Abstract

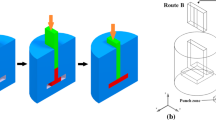

The effect of multi-pass multi-directional forging (MDF) on the microstructure and mechanical properties of Zn–22Al–xSi (X = 4 and 8 wt. %) alloy, also known as SiP/ZA22 composite, was investigated. MDF process was applied at 100 °C for one, three, and five passes with the strain of 0.47 per pass. According to the results, MDF refined and homogenized the composites microstructure so that the average size of primary Si (SiP) particles reduced from 25.0 µm and 30.4 µm in as-cast ZA22-4Si and ZA22-8Si composites to about 6.2 µm and 7.3 µm in five-pass MDFed condition, respectively, and their distribution shifted to the smaller size range. Mechanical properties tests revealed that multi-pass MDF has softened the investigated composite. For instance, the hardness, tensile strength, and shear strength of ZA22-4Si composite reduced from 83 HV, 280 MPa, and 165 MPa in as-cast condition to about 58 HV, 160 MPa, and 118 MPa in the five-pass MDFed sample, respectively. This is while its fracture strain increased from 15% to about 40% with the strain rate of 1.2 × 10–3 s−1.

Similar content being viewed by others

References

Sharath PC, Udupa KR, Kumar GVP. Effect of multi directional forging on the microstructure and mechanical properties of Zn-24 wt% Al-2 wt% Cu alloy. Trans Indian Ins Metals. 2017;70(1):89–96.

Liu Y, Li H-Y, Jiang H-F, Lu X-C. Effects of heat treatment on microstructure and mechanical properties of ZA27 alloy. Trans Nonferrous Met Soc China. 2013;23:642–9.

Savaşkan T, Aydıner A. Effects of silicon content on the mechanical and tribological properties of monotectoid-based zinc–aluminium–silicon alloys. Wear. 2004;257:377–88.

Turk A, Durman M, Sabri Kayali E. The effect of manganese on the microstructure and mechanical properties of zinc–aluminium based ZA-8 alloy. J Mater Sci. 2007;42:8298–305.

Al-Qawabah S, Zaid AIO. Effect of Mo addition to ZA22 alloy grain refined by Ti-B on its metallurgical and mechanical characteristics in the as cast condition. Mater Sci Forum. 2019;886:64–8.

Kurnaz SC, Sevik H, Türk A, Ozsarac U. The Effect of Ti–B and Sr on the mechanical behaviour of the Zinc–Aluminum-based ZA-12 alloy produced by gravity casting. Int. J. Mat. Res. (formerly Z Metallkd). 2006;97(8):1152–7.

Anjan BN, Preetham Kumar GV. Microstructure and mechanical properties of ZA27 based SiC reinforced composite processed by multi directional forging. Mater Res Exp. 2018;5(10):106523.

Zaid AIO, Mostafa AO. Comparison between Mo addition to zinc aluminum alloy, ZA22, grain refined by Ti and Ti-B after pressing by the equal channel angular press. ECAP Int J Sci Eng Res. 2016;7(5):1133–8.

Prasad BK. Tensile properties of some zinc-based alloys comprising 27.5% Al: effects of alloy microstructure, composition and test conditions. Mater Sci Eng A. 1998;245A:257–66.

Dorantes-Rosales HJ, López-Hirata VM, Esquivel-González R, González-Velazquez JL, Moreno-Palmerin J, Torres-Castillo A. Zn–22Al–2Cu alloy phase transformations at different homogenizing temperatures. Met Mater Int. 2012;18(3):385–90.

Michalik R, Chmiela B. Influence of solution heat treatment on structure and mechanical properties of ZnAl22Cu3 alloy. Arch Metall Mater. 2016;61(3):1581–6. https://doi.org/10.1016/j.msea.2005.05.078.

Rajabi F, Taghiabadi R, Shaeri MH. Tribology of Si-rich TIG-deposited coatings on Zn–40Al–2Cu alloy. Surf Eng. 2020. https://doi.org/10.1080/02670844.2020.1728909.

Yousefi D, Taghiabadi R, Shaeri MH, Abedinzadeh P. Enhancing the mechanical properties of Si particle reinforced ZA22 composite by Ti–B modification. Int J Metalcast. 2020. https://doi.org/10.1007/s40962-020-00447-w.

Savaşkan T, Bican O. Effects of silicon content on the microstructural features and mechanical and sliding wear properties of Zn–40Al–2Cu–(0–5)Si alloys. Mater Sci Eng A. 2005;404(1–2):259–69. https://doi.org/10.1016/j.msea.2005.05.078.

Michalik R. The effect of modification with rare earth elements on ZnAl22Cu3 alloy structure and mechanical properties. Arch Metall Mater. 2013;58(1):49–53.

Zhang S, Zhao D. Aerospace materials handbook. USA: CRC Press; 2013.

Ansarian I, Shaeri MH, Ebrahimi M, Minárik P, Bartha K. Microstructure evolution and mechanical behaviour of severely deformed pure titanium through multi directional forging. J Alloys Comp. 2019;776:83–5.

Dashti A, Shaeri MH, Taghiabadi R, Djavanroodi F, Vali Ghazvini F, Javadi H. Microstructure, texture, electrical and mechanical properties of AA-6063 processed by multi directional forging. Mater. 2018;11(12):2419.

Gupta M, Ling S. Microstructure and mechanical properties of hypo/hyper-eutectic Al–Si alloys using a near-net shape forming technique. J Alloys Comp. 1999;287:284–94.

Lachowicz MM, Lachowicz MB. Intergranular corrosion of the as cast hypoeutectic zinc–aluminium alloy. Arch Foundry Eng. 2017;17(3):79–84.

Agapie M, Varga B. Analysis of phase transformations in eutectoid Zn–Al alloys. In: Proceedings of the 5th Int. Conf. Adv. Comp. Mater. Eng. Brasov, Romania, 2014;(1), pp 7–12.

Arif MAM, Omar MZ, Muhamad N, Syarif J, Kapranos P. Microstructural evolution of solid-solution-treated Zn–22Al in the semisolid state. J Mater Sci Technol. 2013;29(8):765–74.

Warmuzek M. Aluminium-silicon casting alloys: atlas of microfractographs, Materials Park, OH, USA. In: ASM Int., 2004.

Ma K, Hu T, Yang H, Topping T, Yousefiani A, Lavernia EJ, Schoenung JM. Coupling of dislocations and precipitates: impact on the mechanical behavior of ultrafine grained Al–Zn–Mg alloys. Acta Mater. 2016;103:153–4.

Edalati K, Hashiguchi Y, Iwaoka H, Matsunaga H, Valiev RZ, Horita Z. Long-time stability of metals after severe plastic deformation: softening and hardening by self-annealing versus thermal stability. Mater Sci Eng A. 2018;729:340–8.

Lapovok R, Toth LS, Molinari A, Estrin Y. Strain localization patterns under equal-channel angular pressing. J Mech Phys Solids. 2009;57:122–36.

Zhang NX, Kawasaki M, Huang Y, Langdon TG. The significance of self-annealing in two-phase alloys processed by high-pressure torsion. IOP Conf Ser Mater Sci Eng. 2014;63(1):012126.

Purcek G, Altan BS, Miskioglu I, Ooi PH. Processing of eutectic Zn–5% Al alloy by equal-channel angular pressing. J Mater Process Technol. 2004;148(3):279–87.

Wu Z, Sandlöbes S, Wu L, Hu W, Gottstein G, Korte-Kerzel S. Mechanical behaviour of Zn–Al–Cu–Mg alloys: Deformation mechanisms of as-cast microstructures. Mater Sci Eng A. 2016;651:675–7.

Wu Z, Sandlöbes S, Rao J, Gibson JSL, Berkels B, Korte-Kerzel S. Local mechanical properties and plasticity mechanisms in a Zn–Al eutectic alloy. Mater Des. 2018;157:337–50.

Sharath PC, Udupa KR, Kumar GVP. Effect of multi directional forging on impression creep behavior of Zn–24Al–2Cu alloy. Mater Today Proc. 2018;5(9):18211–20 (Part 3).

Demirtas M, Purcek G, Yanar H, Zhang ZJ, Zhang ZF. Effect of different processes on lamellar-free ultrafine grain formation, room temperature superplasticity and fracture mode of Zn–22Al alloy. J Alloys Comp. 2016;663(5):775–83.

Tanaka T, Higashi K. Superplasticity at room temperature in Zn–22Al alloy processed by equal-channel-angular extrusion. Mater Trans. 2000;45(4):1261–5.

Yang CF, Pan JH, Chuang MC. Achieving high strain rate superplasticity via severe plastic deformation processing. J Mater Sci. 2008;43(18):6260–6.

Tanaka T, Makii K, Kushibe A, Higashi K. Room temperature deformation behavior of Zn-22 mass% Al alloy with nanocrystalline structure. Mater Trans. 2002;43(10):2449–544.

Kawasaki M, Langdon TG. Grain boundary sliding in a superplastic Zinc–Aluminum alloy processed using severe plastic deformation. Mater Trans. 2008;49(1):84–9.

Hankin G, Toloczko M, Hamilton ML, Faulkner RG. Validation of the shear punch–tensile correlation technique using irradiated materials. J Nucl Mater. 1998;258:1651–6.

Karthik V, Padmanabhan V, Vijayraghavan A, Kasiviswanathan KV, Raj B. Tensile–shear correlations obtained from shear punch test technique using a modified experimental approach. J Nucl Mater. 2009;393(3):42532.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors had no funding sources or conflict of interest to report.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yousefi, D., Taghiabadi, R., Shaeri, M.H. et al. Microstructural evolution and mechanical properties of multi-directionally forged SiP/ZA22 composite. Archiv.Civ.Mech.Eng 20, 118 (2020). https://doi.org/10.1007/s43452-020-00124-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00124-z