Abstract

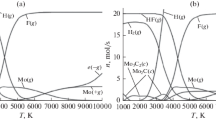

A procedure was developed to model the gas-dynamic and thermal conditions of the production of powdered silicon from silicon tetrachloride and tetrafluoride in a high-frequency induction plasma chemical reactor. The model includes a description of the turbulent flow of a mixture of ideal viscous compressible gases while taking into account the induction heating of the gas by conduction, convection, and radiation, as well as taking into account the effect of the electromagnetic force on plasma motion. The powdered particles form according to the results of the thermodynamic calculations, and the particle distribution in the flow is described by the diffusion mechanism. The results of modeling the conversion of volatile silicon chloride and fluoride in a swirl-stabilized high-frequency induction plasmatron are presented.

Similar content being viewed by others

REFERENCES

Sivoshinskaya, T.I., Grankov, I.V., Shabalin, Yu.P., and Ivanov, L.S., Pererabotka tetrakhlorida kremniya, obrazuyushchegosya v proizvodstve poluprovodnikovogo kremniya. Obzornaya informatsiya. Seriya: Proizvodstvo redkikh metallov i poluprovodnikovykh materialov. Vypusk 2 (Processing of Silicon Tetrachloride Formed in the Production of Semiconductor Silicon: Survey Information, Series in Production of Rare Metals and Semiconductor Materials, vol. 2), Moscow: Tsentr. Nauchno-Issled. Inst. Ekon. i Inf. Tsvetn. Metall., 1989.

Taylor, P.A., Purification techniques and analytical methods for gaseous and metallic impurities in high-purity silane, J. Cryst. Growth, 1988, vol. 89, no. 1, pp. 28–38. https://doi.org/10.1016/0022-0248(88)90068-1

Nuss, J.W. and Urry, G.J., J. Inorg. Nucl. Chem., 1964, vol. 26, p. 435.

Sarma, K.R. and Rice, M.J., Jr., US Patent 4309259, 1982.

Sarma, K.R. and Chanley, C.S., US Patent 4542004, 1985.

Lepage, J.-L and Simon, G., Fr. Patent 2530638, 1985.

Gromov, G.N., Bolgov, M.V., Muravitskii, S.A., et al., RF Patent 2350558, 2009.

Lu, Z. and Zhang, W., Hydrogenation of silicon tetrachloride in microwave plasma, Chin. J. Chem. Eng., 2014, vol. 22, no. 2, pp. 227–233. https://doi.org/10.1016/S1004-9541(14)60025-2

Wu, L., Ma, Z., He, A., and Wang, J., Studies on destruction of silicon tetrachloride using microwave plasma jet, J. Hazard. Mater., 2010, vol. 173, nos. 1–3, pp. 305–309. https://doi.org/10.1016/j.jhazmat.2009.08.095

Wu, L., Ma, Z., He, A., and Wang, J., Decomposition of silicon tetrachloride by microwave plasma jet at atmospheric pressure, Inorg. Mater., 2009, vol. 45, no. 12, article no. 1403. https://doi.org/10.1134/S0020168509120188

Deryzemlia, A.M., Kryshtal, P.G., Malykhin, D.G., Radchenko, V.I., and Shirokov, B.M., Deposition of nanocrystalline silicon films into low frequency induction RF discharge, Probl. At. Sci. Technol., 2014, no. 1 (89), p. 147.

Loginov, A.V. and Garbar, A.M., Silicon tetrafluoride: Properties, production, and applications, Vysokochist. Veshchestva, 1989, no. 5, p. 27.

Tumanov, Yu.N., Plazmennye i vysokochastotnye protsessy polucheniya i obrabotki materialov v yadernom toplivnom tsikle: nastoyashchee i budushchee (Plasma and High-Frequency Processes for Production and Processing of Materials in the Nuclear Fuel Cycle: The Present and the Future), Moscow: Fizmatlit, 2003.

Boone, J.E., Richards, D.M., and Bossier, J.A., US Patent 4309259, 1991.

Kut’in, A.M., Polyakov, V.S., and Sennikov, P.G., Abstracts of Papers, V Mezhdunarodnaya konferentsiya “Kremnii 2008” (V International Conference “Silicon 2008”), Chernogolovka: Granitsa, 2008, p. 178.

Djeridane, Y., Abramov, A., and Roca i Cabarrocas, P., Thin Solid Films, 2007, vol. 515, p. 7451.

Kumar, S., Brenot, R., Kalache, B., Tripathi, V., Vanderhaghen, R., Drevillon, B., and Roca i Cabarrocas, P., Solid State Phenom., 2001, vols. 80–81, p. 237.

Bruno, G., Capezzuto, P., and Cicala, G., RF glow discharge of SiF4-H2 mixtures: Diagnostics and modeling of the a-Si plasma deposition process, J. Appl. Phys., 1991, vol. 69, no. 10, p. 7256.

Vodopyanov, A.V., Golubev, S.V., Mansfeld, D.A., Sennikov, P.G., and Drozdov, Yu.N., Experimental investigations of silicon tetrafluoride decomposition in ECR discharge plasma, Rev. Sci. Instrum., 2011, vol. 82, article no. 063503.

Nagano, M., Mriya, T., et al., US Patent 0250764, 2004.

Kornev, R.A., Shabarova, L.V., and Shishkin, A.I., Gas-dynamic and thermal processes in a high-frequency induction plasma torch with tangential stabilization of the gas flow, Theor. Found. Chem. Eng., 2017, vol. 51, no. 5, pp. 736–741. https://doi.org/10.1134/S0040579517050323

Kornev, R.A., Sennikov, P.G., Shabarova, L.V., Shishkin, A.I., Drozdova, T.A., and Sintsov, S.V., Reduction of boron trichloride in atmospheric-pressure argon–hydrogen radiofrequency induction plasma, High Energy Chem., 2019, vol. 53, no. 3, pp. 246–253. https://doi.org/10.1134/S001814391903010X

Matveev, I., Matveyeva, S., and Zverev, S., Experimental investigations of the APT-60 high-pressure inductively coupled plasma system on different plasma gases, IEEE Trans. Plasma Sci., 2014, vol. 42, no. 12, p. 3891. https://doi.org/10.1109/TPS.2014.2362414

Bernardi, D., Colombo, V., Ghedini, E., and Mentrelli, A., Three-dimensional modeling of inductively coupled plasma torches, Pure Appl. Chem., 2005, vol. 77, no. 2, p. 359.

Fathalizadeh, A., Pham, T., Mickelson, W., and Zettl, A., Scaled synthesis of boron nitride nanotubes, nanoribbons, and nanococoons using direct feedstock injection into an extended-pressure, inductively-coupled thermal plasma, Nano Lett., 2014, vol. 14, p. 4881.

Karengin, A.G., Plazmennye tekhnologii pererabotki veshchestv (Plasma Technologies for Substance Processing), Tomsk: Tomsk. Politekh. Univ., 2008, part 1.

Mostaghimi, J. and Boulos, M.I., Two-dimensional electromagnetic field effects in induction plasma modelling, Plasma Chem. Plasma Process., 1989, vol. 9, no. 1, p. 25.

Walas, S.M., Phase Equilibria in Chemical Engineering, Boston: Butterworth, 1985.

Xue, S., Proulx, P., and Boulos, M.I., Extended-field electromagnetic model for inductively coupled plasma, J. Phys. D: Appl. Phys., 2001, vol. 34, p. 1897.

Grishin, Yu.M. and Myao, L., Numerical simulation of plasmadynamic processes in a technological high-frequency induction plasma generator with gas cooling, Nauka Obraz. MGTU im. N.E. Baumana, 2016, no. 05, p. 104.

Rehmet, C., Cao, T. and Cheng, Y., Numerical study of Si nanoparticles formation by SiCl4 hydrogenation in RF plasma, Plasma Sources Sci. Technol., 2016, vol. 25, no. 2, article no. 025011.

Ivanov, D.V. and Zverev, S.G., Mathematical simulation of processes in ICP/RF plasma torch for plasma chemical reactions, IEEE Trans. Plasma Sci., 2017, vol. 45, no. 12, p. 3125.

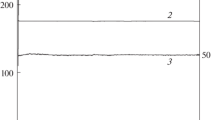

Shabarova, L.V., Kornev, R.A., and Sennikov, P.G., Simulation of gas-dynamic and thermal processes in vortex-stabilized, inductively coupled argon–hydrogen plasma, High Energy Chem., 2018, vol. 52, no. 5, pp. 423–428. https://doi.org/10.1134/S0018143918050120

Anderson, D.A., Tannehill, J.C., and Pletcher, R.H, Computational Fluid Mechanics and Heat Transfer, Series in Computational Methods in Mechanics and Thermal Sciences, New York: Hemisphere, 1984.

Bystrov, Yu.A., Isaev, S.A., Kudryavtsev, N.A., and Leont’ev, A.I., Chislennoe modelirovanie vikhrevoi intensifikatsii teploobmena v paketakh trub (Numerical Simulation of the Vortex Intensification of Heat Transfer in Tube Bundles), St. Petersburg: Sudostroenie, 2005.

Vorob’ev, A.Kh., Diffuzionnye zadachi v khimicheskoi kinetike (Diffusion Problems in Chemical Kinetics), Moscow: Mosk. Gos. Univ., 2003.

Murphy, A.B., Transport coefficients of hydrogen and argon–hydrogen plasmas, Plasma Chem. Plasma Process., 2000, vol. 20, no. 3, p. 279.

Gamburg, D.Yu., Vodorod. Svoistva, poluchenie, khranenie, transportirovanie, primenenie (Hydrogen: Properties, Production, Storage, Transportation, and Applications), Moscow: Khimiya, 1989.

Bretsznajder, S., Własności gazów i cieczy, Series in Inżynieria Chemiczna, Warszawa: Wydawnictwa Naukowo-Techniczne, 1962.

Abramov, A.N., Plekhovich, A.D., Kut’in, A.M., Yashkov, M.V., and Guryanov, A.N., Analysis of mullite formation in the core glass of a chromium-doped aluminosilicate fiber, Inorg. Mater., 2018, vol. 54, no. 9, pp. 940–948. https://doi.org/10.1134/S0020168518090017

Kourkkari, P. and Pajarre, R., A Gibbs energy minimization method for constrained and partial equilibria, Pure Appl. Chem., 2011, vol. 83, p. 1243.

Iorish, V.S., Belov, G.V., and Yungman, V.S., The IVTAN TERMO software package for Windows and its use in applied thermodynamic analysis, Preprint of the Joint Institute for High Temperatures, Russian Academy of Sciences, Moscow, 1998, no. 8-415.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Glyanchenko

Rights and permissions

About this article

Cite this article

Shabarova, L.V., Plekhovich, A.D., Kut’in, A.M. et al. Modeling Thermal Gas Dynamic Processes of the Production of Silicon from Its Halides. Theor Found Chem Eng 54, 631–640 (2020). https://doi.org/10.1134/S0040579520040260

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579520040260