Abstract

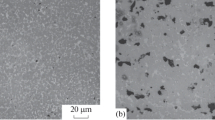

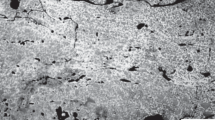

This paper studies the formation of cermet coatings by a combined additive manufacturing technology on the basis of cold gas dynamic spraying and subsequent laser irradiation. The coatings are made of titanium and nickel metal powders with ceramic particles of tungsten carbide and boron carbide. Optimal energy parameters are determined for coating deposition by cold gas dynamic spraying and subsequent laser irradiation for powder compositions with different ceramic particles. The microstructure of deposited coatings is studied, and their mechanical properties are measured. It is shown that the combined method of cold gas dynamic spraying and laser irradiation can be used to produce a single-layer cermet coating up to 1 mm thick by sequentially depositing a mixture of powders of different composition, such as B4C–Ni, B4C–Ti, WC–Ti. Based on the obtained experimental data, a technique is proposed for a layer-by-layer deposition of thick (≈4 mm) cermet coatings of composition 40% WC + 60% (0.94Ti + 0.06Al) by cold gas dynamic spraying and subsequent laser irradiation.

Similar content being viewed by others

REFERENCES

Choong, Y.C., Maleksaeedi, S., Eng, H., Wei, J., and Su, P., 4D Printing of High Performance Shape Memory Polymer Using Stereolithography, Mater. Des., 2017, vol. 126, pp. 219–225.

Gan, M. and Wong, C., Properties of Selective Laser Melted Spodumene Glass-Ceramic, J. Eur. Ceram. Soc., 2017, vol. 37, no. 13, pp. 4147–4154.

Miracle, D.B., Metal Matrix Composites from Science to Technological Significance, Compos. Sci. Technol., 2005, vol. 65, pp. 15–16.

Meng, Q.W., Geng, T.L., and Zhang, B.Y., Laser Cladding of Ni-Base Composite Coatings onto Ti–6Al–4V Substrates with Pre-Placed B4C + NiCrBSi Powders, Surf. Coat. Technol., 2006, vol. 200, pp. 4923–4928.

Chaliampalias, D., Vourlias, G., Pavlidou, E., Skolianos, S., Chrissafis, K., and Stergioudis, G., Comparative Examination of the Microstructure and High Temperature Oxidation Performance of NiCrBSi Flame Sprayed and Pack Cementation Coatings, Appl. Surf. Sci., 2009, vol. 255, p. 3605.

Guo, C., Zhou, J., Chen, J., Zhao, J., Yu, Y., and Zhou, H., High Temperature Wear Resistance of Laser Cladding NiCrBSi and NiCrBSi/WC-Ni Composite Coatings,Wear, 2011, vol. 270, no. 7–8, pp. 492–498.

Tobar, M., Alvarez, C., Amado, J., Rodriguez, G., and Yanez, A., Morphology and Characterization of Laser Clad Composite NiCrBSi–WC Coatings on Stainless Steel,Surf. Coat. Technol., 2006, vol. 200, pp. 6313–6317.

Bonny, K., Baets, P., Vleugels, J., Huang, S., and Lauwers, B., Dry Reciprocating Sliding Friction and Wear Response of WC-Ni Cemented Carbides, Tribol. Lett., 2008, vol. 31, no. 3, pp. 199–209.

Pouzet, S., Peyre, P., Gorny, C., Castelnau, O., Baudin, T., Brisset, F., Colin, C., and Gadaud, P., Additive Layer Manufacturing of Titanium Matrix Composites Using the Direct Metal Deposition Laser Process, Mater. Sci. Eng. A, 2016, vol. 677, pp. 171–181.

Cai, C., Song, B., Qiu, C., Li, L., Xue, P., Wei, Q., Zhou, J., Nan, H., Chen, H., and Shi, Y., Hot Isostatic Pressing of In-Situ TiB/Ti–6Al–4V Composites with Novel Reinforcement Architecture, Enhanced Hardness and Elevated Tribological Properties, J. Alloys Comp., 2017, vol. 710, pp. 364–374.

Saito, T., Furuta, T., and Yamaguchi, T.,Development of Low Cost Titanium Alloy Matrix Composites, Recent Advances in Titanium Metal Matrix Composites, Froes, F.H. and Storer, J., Eds., Rosemont: Illinois, 1994.

Ravi Chandran, K.S., Panda, K.B., and Sahay, S.S., TiBw-Reinforced Ti Composites: Processing, Properties, Application Prospects, and Research Needs,JOM, 2004, vol. 56, no. 5, pp. 42–48.

Alkhimov, A.P., Kosarev, V.F., Fomin, V.M., and Klinkov, S.V., Cold Gas Dynamic Spraying. Theory and Applications, Moscow: Fizmatlit, 2010.

Fomin, V.M., Golyshev, A.A., Kosarev, V.F., Malikov, A.G., Orishich, M.A., Ryashin, N.S., Filippov, A.A., and Shikalov, V.S., Creation of Heterogeneous Materials on the Basis of B4C and Ni Powders by the Method of Cold Spraying with Subsequent Layer-by-Layer Laser Treatment,J. Appl. Mech. Tech. Phys., 2017, vol. 58, no. 5, pp. 947–955.

Marrocco, T., Hussain, T., Mccortney, D.G., and Shipway, P., Corrosion Performance of Laser Posttreated Cold Sprayed Titanium Coatings, J. Therm. Spray Technol., 2011, vol. 20, pp. 909–917.

Sova, A., Grigoriev, S., Okunkova, A.A., and Smurov, I., Cold Spray Deposition of 316L Stainless Steel Coatings on Aluminium Surface with Following Laser Post Treatment,Surf. Coat. Technol., 2013, vol. 235, pp. 283–289.

Tang, J., Mechanical and Tribological Properties of the TiC-TiB2 Composite Coating Deposited on 40Cr-Steel by Electrospark Deposition, Appl. Surf. Sci., 2016, vol. 365, pp. 202–208. doi 10.1016/j.apsusc.2015.12.198

Tijo, D. and Masanta, M., Mechanical Performance of In-Situ TiC-TiB2 Composite Coating Deposited on Ti-6Al–4V Alloy by Powder Suspension Electro-Discharge Coating Process, Surf. Coat. Technol., 2017, vol. 328, pp. 192–203. doi 10.1016/j.surfcoat.2017.08.048

Tijo, D., Masanta, M., and Das, A.K., In-Situ TiC-TiB2 Coating on Ti-6Al-4V Alloy by Tungsten Inert Gas (TIG) Cladding Method: Part I. Microstructure Evolution, Surf. Coat. Technol., 2018, vol. 344, pp. 541–552. doi 10.1016/j.surfcoat.2018.03.082

Tijo, D. and Masanta, M., Effect of Ti/B4C Ratio on the Microstructure and Mechanical Characteristics of TIG Cladded TiC-TiB2 Coating on Ti-6Al-4V Alloy,J. Mater. Proc. Tech., 2019, vol. 266, pp. 184–197.

Li, J., Yu, Zh., Wang, H., and Li, M., Microstructural Characterization of Titanium Matrix Composite Coatings Reinforced by in Situ Synthesized TiB + TiC Fabricated on Ti6Al4V by Laser Cladding, Rare Met., 2010, vol. 29, no. 5, pp. 465. doi 10.1007/s12598-010-0151-y

Tijo, D., and Masanta, M., In-Situ TiC-TiB2 Coating on Ti-6Al-4V Alloy by Tungsten Inert Gas (TIG) Cladding Method: Part II. Mechanical Performance,Surf. Coat. Technol., 2018, vol. 344, pp. 579–589. doi 10.1016/j.surfcoat.2018.03.082

Funding

This work was supported by the Russian Science Foundation grant No. 16-19-10300.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2019, published in Fizicheskaya Mezomekhanika, 2019, Vol. 22, No. 4, pp. 5–15.

Rights and permissions

About this article

Cite this article

Fomin, V.M., Golyshev, A.A., Kosarev, V.F. et al. Deposition of Cermet Coatings on the Basis of Ti, Ni, WC, and B4C by Cold Gas Dynamic Spraying with Subsequent Laser Irradiation. Phys Mesomech 23, 291–300 (2020). https://doi.org/10.1134/S1029959920040025

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959920040025