Abstract

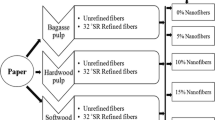

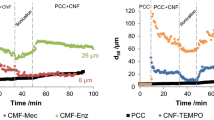

This study aimed to evaluate the effect of nanocellulose addition on the physical–mechanical properties of the paper produced from different fiber blends, besides comparing two nanocellulose addition methods. Three different fibers were used for fiber blending (eucalyptus, sisal, and pine). Handsheets were formed based on the mixing of all possible combinations at a 45/55 ratio in 2% consistency and 60 g/m2. Handsheet reinforcements were performed by two methods: The mixture method (MT) was a mixture of nanocellulose along with pulp during paper formation in 3, 5, and 10% addition; the coating method (CT) was the superficial coating of dry formed papers in 10% addition. Nanocellulose was produced by mechanical microfibrillation of sisal pulp. Handsheets were evaluated by physical and strength properties. Nanocellulose addition increased thickness, volume, grammage, apparent density, opacity, roughness, tensile strength, tensile index, stretch, bursting index, tear index, and fold endurance by 8.7, 8.8, 10.4, 2.1, 4.1, 23.2, 45.7, 31.8, 20.1, 14.2, 21.1, and 271.6% but reduced bulk, brightness, and air permeance by 1.9, 3.4, and 71.7%, respectively. The reinforcement methods presented distinct results. In physical properties, an increasing tendency toward nanocellulose (MT) increase was observed in thickness, grammage, and apparent density despite the decreasing trend in air permeance. No tendency was observed in other physical properties. In general, CT presented higher values of thickness, grammage, bulk, and brightness but lower values of apparent density and opacity, compared to MT. The mixture method showed an increasing tendency in strength properties with the increase of nanocellulose content. CT obtained fewer strength properties compared to MT.

Similar content being viewed by others

References

Adnan S, Azhar AH, Jasmani L, Samsudin MF (2018) Properties of paper incorporated with nanocellulose extracted using microbial hydrolysis assisted shear process. In: IOP conference series: materials science and engineering, p 012022

Akeem Azeez M, Andrew JE, Sithole BB (2016) A preliminary investigation of nigerian Gmelina arborea and Bambusa vulgaris for pulp and paper production. MaderasCiencTecnol. https://doi.org/10.4067/S0718-221X2016005000007

Balea A, Merayo N, Fuente E et al (2016) Valorization of corn stalk by the production of cellulose nanofibers to improve recycled paper properties. BioResources 11:3416–3431

Balea A, Merayo N, Fuente E et al (2018) Cellulose nanofibers from residues to improve linting and mechanical properties of recycled paper. Cellulose 25:1339–1351. https://doi.org/10.1007/s10570-017-1618-x

Balea A, Sanchez-Salvador JL, Monte MC et al (2019) In situ production and application of cellulose nanofibers to improve recycled paper production. Molecules 24:1–13. https://doi.org/10.3390/molecules24091800

Brodin FW, Gregersen ØW, Syverud K (2014) Cellulose nanofibrils: challenges and possibilities as a paper additive or coating material—a review. Nord Pulp Pap Res J 29:156–166

Bufalino L, de SenaNeto AR, Tonoli GHD et al (2015) How the chemical nature of Brazilian hardwoods affects nanofibrillation of cellulose fibers and film optical quality. Cellulose 22:3657–3672. https://doi.org/10.1007/s10570-015-0771-3

Campano C, Merayo N, Balea A et al (2018) Mechanical and chemical dispersion of nanocelluloses to improve their reinforcing effect on recycled paper. Cellulose 25:269–280. https://doi.org/10.1007/s10570-017-1552-y

Chauhan VS, Kumar N, Kumar M, Kumar Chakrabarti S, Thapar SK (2011) Effect of separate and mixed refining of hardwood and softwood pulps on paper properties. J Korea Tech Assoc Pulp Pap Ind 43:1–10

De Souza LGV, Carvalho CWP, Marconcini JM, Ascheri JLR (2009) Propriedades mecânicas de filmes biodegradáveis de amido de mandioca adicionados de nanofibrilas de algodão. [Mechanical properties of biodegradable films of cassava starch added with cotton nanofibrils] An do 10° Congr Bras Polímero

Delgado-Aguilar M, González I, Pèlach MA, De La Fuente E, Negro C, Mutje P (2015a) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22:789–802. https://doi.org/10.1007/s10570-014-0473-2

Delgado-Aguilar M, Tarrés Q, Pèlach MÀ, Mutje P, Fullana-i-Palmer P (2015b) Are cellulose nanofibers a solution for a more circular economy of paper products? Environ Sci Technol 49:12206–12213. https://doi.org/10.1021/acs.est.5b02676

El-Samahy MA, Mohamed SAA, Abdel Rehim MH, Mohram ME (2017) Synthesis of hybrid paper sheets with enhanced air barrier and antimicrobial properties for food packaging. CarbohydrPolym 168:212–219. https://doi.org/10.1016/j.carbpol.2017.03.041

Fathi G, Kasmani JE (2019) Prospects for the preparation of paper money from cotton fibers and bleached softwood kraft pulp fibers with nanofibrillated cellulose. BioResources 14:2798–2811

Ferreira DF (2011) Sisvar: a computer statistical analysis system. Ciência e Agrotecnologia 35:1039–1042. https://doi.org/10.1590/s1413-70542011000600001

Ghazali A, Dermawan YM, MohdZukeri MRH, Ibrahim R, Ghazali S (2014) EFB nano fibrous cells for paper smoothing and improved printability. Adv Mater Res 832:537–542. https://doi.org/10.4028/www.scientific.net/AMR.832.537

González I, Alcala M, Chinga-Carrasco G, Vilaseca F, Boufi S, Mutje P (2014) From paper to nanopaper: evolution of mechanical and physical properties. Cellulose 21:2599–2609. https://doi.org/10.1007/s10570-014-0341-0

González I, Boufi S, Pèlach MA, Alcala M, Vilaseca F, Mutje P (2012) Nanofibrillated cellulose as paper additive in. BioResource 7:5167–5180

Guan M, An X, Liu H (2019) Cellulose nanofiber (CNF) as a versatile filler for the preparation of bamboo pulp based tissue paper handsheets. Cellulose 26:2613–2624. https://doi.org/10.1007/s10570-018-2212-6

Hu L, Zheng G, Yao J et al (2013) Transparent and conductive paper from nanocellulosefiber. Energy Environ Sci 6:513–518. https://doi.org/10.1039/c2ee23635d

Huang W (2018) Cellulose nanopapers. In: Huang W (ed) Nanopapers: from nanochemistry and nanomanufacturing to advanced applications, 1st edn. Elsevier, Amsterdam, pp 121–171

Hubbe M, Ferrer A, Tyagi P et al (2017) Nanocellulose in in thin films, coatings, and plies for packaging applications: a review. BioResources 12:2143–2233. https://doi.org/10.1016/B978-0-08-100957-4.00008-5

IBA (2018) Sumário executivo [executive summary] IBA Indústria Brasileira de Árvores. https://iba.org/datafiles/publicacoes/relatorios/iba-sumarioexecutivo2018.pdf. Accessed 10 June 2019

Johansson C, Bras J, Mondragon I et al (2012) Renewable fibers and bio-based materials for packaging applications—a review of recent developments. BioResources 7:2506–2552. https://doi.org/10.15376/biores.7.2.2506-2552

Kasmani JE (2016) Effects of ozone and nanocellulose treatments on the strength and optical properties of paper made from chemical mechanical pulp. BioResources 11:7710–7720. https://doi.org/10.15376/biores.11.3.7710-7720

Kibblewhite RP (1977) Pulp blends of beaten and unbeaten fibre: effects on paper properties, and possible commercial implications. N Z J For Sci 7:250–257

Klemm D, Cranston ED, Fischer D et al (2018) Nanocellulose as a natural source for groundbreaking applications in materials science: today’s state. Mater Today 21:720–748. https://doi.org/10.1016/j.mattod.2018.02.001

Kose R, Yamaguchi K, Okayama T (2015) Influence of addition of fine cellulose fibers on physical properties and structure of paper. Sen’iGakkaishi 71:85–90

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. CarbohydrPolym 90:735–764. https://doi.org/10.1016/j.carbpol.2012.05.026

Miao C, Du H, Parit M et al (2020) Superior crack initiation and growth characteristics of cellulose nanopapers. Cellulose 27:3181–3195. https://doi.org/10.1007/s10570-020-03015-x

Nair SS, Zhu J, Deng Y, Ragauskas AJ (2014) High performance green barriers based on nanocellulose. Sustain Chem Process 2:1–7. https://doi.org/10.1186/s40508-014-0023-0

Pego MFF (2020) Papers development from blending of different natural fibers and nanocellulose addition. Thesis, Universidade Federal de Lavras

Qi Y, Zhang H, Xu D et al (2020) Screening of nanocellulose from different biomass resources and its integration for hydrophobic transparent nanopaper. Molecules 25:1–9

Rezayati Charani P, Dehghani-Firouzabadi M, Afra E, Blademo A, Naderi A, Lindström T (2013) Production of microfibrillated cellulose from unbleached kraft pulp of Kenaf and Scotch Pine and its effect on the properties of hardwood kraft: microfibrillated cellulose paper. Cellulose 20:2559–2567. https://doi.org/10.1007/s10570-013-9998-z

Sirviö BJ, Nurminen I (2004) Systematic changes in paper properties caused by fines. Pulp Pap Can 105:39–42

TAPPI Tappi Standards: Testing Methods, Recommended Practices, Specifications of the Technical Association of the Pulp and Paper Industry. Test methods (1997–2006). Tappi Press, Atlanta

Vallejos ME, Felissia FE, Area MC, Ehman NV, Tarres Q, Mutje P (2016) Nanofibrillated cellulose (CNF) from eucalyptus sawdust as a dry strength agent of unrefined eucalyptus handsheets. CarbohydPolym 139:99–105. https://doi.org/10.1016/j.carbpol.2015.12.004

Verdejo M, Bismarck A (2017) Upgrading the properties of woven and non-woven (ligno)cellulosic fibre preforms with nanocellulose. In: Lee KY (ed) Nanocellulose and sustainability production, properties, applications, and case studies. CRC Press, Boca Raton, pp 197–216

Viana LC, Muniz GIB, Magalhães WLE (2017) Propriedades físicas e mecânicas de filmes nanoestruturados obtidos a partir de polpa Kraft de Pinus sp. nãobranqueada (Physical and mechanical properties of nano-structured films produced from the unbleached Pinus sp. kraft pulp). Sci For 45:653–662

Zhu H, Fang Z, Preston C, Li Y, Hu L (2014) Transparent paper: fabrications, properties, and device applications. Energy Environ Sci 7:269–287. https://doi.org/10.1039/c3ee43024c

Acknowledgements

The authors would like to thank Klabin and Lwarcell S.A, Instituto de Pesquisas Tecnológicas – IPT and Universidade Federal de Lavras. This research was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brazil (CAPES)—Finance Code 001.

Funding

Funding was provided by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – CAPES.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pego, M.F.F., Bianchi, M.L. & Yasumura, P.K. Nanocellulose reinforcement in paper produced from fiber blending. Wood Sci Technol 54, 1587–1603 (2020). https://doi.org/10.1007/s00226-020-01226-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-020-01226-w