Abstract

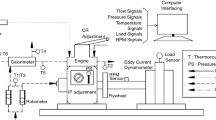

Optimum engine operating parameters on VCR engine performance and emission analysis is a challenging scenario towards the stringent emission control policies adopted by the globe. The engine operating parameters such as compression ratio (CR), fuel blends and fuel injection pressure (FIP) were implemented on VCR engine to improve its performance and to control its gaseous emissions. The input variable were chosen as FIP (185 bar,205 bar &225 bar), CR (18:1,19:1,20:1,21:1 & 22:1) and fuel blends (B20 & diesel) as parameters for designing the experiments using DoE. The predicted mathematical model was recognized by p-test and R2 value using RSM approach to find optimum CR and FIP of biodiesel blend in comparison with standard diesel. The responses such as maximum rise in in-cylinder pressure, exhaust gas temperature, HRR, BTE, SFC and various gas emissions of CO, HC, CO2 and NOx on VCR engine analysis were predicted. The optimized engine characteristics such as combustion and emissions were improved with CR21, FIP 225 bar of 20% biodiesel blends in comprehend with neat diesel in detailed experimental investigation at a load of 0.46 MPa of BMEP with a constant speed of 1500 rpm. The superior BTE with lower SFC was attained through a FIP of 225 bar and on CR 21 compared with that of diesel and other fuel injection pressures. The carbon monoxide and hydrocarbon emission were reduced substantially at 225 bar injection pressure and on CR 21. The acceptable limits CO2 and NOx emission are observed and compared with neat diesel with a FIP of 225 bar and on CR 21.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- B20:

-

Biodiesel 20% and diesel 80%

- HRR :

-

heat release rate (J/°CA)

- RSM:

-

Response surface methodology

- ANOVA:

-

Analysis of Variance

- FFA:

-

free fatty acid

- EGT:

-

Exhaust gas temperature (°C)

- MRSO:

-

Methyl esters of rubber seed oil

- LHV:

-

Lower heating value (MJkg−1)

- DI:

-

Direct injection

- VCR:

-

variable compression ratio

- CA:

-

Crank angle

- BP:

-

brake power (kW)

- FIP:

-

Fuel injection pressure (bar)

- RSO:

-

Rubber seed oil

- SFC:

-

Specific fuel consumption (kgs−1 kW−1)

- PC:

-

Personal computer

- BTE:

-

brake thermal efficiency (%)

- BTDC:

-

before top dead center

- ROPR:

-

Rate of pressure rise (bar)

- CO:

-

carbon monoxide (%)

- CD:

-

Combustion duration

- CR:

-

compression ratio

- CI:

-

Compression ignition

- CO2 :

-

carbon di-oxide emission (%)

- ID:

-

Ignition delay

- DoE:

-

Design of Experiments

- BSEC:

-

Brake specific energy consumption (MJ/kWh)

- HC:

-

hydro carbon emission (ppm)

- IP:

-

Injection pressure (bar)

- A/F:

-

Air-fuel ratio

- NOx :

-

Oxides of nitrogen emission (ppm)

- U:

-

Uncertainty (%)

- W:

-

Load (kg)

- P max :

-

Maximum cylinder pressure

- T:

-

Temperature (K)

- Stoic:

-

Stoichiometric

- r:

-

Dynamometer arm radius (m)

- t:

-

Residence time

- V:

-

Volume (m3)

- R 2 :

-

Determination coefficient

- p-test:

-

Probability test

- Cp :

-

Specific heat (kJ/kg K)

- Qn :

-

Net heat release rate (kW)

- N:

-

Revolution per minute (rpm)

- m f :

-

Mass of fuel consumed (kg/h)

- k:

-

Specific heat ratio

- ɵ:

-

Crank angle

- Φ:

-

Equivalence ratio

- Qloss :

-

Heat loss in cylinder wall (kW)

- Qin :

-

Gross heat release rate (kW)

References

Ramadhas AS, Jayaraj S, Muraleedharan C (2004) Use of vegetable oils as IC engine fuels—a review. Renew Energy 29(5):727–742

No S-Y (2011) Inedible vegetable oils and their derivatives for alternative diesel fuels in CI engines: a review. Renew Sust Energ Rev 15(1):131–149

Santhosh M, Padmanaban KP (2016) Experimental investigation on engine performances, combustion characteristics and emission of exhaust gases of VCR engine fuelled with cottonseed oil methyl ester blended with diesel. Int J Green Energy 13(14):1534–1545

Singh B, Shukla SK (2016) Experimental analysis of combustion characteristics on a variable compression ratio engine fuelled with biodiesel (castor oil) and diesel blends. Biofuels 7(5):471–477

Sayin C, Gumus M (2011) Impact of compression ratio and injection parameters on the performance and emissions of a DI diesel engine fueled with biodiesel-blended diesel fuel. Appl Therm Eng 31(16):3182–3188

Sivapirakasam, S. P., et al. (2012) "Optimization of Biodiesel Production Using RSM and Study of Combustion Characteristics on DI Diesel Engine." ASME 2012 International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers

Sivaramakrishnan K (2018) Investigation on performance and emission characteristics of a variable compression multi fuel engine fuelled with Karanja biodiesel–diesel blend. Egypt J Pet 27(2):177–186

Ramadhas AS, Jayaraj S, Muraleedharan C (2005) Biodiesel production from high FFA rubber seed oil. Fuel 84(4):335–340

Geo VE, Nagarajan G, Nagalingam B (2008) Studies on dual fuel operation of rubber seed oil and its bio-diesel with hydrogen as the inducted fuel. Int J Hydrog Energy 33(21):6357–6367

Ramadhas AS, Muraleedharan C, Jayaraj S (2005) Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil. Renew Energy 30(12):1789–1800

Kumar BR, Muthukkumar T, Krishnamoorthy V, Saravanan S (2016) A comparative evaluation and optimization of performance and emission characteristics of a DI diesel engine fueled with n-propanol/diesel, n-butanol/diesel and n-pentanol/diesel blends using response surface methodology. RSC Adv 6(66):61869–61890

Murugapoopathi, S., Vasudevan, D., & Karthikeyan, S. (2019). Prediction of performance and emission characteristics of biodiesel blends-response surface methodology approach. In AIP Conference Proceedings (Vol. 2161, No. 1, p. 020014). AIP publishing LLC

Hirkude J, Padalkar A, Shaikh S, Veigas A (2013) Effect of compression ratio on performance of CI engine fuelled with biodiesel from waste fried oil using response surface methodology. Int J Energy Eng 3(5):227–233

Shirneshan AR, Almassi M, Ghobadian B, Najafi GH (2014) Investigating the effects of biodiesel from waste cooking oil and engine operating conditions on the diesel engine performance by response surface methodology. Iranian J Sci Technol. Trans Mech Eng 38(M2):289

Berber A (2016) Mathematical model for fuel flow performance of diesel engine. Int J Automotive Eng Technol 5(1):17–24

Ileri E, Karaoglan AD, Atmanli A (2013) Response surface methodology based prediction of engine performance and exhaust emissions of a diesel engine fuelled with canola oil methyl ester. J Renew Sustainable Energy 5(3):033132

Choudhary AK, Chelladurai H, Kannan C (2015) Optimization of combustion performance of bioethanol (water hyacinth) diesel blends on diesel engine using response surface methodology. Arab J Sci Eng 40(12):3675–3695

Sivaramakrishnan K, Ravikumar P (2014) Optimization of operational parameters on performance and emissions of a diesel engine using biodiesel. Int J Environ Sci Technol 11(4):949–958

Adam IK, Aziz ARA, Yusup S, Heikal M, Hagos F (2016) Optimization of performance and emissions of a diesel engine fuelled with rubber seed-palm biodiesel blends using response surface method. Asian J Appl Sci (ISSN: 2321–0893). 4(02)

Ganapathy T, Gakkhar RP, Murugesan K (2011) Optimization of performance parameters of diesel engine with Jatropha biodiesel using response surface methodology. Int J Sustain Energy 30(sup1):S76–S90

Murugapoopathi S, Vasudevan D (2019) Energy and exergy analysis on variable compression ratio multi-fuel engine. J Therm Anal Calorim 136(1):255–266

Muralidharan K, Vasudevan D (2011) Performance, emission and combustion characteristics of a variable compression ratio engine using methyl esters of waste cooking oil and diesel blends. Appl Energy 88(11):3959–3968

Santhosh M, Padmanaban KP (2016) Experimental studies on variable compression ratio engine fuelled with cottonseed oil methyl ester biodiesel. Int J Oil, Gas Coal Technol 12(1):81–104

Mohan B, Yang W, Raman V, Sivasankaralingam V, Chou SK (2014) Optimization of biodiesel fueled engine to meet emission standards through varying nozzle opening pressure and static injection timing. Appl Energy 130:450–457

Muralidharan K, Vasudevan D, Sheeba KN (2011) Performance, emission and combustion characteristics of biodiesel fuelled variable compression ratio engine. Energy 36(8):5385–5393

Purushothaman K, Nagarajan G (2009) Effect of injection pressure on heat release rate and emissions in CI engine using orange skin powder diesel solution. Energy Convers Manag 50(4):962–969

Rao, Prasad GA, Mohan PR (2003) Effect of supercharging on the performance of a DI diesel engine with cotton seed oil. Energy Convers Manag 44(6):937–944

Murugapoopathi S, Vasudevan D (2019) Performance, combustion and emission characteristics on VCR multi-fuel engine running on methyl esters of rubber seed oil. J Therm Anal Calorim 138(2):1329–1343

Nayyar, A., Sharma, D., Soni, S. L., Gautam, V., Kumar, C., & Augustine, M. (2019). Study of performance and emissions of a stationary DI variable compression ratio CI engine fueled with n-butanol/diesel blends using Taguchi technique: analytical and experimental analysis. Energy Sourc, Part A: Recover, Utilization, Environ Eff. :1-27

Saravanan S, Nagarajan G, Rao GLN, Sampath S (2010) Combustion characteristics of a stationary diesel engine fuelled with a blend of crude rice bran oil methyl ester and diesel. Energy 35(1):94–100

Myers RH, Montgomery DC, Anderson-Cook CM (1995) Response surface methodology: process and product optimization using designed experiments. John Wiley& Sons. Inc., New York, NY, pp 134–174

Murugapoopathi, T. R., & Vasudevan, D. RSM based Empirical Model for the Performance and Emission Characteristics of ROME Biodiesel. Ratio. 4, 0

Myers RH, Montgomery DC, Anderson-Cook CM (2002) Process and product optimization using designed experiments. Response Surf Methodol 2:328–335

Ganesan, V. (2012). Internal combustion engines. McGraw Hill Education (India) Pvt Ltd.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Novelty of work

The unused rubber seed oil finds partial replacement of conventional diesel in agricultural tractor fuel requirement in TamilNadu, India. The performance and combustion improvements of biodiesel utilization in agricultural engine using CR, IP and fuel requirement were carried out in this study. Possibility of using RSM modelling for combustion analysis of 20% RSO biodiesel blends and diesel in VCR engine. The results of regression modelling were implemented in VCR engine to verify it through the detailed experimental investigation of combustion and emission analysis. The robust mathematical model was estimated using RSM modelling. The most effective model can be used for calculating combustion analysis for future study in engine analysis.

Rights and permissions

About this article

Cite this article

Murugapoopathi, S., Vasudevan, D. Experimental and numerical findings on VCR engine performance analysis on high FFA RSO biodiesel as fuel using RSM approach. Heat Mass Transfer 57, 495–513 (2021). https://doi.org/10.1007/s00231-020-02961-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02961-3