that they use, and therefore spikes in consumption can have a considerable effect on the facilities energy bill, and thus should be avoided in order to avoid additional charges for energy which is not utilised. Such a spike can be identified and avoided by determining the relationship between HVAC systems and machining schedules and processes, in order to more effectively and efficiently control the building energy management system.

To assess the accuracy of the model, R2 and the root mean squared error (RMSE) were used. RMSE was used to compare individual models throughout the optimisation process. K-fold cross validation resampling method was used to evaluate the model on the data available. For the final model, an R2 value of 0.925 and RMSE value of 5.05 was obtained.

A sensitivity analysis was performed on the data in order to determine the importance of input parameters on the outputs (Table 2). Although manufacturing demand and dry bulb temperature were found to be of higher importance than humidity, wind speed and cloud cover, these features remained within the dataset. It was concluded that these climatic features were required in order to determine the impact of seasonal variations on building energy demand and determine the impact of solar gain.

The model predicted workshop air temperature and building energy consumption with errors of 2.07 and 5.90% accuracy respectively, when presented with a new unseen dataset. This is comparable with the 10% model accuracy achieved for coupling of simulation with machine learning to forecast energy consumption based on meteorological data by Neto and Fiorelli (2008). Figure 5 displays both predicted and observed values for a period of 7 days.

A larger error of 26.8% was obtained in the prediction of relative humidity within the workshop. It was concluded that such a result was obtained as the model was not able to determine downtime of machines, and thus predicted process waste heat overnight, resulting in high predicted relative humidity overnight. The data used in the predictions was based on analysis of a 7-day period (8 h machining over 5 working days plus a 2-day weekend), and therefore contained data from variables overnight. Due to no machining activity overnight, collected process waste heat values were zero. The neural network model predicted non-zero negligible values, however due to the zero value, all these negligible data values obtained a percentage error of 100%. It was determined that as these values were obtained overnight, and are therefore not of interest, these would be excluded from further analysis. The resulting error for process waste heat during times of machining was 3.20%.

Table 3 summarises the errors for output parameters for the model.

On analysis of data, it was concluded that the time of day should be included as an input in order to determine the impact of machine downtime overnight.

Such large fluctuations in data results in higher errors in predictions, and highlights the need for further data collection in order to provide the network with more training data.

Using energy predictions based on upcoming production requirements, machining schedules were optimised in order to reduce spikes in energy consumption, and produce a smoother consumption profile to avoid the significant costs associated with energy fluctuations (Fig. 6). Machining output was monitored to ensure sufficient production output (Fig. 7).

Through the use of energy consumption prediction, spikes in energy consumption could be identified. Upon identification of these spikes, manufacturing schedules were optimised based upon process waste heat and external weather conditions, as well as job requirements. Energy intensive machining was scheduled to avoid peak mid-day temperatures in order to avoid excessive demand on HVAC systems for the removal of both excess machine waste heat and solar gains. Spikes in consumption were avoided by varying resource allocation, and ensuring jobs for a specific machine were performed in the same time slot to avoid excessive machine utilisation. The neural networks were used to predict indoor conditions associated with the optimised schedules to ensure that thermal comfort for occupants was maintained.

6 Conclusion

This study has demonstrated the importance of accounting for manufacturing equipment and demand in the analysis of building energy consumption in order to capture all interacting thermal and energy flows. The use of simulation in energy analysis is an effective tool at developing a model that is cost effective, non-intrusive, easy to modify and allows multiple scenarios to be tested.

ANNs have been used extensively for energy prediction in commercial buildings, with this study highlighting their potential in manufacturing environments to predict indoor conditions. Whilst considerable error was obtained for the prediction of relative humidity in the workshop, the power profiles model was able to predict workshop air temperature and building energy consumption to accuracies of 2.07 and 5.90% respectively.

Larger errors were obtained for parameters predicted overnight, with waste heat from machining being generated in predictions overnight, which impacted errors for the model. This suggests that the inclusion of time of day as an input parameter would increase the accuracy of predictions.

Using energy predictions based on upcoming production requirements, machining schedules were optimised to reduce spikes in energy consumption, and produced a smoother consumption profile to avoid the significant costs associated with energy fluctuations.

This is a preliminary study and further work includes model modification with additional time based input parameters, along with larger datasets to predict energy consumption to a higher accuracy. Further work is being carried out using recurrent neural networks, which are used to process sequences and are therefore commonly used for sensor measurement analysis. The production of a framework for the reduction of energy demand from HVAC systems within manufacturing is the next step in this study.

References

ASHRAE (2017) Standard 55-thermal environmental conditions for human occupancy

Agency IE (2017) Key world energy statistics 2017

Azadeh MA, Sohrabkhani S (2006) Annual electricity consumption forecasting with neural network in high energy consuming industrial sectors of Iran. Proc IEEE Int Conf Ind Technol 49:2166–2171

Baeten B, Rogiers F, Helsen L (2017) Reduction of heat pump induced peak electricity use and required generation capacity through thermal energy storage and demand response. Appl Energy 195:184–195

CIBSE (2016) Guide A-environmental design

Cupek R, Ziebinski A, Zonenberg D, Drewniak M (2017) Determination of the machine energy consumption profiles in the mass-customised manufacturing. Int J Comput Integr Manuf 00(00):1–25

Debnath KB, Mourshed M (2018) Forecasting methods in energy planning models. Renew Sustain Energy Rev 88:297–325

Gazprom (2017) The ultimate energy efficiency guide for manufacturing businesses, 2017. [Online]. https://www.gazprom-energy.co.uk/blog/the-ultimate-energy-efficiency-guide-for-manufacturing-businesses/. Accessed 07 Sep 2018

González PA, Zamarreño JM (2005) Prediction of hourly energy consumption in buildings based on a feedback artificial neural network. Energy Build 37(6):595–601

Harish VSKV, Kumar A (2016) A review on modeling and simulation of building energy systems. Renew Sustain Energy Rev 56:1272

IES-VE, “IES-VE.” [Online]. https://www.iesve.com/. Accessed 13 Nov 2018

Javeed NS, Al-Garni AZ (1995) Forecasting electric energy consumption using neural networks. Energy Policy 23(12):1097–1104

Jurasz J, Campana PE (2019) The potential of photovoltaic systems to reduce energy costs for office buildings in time-dependent and peak-load-dependent tariffs. Sustain Cities Soc 44:871–879

Lanner, “Witness Simulation Software,” 2017. [Online]. https://www.lanner.com/technology/witness-simulation-software.html. Accessed 13 Nov 2017

Nakayama H, Arakawa M, Sasaki R (2002) Simulation-based optimization using computational intelligence. Optim Eng 3:201–214

Nasr GE, Badr EA, Younes MR, Min D, Lo H, Min M (2001) Neural networks in forecasting electrical energy consumption, pp 489–492

Neto AH, Fiorelli FAS (2008) Comparison between detailed model simulation and artificial neural network for forecasting building energy consumption. Energy Build 40(12):2169–2176

Petri I, Li H, Rezgui Y, Yang C, Yuce B, Jayan B (2014) A modular optimisation model for reducing energy consumption in large scale building facilities. Renew Sustain Energy Rev 38:990–1002

Scikit-learn, “scikit learn,” 2020. [Online]. https://scikit-learn.org. Accessed 14 Dec 2018

Tolk A (2015) The next generation of modeling & simulation : integrating big data and deep learning. Summer SimulConf 9:1–8

Voet H, Garretson IC, Falk B, Schmitt RH, Linke BS (2018) Peak power load and energy costs using the example of the startup and idling of a grinding machine. Proc CIRP 69(May):324–329

Zhang JL, Ponnambalam K (2006) Hydro energy management optimization in a deregulated electricity market. Optim. Eng. 7:47–61

Acknowledgements

The authors would like to acknowledge the financial contribution provided by the Engineering and Physical Sciences Research Council (EPSRC) and the University of Strathclyde that has enabled the production of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mawson, V.J., Hughes, B.R. Coupling simulation with artificial neural networks for the optimisation of HVAC controls in manufacturing environments. Optim Eng 22, 103–119 (2021). https://doi.org/10.1007/s11081-020-09567-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11081-020-09567-y