Abstract

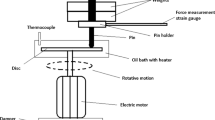

This paper is devoted to investigate the friction-reducing and wear protection performance of TiO2 nanoparticles as lubricant additive in fully formulated engine oil. The phase of TiO2 nanoparticles, synthesized by a sol–gel process, was characterized by XRD. A four-ball tribometer was used to compare the friction coefficient and wear when lubricated by engine oil in absence and presence of TiO2 nanoparticles. The surface chemistry of tribofilm was observed by XPS. The experiments showed that phase of TiO2 nanoparticles plays great role in determining the friction-reducing and wear protection of engine oil containing TiO2 nanoparticles. TiO2 nanoparticles upon calcination at 300 °C are amorphous, showing lowest hardness and then best friction-reducing and wear protection performance in engine oil. Rutile nanoparticles obtained upon calcination at the temperature above 700 °C, on the contrary, act as abrasive in the sliding contact and present larger wear than the blank engine oil.

Amorphous TiO2 nanoparticles calcinated at 300 °C presents lowest average coefficient of friction and wear scar diameter in engine oil.

Highlights

-

The tribological performances of TiO2 nanoparticles (NPs) in the engine oil are investigated.

-

The phase of TiO2 NPs plays role in determining tribological performance of oil with TiO2 NPs.

-

Amorphous TiO2 NPs calcinated at 300 °C show lowest hardness and best wear protection in oil.

-

Rutile NPs upon calcination at >700 °C act as abrasive and present larger wear than blank engine oil.

Similar content being viewed by others

References

Holmberg K, Erdemir A (2019) The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars. Tribol Int 135:389–396

Spikes H (2004) The history and mechanisms of ZDDP. Tribol Lett 17:469–489

Mosey NJ, Müser MH, Woo TK (2005) Molecular mechanisms for the functionality of lubricant additives. Science 307:1612–1615

Gosvami NN, Bares JA, Mangolini F, Konicek AR, Yablon DG, Carpick RW (2015) Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts. Science 348:102–106

Barnes AM, Bartle KD, Thibon VRA (2001) A review of zinc dialkyldithiophosphates (ZDDPS): characterisation and role in the lubricating oil. Tribol Int 34:389–395

Spikes H (2008) Low‐and zero‐sulphated ash, phosphorus and sulphur anti‐wear additives for engine oils. Lubr Sci 20:103–136

Uflyand IE, Zhinzhilo VA, Burlakova VE (2019) Metal-containing nanomaterials as lubricant additives: State-of-the-art and future development. Friction 7:93–116

Dai W, Kheireddin B, Gao H, Liang H (2016) Roles of nanoparticles in oil lubrication. Tribol Int 102:88–98

Gulzar M, Masjuki HH, Kalam MA, Varman M, Zulkifli NWM, Mufti RA, Zahid R (2016) Tribological performance of nanoparticles as lubricating oil additives. J Nanopart Res 223:25

Kogovšek J, Kalin M (2019) Lubrication performance of graphene-containing oil on steel and DLC-coated surfaces. Tribol Int 138:59–67

Gupta MK, Bijwe J, Padhan M (2018) Role of size of hexagonal boron nitride particles on tribo-performance of nano and micro oils. Lubr Sci 30:441–456

Tao C, Wang B, Barber GC, Schall JD, Lan H (2019) Tribological behaviour of SnO2 nanoparticles as an oil additive on brass. Lubr Sci 30:247–255

Gao K, Chang Q, Wang B (2020) The dispersion and tribological performances of magnesium silicate hydroxide nanoparticles enhanced by Span60 oleogel. J Sol-Gel Sci Technol 94:165–173

Ghaednia H, Hossain MS, Jackson RL (2016) Tribological performance of silver nanoparticle-enhanced polyethylene glycol lubricants. Tribol Trans 59:585–592

Liu T, Zhou C, Gao C, Zhang Y, Yang G, Zhang P, Zhang S (2020) Preparation of Cu@ SiO2 composite nanoparticle and its tribological properties as water‐based lubricant additive. Lubr Sci 32:69–79

Sharma V, Timmons RB, Erdemir A, Aswath PB (2019) Interaction of plasma functionalized TiO2 nanoparticles and ZDDP on friction and wear under boundary lubrication. Appl Surf Sci 489:372–383

Alazemi AA, Etacheri V, Dysart AD, Stacke L-E, Pol VG, Sadeghi F (2015) Ultrasmooth submicrometer carbon spheres as lubricant additives for friction and wear reduction. ACS Appl Mater Inter 7:5514–5521

Lv X, Cao L, Yang T, Wan Y, Gao J (2020) Lubricating behavior of submicrometer carbon spheres as lubricant additives. Particul Sci Technol 38:568–572

Schneider J, Matsuoka M, Takeuchi M, Zhang J, Horiuchi Y, Bahnemann DW (2014) Understanding TiO2 Photocatalysis: Mechanisms and Materials. Chem Rev 114:9919–9986

Bernardes JC, Pinheiro GK, Muller D, Latocheski E, Domingos JB, Rambo CR (2020) Novel modified nonalkoxide sol-gel synthesis of multiphase high surface area TiO2 aerogels for photocatalysis. J Sol-Gel Sci Technol 94:425–434

Diebold U (2003) The surface science of titanium dioxide. Surf Sci Rep. 48:53–229

Pelaez M, Nolan NT, Pillai SC, Seery MK, Falaras P, Kontos AG, Dunlop PSM, Hamilton JWJ, Byrne JA, O’Shea K, Entezari MH, Dionysiou DD (2012) A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl Catal B-Environ 125:331–349

Bernardes JC, Pinheiro GK, Muller D, Latocheski EB, Domingos JB, Rambo CR (2020) Novel modified nonalkoxide sol–gel synthesis of multiphase high surface area TiO2 aerogels for photocatalysis. J Sol-Gel Sci Technol 94:425–434

John AK, Palaty S (2018) Influence of solvent and pH on the synthesis of visible light active titanium dioxide nano particles. J Sol-Gel Sci Technol 87:391–399

Langlet M, Burgos M, Coutier C, Jimenez C, Morant C, Manso M (2001) Low temperature preparation of high refractive index and mechanically resistant sol-gel TiO2 films for multilayer antireflective coating applications. J Sol-Gel Sci Technol 22:139–150

Wan Y, Chao W, Liu Y, Zhang J (2011) Tribological performance of fluoroalkylsilane modification of sol-gel TiO2 coating. J Sol-Gel Sci Technol 57:193–197

Ćurkovi L, Otmačić Ćurkovi H, Salopek S, Majić Renjo M, Šegota S (2013) Enhancement of corrosion protection of AISI 304 stainless steel by nanostructured sol-gel TiO2 films. Corros Sci 77:176–184

Dhiflaoui H, Kaouther K, ben cheikh Larby A (2017) Wear behavior and mechanical properties of TiO2 coating deposited electrophoretically on 316 L stainless steel. J Tribol 031603:7

Cao L, Liu J, Wan Y, Yang S, Gao J, Pu J (2018) Low-friction carbon-based tribofilm from poly-alpha-olefin oil on thermally oxidized Ti6Al4V. Surf Coat Technol 337:471–477

Zhang L, Chen L, Wan H, Chen J, Zhou H (2011) Synthesis and tribological properties of stearic acid-modified anatase (TiO2) nanoparticles. Tribol Lett 41:409–416

Hu ZS, Dong JX (1998) Study on antiwear and reducing friction additive of nanometer titanium oxide. Wear 216:92–96

Ingole S, Charanpahari A, Kakade A, Umare SS, Bhatt DV, Menghani J (2013) Tribological behavior of nano TiO2 as an additive in base oil. Wear 301:776–785

Ilie F, Covaliu C (2016) Tribological properties of the lubricant containing titanium dioxide nanoparticles as an additive. Lubricants 12:13

Wu Y, Kao M (2011) Using TiO2 nanofluid additive for engine lubrication oil. Ind Lubr Tribol 63:440–445

Hong FT, Schneider A, Sarathy SM (2020) Enhanced lubrication by core-shell TiO2 nanoparticles modified with gallic acid ester. Tribol Int 106263:10

Kao M-J, Lin C-R (2009) Evaluating the role of spherical titanium oxide nanoparticles in reducing friction between two pieces of cast iron. J Alloy Compd 483:456–459

Reyes-Coronado D, Rodríguez-Gattorno G, Espinosa-Pesqueira ME, Cab C, De Coss R, Oskam G (2008) Phase-pure TiO2 nanoparticles: anatase, brookite and rutile. Nanotechnology 145605:10

Luttrell T, Halpegamage S, Tao J, Kramer A, Sutter E, Batzill M (2015) Why is anatase a better photocatalyst than rutile?—Model studies on epitaxial TiO2 films. Sci Rep 4043:7

Liu L, Zhao H, Andino JM, Li Y (2012) Photocatalytic CO2 reduction with H2O on TiO2 nanocrystals: Comparison of anatase, rutile, and brookite polymorphs and exploration of surface chemistry. ACS Catal 2:1817–1828

Chen Y-F, Lee C-Y, Yeng M-Y, Chiu H-T (2003) The effect of calcination temperature on the crystallinity of TiO2 nanopowders. J Cryst Growth 247:363–370

Golubović A, Simović B, Šćepanović M, Mijin D, Matković A, Grujić-Brojčin M, Babić B (2015) Synthesis of anatase nanopowders by sol-gel method and influence of temperatures of calcination to their photocatalitic properties. Sci Sinter 47:41–49

Wu YY, Tsui WC, Liu TC (2007) Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 262:819–825

Zhou X, Fu X, Shi H, Hu Z (2007) Lubricating properties of Cyanex 302-modified MoS2 microspheres in base oil 500SN. Lubr Sci 19:71–79

Liu G, Li X, Qin B, Xing D, Guo Y, Fan R (2004) Investigation of the mending effect and mechanism of copper nano-particles on a tribologically stressed surface. Tribol Lett 17:961–966

Guo D, Xie G, Luo J (2014) Mechanical properties of nanoparticles: basics and applications. J Phys D Appl Phys 013001:25

Acknowledgements

The authors acknowledge the financial support by National Natural Science Foundation of China [51975304], Natural Science Foundation of Shandong Province, China [ZR2019MEE016] and Postdoctoral program of Qingdao City, China. YW thanks Prof. Chonghai Xu for his helpful discussion.

Funding

YW acknowledge the financial support by National Natural Science Foundation of China [51975304] and Natural Science Foundation of Shandong Province, China [ZR2019MEE016]. CL acknowledge the financial support by Postdoctoral Program of Qingdao City, China.

Author information

Authors and Affiliations

Contributions

YW and LC designed research, YL performed research, CQ and YW analyzed data, LC, CQ, and YW wrote the paper

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, L., Li, Y., Wan, Y. et al. The effect of TiO2 phase on the lubricating performance of sol–gel-derived TiO2 nanoparticles in fully formulated engine oil. J Sol-Gel Sci Technol 96, 327–335 (2020). https://doi.org/10.1007/s10971-020-05354-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05354-4