Abstract

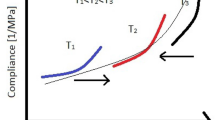

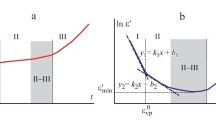

Nonlinear viscoelastic behaviour of –COOH functionalized multi-walled carbon nanotubes reinforced polypropylene nanocomposites is examined up to 2% MWCNT concentration. Isochronal creep and strain recovery experiments are conducted in dynamic mechanical analyser with oscillatory inputs. Creep stress level of 5 MPa is selected and successive creep and recovery experiments are performed at \(-\,20\,^\circ \)C, \(25\,^\circ \)C and \(50\,^\circ \)C to analyse the effect of temperature and MWCNT concentration on strain developed during creep loading and strain recovery stages. A well-known Schapery nonlinear viscoelastic solid model with Zapas–Crissman viscoplastic term is fitted to the experimental observations. Stress-dependent nonlinear model parameters are obtained under temperature and MWCNT loading. Viscoelastic and viscoplastic strains are predicted at the end of recovery period. High temperatures and low concentrations of MWCNT are observed to cause higher viscoplastic strain. Strengthening MWCNT up to 1% improves the thermomechanical behaviour and viscoelastic recovery and decreases the viscoplastic strain in nanocomposites. Temperature-dependent compliance behaviour of nanocomposites is investigated with Williams–Landel–Ferry model and Arrhenius model using time–temperature superposition principle.

Similar content being viewed by others

References

Bikiaris, D.: Microstructure and properties of polypropylene carbon nanotube nanocomposites. Materials 3, 2884–2946 (2010)

Szpieg, M., Giannadakis, K., Varna, J.: Time dependent nonlinear behavior of recycled polypropylene in high tensile stress loading. J. Thermoplast. Compos. Mater. 24, 625–652 (2011)

Lou, Y.C., Schapery, R.A.: Viscoelastic characterization of a nonlinear fiber reinforced plastic. J. Compos. Mater. 5, 208–234 (1971)

Megnis, M., Varna, J., Allen, D.H., Holmberg, A.: Micromechanical modeling of viscoelastic response of GMT composite. J. Compos. Mater. 35(10), 849–882 (2001)

Tserpes, K.I., Chanteli, A., Pantelakis, S.: Mechanical and nanomechanical properties of MWCNT/PP nanocomposite. Dev. Fract. Fatigue Assess. Mater. Struct. 46, 73–83 (2018)

Chanteli, A., Tserpes, K.I.: Finite element modeling of carbon nanotube agglomerates in polymers. Compos. Struct. 132, 1141–1148 (2015)

Pegel, S., Potschke, P., Villmow, T., Stoyan, D., Heinrich, G.: Spatial statistics of carbon nanotube polymer composites. Polymer 5, 2123–2132 (2009)

Li, C., Pang, X.J., Qu, M.J., Jhang, Q.T., Wang, B., Zhang, B.L.: Fabrication and characterization of polycarbonate/carbon nanotubes composites. Compos. Part A 37, 1485–1489 (2005)

Khare, V., Srivastava, S., Kamle, S., Kamath, G.M.: Effect of filler functionalization on the thermomechanical behavior of polypropylene nanocomposites. Procedia Struct. Integr. 14, 215–225 (2019)

Zapas, L.J., Crissman, J.M.: Creep and recovery behavior of ultra high molecular weight polyethylene in the region of small uniaxial deformations. Polymer 25(1), 57–62 (1984)

Roylance, D.: Engineering viscoelasticity. Mechanics of materials course, MIT3 11F99 visco (2001)

Christensen, R.M.: Theory of Viscoelasticity, 2nd edn. Academic Press, New York (1982)

Papanicolaou, G.C., Zaoutsos, S.P.: Viscoelastic Constitutive Modeling of Creep and Stress Relaxation in Polymers and Polymer Matrix Composites. Woodhead, Sawston (2011)

Tuttle, M.E., Brinson, H.F.: Prediction of the long term creep compliance of general composite laminates. Exp. Mech. 26, 89–102 (1985)

Schapery, R.A.: Nonlinear viscoelastic solids. Int. J. Solids Struct. 37, 359–366 (2000)

Schapery, R.A.: A theory of nonlinear thermoviscoelasticity based on irreversible thermodynamics. In: The Fifth National Congress of Applied Mechanics (1966)

Jia, Y., Peng, K., Gong, X.L., Zhang, Z.: Creep and recovery of polypropylene/carbon nanotube composites. Int. J. Plast. 27, 1239–1251 (2011)

Papanicolaou, G.C., Xepapadaki, A.G., Pavlopoulou, S., Zaoutsos, S.P.: On the investigation of the stress threshold from linear to nonlinear viscoelastic behaviour of polymer matrix particulate composites. Mech. Time Depend. Mater. 13, 261–274 (2009)

Schapery, R.A.: An engineering theory of nonlinear viscoelasticity with applications. Int. J. Solid Struct. 2, 407 (1966)

Schapery, R.A.: On the characterization of nonlinear viscoelastic materials. Polym. Eng. Sci. 9, 295 (1969)

Kshitish, A.P.: Linear and nonlinear viscoelastic characterization of proton exchange membranes and stress modeling for fuel cell application. Doctor of Philosophy thesis (2009)

Ikeda, M., Aniya, M.: Bond strength coordination number fluctuation model of viscosity: an alternative model for the Vogel–Fulcher–Tammann equation and an application to bulk metallic glass forming liquids. Materials 3, 5246–5262 (2010)

Haj-ali, R.M., Muliana, A.H.: Numerical finite element formulation of the Schapery nonlinear viscoelastic material model. Int. J. Numer. Methods Eng. 59, 25–45 (2004)

Castillo, E.D., Basanez, L., Gil, E.: Modeling nonlinear viscoelastic behavior under large deformations. Int. J. Nonlinear Mech. 57, 154–162 (2013)

Holmes, D.W., Loughran, J.G., Suehreke, H.: Constitutive model for large strain deformation of semicrystalline polymers. Mech. Time Depend. Mater. 10, 281–313 (2007)

Marklund, E., Varna, J., Wallstorm, L.: Nonlinear viscoelasticity and viscoplasticity of flax/polypropylene composites. J. Eng. Mater. Technol. 128(4), 527–536 (2006)

Lourakis, M.: Levenberg–Marquardt nonlinear least squares algorithms in c/c++. Technical report. http://users.ics.forth.gr/ lourakis/levmar/ (2008)

Shapery, R.A.: Nonlinear viscoelastic and viscoplastic constitutive equations based on thermodynamics. Mech. Time Depend. Mater. 1, 209–240 (1997)

Arvanitakis, A.I.: A constitutive level-set model for shape memory polymers and shape memory polymeric composites. Arch. Appl. Mech. 89, 1939–1951 (2019)

Yang, Z., Wu, P., Liu, W.: Time-dependent behavior of laminated functionally graded beams bonded by viscoelastic interlayer based on the elasticity theory. Arch. Appl. Mech. 90, 1457–1473 (2020)

Begun, A.S., Burenin, A.A., Kovtanyuk, L.V., Lamza, A.O.: On the mechanisms of production of large irreversible strains in materials with elastic, viscous and plastic properties. Arch. Appl. Mech. 90, 829–845 (2020)

Marklund, E., Eitzenberger, J., Varna, J.: Nonlinear viscoelastic viscoplastic material model including stiffness degradation for hemp/lignin composites. Compos. Sci. Technol. 68, 2156–2162 (2008)

Tuttle, M.E., Pasricha, A., Emery, A.F.: The nonlinear viscoelastic–viscoplastic behavior of im7/5260 composites subjected to cyclic loading. J. Compos. Mater. 29(15), 2025–2046 (1995)

Pasricha, A., Dillard, D.A., Tuttle, M.E.: Effect of physical aging and variable stress history on the strain response of polymeric composites. Compos. Sci. Technol. 57(9–10), 1271–1279 (1997)

Khare, V., Kamle, S.: Development of master curves for nonlinear viscoelastic behaviour of nanofiller-reinforced composites. Int. J. Adv. Eng. Sci. Appl. Math. (2020). https://doi.org/10.1007/s12572-020-00270-w

Metravib. DMA 100+ Dynatest and Multitest User manual. Metravib (2009)

Zare, Y., Park, S.P., Rhee, K.Y.: Analysis of complex viscosity and shear thinning behavior in poly (lactic acid)/poly (ethylene oxide)/carbon nanotubes biosensor based on Carreau-Yasuda model. Results Phys. 13, 102245 (2019)

Cheng, H.K.F., Chong, M.F., Liu, E., Zhou, K., Li, L.: Thermal decomposition kinetics of multiwalled carbon nanotube polypropylene nanocomposites. J. Therm. Anal. Calorim. 117, 63–71 (2014)

Patti, A., Barretta, R., Marotti, F., de Sciarra, G., Mensitieri, C.Menna, Russo, P.: Flexural properties of multi-wall carbon nanotube polypropylene composites: experimental investigation and nonlocal modeling. Compos. Struct. 131, 282–9 (2015)

Acknowledgements

The authors express their sincere thanks to Department of Material science and Engineering for providing FESEM facility and Department of Aerospace engineering for DMA and TGA facilities. Authors gratefully acknowledge Mr. Lavendra singh at structures laboratory for his valuable suggestion during dynamic experiments. Financial assistance from MHRD, New Delhi, is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khare, V., Kamle, S. Effect of temperature and filler volume fraction on the creep and recovery behaviour of MWCNT–COOH–reinforced polypropylene films. Arch Appl Mech 91, 979–995 (2021). https://doi.org/10.1007/s00419-020-01800-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-020-01800-5