Abstract

Closed-cell A356 aluminum foams have been produced by the addition of calcium carbonate (CaCO3) powder as a foaming agent to the molten aluminum without any stabilizer particles. The foaming process is performed by the addition of 2.5–3.5 wt% CaCO3 and has relative density ranges of 0.12–0.44 and cell sizes of 1.5–3.1 mm with uniform cell structures. The foaming stabilizing mechanism and effect of foaming conditions such as the amount of foaming agent, casting holding and mixing time at the furnace on the foamed samples were investigated. The stabilizing mechanism is because of the foaming gas (CO2)/melt reaction during the foaming procedure and producing some solid particles such as CaO, Al2O3 and MgO. The optimum foamed aluminum with uniform cell size distribution was obtained at 4-min mixing time and 10-min holding time with 3 wt% CaCO3 foaming agent. The porosity of aluminum foam increased as the holding time increased from 60 to 86%. Also, the average cell size increased from 1.5 to 3.1 mm when the amount of CaCO3 increased from 2.5 wt% to 3.5 wt%, respectively.

Similar content being viewed by others

References

H.P. Degischer, B. Kriszt, Handbook of cellular metals: Production, Processing, Applications (Wiley-VCH Verlag GmbH & Co, Germany, 2002)

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, H.N.G. Wadley, Metal Foams-A Design Guide (Butterworth-Heinemann, London, 2000)

F. Binesh, J. Zamani, M. Ghiasvand, Ordered structure composite metal foams produced by casting. Int. J. Metalcast. 12, 89–96 (2018)

C.C. Yang, H. Nakae, The effects of viscosity and cooling conditions on the foamability of aluminum alloy. J. Mater. Process. Technol. 141, 202–205 (2003)

Z.L. Song, J.S. Zhu, L.Q. Ma, D.P. He, Evolution of foamed aluminum structure in foaming process. Mater. Sci. Eng. A 298(1–2), 137–143 (2001)

S. Sasikumar, K. Georgy, M. Mukherjee, G.S. Vinod Kumar, Foam stabilization by aluminum powder. Mater. Lett. (2019). https://doi.org/10.1016/j.matlet.2019.127142

V. Gergely, D.C. Curran, T.W. Clyne, The FOAMCARP process: foaming of aluminium MMCs by the chalk-aluminium reaction in precursors. Compos. Sci. Technol. 63, 2301–2305 (2003)

M. Haesche, D. Lehmhus, J. Weise, M. Wichmann, I. Cristina, Carbonates as foaming agent in chip-based aluminium foam precursor. J. Mater. Sci. Technol. 26(9), 845–850 (2010)

T. Nakamura, S. Gnyloskurenko, K. Sakamoto, A. Byakova, R. Ishikawa, Development of new foaming agent for metal foam. Mater. Trans. 43, 1191–1194 (2002)

A. Byakova, I. Kartuzov, T. Nakamura, S. Gnyloskurenko, The role of foaming agent and processing route in mechanical performance of fabricated aluminum foams. Proc. Mater. Sci. 4, 109–114 (2014)

V. Gergely, D.C. Curran, T.W. Clyne, A. Ghosh, T. Sanders, D. Claar Processing and Properties of Lightweight Cellular Metals and Structures, TMS, Warrendale, pp. 97–101 (2002)

A. Byakova, Y. Bezim’yanny, S. Gnyloskurenko, T. Nakamura, Fabrication method for closed-cell aluminium foam with improved sound absorption ability. Proc. Mater. Sci. 4, 9–14 (2014)

S.F. Fischer, P. Schuler, C. Fleck, A. Buhrig-Polaczek, Influence of the casting and mould temperatures on the (micro)structure and compression behaviour of investment-cast open-pore aluminium foams. Acta Mater. 61, 5152–5161 (2013)

G. Avinash, V. Harika, Ch Sandeepika, R. Kumar, N. Gupta, Porosity control in aluminium foams using different additives. Mater. Today Proc. 18, 1054–1057 (2019)

J. Banhart, Light-metal foams—history of innovation and technological challenges. Adv. Eng. Mater. 3, 15 (2013). https://doi.org/10.1002/adem.201200217

D.P. Papadopoulos, H. Omar, F. Stergioudi, S.A. Tsipas, H. Lefakis, N. Michailidis, A novel method for producing Al-foams and evaluation of their compression behavior. J Porous Mater 17, 773–777 (2010). https://doi.org/10.1007/s10934-009-9349-5

J. Lázaro, E. Solórzano, M.A. Rodríguez-Pérez, Alternative carbonates to produce aluminium foams via melt route. Proc. Mater. Sci. 4, 275–280 (2014)

M. Malekjafarian, S.K. Sadrnezhaad, Closed-cell Al alloy composite foams: production and characterization. Mater. Des. 42, 8–12 (2012)

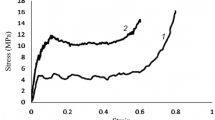

M. Heidari Ghaleh, N. Ehsani, H.R. Baharvandi, Compressive properties of A356 closed-cell aluminum foamed with a CaCO3 foaming agent without stabilizer particles. Metals Mater. Int. 2(1), 1–7 (2020). https://doi.org/10.1007/s12540-020-00807-5

J. Kahani, S. Bazzaz, F. Moghaddasi, A. Kahani, A study of fabricating and compressive properties of cellular Al–Si (355.0) foam using TiH2. Mater. Des. 55, 792–797 (2014)

I. Barin, O. Knake, O. Kubaschewski, Thermodynamic Properties of Inorganic Substances (Springer, Berlin, 1977)

D.R. Gaskell, Introduction to the thermodynamics of materials (Taylor & Francis, Washington DC, 1995)

W.Y. Jang, W.Y. Hsieh, C.C. Miao, Y.C. Yen, Microstructure and mechanical properties of ALPORAS closed-cell aluminium foam. Mater. Charact. 107, 228–238 (2015)

S. Sowmiya, P. Nallanukala, J. Anburaj, B. Simhachalam, Development of metallic aluminium foam casting using calcium carbonate precursors for side impact beam application. Mater. Today Proc. 5, 20362–20370 (2018)

W. Deqing, Sh Ziyuan, Effect of ceramic particles on cell size and wall thickness of aluminum foam. Mater. Sci. Eng. A 361, 45 (2003)

C.C. Yang, H. Nakae, Foaming characteristics control during production of aluminum alloy foam. J. Alloy. Compd. 313(1–2), 188–191 (2000)

W. Deqing, X. Weiwei, S. Ziyuan, Cell size prediction of a closed aluminum foam. Mater. Sci. Eng. A 431(1–2), 298–305 (2006)

W. Deqing, M. Xiangjun, X. Weiwei, S. Ziyuan, Effect of processing parameters on cell structure of an aluminum foam. Mater. Sci. Eng. A 420(1–2), 235–239 (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghaleh, M.H., Ehsani, N. & Baharvandi, H.R. High-Porosity Closed-Cell Aluminum Foams Produced by Melting Method Without Stabilizer Particles. Inter Metalcast 15, 899–905 (2021). https://doi.org/10.1007/s40962-020-00528-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00528-w