Abstract

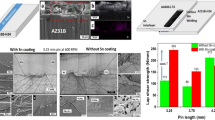

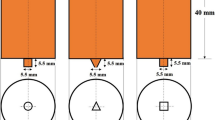

In the present work, friction stir welding of 3-mm-thick AA6061-T6 Al alloy and AZ31B-H24 Mg alloy sheets was carried out in lap configuration with Al alloy on top. Experiments were carried out by varying the pin length (3.25, 3.75, and 4.25 mm) and tool rotation speed (600, 800, and 1000 RPM). Microstructures of the joint cross-section revealed the presence of a compound intermetallic layer along the interface consisting of Al-rich (Al3Mg2) intermetallic compound near the Al alloy side, and Mg-rich intermetallic compound (Mg17Al12) near the Mg alloy side. The formation of a eutectic mixture of Mg solid solution and Mg17Al12 was observed at the hook on either side. Two modes of failure were observed; Mode 1 through the interface and Mode 2 due to failure of the sheet. The Mode 1 failure strengths obtained were the highest (148 ± 6 N/mm) compared to the literature and were obtained for the 3.25 and 3.75 mm pin at 800 RPM. A lap shear strength of 212 ± 6 N/mm was obtained with 4.25 mm pin length at 600 RPM, which is the highest reported so far and was attributed to Mode 2 failure. The effect of interface pull-up, angle of the interface at the advancing side, and distribution of intermetallic compounds on the lap-shear strength are discussed.

Similar content being viewed by others

References

1 B.L. Mordike and T. Ebert: Mater. Sci. Eng. A, 2001, vol. 302, pp. 37–45.

B. Guang, L. Song, and A. Atrens: Adv. Eng. Mater., 1999, pp. 11–33.

3 H. Friedrich and S. Schumann: J. Mater. Process. Technol., 2001, vol. 117, pp. 276–81.

Murray J.L: Bin. Alloy Phase Diagrams, Second Ed., T.B. Massalski, ed., ASM International, Materials Park, Ohio, 1990, pp. 169–71.

5 R.S. Mishra and Z.Y. Ma: Mater. Sci. Eng. R Reports, 2005, vol. 50, pp. 1–78.

6 C.M. Chen and R. Kovacevic: Int. J. Mach. Tools Manuf., 2004, vol. 44, pp. 1205–14.

7 J. Ouyang, E. Yarrapareddy, and R. Kovacevic: J. Mater. Process. Technol., 2006, vol. 172, pp. 110–22.

8 Y.C. Chen and K. Nakata: Mater. Des., 2009, vol. 30, pp. 469–74.

9 M. Fazel-Najafabadi, S.F. Kashani-Bozorg, and A. Zarei-Hanzaki: Mater. Des., 2010, vol. 31, pp. 4800–7.

10 Y. Li, L.E. Murr, and J.C. McClure: Mater. Sci. Eng. A, 1999, vol. 271, pp. 213–23.

11 A.C. Somasekharan and L.E. Murr: Mater. Charact., 2004, vol. 52, pp. 49–64.

12 Y.S. Sato, S.H.C. Park, M. Michiuchi, and H. Kokawa: Scr. Mater., 2004, vol. 50, pp. 1233–6.

13 N. Yamamoto, J. Liao, S. Watanabe, and K. Nakata: Mater. Trans., 2009, vol. 50, pp. 2833–8.

S. Ji, X. Meng, Z. Liu, R. Huang, and Z. Li (2017) Mater. Lett., https://doi.org/10.1016/j.matlet.2017.05.011.

15 Z. Liu, X. Meng, S. Ji, Z. Li, and L. Wang: J. Manuf. Process., 2018, vol. 31, pp. 552–9.

16 X. Lv, C.S. Wu, C. Yang, and G.K. Padhy: J. Mater. Process. Technol., 2018, vol. 254, pp. 145–57.

17 K.P. Mehta, P. Carlone, A. Astarita, F. Scherillo, F. Rubino, and P. Vora: Mater. Sci. Eng. A, 2019, vol. 759, pp. 252–61.

18 Y.C. Chen and K. Nakata: Scr. Mater., 2008, vol. 58, pp. 433–6.

19 V. Firouzdor and S. Kou: Supp. to Weld. J., 2009, vol. 88, pp. 213–24.

20 J. Mohammadi, Y. Behnamian, A. Mostafaei, H. Izadi, T. Saeid, A.H. Kokabi, and A.P. Gerlich: Mater. Charact., 2015, vol. 101, pp. 189–207.

21 S. Ji, Z. Li, L. Zhang, Z. Zhou, and P. Chai: Mater. Des., 2016, vol. 103, pp. 160–70.

22 H.M. Rao, B. Ghaffari, W. Yuan, J.B. Jordon, and H. Badarinarayan: Mater. Sci. Eng. A, 2016, vol. 651, pp. 27–36.

23 S. Tan, F. Zheng, J. Chen, J. Han, Y. Wu, and L. Peng: J. Magnes. Alloy., 2017, vol. 5, pp. 56–63.

24 S. Niu, S. Ji, D. Yan, X. Meng, and X. Xiong: J. Mater. Process. Technol., 2019, vol. 263, pp. 82–90.

25 S. Ji, S. Niu, J. Liu, and X. Meng: J. Mater. Process. Technol., 2019, vol. 267, pp. 141–51.

26 Y. Gao, K. Nakata, K. Nagatsuka, Y. Shibata, and M. Amano: J. Mater. Process. Technol., 2016, vol. 229, pp. 313–21.

27 S.D. Ji, Q. Wen, and Z.W. Li: J. Mater. Sci. Technol., 2020, vol. 48, pp. 23–30.

28 L. Cederqvist and A.P. Reynolds: Supp. to Weld. J., 2001, vol. 80, pp. 281–7.

29 G. Buffa, G. Campanile, L. Fratini, and A. Prisco: Mater. Sci. Eng. A, 2009, vol. 519, pp. 19–26.

30 A. Chapuis and J.H. Driver: Acta Mater., 2011, vol. 59, pp. 1986–94.

31 T.U. Seidel and A.P. Reynolds: Metall. Mater. Trans. A, 2001, vol. 32, pp. 2879–84.

32 J.W. Pew, T.W. Nelson, and C.D. Sorensen: Sci. Technol. Weld. Join., 2007, vol. 12, pp. 341–7.

Y.K. Y.K. Yang, H. Dong, H. Cao, Y.A. Chang, and S. Kou: Supp. to Weld. J., 2008, vol. 87, pp. 167–77.

V. Firouzdor and S. Kou: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2010, vol. 41, pp. 2914–35.

35 R. Nandan, G.G. Roy, and T. Debroy: Met. Mater. Trans. A, 2006, vol. 37A, pp. 1247–59.

36 R. Nandan, T. Debroy, and H.K.D.H. Bhadeshia: Prog. Mater. Sci., 2008, vol. 53, pp. 980–1023.

37 J.L. Song, S.B. Lin, C.L. Yang, and C.L. Fan: J. Alloys Compd., 2009, vol. 488, pp. 217–22.

S. Babu, S.K. Panigrahi, G.D. JanakiRam, P. V. Venkitakrishnan, and R. SureshKumar: J. Mater. Process. Technol., 2018, vol. 266, pp. 155–64.

39 L. Boccarusso, A. Astarita, P. Carlone, F. Scherillo, F. Rubino, and A. Squillace: J. Manuf. Process., 2019, vol. 44, pp. 376–88.

V. Firouzdor and S. Kou: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2010, vol. 41, pp. 3238–51.

41 H.M. Rao, W. Yuan, and H. Badarinarayan: Mater. Des., 2015, vol. 66, pp. 235–45.

42 H. Schmidt, J. Hattel, and J. Wert: Model. Simul. Mater. Sci. Eng., 2004, vol. 12, pp. 143–57.

Acknowledgments

One of the authors (S.R. Bakshi) acknowledges funding from Institute Research and Development Award (Junior Level) of IIT Madras (MET1617839RFIRSRRB) for carrying out the work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 19, 2020; accepted September 6, 2020.

Rights and permissions

About this article

Cite this article

Bandi, A., Bakshi, S.R. Effect of Pin Length and Rotation Speed on the Microstructure and Mechanical Properties of Friction Stir Welded Lap Joints of AZ31B-H24 Mg Alloy and AA6061-T6 Al Alloy. Metall Mater Trans A 51, 6269–6282 (2020). https://doi.org/10.1007/s11661-020-06020-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06020-8