Accurate Design of Solar Selective Absorber Based on Measured Optical Constants of Nano-thin Cr Film

Abstract

:1. Introduction

2. Numerical Design

3. Experimental Details

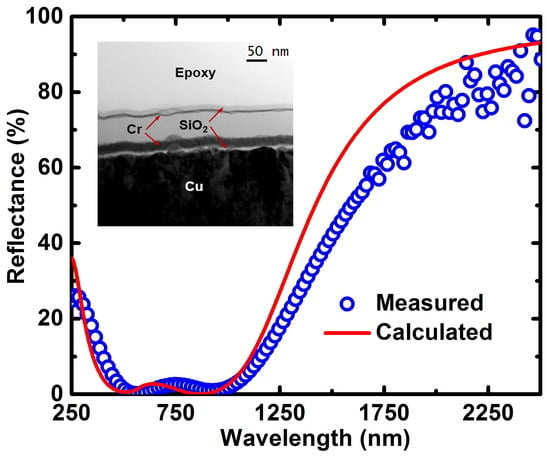

4. Results and Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.; Gao, J.; Hu, H.; Zhang, H.; Liang, L.; Javaid, K.; Zhuge, F.; Cao, H.; Wang, L. High-temperature tolerance in WTi-Al2O3 cermet-based solar selective absorbing coatings with low thermal emissivity. Nano Energy 2017, 37, 232–241. [Google Scholar] [CrossRef]

- Hu, E.-T.; Guo, S.; Gu, T.; Zang, K.-Y.; Tu, H.-T.; Cai, Q.-Y.; Yu, K.; Wei, W.; Zheng, Y.-X.; Wang, S.-Y.; et al. High efficient and wide-angle solar absorption with a multilayered metal-dielectric film structure. Vacuum 2017, 146, 194–199. [Google Scholar] [CrossRef]

- Bermel, P.; Lee, J.; Joannopoulos, J.D.; Celanovic, I.M.S. Selective Solar Absorbers. In Annual Review of Heat Transfer; Chen, G., Prasad, V., Jaluria, Y., Karni, J., Eds.; Begell House, Inc.: New York, NY, USA, 2012; pp. 231–254. [Google Scholar]

- Zhou, L.; Tan, Y.; Wang, J.; Xu, W.; Yuan, Y.; Cai, W.; Zhu, S.; Zhu, J. 3D self-assembly of aluminium nanoparticles for plasmon-enhanced solar desalination. Nat. Photonics 2016, 10, 393. [Google Scholar] [CrossRef]

- Wang, H.; AlShehri, H.; Su, H.; Wang, L. Design, fabrication and optical characterizations of large-area lithography-free ultrathin multilayer selective solar coatings with excellent thermal stability in air. Sol. Energy Mater. Sol. Cells 2018, 174, 445–452. [Google Scholar] [CrossRef]

- Dyachenko, P.N.; Molesky, S.; Petrov, A.; Störmer, M.; Krekeler, T.; Lang, S.; Ritter, M.; Jacob, Z.; Eich, M. Controlling thermal emission with refractory epsilon-near-zero metamaterials via topological transitions. Nat. Commun. 2016, 7, 11809. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kennedy, C.E. Review of Mid-to High-Temperature Solar Selective Absorber Materials; NREL/TP-520-31267; National Renewable Energy Laboratory: Golden, CO, USA, 2002.

- Ning, Y.; Wang, W.; Wang, L.; Sun, Y.; Song, P.; Man, H.; Zhang, Y.; Dai, B.; Zhang, J.; Wang, C.; et al. Optical simulation and preparation of novel Mo/ZrSiN/ZrSiON/SiO2 solar selective absorbing coating. Sol. Energy Mater. Sol. Cells 2017, 167, 178–183. [Google Scholar] [CrossRef]

- Sakurai, A.; Tanikawa, H.; Yamada, M. Computational design for a wide-angle cermet-based solar selective absorber for high temperature applications. J. Quant. Spectrosc. Racdiat. Transf. 2014, 132, 80–89. [Google Scholar] [CrossRef]

- Chester, D.; Bermel, P.; Joannopoulos, J.D.; Soljacic, M.; Celanovic, I. Design and global optimization of high-efficiency solar thermal systems with tungsten cermets. Opt. Express 2011, 19 (Suppl. 3), A245. [Google Scholar] [CrossRef]

- Li, X.-F.; Chen, Y.-R.; Miao, J.; Zhou, P.; Zheng, Y.-X.; Chen, L.; Lee, Y.-P. High solar absorption of a multilayered thin film structure. Opt. Express 2007, 15, 1907–1912. [Google Scholar] [CrossRef]

- Zhou, W.-X.; Shen, Y.; Hu, E.-T.; Zhao, Y.; Sheng, M.-Y.; Zheng, Y.-X.; Wang, S.-Y.; Lee, Y.-P.; Wang, C.-Z.; Lynch, D.W.; et al. Nano-Cr-film-based solar selective absorber with high photo-thermal conversion efficiency and good thermal stability. Opt. Express 2012, 20, 28953–28962. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.-P.; Lee, C.-T.; Liao, W.B.; Chang, Y.-C.; Chen, Y.-S.; Li, M.-C.; Lee, C.-C.; Kuo, C.-C. Analysis of High-Efficiency Mo-Based Solar Selective Absorber by Admittance Locus Method. Coatings 2019, 9, 256. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Zheng, W.; Lin, L.; Qu, Y.; Lai, F. Colored solar selective absorbing coatings with metal Ti and dielectric AlN multilayer structure. Sol. Energy Mater. Sol. Cells 2013, 115, 145–150. [Google Scholar] [CrossRef]

- Meng, J.-P.; Liu, X.-P.; Fu, Z.-Q.; Zhang, K. Optical design of Cu/Zr0.2AlN0.8/ZrN/AlN/ZrN/AlN/Al34O62N4 solar selective absorbing coatings. Sol. Energy 2017, 146, 430–435. [Google Scholar] [CrossRef]

- Rodriguez-Palomo, A.; Céspedes, E.; Hernández-Pinilla, D.; Prieto, C. High-temperature air-stable solar selective coating based on MoSi2–Si3N4 composite. Sol. Energy Mater. Sol. Cells 2018, 174, 50–55. [Google Scholar] [CrossRef]

- Thomas, N.H.; Chen, Z.; Fan, S.; Minnich, A.J. Semiconductor-based Multilayer Selective Solar Absorber for Unconcentrated Solar Thermal Energy Conversion. Sci. Rep. 2017, 7, 5362. [Google Scholar] [CrossRef]

- Chen, W.; Liu, J.; Ma, W.-Z.; Yu, G.-X.; Chen, J.-Q.; Cai, H.-Y.; Yang, C.-F. Numerical Study of Multilayer Planar Film Structures for Ideal Absorption in the Entire Solar Spectrum. Appl. Sci. 2020, 10, 3276. [Google Scholar] [CrossRef]

- Blandre, E.; Shimizu, M.; Kohiyama, A.; Yugami, H.; Chapuis, P.-O.; Vaillon, R. Spectrally shaping high-temperature radiators for thermophotovoltaics using Mo-HfO2 trilayer-on-substrate structures. Opt. Express 2018, 26, 4346. [Google Scholar] [CrossRef]

- Shimizu, M.; Kohiyama, A.; Yugami, H. Evaluation of thermal stability in spectrally selective few-layer metallo-dielectric structures for solar thermophotovoltaics. J. Quant. Spectrosc. Radiat. Transf. 2018, 212, 45–49. [Google Scholar] [CrossRef]

- Hu, E.-T.; Liu, X.-X.; Yao, Y.; Zang, K.-Y.; Tu, Z.-J.; Jiang, A.-Q.; Yu, K.; Zheng, J.; Wei, W.; Zheng, Y.-X.; et al. Multilayered metal-dielectric film structure for highly efficient solar selective absorption. Mater. Res. Express 2018, 5, 066428. [Google Scholar] [CrossRef]

- Sergeant, N.P.; Pincon, O.; Agrawal, M.; Peumans, P. Design of wide-angle solar-selective absorbers using aperiodic metal-dielectric stacks. Opt. Express 2009, 17, 22800–22812. [Google Scholar] [CrossRef]

- El-Mahallawy, N.A.; Atia, M.R.; Khaled, A.; Shoeib, M. Design and simulation of different multilayer solar selective coatings for solar thermal applications. Mater. Res. Express 2018, 5, 046402. [Google Scholar] [CrossRef]

- Du, M.; Hao, L.; Mi, J.; Lv, F.; Liu, X.; Jiang, L.; Wang, S. Optimization design of Ti0.5Al0.5N/Ti0.25Al0.75N/AlN coating used for solar selective applications. Sol. Energy Mater. Sol. Cells 2011, 95, 1193–1196. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, C.; Sun, Y.; Xue, Y.; Ning, Y.; Wang, W.; Zhao, S.; Tomasella, E.; Bousquet, A. Optical simulation and experimental optimization of Al/NbMoN/NbMoON/SiO2 solar selective absorbing coatings. Sol. Energy Mater. Sol. Cells 2015, 134, 373–380. [Google Scholar] [CrossRef]

- Gremion, C.; Seassal, C.; Drouard, E.; Gerthoffer, A.; Pelissier, N.; Ducros, C. Design, properties and degradation mechanisms of Pt-Al2O3 multilayer coating for high temperature solar thermal applications. Surf. Coat. Technol. 2015, 284, 31–37. [Google Scholar] [CrossRef]

- Kraemer, D.; Jie, Q.; McEnaney, K.; Cao, F.; Liu, W.-S.; Weinstein, L.A.; Loomis, J.; Ren, Z.; Chen, G. Concentrating solar thermoelectric generators with a peak efficiency of 7.4%. Nat. Energy 2016, 1, 16153. [Google Scholar] [CrossRef] [Green Version]

- Jung, Y.S.; Jeong, D.H.; Kang, S.B.; Kim, F.; Jeong, M.H.; Lee, K.-S.; Son, J.S.; Baik, J.M.; Kim, J.; Choi, K.J. Wearable solar thermoelectric generator driven by unprecedentedly high temperature difference. Nano Energy 2017, 40, 663–672. [Google Scholar] [CrossRef]

- Zhu, W.; Deng, Y.; Cao, L. Light-concentrated solar generator and sensor based on flexible thin-film thermoelectric device. Nano Energy 2017, 34, 463–471. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: New York, NY, USA, 1998. [Google Scholar]

- Liu, M.-H.; Hu, E.-T.; Yao, Y.; Zang, K.-Y.; He, N.; Li, J.; Zheng, Y.-X.; Wang, S.-Y.; Yoshie, O.; Lee, Y.; et al. High efficiency of photon-to-heat conversion with a 6-layered metal/dielectric film structure in the 250–1200 nm wavelength region. Opt. Express 2014, 22, A1843–A1852. [Google Scholar] [CrossRef]

- Hu, E.-T.; Zhang, R.-J.; Cai, Q.-Y.; Wang, Z.-Y.; Xu, J.-P.; Zheng, Y.-X.; Wang, S.-Y.; Wei, Y.-F.; Huang, R.-Z.; Chen, L. Study of the thickness effect on the dielectric functions by utilizing a wedge-shaped Ti film sample with continuously varied thickness. Appl. Phys. A 2015, 120, 875. [Google Scholar] [CrossRef]

- Gao, X.-H.; Guo, Z.-M.; Geng, Q.-F.; Ma, P.-J.; Liu, G. Structure, optical properties and thermal stability of TiC-based tandem spectrally selective solar absorber coating. Sol. Energy Mater. Sol. Cells 2016, 157, 543–549. [Google Scholar] [CrossRef]

- Zhang, K.; Hao, L.; Du, M.; Mi, J.; Wang, J.-N.; Meng, J.-P. A review on thermal stability and high temperature induced ageing mechanisms of solar absorber coatings. Renew. Sustain. Energ. Rev. 2017, 67, 1282–1299. [Google Scholar] [CrossRef]

- Macleod, H.A. Thin-Film Optical Filters, 4th ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Skowroński, Ł.; Szczesny, R.; Zdunek, K. Optical and microstructural characterization of amorphous-like Al2O3, SnO2 and TiO2 thin layers deposited using a pulse gas injection magnetron sputtering technique. Thin Solid Film 2017, 632, 112–118. [Google Scholar] [CrossRef]

- Hu, E.-T.; Guo, S.; Gu, T.; Zang, K.-Y.; Yao, Y.; Wang, Z.-Y.; Yu, K.; Wei, W.; Zheng, Y.-X.; Wang, S.-Y.; et al. Enhancement of solar absorption by a surface-roughened metal–dielectric film structure. Jpn. J. Appl. Phys. 2017, 56, 112301. [Google Scholar] [CrossRef]

- Cai, Q.-Y.; Zheng, Y.-X.; Mao, P.-H.; Zhang, R.-J.; Zhang, D.-X.; Liu, M.-H.; Chen, L.-Y. Evolution of optical constants of silicon dioxide on silicon from ultrathin films to thick films. J. Phys. D Appl. Phys. 2010, 43, 445302. [Google Scholar] [CrossRef]

- Chipperfield, J.A.; Fleming, P.J. The MATLAB genetic algorithm toolbox. In Proceedings of the IEE Colloquium on Applied Control Techniques Using MATLAB 1995, London, UK, 26 January 1995; pp. 10/1–10/4. [Google Scholar]

- Rakić, A.D.; Djurišić, A.B.; Elazar, J.M.; Majewski, M.L. Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt. 1998, 37, 5271. [Google Scholar] [CrossRef] [PubMed]

- Aspnes, D.E. Optical properties of thin films. Thin Solid Film 1982, 89, 249. [Google Scholar] [CrossRef]

- Tompkins, H.G.; Baker, H.J.; Convey, D. Effect of process parameters on the optical constants of thin metal films. Surf. Interface Anal. 2015, 29, 227–231. [Google Scholar] [CrossRef]

- Savaloni, H.; Khakpour, A.R. Substrate temperature dependence on the optical properties of Cu and Ag thin films. Eur. Phys. J. Appl. Phys. 2005, 31, 101–112. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.-Y.; Hu, E.-T.; Cai, Q.-Y.; Wang, J.; Tu, H.-T.; Yu, K.-H.; Chen, L.-Y.; Wei, W. Accurate Design of Solar Selective Absorber Based on Measured Optical Constants of Nano-thin Cr Film. Coatings 2020, 10, 938. https://doi.org/10.3390/coatings10100938

Wang Z-Y, Hu E-T, Cai Q-Y, Wang J, Tu H-T, Yu K-H, Chen L-Y, Wei W. Accurate Design of Solar Selective Absorber Based on Measured Optical Constants of Nano-thin Cr Film. Coatings. 2020; 10(10):938. https://doi.org/10.3390/coatings10100938

Chicago/Turabian StyleWang, Zheng-Yong, Er-Tao Hu, Qing-Yuan Cai, Jing Wang, Hua-Tian Tu, Ke-Han Yu, Liang-Yao Chen, and Wei Wei. 2020. "Accurate Design of Solar Selective Absorber Based on Measured Optical Constants of Nano-thin Cr Film" Coatings 10, no. 10: 938. https://doi.org/10.3390/coatings10100938