Abstract

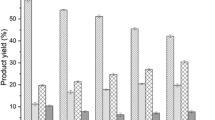

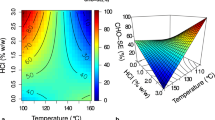

In this study, biomasses of microalgae Scenedesmus and Synechocystis species were thermochemically converted to biofuel in a fast pyrolysis process. The effect of pyrolysis temperature on the products yield was investigated. The optimal pyrolysis temperature for Scenedesmus and Synechocystis biomass was 500 °C and 600 °C, respectively, resulting in higher bio-oil yield of 35.3 wt% and 21.1 wt%. The produced bio-oil had higher high heating value (HHV) (35–40 MJ/kg) than that of beech wood source bio-oil (23–35 MJ/kg). The obtained biochar had low surface area but with considerable nitrogen, phosphorus, and other mineral content was suggested as fertilizer. It was concluded that the microalgae type and its cultivation and harvesting method affects the characteristics of the products and final energy efficiency as well. Energy efficiency assessment showed that the technology needs to be improved substantially to reduce the energy demand in cultivation, harvest, and pyrolysis step to be energy efficient.

Similar content being viewed by others

Data Availability

All of the obtained data are provided in the manuscript.

References

Trinh TN, Jensen PA, Dam-Johansen K, Knudsen NO, Sørensen HR, Hvilsted S (2013) Comparison of lignin, macroalgae, wood, and straw fast pyrolysis. Energy Fuel 27(3):1399–1409. https://doi.org/10.1021/ef301927y

Bennion EP, Ginosar DM, Moses J, Agblevor F, Quinn JC (2015) Lifecycle assessment of microalgae to biofuel: comparison of thermochemical processing pathways. Appl Energy 154:1062–1071. https://doi.org/10.1016/j.apenergy.2014.12.009

Lee RA, Lavoie J-M (2013) From first- to third-generation biofuels: challenges of producing a commodity from a biomass of increasing complexity. Anim Front 3(2):6–11. https://doi.org/10.2527/af.2013-0010

Derakhshandeh M, Tezcan Un U (2019) Optimization of microalgae Scenedesmus SP. growth rate using a central composite design statistical approach. Biomass Bioenergy 122:211–220. https://doi.org/10.1016/j.biombioe.2019.01.022

Harman-Ware AE, Morgan T, Wilson M, Crocker M, Zhang J, Liu K, Stork J, Debolt S (2013) Microalgae as a renewable fuel source: fast pyrolysis of Scenedesmus sp. Renev Energy 60:625–632. https://doi.org/10.1016/j.renene.2013.06.016

Derakhshandeh M, Atici T, Un UT (2019) Lipid extraction from microalgae Chlorella and Synechocystis sp. using glass microparticles as disruption enhancer. Energy Environ UK 30(8):1341–1355. https://doi.org/10.1177/0958305X19837463

Choi S-A, Lee J-S, Oh Y-K, Jeong M-J, Kim SW, Park J-Y (2014) Lipid extraction from Chlorella vulgaris by molten-salt/ionic-liquid mixtures. Algal Res 3:44–48. https://doi.org/10.1016/j.algal.2013.11.013

Brennan L, Owende P (2010) Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sust Energ Rev 14(2):557–577. https://doi.org/10.1016/j.rser.2009.10.009

Kandasamy S, Zhang B, He Z, Chen H, Feng H, Wang Q, Wang B, Ashokkumar V, Siva S, Bhuvanendran N (2020) Effect of low-temperature catalytic hydrothermal liquefaction of Spirulina platensis. Energy 190:116236. https://doi.org/10.1016/j.energy.2019.116236

Shuping Z, Yulong W, Mingde Y, Chun L, Junmao T (2010) Pyrolysis characteristics and kinetics of the marine microalgae Dunaliella tertiolecta using thermogravimetric analyzer. Bioresour Technol 101(1):359–365. https://doi.org/10.1016/j.biortech.2009.08.020

Sotoudehniakarani F, Alayat A, McDonald AG (2019) Characterization and comparison of pyrolysis products from fast pyrolysis of commercial Chlorella vulgaris and cultivated microalgae. J Anal Appl Pyrolysis 139:258–273. https://doi.org/10.1016/j.jaap.2019.02.014

Wang K, Brown RC, Homsy S, Martinez L, Sidhu SS (2013) Fast pyrolysis of microalgae remnants in a fluidized bed reactor for bio-oil and biochar production. Bioresour Technol 127:494–499. https://doi.org/10.1016/j.biortech.2012.08.016

Anand V, Sunjeev V, Vinu R (2016) Catalytic fast pyrolysis of Arthrospira platensis (spirulina) algae using zeolites. J Anal Appl Pyrolysis 118:298–307

Miao X, Wu Q, Yang C (2004) Fast pyrolysis of microalgae to produce renewable fuels. J Anal Appl Pyrolysis 71(2):855–863. https://doi.org/10.1016/j.jaap.2003.11.004

Mohan D, Pittman CU, Steele PH (2006) Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuel 20(3):848–889

Vardon DR, Sharma BK, Blazina GV, Rajagopalan K, Strathmann TJ (2012) Thermochemical conversion of raw and defatted algal biomass via hydrothermal liquefaction and slow pyrolysis. Bioresour Technol 109:178–187. https://doi.org/10.1016/j.biortech.2012.01.008

Miao X, Wu Q (2004) High yield bio-oil production from fast pyrolysis by metabolic controlling of Chlorella protothecoides. J Biotechnol 110(1):85–93. https://doi.org/10.1016/j.jbiotec.2004.01.013

Yang C, Li R, Qiu Q, Yang H, Zhang Y, Yang B, Wu J, Li B, Wang W, Ding Y (2020) Pyrolytic behaviors of Scenedesmus obliquus over potassium fluoride on alumina. Fuel 263:116724. https://doi.org/10.1016/j.fuel.2019.116724

Chen C, Tang J, Guo C, Huang H (2019) Effect of composite additives on microwave-assisted pyrolysis of microalgae. Energy Source PART A:1–11. https://doi.org/10.1080/15567036.2019.1649328

Xie Q, Addy M, Liu S, Zhang B, Cheng Y, Wan Y, Li Y, Liu Y, Lin X, Chen P, Ruan R (2015) Fast microwave-assisted catalytic co-pyrolysis of microalgae and scum for bio-oil production. Fuel 160:577–582. https://doi.org/10.1016/j.fuel.2015.08.020

Casazza AA, Spennati E, Converti A, Busca G (2020) Production of carbon-based biofuels by pyrolysis of exhausted Arthrospira platensis biomass after protein or lipid recovery. Fuel Process Technol 201:106336

Zainan NH, Srivatsa SC, Li F, Bhattacharya S (2018) Quality of bio-oil from catalytic pyrolysis of microalgae Chlorella vulgaris. Fuel 223:12–19. https://doi.org/10.1016/j.fuel.2018.02.166

Aysu T, Ola O, Maroto-Valer MM, Sanna A (2017) Effects of titania based catalysts on in-situ pyrolysis of Pavlova microalgae. Fuel Process Technol 166:291–298. https://doi.org/10.1016/j.fuproc.2017.05.001

Chan YH, Yusup S, Quitain AT, Tan RR, Sasaki M, Lam HL, Uemura Y (2015) Effect of process parameters on hydrothermal liquefaction of oil palm biomass for bio-oil production and its life cycle assessment. Energy Convers Manag 104:180–188. https://doi.org/10.1016/j.enconman.2015.03.075

Grierson S, Strezov V, Bengtsson J (2013) Life cycle assessment of a microalgae biomass cultivation, bio-oil extraction and pyrolysis processing regime. Algal Res 2(3):299–311. https://doi.org/10.1016/j.algal.2013.04.004

Peters JF, Banks SW, Bridgwater AV, Dufour J (2017) A kinetic reaction model for biomass pyrolysis processes in Aspen Plus. Appl Energy 188:595–603. https://doi.org/10.1016/j.apenergy.2016.12.030

Derakhshandeh M, Atici T, Un UT (2020) Evaluation of wild-type microalgae species biomass as carbon dioxide sink and renewable energy resource. Waste Biomass Valoriz:1–17. https://doi.org/10.1007/s12649-020-00969-8

Rippka R, Deruelles J, Waterbury JB, Herdman M, Stanier RY (1979) Generic assignments, strain histories and properties of pure cultures of cyanobacteria. Microbiology 111(1):1–61. https://doi.org/10.1099/00221287-111-1-1

Singh G, Patidar S (2018) Microalgae harvesting techniques: a review. J Environ Manag 217:499–508. https://doi.org/10.1016/j.jenvman.2018.04.010

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Phys 37(8):911–917. https://doi.org/10.1139/o59-099

Dubois M, Gilles KA, Hamilton JK, Rebers P, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28(3):350–356. https://doi.org/10.1021/ac60111a017

Lourenço SO, Barbarino E, Lavín PL, Lanfer Marquez UM, Aidar E (2004) Distribution of intracellular nitrogen in marine microalgae: calculation of new nitrogen-to-protein conversion factors. Eur J Phycol 39(1):17–32. https://doi.org/10.1080/0967026032000157156

Meraz L, Domínguez A, Kornhauser I, Rojas F (2003) A thermochemical concept-based equation to estimate waste combustion enthalpy from elemental composition☆. Fuel 82(12):1499–1507. https://doi.org/10.1016/S0016-2361(03)00075-9

Jena U, Das KC, Kastner JR (2011) Effect of operating conditions of thermochemical liquefaction on biocrude production from Spirulina platensis. Bioresour Technol 102(10):6221–6229. https://doi.org/10.1016/j.biortech.2011.02.057

Kim KH, Kim J-Y, Cho T-S, Choi JW (2012) Influence of pyrolysis temperature on physicochemical properties of biochar obtained from the fast pyrolysis of pitch pine (Pinus rigida). Bioresour Technol 118:158–162. https://doi.org/10.1016/j.biortech.2012.04.094

Ates F, Işıkdağ MA (2008) Evaluation of the role of the pyrolysis temperature in straw biomass samples and characterization of the oils by GC/MS. Energy Fuel 22(3):1936–1943. https://doi.org/10.1021/ef7006276

Meesuk S, Cao J-P, Sato K, Ogawa Y, Takarada T (2011) Fast pyrolysis of rice husk in a fluidized bed: effects of the gas atmosphere and catalyst on bio-oil with a relatively low content of oxygen. Energy Fuel 25(9):4113–4121. https://doi.org/10.1021/ef200867q

Choi HL, Sudiarto SIA, Renggaman A (2014) Prediction of livestock manure and mixture higher heating value based on fundamental analysis. Fuel 116:772–780. https://doi.org/10.1016/j.fuel.2013.08.064

Greenhalf CE, Nowakowski DJ, Harms AB, Titiloye JO, Bridgwater AV (2013) A comparative study of straw, perennial grasses and hardwoods in terms of fast pyrolysis products. Fuel 108:216–230. https://doi.org/10.1016/j.fuel.2013.01.075

Grierson S, Strezov V, Shah P (2011) Properties of oil and char derived from slow pyrolysis of Tetraselmis chui. Bioresour Technol 102(17):8232–8240. https://doi.org/10.1016/j.biortech.2011.06.010

Zhao C, Kou Y, Lemonidou AA, Li X, Lercher JA (2009) Highly selective catalytic conversion of phenolic bio-oil to alkanes. Angew Chem 121(22):4047–4050. https://doi.org/10.1002/anie.200900404

Netscher T (2007) Synthesis of vitamin E. Vitam Horm 76:155–202. https://doi.org/10.1016/S0083-6729(07)76007-7

Torri C, Lesci IG, Fabbri D (2009) Analytical study on the production of a hydroxylactone from catalytic pyrolysis of carbohydrates with nanopowder aluminium titanate. J Anal Appl Pyrolysis 84(1):25–30. https://doi.org/10.1016/j.jaap.2008.10.002

Dilcio Rocha J, Luengo CA, Snape CE (1999) The scope for generating bio-oils with relatively low oxygen contents via hydropyrolysis. Org Geochem 30(12):1527–1534. https://doi.org/10.1016/S0146-6380(99)00124-2

Li J, Yan R, Xiao B, Wang X, Yang H (2007) Influence of temperature on the formation of oil from pyrolyzing palm oil wastes in a fixed bed reactor. Energy Fuel 21(4):2398–2407. https://doi.org/10.1021/ef060548c

Onay O (2007) Influence of pyrolysis temperature and heating rate on the production of bio-oil and char from safflower seed by pyrolysis, using a well-swept fixed-bed reactor. Fuel Process Technol 88(5):523–531. https://doi.org/10.1016/j.fuproc.2007.01.001

Guo F, Wang X, Yang X (2017) Potential pyrolysis pathway assessment for microalgae-based aviation fuel based on energy conversion efficiency and life cycle. Energy Convers Manag 132:272–280. https://doi.org/10.1016/j.enconman.2016.11.020

Jena U, Das KC, Kastner JR (2012) Comparison of the effects of Na2CO3, Ca3(PO4)2, and NiO catalysts on the thermochemical liquefaction of microalga Spirulina platensis. Appl Energy 98:368–375. https://doi.org/10.1016/j.apenergy.2012.03.056

Saudi Aramco Anual Review 2016, The many layers of oppurtunity (2016). Aramco Company

Acknowledgments

We thank “Plants, Drugs and Scientific Research Center of Anadolu university” (Anadolu Üniversitesi Bitki, İlaç ve Bilimsel Araştırmalar Merkezi, AÜBİBAM) for their support regarding analyses.

Funding

This project was funded by the Anadolu University through research project no. 1702F050.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Code Availability

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 2114 kb)

Rights and permissions

About this article

Cite this article

Derakhshandeh, M., Ateş, F. & Tezcan Un, U. Renewable Bio-Oil from Pyrolysis of Synechocystis and Scenedesmus Wild-Type Microalgae Biomass. Bioenerg. Res. 14, 991–1001 (2021). https://doi.org/10.1007/s12155-020-10200-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10200-0