Abstract

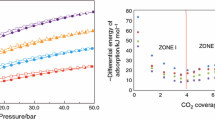

In this study, the method regarding preparation of a tea residue-based activated carbon (AC) was provided. The physicochemical property and adsorption performance of the obtained AC were also investigated. The preparation of AC mainly includes the carbonization at 350 °C and activation by potassium hydroxide (KOH). The activation parameters including temperature, time and dosage of KOH are crucial to the physicochemical property of AC samples. According to the ANOVA analysis, the optimum activation conditions are determined as activation temperature of 900 °C, activation time of 60 min and mixture ratio of char and KOH of 3:2. The N2 adsorption/desorption and scanning electron microscopy (SEM) characterizations confirm that AC obtained at the above-mentioned optimum activation conditions, designated as AC7, possesses well-developed porosity. The Langmuir model well describes the adsorption equilibrium of o-cresol on sample AC7. The maximum o-cresol adsorption capacity obtained from the Langmuir model increases with the elevated temperature. The maximum adsorption capacity of o-cresol on sample AC7 could reach up to 476 mg g−1, which is higher than that of other reported AC samples. The adsorption kinetics of o-cresol on sample AC7 follows the pseudo-second-order model. The generated pseudo-second-order rate constant of o-cresol adsorption on sample AC7 rises with the operating temperature. The adsorption thermodynamics study shows that o-cresol adsorption on sample AC7 is spontaneous and endothermic. Apart from the physisorption, the chemisorption does exist between o-cresol and sample AC7. Particularly, the π–π dispersion interaction plays a dominant role during o-cresol adsorption on sample AC7.

Similar content being viewed by others

References

Dąbrowski, A.; Podkościelny, P.; Hubicki, Z.; Barczak, M.: Adsorption of phenolic compounds by activated carbon-a critical review. Chemosphere 58(8), 1049–1070 (2005). https://doi.org/10.1016/j.chemosphere.2004.09.067

Altenor, S.; Carene, B.; Emmanuel, E.; Lambert, J.; Ehrhardt, J.-J.; Gaspard, S.: Adsorption studies of methylene blue and phenol onto vetiver roots activated carbon prepared by chemical activation. J. Hazard. Mater. 165(1), 1029–1039 (2009). https://doi.org/10.1016/j.jhazmat.2008.10.133

Hamitouche, A.Y.-E.; Bendjama, Z.; Amrane, A.; Kaouah, F.: Biodegradation of o-Cresol by a Pseudomonas spp. In: Dincer, I., Colpan, C.O., Kizilkan, O., Ezan, M.A. (eds.) Progress in Clean Energy, Volume 1: Analysis and Modeling, pp. 713–724. Springer, Cham (2015)

Kavitha, V.; Palanivelu, K.: Destruction of cresols by Fenton oxidation process. Water Res. 39(13), 3062–3072 (2005). https://doi.org/10.1016/j.watres.2005.05.011

Irani, M.; Rad, L.R.; Pourahmad, H.; Haririan, I.: Optimization of the combined adsorption/photo-Fenton method for the simultaneous removal of phenol and paracetamol in a binary system. Micropor. Mesopor. Mater. 206, 1–7 (2015). https://doi.org/10.1016/j.micromeso.2014.12.009

Annachhatre, A.P.; Gheewala, S.H.: Biodegradation of chlorinated phenolic compounds. Biotechnol. Adv. 14(1), 35–56 (1996). https://doi.org/10.1016/0734-9750(96)00002-X

Melián, E.P.; Díaz, O.G.; Araña, J.; Rodríguez, J.M.D.; Rendón, E.T.; Melián, J.A.H.: Kinetics and adsorption comparative study on the photocatalytic degradation of o-, m- and p-cresol. Catal. Today 129(1), 256–262 (2007). https://doi.org/10.1016/j.cattod.2007.08.003

Pal, B.; Hata, T.; Goto, K.; Nogami, G.: Photocatalytic degradation of o-cresol sensitized by iron–titania binary photocatalysts. J. Mol. Catal. A: Chem. 169(1), 147–155 (2001). https://doi.org/10.1016/S1381-1169(00)00549-5

Zhang, T.; Márquez-Hernández, L.I.; Arnold, R.G.; Diefenthal, G.; Sáez, A.E.: Modeling the UV/H2O2 oxidation of phenolic compounds in a continuous-flow reactor with reflective walls. J. Environ. Chem. Eng. 7(3), 103150 (2019). https://doi.org/10.1016/j.jece.2019.103150

Hou, B.L.; Kuang, Y.; Han, H.J.; Liu, Y.; Ren, B.Z.; Deng, R.J.; Hursthouse, A.S.: Enhanced performance and hindered membrane fouling for the treatment of coal chemical industry wastewater using a novel membrane electro-bioreactor with intermittent direct current. Bioresour. Technol. 271, 332–339 (2019). https://doi.org/10.1016/j.biortech.2018.09.063

Thue, P.S.; dos Reis, G.S.; Lima, E.C.; Sieliechi, J.M.; Dotto, G.L.; Wamba, A.G.N.; Dias, S.L.P.; Pavan, F.A.: Activated carbon obtained from sapelli wood sawdust by microwave heating for o-cresol adsorption. Res. Chem. Intermediat. 43(2), 1063–1087 (2017). https://doi.org/10.1007/s11164-016-2683-8

Spessato, L.; Bedin, K.C.; Cazetta, A.L.; Souza, I.P.A.F.; Duarte, V.A.; Crespo, L.H.S.; Silva, M.C.; Pontes, R.M.; Almeida, V.C.: KOH-super activated carbon from biomass waste: insights into the paracetamol adsorption mechanism and thermal regeneration cycles. J. Hazard. Mater. 371, 499–505 (2019). https://doi.org/10.1016/j.jhazmat.2019.02.102

Yang, G.D.; Tang, L.; Zeng, G.M.; Cai, Y.; Tang, J.; Pang, Y.; Zhou, Y.Y.; Liu, Y.Y.; Wang, J.J.; Zhang, S.; Xiong, W.P.: Simultaneous removal of lead and phenol contamination from water by nitrogen-functionalized magnetic ordered mesoporous carbon. Chem. Eng. J. 259, 854–864 (2015). https://doi.org/10.1016/j.cej.2014.08.081

Wang, Y.B.; Su, X.L.; Xu, Z.; Wen, K.; Zhang, P.; Zhu, J.X.; He, H.P.: Preparation of surface-functionalized porous clay heterostructures via carbonization of soft-template and their adsorption performance for toluene. Appl. Surf. Sci. 363, 113–121 (2016). https://doi.org/10.1016/j.apsusc.2015.11.261

Garg, U.K.; Kaur, M.P.; Garg, V.K.; Sud, D.: Removal of hexavalent chromium from aqueous solution by agricultural waste biomass. J. Hazard. Mater. 140(1), 60–68 (2007). https://doi.org/10.1016/j.jhazmat.2006.06.056

Dubey, S.P.; Gopal, K.: Adsorption of chromium(VI) on low cost adsorbents derived from agricultural waste material: a comparative study. J. Hazard. Mater. 145(3), 465–470 (2007). https://doi.org/10.1016/j.jhazmat.2006.11.041

Cazetta, A.L.; Vargas, A.M.M.; Nogami, E.M.; Kunita, M.H.; Guilherme, M.R.; Martins, A.C.; Silva, T.L.; Moraes, J.C.G.; Almeida, V.C.: NaOH-activated carbon of high surface area produced from coconut shell: kinetics and equilibrium studies from the methylene blue adsorption. Chem. Eng. J. 174(1), 117–125 (2011). https://doi.org/10.1016/j.cej.2011.08.058

Hameed, B.H.; Din, A.T.M.; Ahmad, A.L.: Adsorption of methylene blue onto bamboo-based activated carbon: kinetics and equilibrium studies. J. Hazard. Mater. 141(3), 819–825 (2007). https://doi.org/10.1016/j.jhazmat.2006.07.049

Yalçın, N.; Sevinç, V.: Studies of the surface area and porosity of activated carbons prepared from rice husks. Carbon 38(14), 1943–1945 (2000). https://doi.org/10.1016/S0008-6223(00)00029-4

Rai, M.K.; Shahi, G.; Meena, V.; Meena, R.; Chakraborty, S.; Singh, R.S.; Rai, B.N.: Removal of hexavalent chromium Cr(VI) using activated carbon prepared from mango kernel activated with H3PO4. Resour. Effic. Technol. 2, S63–S70 (2016). https://doi.org/10.1016/j.reffit.2016.11.011

Wong, S.; Lim, Y.; Ngadi, N.; Mat, R.; Hassan, O.; Inuwa, I.M.; Mohamed, N.B.; Low, J.H.: Removal of acetaminophen by activated carbon synthesized from spent tea leaves: equilibrium, kinetics and thermodynamics studies. Powder Technol. 338, 878–886 (2018). https://doi.org/10.1016/j.powtec.2018.07.075

Malhotra, M.; Suresh, S.; Garg, A.: Tea waste derived activated carbon for the adsorption of sodium diclofenac from wastewater: adsorbent characteristics, adsorption isotherms, kinetics, and thermodynamics. Environ. Sci. Pollut. Res. 25(32), 32210–32220 (2018). https://doi.org/10.1007/s11356-018-3148-y

Liu, Z.J.; Huang, H.H.: Preparation and characterization of cellulose composite hydrogels from tea residue and carbohydrate additives. Carbohyd. Polym. 147, 226–233 (2016). https://doi.org/10.1016/j.carbpol.2016.03.100

Kan, Y.J.; Yue, Q.Y.; Li, D.; Wu, Y.W.; Gao, B.Y.: Preparation and characterization of activated carbons from waste tea by H3PO4 activation in different atmospheres for oxytetracycline removal. J. Taiwan Inst. Chem. Eng. 71, 494–500 (2017). https://doi.org/10.1016/j.jtice.2016.12.012

Zhang, C.; van Krimpen, M.M.; Sanders, J.P.M.; Bruins, M.E.: Improving yield and composition of protein concentrates from green tea residue in an agri-food supply chain: effect of pre-treatment. Food Bioprod. Process. 100, 92–101 (2016). https://doi.org/10.1016/j.fbp.2016.06.001

Peng, C.; Yan, X.B.; Wang, R.T.; Lang, J.W.; Ou, Y.J.; Xue, Q.J.: Promising activated carbons derived from waste tea-leaves and their application in high performance supercapacitors electrodes. Electrochim. Acta 87, 401–408 (2013). https://doi.org/10.1016/j.electacta.2012.09.082

Inal, I.I.G.; Holmes, S.M.; Banford, A.; Aktas, Z.: The performance of supercapacitor electrodes developed from chemically activated carbon produced from waste tea. Appl. Surf. Sci. 357, 696–703 (2015). https://doi.org/10.1016/j.apsusc.2015.09.067

Gundogdu, A.; Duran, C.; Senturk, H.B.; Soylak, M.; Imamoglu, M.; Onal, Y.: Physicochemical characteristics of a novel activated carbon produced from tea industry waste. J. Anal. Appl. Pyrol. 104, 249–259 (2013). https://doi.org/10.1016/j.jaap.2013.07.008

Li, Y.H.; Du, Q.J.; Wang, X.D.; Zhang, P.; Wang, D.C.; Wang, Z.H.; Xia, Y.Z.: Removal of lead from aqueous solution by activated carbon prepared from Enteromorpha prolifera by zinc chloride activation. J. Hazard. Mater. 183(1), 583–589 (2010). https://doi.org/10.1016/j.jhazmat.2010.07.063

Liu, Q.S.; Zheng, T.; Wang, P.; Guo, L.: Preparation and characterization of activated carbon from bamboo by microwave-induced phosphoric acid activation. Ind. Crop. Prod. 31(2), 233–238 (2010). https://doi.org/10.1016/j.indcrop.2009.10.011

Moralı, U.; Demiral, H.; Şensöz, S.: Optimization of activated carbon production from sunflower seed extracted meal: taguchi design of experiment approach and analysis of variance. J. Clean. Prod. 189, 602–611 (2018). https://doi.org/10.1016/j.jclepro.2018.04.084

El-Hendawy, A.-N.A.: Influence of HNO3 oxidation on the structure and adsorptive properties of corncob-based activated carbon. Carbon 41(4), 713–722 (2003). https://doi.org/10.1016/S0008-6223(03)00029-0

El-Hendawy, A.-N.A.; Samra, S.E.; Girgis, B.S.: Adsorption characteristics of activated carbons obtained from corncobs. Colloids Surf. A 180(3), 209–221 (2001). https://doi.org/10.1016/S0927-7757(00)00682-8

Ahmedna, M.; Marshall, W.E.; Husseiny, A.A.; Rao, R.M.; Goktepe, I.: The use of nutshell carbons in drinking water filters for removal of trace metals. Water Res. 38(4), 1062–1068 (2004). https://doi.org/10.1016/j.watres.2003.10.047

Tan, I.A.W.; Ahmad, A.L.; Hameed, B.H.: Preparation of activated carbon from coconut husk: optimization study on removal of 2,4,6-trichlorophenol using response surface methodology. J. Hazard. Mater. 153(1), 709–717 (2008). https://doi.org/10.1016/j.jhazmat.2007.09.014

Oh, G.H.; Park, C.R.: Preparation and characteristics of rice-straw-based porous carbons with high adsorption capacity. Fuel 81(3), 327–336 (2002). https://doi.org/10.1016/S0016-2361(01)00171-5

Stavropoulos, G.G.; Zabaniotou, A.A.: Production and characterization of activated carbons from olive-seed waste residue. Micropor. Mesopor. Mater. 82(1), 79–85 (2005). https://doi.org/10.1016/j.micromeso.2005.03.009

Tay, J.H.; Chen, X.G.; Jeyaseelan, S.; Graham, N.: Optimising the preparation of activated carbon from digested sewage sludge and coconut husk. Chemosphere 44(1), 45–51 (2001). https://doi.org/10.1016/S0045-6535(00)00383-0

Girgis, B.S.; Yunis, S.S.; Soliman, A.M.: Characteristics of activated carbon from peanut hulls in relation to conditions of preparation. Mater. Lett. 57(1), 164–172 (2002). https://doi.org/10.1016/S0167-577X(02)00724-3

Aygün, A.; Yenisoy-Karakaş, S.; Duman, I.: Production of granular activated carbon from fruit stones and nutshells and evaluation of their physical, chemical and adsorption properties. Micropor. Mesopor. Mater. 66(2), 189–195 (2003). https://doi.org/10.1016/j.micromeso.2003.08.028

Suhas, Carrott, P.J.M., Ribeiro Carrott, M.M.L., Singh, R., Singh, L.P., Chaudhary, M.: An innovative approach to develop microporous activated carbons in oxidising atmosphere. J. Clean. Prod. 156, 549–555 (2017). https://doi.org/10.1016/j.jclepro.2017.04.078

Dhorabe, P.T.; Lataye, D.H.; Tenpe, A.R.; Ingole, R.S.: Adsorption of p-nitrophenol onto acacia glauca saw dust and waste orange peels activated carbon: application of Taguchi’s design of experiment. SN Appl. Sci. 1(3), 250 (2019). https://doi.org/10.1007/s42452-019-0264-3

Samantray, R.; Mishra, S.C.: Saccharum spontaneum, a precursor of sustainable activated carbon: synthesis, characterization and optimization of process parameters and its suitability for supercapacitor applications. Diam. Relat. Mater. 101, 107598 (2020). https://doi.org/10.1016/j.diamond.2019.107598

Supong, A.; Bhomick, P.C.; Baruah, M.; Pongener, C.; Sinha, U.B.; Sinha, D.: Adsorptive removal of Bisphenol A by biomass activated carbon and insights into the adsorption mechanism through density functional theory calculations. Sustain. Chem. Pharm. 13, 100159 (2019). https://doi.org/10.1016/j.scp.2019.100159

Yang, R.T.: Adsorbents: Fundamentals and applications. Wiley, New York (2003)

Sing, K.S.W.: Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). In Pure Appl Chem. vol. 57. vol. 4, p. 603. (1985)

Brunauer, S.; Deming, L.S.; Deming, W.E.; Teller, E.: On a theory of the van der Waals adsorption of gases. J. Am. Chem. Soc. 62(7), 1723–1732 (1940). https://doi.org/10.1021/ja01864a025

Zhang, D.F.; Zhang, J.; Huo, P.L.; Wang, Q.Q.; Wang, H.H.; Jiang, W.P.; Tao, J.; Zhu, L.: Influences of SO2, NO, and CO2 exposure on pore morphology of various rank coals: implications for coal-fired flue gas sequestration in deep coal seams. Energy Fuels 30(7), 5911–5921 (2016). https://doi.org/10.1021/acs.energyfuels.6b00220

Chowdhury, S.R.; Yanful, E.K.; Pratt, A.R.: Recycling of nickel smelter slag for arsenic remediation-an experimental study. Environ. Sci. Pollut. Res. 21(17), 10096–10107 (2014). https://doi.org/10.1007/s11356-014-2892-x

Zhang, D.F.; Wang, H.H.; Wang, Q.Q.; Li, W.; Jiang, W.P.; Huo, P.L.; Zhang, J.; Zhu, L.; Duan, G.Q.; Du, C.C.: Interactions of nitric oxide with various rank coals: implications for oxy-coal combustion flue gas sequestration in deep coal seams with enhanced coalbed methane recovery. Fuel 182, 704–712 (2016). https://doi.org/10.1016/j.fuel.2016.06.018

Zmudzinski, W.: Removal of o-cresol from water by adsorption/photocatalysis. Pol. J. Environ. Stud. 19(6), 1353–1359 (2010)

Flores-Cano, J.V.; Sánchez-Polo, M.; Messoud, J.; Velo-Gala, I.; Ocampo-Pérez, R.; Rivera-Utrilla, J.: Overall adsorption rate of metronidazole, dimetridazole and diatrizoate on activated carbons prepared from coffee residues and almond shells. J. Environ. Manage. 169, 116–125 (2016). https://doi.org/10.1016/j.jenvman.2015.12.001

Yin, W.Q.; Dai, D.; Hou, J.H.; Wang, S.S.; Wu, X.G.; Wang, X.Z.: Hierarchical porous biochar-based functional materials derived from biowaste for Pb(II) removal. Appl. Surf. Sci. 465, 297–302 (2019). https://doi.org/10.1016/j.apsusc.2018.09.010

Do, D.D.: Adsorption analysis: Equilibria and kinetics. Imperial College Press, London (1998)

Wang, Z.F.; Zhang, X.M.; Liu, X.L.; Zhang, Y.G.; Zhao, W.M.; Li, Y.Y.; Qin, C.L.; Bakenov, Z.: High specific surface area bimodal porous carbon derived from biomass reed flowers for high performance lithium-sulfur batteries. J. Colloid Interf. Sci. 569, 22–33 (2020). https://doi.org/10.1016/j.jcis.2020.02.062

Hu, P.; Chen, C.J.; Zeng, R.; Xiang, J.W.; Huang, Y.; Hou, D.F.; Li, Q.; Huang, Y.H.: Facile synthesis of bimodal porous graphitic carbon nitride nanosheets as efficient photocatalysts for hydrogen evolution. Nano Energy 50, 376–382 (2018). https://doi.org/10.1016/j.nanoen.2018.05.066

Peer, M.; Qajar, A.; Rajagopalan, R.; Foley, H.C.: Synthesis of carbon with bimodal porosity by simultaneous polymerization of furfuryl alcohol and phloroglucinol. Micropor. Mesopor. Mater. 196, 235–242 (2014). https://doi.org/10.1016/j.micromeso.2014.05.020

Oemar, B.; Chang, W.-C.: Taguchi method for optimizing process parameters in the production of activated carbon from rubber seed shell. Int. J. Adv. Manuf. Tech. 107(11), 4609–4620 (2020). https://doi.org/10.1007/s00170-020-05344-4

Syed-Hassan, S.S.A.; Zaini, M.S.M.: Optimization of the preparation of activated carbon from palm kernel shell for methane adsorption using Taguchi orthogonal array design. Korean J. Chem. Eng. 33(8), 2502–2512 (2016). https://doi.org/10.1007/s11814-016-0072-z

Zhang, D.F.; Jia, S.Q.; Wang, H.H.; Huo, P.L.; Zhang, J.; Tao, J.: Interactions of sulfur dioxide with coals: implications for oxy-coal combustion flue gas sequestration in deep coal seams. Energy Fuels 31(5), 5333–5343 (2017). https://doi.org/10.1021/acs.energyfuels.7b00136

Yu, B.; Zhang, Y.; Shukla, A.; Shukla, S.S.; Dorris, K.L.: The removal of heavy metal from aqueous solutions by sawdust adsorption - removal of copper. J. Hazard. Mater. 80(1), 33–42 (2000). https://doi.org/10.1016/S0304-3894(00)00278-8

Langmuir, I.: The constitution and fundamental properties of solids and liquids. Part I. Solids. J. Am. Chem. Soc. 38(11), 2221–2295 (1916). https://doi.org/10.1021/ja02268a002

Toh, R.-H.; Lim, P.-E.; Seng, C.-E.; Adnan, R.: Immobilized acclimated biomass-powdered activated carbon for the bioregeneration of granular activated carbon loaded with phenol and o-cresol. Bioresour. Technol. 143, 265–274 (2013). https://doi.org/10.1016/j.biortech.2013.05.126

Kew, S.-L.; Adnan, R.; Lim, P.-E.; Seng, C.-E.: Bioregeneration of cresol-loaded granular activated carbon using immobilized biomass: effects of operational factors and chemical structure of cresol isomers. J. Taiwan Inst. Chem. Eng. 63, 386–395 (2016). https://doi.org/10.1016/j.jtice.2016.03.039

Juang, R.-S.; Wu, F.-C.; Tseng, R.-L.: Adsorption isotherms of phenolic compounds from aqueous solutions onto activated carbon fibers. J. Chem. Eng. Data 41(3), 487–492 (1996). https://doi.org/10.1021/je950238g

Leite, A.B.; Saucier, C.; Lima, E.C.; dos Reis, G.S.; Umpierres, C.S.; Mello, B.L.; Shirmardi, M.; Dias, S.L.P.; Sampaio, C.H.: Activated carbons from avocado seed: optimisation and application for removal of several emerging organic compounds. Environ. Sci. Pollut. R. 25(8), 7647–7661 (2018). https://doi.org/10.1007/s11356-017-1105-9

Malkoc, E.; Nuhoglu, Y.: Removal of Ni(II) ions from aqueous solutions using waste of tea factory: adsorption on a fixed-bed column. J. Hazard. Mater. 135(1), 328–336 (2006). https://doi.org/10.1016/j.jhazmat.2005.11.070

Mohan, D.; Singh, K.P.: Single- and multi-component adsorption of cadmium and zinc using activated carbon derived from bagasse-an agricultural waste. Water Res. 36(9), 2304–2318 (2002). https://doi.org/10.1016/S0043-1354(01)00447-X

Ho, Y.S.; McKay, G.: Kinetic models for the sorption of dye from aqueous solution by wood. Process. Saf. Environ. 76(2), 183–191 (1998). https://doi.org/10.1205/095758298529326

Ho, Y.S.; McKay, G.: The kinetics of sorption of divalent metal ions onto sphagnum moss peat. Water Res. 34(3), 735–742 (2000). https://doi.org/10.1016/S0043-1354(99)00232-8

Ho, Y.S.; McKay, G.: Pseudo-second order model for sorption processes. Process Biochem. 34(5), 451–465 (1999). https://doi.org/10.1016/S0032-9592(98)00112-5

Azari, A.; Nabizadeh, R.; Nasseri, S.; Mahvi, A.H.; Mesdaghinia, A.R.: Comprehensive systematic review and meta-analysis of dyes adsorption by carbon-based adsorbent materials: classification and analysis of last decade studies. Chemosphere 250, 126238 (2020). https://doi.org/10.1016/j.chemosphere.2020.126238

Aichour, A.; Zaghouane-Boudiaf, H.: Highly brilliant green removal from wastewater by mesoporous adsorbents: kinetics, thermodynamics and equilibrium isotherm studies. Microchem. J. 146, 1255–1262 (2019). https://doi.org/10.1016/j.microc.2019.02.040

Kennedy, L.J.; Vijaya, J.J.; Sekaran, G.; Kayalvizhi, K.: Equilibrium, kinetic and thermodynamic studies on the adsorption of m-cresol onto micro- and mesoporous carbon. J. Hazard. Mater. 149(1), 134–143 (2007). https://doi.org/10.1016/j.jhazmat.2007.03.061

Zhu, Y.; Kolar, P.: Adsorptive removal of p-cresol using coconut shell-activated char. J. Environ. Chem. Eng. 2(4), 2050–2058 (2014). https://doi.org/10.1016/j.jece.2014.08.022

Zhu, Y.; Kolar, P.: Investigation of adsorption of p-cresol on coconut shell-derived activated carbon. J. Taiwan Inst. Chem. Eng. 68, 138–146 (2016). https://doi.org/10.1016/j.jtice.2016.07.044

Mansour, F.; Al-Hindi, M.; Yahfoufi, R.; Ayoub, G.M.; Ahmad, M.N.: The use of activated carbon for the removal of pharmaceuticals from aqueous solutions: a review. Rev. Environ. Sci. Bio. 17(1), 109–145 (2018). https://doi.org/10.1007/s11157-017-9456-8

Andersson, K.I.; Eriksson, M.; Norgren, M.: Removal of lignin from wastewater generated by mechanical pulping using activated charcoal and fly ash: adsorption isotherms and thermodynamics. Ind. Eng. Chem. Res. 50(13), 7722–7732 (2011). https://doi.org/10.1021/ie200378s

Borah, L.; Goswami, M.; Phukan, P.: Adsorption of methylene blue and eosin yellow using porous carbon prepared from tea waste: adsorption equilibrium, kinetics and thermodynamics study. J. Environ. Chem. Eng. 3(2), 1018–1028 (2015). https://doi.org/10.1016/j.jece.2015.02.013

Kelemen, S.R.; Kwiatek, P.J.: Quantification of organic oxygen species on the surface of fresh and reacted argonne premium coal. Energy Fuels 9(5), 841–848 (1995). https://doi.org/10.1021/ef00053a016

Luo, C.J.; Zhang, D.F.; Lun, Z.M.; Zhao, C.P.; Wang, H.T.; Pan, Z.J.; Li, Y.H.; Zhang, J.; Jia, S.Q.: Displacement behaviors of adsorbed coalbed methane on coals by injection of SO2/CO2 binary mixture. Fuel 247, 356–367 (2019). https://doi.org/10.1016/j.fuel.2019.03.057

Mattson, J.A.; Mark, H.B.; Malbin, M.D.; Weber, W.J.; Crittenden, J.C.: Surface chemistry of active carbon: specific adsorption of phenols. J. Colloid Interface Sci. 31(1), 116–130 (1969). https://doi.org/10.1016/0021-9797(69)90089-7

Acknowledgements

This work is conducted with funding from the project supported by the Science Foundation of the Education Department of Yunnan Province (Grant No. 2015Y063), the Analysis and Measurement Foundation of Kunming University of Science and Technology (Grant No. 2016T20110217), the National Training Program of Innovation and Entrepreneurship for Undergraduates (Grant No. 201710674032) and Laboratory Construction and Management Foundation of Kunming University of Science and Technology (Grant No. SYYJ33).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tao, J., Fu, X., Du, C. et al. Tea Residue-Based Activated Carbon: Preparation, Characterization and Adsorption Performance of o-Cresol. Arab J Sci Eng 46, 6243–6258 (2021). https://doi.org/10.1007/s13369-020-04968-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04968-8