Abstract

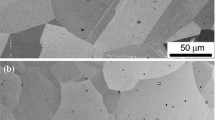

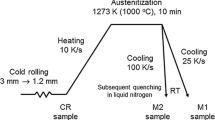

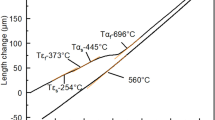

The influence of microstructural characteristics on Lüders strain and mechanical properties was explored by means of altering thermo-mechanical circumstances in an intercritical annealing (IA) medium-Mn Fe-11Mn-0.09C-0.25Si (wt.%) steel. By IA of cold-rolled samples with severe plastic deformation, exclusively equiaxed dual phases were obtained because of active recovery and recrystallization. The equiaxed austenite (\(\upgamma_{\text E}\)) with a larger size and inadequate chemical concentration was more readily transformed into martensite, and subsequent transformation-induced plasticity (TRIP) effect was triggered actively at relatively higher IA temperature, lessening localized deformation. In addition, grown-in dislocations were prone to multiply and migrate around a broad mean free path for coarser equiaxed ferrite (\(\upalpha_{\text E}\)) due to weakening dynamic recovery; therefore, it was the ensuing increased mobility of dislocations instead of reserving plentiful initial dislocation density that facilitated the propagation velocity of Lüders bands and the accumulation of work hardening. In contrast, the bimodal-grained microstructure with lath-like and equiaxed austenite (\(\upgamma_{\text L} + \upgamma_{\text E}\)) satisfactorily contributed to a smaller yield point elongation (YPE) without compromise of comprehensive mechanical properties on the grounds that austenitic gradient stability gave rise to discontinuous but sustainable TRIP effect and incremental work hardening. Hence, Lüders strain is closely related to the absence of work hardening in the region which yields locally. It follows that the decreased stability of retained austenite, favorable mobility of dislocations and the bimodal-grained structure all prominently make up for the insufficiency of work hardening, thereof resulting in a limited YPE.

Similar content being viewed by others

References

S. Yan, X.H. Liu, T.S. Liang, Y. Zhao, Mater. Sci. Eng. A 712 (2018) 332–340.

S. Yan, T.L. Li, T.S. Liang, J.Q. Chen, Y. Zhao, X.H. Liu, Mater. Sci. Eng. A 758 (2019) 79–85.

B. Hu, H.W. Luo, F. Yang, H. Dong, J. Mater. Sci. Technol. 33 (2017) 1457–1464.

M. Lei, W.J. Hui, J.J. Wang, Y.J. Zhang, X.L. Zhao, J. Iron Steel Res. Int. 27 (2020) 537–548.

Z.H. Cai, S.Y. Jing, H.Y. Li, K.M. Zhang, R.D.K. Misra, H. Ding, Z.Y. Tang, Mater. Sci. Eng. A 739 (2019) 17–25.

S.L. Chen, Z.X. Cao, C. Wang, C.X. Huang, D. Ponge, W.Q. Cao, J. Iron Steel Res. Int. 26 (2019) 1209–1218.

Z.H. Cai, B. Cai, H. Ding, Y. Chen, R.D.K. Misra, Mater. Sci. Eng. A 676 (2016) 263–270.

S. Lee, B.C. De Cooman, Metall. Mater. Trans. A 45 (2014) 5009–5016.

F. Yang, H.W. Luo, E.X. Pu, S.L. Zhang, H. Dong, Int. J. Plast. 103 (2018) 188–202.

A.H. Cottrell, B.A. Bilby, Proceed. Phys. Soc. Sect. A 62 (1949) 49–62.

P.J. Gibbs, B.C. De Cooman, D.W. Brown, B. Clausen, J.G. Schroth, M.J. Merwin, D.K. Matlock, Mater. Sci. Eng. A 609 (2014) 323–333.

J.H. Ryu, D.I. Kim, H.S. Kim, H.K.D.H. Bhadeshia, D.W. Suh, Scripta Mater. 63 (2010) 297–299.

X.G. Wang, L. Wang, M.X. Huang, Mater. Sci. Eng. A 674 (2016) 59–63.

H.W. Luo, H. Dong, M.X. Huang, Mater. Des. 83 (2015) 42–48.

J. Han, S.H. Kang, S.J. Lee, Y.K. Lee, J. Alloy. Compd. 681 (2016) 580–588.

B.H. Sun, F. Fazeli, C. Scott, B.Q. Guo, C. Aranas Jr., X. Chu, M. Jahazi, S. Yue, Mater. Sci. Eng. A 729 (2018) 496–507.

T. Furukawa, H. Huang, O. Matsumura, Mater. Sci. Technol. 10 (1994) 964–970.

S. Lee, Y. Estrin, B.C. De Cooman, Metall. Mater. Trans. A 44 (2013) 3136–3146.

B.H. Sun, F. Fazeli, C. Scott, N. Brodusch, R. Gauvin, S. Yue, Acta Mater. 148 (2018) 249–262.

S. Lee, S.J. Lee, B.C. De Cooman, Scripta Mater. 65 (2011) 225–228.

A. García-Junceda, C. Capdevila, F.G. Caballero, C.G. De Andrés, Scripta Mater. 58 (2008) 134–137.

X.C. Xiong, B. Chen, M.X. Huang, J.F. Wang, L. Wang, Scripta Mater. 68 (2013) 321–324.

W.S. Li, H.Y. Gao, H. Nakashima, S. Hata, W.H. Tian, Mater. Sci. Eng. A 649 (2016) 417–425.

B.B. He, B. Hu, H.W. Yen, G.J. Cheng, Z.K. Wang, H.W. Luo, M.X. Huang, Science 357 (2017) 1029–1032.

J. Han, S.J. Lee, J.G. Jung, Y.K. Lee, Acta Mater. 78 (2014) 369–377.

G.A. Calligaris, T.L.T. Da Silva, A.P.B. Ribeiro, A.O. Dos Santos, L.P. Cardoso, Chem. Phys. Lipids 212 (2018) 51–60.

H. Naji, J. Khalil-Allafi, V. Khalili, Mater. Chem. Phys. 241 (2019) 122317.

P. Chatterjee, A. Chakraborty, A.K. Mukherjee, Spectrochim. Acta Part A Molecul. Biomolecul. Spectrosc. 200 (2018) 33–42.

G.K. Williamson, W.H. Hall, Acta Metall. 1 (1953) 22–31.

P. Scherrer, in: Kolloidchemie Ein Lehrbuch, Springer, 1912, pp. 387–409.

Z.X. Yang, Y. Huang, G.N. Chen, Z.P. Guo, S.Y. Cheng, S.Z. Huang, Sens. Actuators B Chem. 140 (2009) 549–556.

G.K. Williamson, R.E. Smallman, Hilos. Mag. 1 (1956) 34–46.

R. Kishor, L. Sahu, K. Dutta, A.K. Mondal, Mater. Sci. Eng. A 598 (2014) 299–303.

N.H. Van Dijk, A.M. Butt, L. Zhao, J. Sietsma, S.E. Offerman, J.P. Wright, S. Van Der Zwaag, Acta Mater. 53 (2005) 5439–5447.

D.Z. Yang, E.L. Brown, D.K. Matlock, G. Krauss, Metall. Trans. A 16 (1985) 1523–1526.

X. Li, R. Song, N. Zhou, J. Li, Scripta Mater. 154 (2018) 30–33.

C.I. Garcia, A.J. Deardo, Metall. Trans. A 12 (1981) 521–530.

O. Dmitrieva, D. Ponge, G. Inden, J. Millán, P. Choi, J. Sietsma, D. Raabe, Acta Mater. 59 (2011) 364–374.

R.R. Judd, H.W. Paxton, Trans. Met. Soc. AIME 242 (1968) 206–215.

G.A. Roberts, R.F. Mehl, Trans. ASM 31 (1943) 613–650.

J.H. Ryu, J.I. Kim, H.S. Kim, C.S. Oh, H.K.D.H. Bhadeshia, D.W. Suh, Scripta Mater. 68 (2013) 933–936.

W. Roberts, S. Karlsson, Y. Bergström, Mater. Sci. Eng. 11 (1973) 247–254.

S. Lee, S.J. Lee, B.C. De Cooman, Acta Mater. 59 (2011) 7546–7553.

X.G. Wang, B.B. He, C.H. Liu, C. Jiang, M.X. Huang, Materialia 6 (2019) 100288.

H. Matsumoto, H. Yoneda, K. Sato, S. Kurosu, E. Maire, D. Fabregue, T.J. Konno, A. Chiba, Mater. Sci. Eng. A 528 (2011) 1512–1520.

J. Shi, X. Sun, M. Wang, W. Hui, H. Dong, W. Cao, Scripta Mater. 63 (2010) 815–818.

B. Sun, N. Vanderesse, F. Fazeli, C. Scott, J. Chen, P. Bocher, M. Jahazi, S. Yue, Scripta Mater. 133 (2017) 9–13.

Z.C. Li, X.T. Zhang, Y.J. Mou, R.D.K. Misra, L.F. He, H.P. Li, Mater. Sci. Eng. A 746 (2019) 363–371.

H. Wang, Y. Zhang, G. Yuan, J. Kang, Y. Wang, R.D.K. Misra, G. Wang, Mater. Sci. Eng. A 737 (2018) 176–181.

B.B. He, Z.Y. Liang, M.X. Huang, Scripta Mater. 150 (2018) 134–138.

M. Kamaya, Mater. Charact. 66 (2012) 56–67.

A. Ramazani, K. Mukherjee, A. Schwedt, P. Goravanchi, U. Prahl, W. Bleck, Int. J. Plast. 43 (2013) 128–152.

E. De Moor, D.K. Matlock, J.G. Speer, M.J. Merwin, Scripta Mater. 64 (2011) 185–188.

J.J. Wang, S. Van Der Zwaag, Metall. Mater. Trans. A 32 (2001) 1527–1539.

D. Kuhlmann-Wilsdorf, Mater. Sci. Eng. A 113 (1989) 1–41.

J.S. Hayes, R. Keyte, P.B. Prangnell, Mater. Sci. Technol. 16 (2000) 1259–1263.

J.W. Wyrzykowski, M.W. Grabski, Mater. Sci. Eng. 56 (1982) 197–200.

C.Y. Yu, P.W. Kao, C.P. Chang, Acta Mater. 53 (2005) 4019–4028.

V. Patlan, A. Vinogradov, K. Higashi, K. Kitagawa, Mater. Sci. Eng. A 300 (2001) 171–182.

B. Devincre, T. Hoc, L. Kubin, Science 320 (2008) 1745–1748.

P.H. Chang, A.G. Preban, Acta Metall. 33 (1985) 897–903.

M. Yang, Y. Pan, F. Yuan, Y. Zhu, X. Wu, Mater. Res. Lett. 4 (2016) 145–151.

X.L. Liu, Q.Q. Xue, W. Wang, L.L. Zhou, P. Jiang, H.S. Ma, F.P. Yuan, Y.G. Wei, X.L. Wu, Materialia 7 (2019) 100376.

X. Wu, M. Yang, F. Yuan, G. Wu, Y. Wei, X. Huang, Y. Zhu, PNAS 112 (2015) 14501–14505.

J.L. Ning, Y.T. Zhang, L. Huang, Y.L. Feng, Mater. Des. 120 (2017) 280–290.

B. Yang, H. Vehoff, Acta Mater. 55 (2007) 849–856.

K. Steineder, D. Krizan, R. Schneider, C. Béal, C. Sommitsch, Acta Mater. 139 (2017) 39–50.

Acknowledgements

The authors gratefully acknowledge the support of the National Key Research and Development Program of Thirteenth Five-Year Plan Period (Grant No. 2017YFB0304400) and the National Natural Science Foundation of China (Grant No. 51574028).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, S., Chen, Wj., Zhao, Zz. et al. Effect of microstructure evolution on Lüders strain and tensile properties in an intercritical annealing medium-Mn steel. J. Iron Steel Res. Int. 28, 762–772 (2021). https://doi.org/10.1007/s42243-020-00498-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00498-7