Abstract

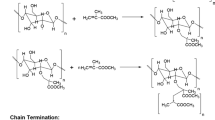

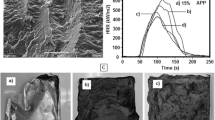

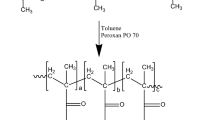

This research paper deals with the graft copolymerisation of methyl methacrylate (MMA) on the backbone of Meizotropis Pellita fibres (MPF), which was successfully carried out under aqueous medium using Fenton's reagent [ferrous ammonium sulphate (FAS) (8.0 × 10–3 M) and H2O2 (0.12 M)] as a redox initiator to impart hydrophobic properties. Grafting was optimized under different conditions concerning time, temperature, monomer ratio, material to liquor ratio and initiator concentration. Maximum graft yield percentage obtained was 120%. The grafted MPF was characterized using Fourier transform infrared (FTIR) spectroscopy, scanning electron microscopy (SEM), thermogravimetric analysis (TGA) and X-ray diffraction (XRD) studies. The FTIR spectroscopic data showed a peak at 1728 cm−1 of C=O (ester), and another peak at 1650 cm−1 of adsorbed water, which was absent in the grafted fibre. The grafted fibre showed excellent thermal stability with an overall weight loss of 56.5% with a char residue of 33.5%. In addition, X-ray diffraction of MMA-grafted MPF showed 21% crystallinity and crystallinity index of 0.16. These raw and grafted fibres were also subjected to physico-chemical properties like moisture absorbance, swelling behaviour and chemical resistance, which they showed that MMA-grafted MPF exhibited hydrophobic properties. Therefore, due to this hydrophobic behaviour, the oil absorbency of MMA-grafted MPF was studied towards four emulsions: crude oil–saline, engine oil–saline, diesel oil–saline and used engine oil–saline. An MMA-grafted MPF by 120% absorbed 23.60 g of crude oil in the first cycle, 17. 41 g in the second cycle and 14.21 g in the third cycle, whereas 13.14 g of diesel oil was absorbed in the first cycle, 8.24 g in the second cycle and 5.25 g in the third cycle. Similarly, 20.14 g of engine oil was absorbed in the first cycle, 10.00 g in the second cycle and 7.51 g in the third cycle. Lastly, 19.80 g of the engine oil was absorbed in the first cycle, 12.25 g in the second cycle and 7.98 g in the third cycle. These results showed that the oil removal efficiency of the grafted MPF was intact by oil fraction type and they can be applied for all kinds of oil fraction spillage.

Similar content being viewed by others

References

Shriadah MM (1998) Impacts of an oil spill on the marine environment of the United Arab Emirates along the Gulf of Oman. Mar Pollut Bull 36:876–879

Yang L, Bai B, Ding C, Wang H, Suo Y (2016) Synthesis and properties of the rapeseed meal-grafted-poly (methyl methacrylate-co-butyl acrylate) oil-absorbents. RSC Adv 6:9507–9517

Ratcha A, Yoosuk B, Kongparakul S (2014) Grafted methyl methacrylate and butyl methacrylate onto natural rubber foam for oil sorbent. Adv Mater Res 844:385–390

Leighton FA (1993) The toxicity of petroleum oils to birds. Environ Rev 1:92–103

Stephenson R (1997) Effects of oil and other surface-active organic pollutants on aquatic birds. Environ Conserv 24:121–129

Nine MJ, Kabiri S, Sumona AK, Tung TT, Moussa MM, Losic D (2020) Superhydrophobic/superoleophilic natural fibres for continuous oil-water separation and interfacial dye-adsorption. Sep Purif Technol 233:116062

Viju S, Thilagavathi G (2020) Effect of alkali treatment of nettle fibers on oil absorbency. J Nat Fibre 17:1–10

Zhou L, Fu C, Xiao W, Niu B, Sun C, Yu M, Zheng Y (2020) MoS2-roughened hollow-lumen plant fibers with enhanced oil absorption capacity. Cellulose 27:2267–2278

Dos Anjos RB, Hilário LS, de Moraes Juviniano HB, da Silva DR (2020) Crude oil removal using Calotropis procera. Bio Resour 15:5246–5263

Labidi A, Salaberria AM, Labidi J, Abderrabba M (2019) Preparation of novel carboxymethyl chitosan-graft-poly (methylmethacrylate) under microwave irradiation as a chitosan-based material for Hg2+ removal. Microchem J 148:531–540

Kalakoti M, Kumar A (2015) Phytochemical screening of leaf extract of Meizotropis pellita (Patwa): an endangered plant species. Int J Adv Res 3:361–365

Teli MD, Valia SP (2013) Acetylation of banana fibre to improve oil absorbency. Carbohydr Polym 92:328–333

Teli MD, Valia SP (2015) Modification of biomaterials for functional application. Cell Chem Technol 49:3–6

Teli MD, Valia SP (2013) Acetylation of jute fiber to improve oil absorbency. Fiber Polym 14:915–919

Teli MD, Valia SP, Teli M, Valia S (2016) Effect of substrate geometry on oil sorption capacity of raw and chemically modified jute fibre. Int J Eng Technol 3:138–147

Teli MD, Valia SP, Mifta J (2017) Application of functionalized coir fibre as eco-friendly oil sorbent. J Text Inst 108:1106–1111

Teli MD, Valia SP (2016) Grafting of butyl acrylate on to banana fibers for improved oil absorption. J Nat Fibre 13:470–476

Teli MD, Valia SP (2013) Application of modified coir fiber as eco-friendly oil sorbent. J Fash Technol Text Eng 1:1–5

Ali N, El-harbawi M, Jabal AA, Yin C (2012) Characteristics and oil sorption effectiveness of kapok fibre, sugarcane bagasse and rice husks: oil removal suitability matrix. Environ Technol 33:481–486

Lv N, Wang X, Peng S, Luo L, Zhou R (2018) Superhydrophobic/superoleophilic cotton-oil absorbent: preparation and its application in oil/water separation. R Soc Chem 8:30257–30264

Annunciado TR, Sydenstricker THD, Amico SC (2005) Experimental investigation of various vegetable fibers as sorbent materials for oil spills. Mar Pollut Bull 50:1340–1346

Cui Y, Xu G, Liu Y (2014) Oil sorption mechanism and capability of cattail fiber assembly. J Ind Text 43:330–337

Mino G, Kaizerman S (1958) A new method for the preparation of graft copolymers: polymerization initiated by ceric ion redox systems. J Polym Sci 31:242–243

Geacintov N, Stannett V, Abrahamson EW, Hermans JJ (1960) Grafting onto cellulose and cellulose derivatives using ultraviolet irradiation. J Appl Polym Sci 3:54–60

Richards GN (1961) Initiation of graft polymerization on cellulose by hydroxyl radicals and by ceric salts. J Appl Polym Sci 5:539–544

Epstein JA, Bar-Nun A (1964) Electrochemical grafting of methyl methacrylate onto cellulose. J Polym Sci Part B 2:27–28

Rangarao S, Kapur SL (1969) Grafting of acrylonitrile onto cellulose initiated by ceric ion. J Appl Polym Sci 13:2619–2656

Fazilat F, Rostamie SH (1979) Radiation-induced copolymerization of vinyl monomers onto husk and stem of rice cellulose. J Macro Sci Chem 13:1203–1212

Segal LGJMA, Creely JJ, Martin AE Jr, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Kaith BS, Jindal R, Jana AK, Maiti M (2009) Ferrous-persulphate induced graft copolymerization of monomer mixtures onto Saccharum spontaneum-L natural fibre. Iran Polym J 18:789–800

Singha AS, Thakur VK (2008) Fabrication of Hibiscus sabdariffa fibre reinforced polymer composites. Iran Polym J 17:541–553

Ansari IA, East GC, Johnson DJ (2003) Structure–property relationships in natural cellulosic fibres: part III: flax—an oil sorbent. J Text Inst 9:1–5

Kumar V, Naithani S, Pandey D (2011) Optimization of reaction conditions for grafting of α-cellulose isolated from Lantana camara with acrylamide. Carbohydr Polym 86:760–768

Teli MD, Sheikh J (2012) Antibacterial and acid and cationic dyeable bamboo cellulose (rayon) fabric on grafting. Carbohydr Polym 88:1281–1287

Thakur VK, Singha AS, Thakur MK (2012) Graft copolymerization of methyl acrylate onto cellulosic biofibers: synthesis, characterization and applications. J Polym Environ 20:164–174

Singha AS, Rana RK (2010) Microwave induced graft copolymerization of methyl methacrylate onto lignocellulosic fibres. Int J Polym Anal Charact 15:370–386

Sharma G, Naushad M, Pathania D, Mittal A, El-Desoky GE (2015) Modification of Hibiscus cannabinus fiber by graft copolymerization: application for dye removal. Desalin Water Treat 54:3114–3121

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres. Fourier Transfer Mater Anal 3:45–68

Le Troedec M, Sedan D, Peyratout C, Bonnet JP, Smith A, Guinebretiere R, Gloaguen V, Krausz P (2008) Influence of various chemical treatments on the composition and structure of hemp fibres. Compos Part A Appl S 39:514–522

Manring LE (1991) Thermal degradation of poly (methyl methacrylate). 4 Random side-group scission. Macromolecules 24:3304–3309

Wan Z, Xiong Z, Ren H, Huang Y, Liu H, Xiong H, Wu Y, Han J (2011) Graft copolymerization of methyl methacrylate onto bamboo cellulose under microwave irradiation. Carbohydr Polym 83:264–269

Ouajai S, Shanks RA (2005) Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym Degrad Stabil 89:327–335

Kaith BS, Jindal R, Maiti M (2009) Induction of chemical and moisture resistance in Saccharum spontaneum L fibre through graft copolymerization with methyl methacrylate and study of morphological changes. J Appl Polym Sci 113:1781–1791

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781

Doyle CD (1985) Thermogravimetric Analysis. Encyclopaedia of polymer science and engineering. Wiley, New York

Reddy KO, Maheswari CU, Reddy DJP, Rajulu AV (2009) Thermal properties of Napier grass fibre. Mater Lett 63:2390–2392

Ferriol M, Gentilhomme A, Cochez M, Oget N, Mieloszynski JL (2003) Thermal degradation of poly (methyl methacrylate) (PMMA): modelling of DTG and TG curves. Polym Degrad Stabil 79:271–281

Acknowledgements

The authors would like to acknowledge the research facilities that were provided by the Institute of Chemical Technology, Mumbai, in completing this research project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest.

Rights and permissions

About this article

Cite this article

Jadhav, A.C., Jadhav, N.C. Graft copolymerization of methyl methacrylate on Meizotropis Pellita fibres and their applications in oil absorbency. Iran Polym J 30, 9–24 (2021). https://doi.org/10.1007/s13726-020-00869-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-020-00869-7