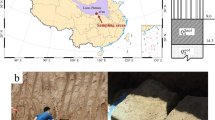

This paper focuses on the influence of joints on seepage capacity of a soil mass, the water infiltration range, the area of the wet zone, and water content distributions. Tests were performed using a self-designed seepage device to determine the hydraulic conductivity of loess samples with natural joints. The test results indicate that joints greatly improve the seepage capacity of a soil mass; the depth and quantity of infiltration for the jointed sample are larger than those for the intact sample. The infiltration depths of the jointed sample are about 2.6 times that of intact specimens, and the measured areas of wet zones of the jointed sample are about 2.2 times that of an intact sample. Due to the existence of the joint, higher water content is observed at the joint location. In comparison, the water content distributions are relatively horizontal for the intact sample.

Similar content being viewed by others

References

J. M. Wang, Y. L. Ni, and J. Z. Sun, “A study on structural joints in loess and its practical applications,” J. Eng. Geol., 2, 31-42 (1994).

C. Louis, “A study of groundwater flow in jointed rock and its influence on the stability of rock masses,” Rock Mech. Res. Rep. 10, Imperial College, London, 91-98 (1969).

D. Elsworth and R. E. Goodman, “Characterization of rock fissure hydraulic conductivity using idealized wall roughness profiles,” Int. J. Rock Mech. Min. Sci. Geomech. Abstr., 23, 233-243 (1986).

Y. W. Tsang and P. A. Witherspoon, “Hydromechanical behavior of a deformable rock fracture subject to normal stress,” J. Geophys. Res. Solid Earth, 86, 9287-9298 (1981).

C. C. Xia, W. Wang, and S. D. Cao, “Flow characteristics of joints under different contact conditions,” Chin. J. Rock Mech. Eng., 29,1297-1306 (2010).

Z. D. Du, Y. J. Zhao, and J. R. Cheng, “Research on the seepage test of unsaturated loess,” Hydrogeol. Eng. Geol., 24, 50-51 (1997).

S. Hu, “Analysis on spatial displacement of surrounding rock based on engineering properties of loess,” China Civ. Eng. J., 46, 117-122 (2013).

Q. G. Liang, J. Li, and D. W. Li, “Some problems on surrounding rock classification of loess tunnels,” China J. Geotech. Eng., 33, 170-176 (2011).

S. H. Zhong, “Influence of included tectonic joints on stability of tunnels in the loess,” China J. Geotech. Eng., 5, 68-77 (1983).

T. H. Wang, Y. Luo, and H. Zhang, “Two-dimensional steady flow rate equation for loess joints,” China J. Geotech. Eng., 35, 1115-1120 (2013).

Y. Luo, T. H. Wang, and J. J. Wang, “Finite element seepage flow model for unsaturated loess with joints,” J. Eng. Geol., 22, 1115-1122 (2014).

X. J. Liu, Q. Kong, and X. Zheng, “Experimental study on the seepage feature of natural loess joint,” in: Fatahi B., Mwanza A., and Chang D. (eds) Sustainable Design and Construction for Geomaterials and Geostructures. GeoChina 2018. Sustainable Civil Infrastructures. Springer (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Osnovaniya, Fundamenty i Mekhanika Gruntov, No. 4, p. 21, July-August, 2020.

Rights and permissions

About this article

Cite this article

Liu, X., Lin, C., Zhang, X. et al. Model Test Study on Seepage of Jointed Loess. Soil Mech Found Eng 57, 316–321 (2020). https://doi.org/10.1007/s11204-020-09672-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11204-020-09672-1