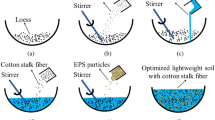

A new method for treatment of dredger fill was proposed to address its low bearing capacity, high consolidation cost, and long treatment duration. In this method, cotton straw is used as both the draining and reinforcement material. Specifically, cotton straw bundles are driven into the dredged soil and vacuum preloading is then performed. Subsequently, environmentally friendly grout is poured into the cotton straw bundles, and solidified vertical reinforcements are thus formed, allowing dredged soil to be treated. Design parameters for the cotton straw draining were obtained from previous laboratory test. Based on a real-world project, a field test was performed to study treatment of dredged soil through cotton straw drainage and reinforcement, and a comparison was drawn with the traditional cement mixing vertical reinforcement method. The vacuum degree, settlement, and water content of reinforced soil suggested a good ability of cotton straw drainage to solidify dredged soil. The static load test indicated that vertical reinforcement after grouting demonstrated better strength than cement reinforcements. This study provides new insights into the treatment of dredger fill and can broaden the application of cotton straw and also reduce environmental pollution caused by cotton straw burning.

Similar content being viewed by others

References

T. Väisänen, A. Haapala, R. Lappalainen, and L. Tomppo, "Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review," Waste Manage., 54, 62-73 (2016).

F. A. Silva, R. D. Toledo Filho, J. A. Melo Filho, and E. M. Rego Fairbairn, "Physical and mechanical properties of durable sisal fiber-cement composites," Constr. Build. Mater., 24, 777-785 (2010).

P. Methacanon, U. Weerawatsophon, N. Sumransin, C. Prahsarn, and D. T. Bergado, "Properties and potential application of the selected natural fibers as limited life geotextiles," Carbohydr. Polym., 82 (4), 1090-1096 (2010).

T. Ashour, A. Bahnasawey, and W. Wei, "Comprehensive strength of fibre reinforced earth plasters for straw bale buildings," Aust. J. Agric. Eng., 1 (3), 86-92 (2010).

P. G. Greeshma and M. Joseph, "Rice straw reinforcement for improvement in Kuttanad clay," Proc. of Indian Geotechnical Conference, Kochi (2011).

M. Li, S. X. Chai, H. Y. Zhang, H. P. Du, and L. Wei, "Feasibility of saline soil reinforced with treated wheat straw and lime," Soils Found., 52 (2), 228-238 (2012).

M. J. Oslen, A. M. Rikli, and D. N. Sillars, "Investigation of straw wattle influence on surficial slope stability," Transportation Research Board 91st Annual Meeting, Washington (2012).

C. H. Won, M. H. Shin, Y. H. Chor, J. Y. Shin, W. J. Park, and J. D. Choi, "Simulations of runoff using rice straw mats and soil amendments," J. Kor. Soc. Agric. Eng., 54 (2), 95-102 (2012).

D. J. Mitchell, A. P. Barton, M. A. Fullen, T. J. Hocking, B. Z. Wu, and Y. Zheng, "Field studies of the effects of jute geotextiles on runoff and erosion in Shropshire, UK," Soil Use Manage., 19, 182-184 (2003).

C. Liu and X. J. Yu, "Vacuum consolidation of wheat straw roller group and prediction based on grey system model," Electron. J. Geotech. Eng., 21 (21), 7095-7111 (2016).

Y. C. Yang, D. F. Pan, and Z. G. Zhou, "Study on reducing salt of rice straw drainage ditch in coastal saline soil of jiangsu province," Jiangsu J. Agric. Sci., 43 (3), 373-375 (2015).

F. Liu, Y. Wang, R. L. Xiao, J. S. Wu, Y. Li, S. N. Zhang, D. Wang, H. F. Li, and L. Chen, "Influence of substrates on nutrient removal performance of organic channel barriers in drainage ditches," J. Hydrol., 527, 380-386 (2015).

M. S. Shi, Y. B. Deng, T. T. Kong, W. W. Shi, Z. Li, T. T. Shen, and K. Cai, "Research on drainage characteristics of environmental friendly materials," J. Water.Resour. Archit. Eng, 13(3), 45-48 (2015).

G. Z. Xu, X. Y. Yu, F. H. Wu, and Y. Yin, "Feasibility of vacuum consolidation in managing dredged slurries with wheat straw as drainage channels," KSCE J. Civ. Eng., 21(4), 1154-1160 (2017).

F. L. Lu, "Reinforcement effect of cotton straw bales with preloading vacuum in dredger soft soil foundation," M.Sc. Thesis, Anhui University of Science and Technology, Anhui, China (2017).

Z. Zhou, "Study on engineering mechanics test of cotton straw-desulfurization gypsum-based curing pile," M.Sc. Thesis, Anhui University of Science and Technology, Anhui, China (2017)

H. Cao, Y. Feng, and Q. Jin, "Study on gypsum cotton straw slag composite block," New Build. Mater., 1, 55-56 (2013).

S. P. Li, Q. S. Wu, C. S. Zhang, and X. J. Huang, "Preparation and properties of desulfurization gypsum/cotton straw fibers composite wall materials," New Build. Mater., 1, 41-43, (2013).

B. Indraratna, C. Rujikiatkamjorn, and I. Sathananthan, "Radial consolidation of clay using compressibility indices and varying horizontal permeability," Can. Geotech. J., 42(5), 1330-1341 (2005).

H. Gram, "Durability of natural fibres in concrete," Swedish Cement and Concrete Research Institute, Stockolm (1983).

G. Ramakrishna and T. Sundararajan, "Studies on the durability of natural fibres and the effect of corroded fibres on the strength of mortar," Cem. Concr. Compos., 27(5), 575-582 (2005).

R. D. Toledo Filho, K. Scrivener, G. L. England, and K. Gh.avami, "Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites," Cem. Concr. Compos., 22(2), 127-143 (2000).

V. Agopyan, H. Savastano Jr, V. M. John, and M. A. Cincotto, "Developments on vegetable fibrecement based materials in San Paulo, Brazil: an overview," Cem. Concr. Compos., 27(5), 527-536 (2005).

R. M. De Gutierrez, L.N. Diaz, and S. Delvasto, "Effect of pozzolans on the performance of fiber reinforced mortars," Cem. Concr. Compos., 27 (5), 593-598 (2005).

H. Savastano Jr, P.G. Warden, and R. S. P. Coutts, "Potential of alternative fibre cements as building materials for developing areas," Cem. Concr. Compos., 25(6), 585-592 (2003).

B. J. Mohr, J. J. Biernacki, and K. E. Kurtis, "Supplementary cementitious materials for mitigating degradation of kraft pulp fiber-cement composites," Cem. Concr. Res., 37(11), 1531-1543 (2007) .

A. L. F. S. D'Almeida, J. A. Melo Filho, and R. D. Toledo Filho, "Use of curaua fibers as reinforcement in cement composites," Chem. Eng. Trans., 17, 1717-1722 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Osnovaniya, Fundamenty i Mekhanika Gruntov, No. 4, p. 32, July-August, 2020.

Rights and permissions

About this article

Cite this article

Yu, X., Liu, C. & Lu, F. Field Test Study on Treatment of Dredged Soil with Cotton Straw. Soil Mech Found Eng 57, 343–350 (2020). https://doi.org/10.1007/s11204-020-09676-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11204-020-09676-x