Abstract

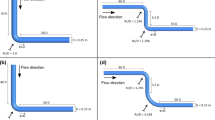

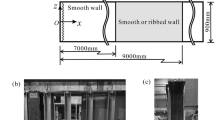

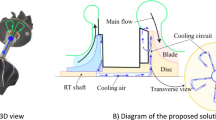

In this work, the behaviors of flow field and pressure fluctuations in both time and frequency domains in an axial flow pump through changing various impeller blade angles are studied and investigated by using a CFD technique. The blade angles are changed between 30°, 45º, 60º and 75º. Numerical results are validated with the experimental values, as a good agreement was found between them. The developed flow analysis shows that the blade angle does influence the different flow behaviors and features, such as the static pressure, turbulent kinetic energy (TKE), pressure fluctuations, axial velocity, radial velocity and tangential velocity. The results have revealed that the TKE rises with flow rate decreases and high static pressure increases at the pump outlet region near the tip blade region. Another conclusion of the study is the fact that the blade angle with 60º is the better one in terms of lower-negative-pressure regions, when compared with the other settings. The first dominated frequency was pump rotational frequency, and the second important frequency is the BPF (blade passing frequency). Furthermore, the results showed that impeller blade angles and unsteady flow have a high influence on the pressure fluctuation amplitude. Moreover, the results of the presented numerical simulation would be useful for a future hydraulic design of an axial pump.

Similar content being viewed by others

Abbreviations

- CFD:

-

Computational fluid dynamics

- 3D:

-

Three-dimensional

- Q :

-

Flow rate

- TKE:

-

Turbulent kinetic energy

- P :

-

Pressure

- n :

-

Number of element

- N :

-

Total number of element

- u, v and w :

-

Velocities in x, y and z

- t :

-

Time

- \( \tau \) :

-

Shear stress

- ρ:

-

Density

- μ:

-

Kinematic viscosity

- θ:

-

Angle

References

Al-Obaidi A (2018) Experimental and numerical investigations on the cavitation phenomenon in a centrifugal pump. Doctoral dissertation, University of Huddersfield

Al-Obaidi AR (2019a) Effects of different turbulence models on three-dimensional unsteady cavitating flows in the centrifugal pump and performance prediction. Int J Nonlinear Sci Numer Simul 20(3–4):487–509

Al-Obaidi AR (2019b) Monitoring the performance of centrifugal pump under single-phase and cavitation condition: a CFD analysis of the number of impeller blades. J. Appl Fluid Mech 12(2):445–459

Al-Obaidi AR (2019) Numerical investigation of flow field behaviour and pressure fluctuations within an axial flow pump under transient flow pattern based on CFD analysis method. In: Journal of Physics: Conference Series (Vol. 1279, No. 1, p. 012069). IOP Publishing.

Al-Obaidi AR (2020a) Influence of guide vanes on the flow fields and performance of axial pump under unsteady flow conditions: numerical study. J Mech Eng Sci 14(2):6570–6593

Al-Obaidi AR (2020b) Investigation of the influence of various numbers of impeller blades on internal flow field analysis and the pressure pulsation of an axial pump based on transient flow behavior. Heat Transf 49(4):2000–2024

Al-Obaidi AR, Mohammed AA (2019) Numerical investigations of transient flow characteristic in axial flow pump and pressure fluctuation analysis based on the CFD technique. J Eng Sci Technol Rev 12(6):70–79

Arnold K, Stewart M (1999) Surface production operations, Volume 2:: Design of gas-handling systems and facilities. Vol. 2. 1999: Gulf Professional Publishing

Cui B, Chen D, Wang C, Zhu Z, Jin Y, Jin Y (2013) Research on performance of centrifugal pump with different-type open impeller. J Therm Sci 22(6):586–591

Dash N, Roy AK, Kumar K (2018) Design and optimization of mixed flow pump impeller blades by varying semi-cone angle. In: IOP Conf Ser Mater Sci Eng (Vol. 330, p. 012095).

El-Sawaf IA, Halawa MA, Younes M A, Teaima IR (2011) Study of the different parameters that influence on the performance of water jet pump. In: Fifteenth international water technology conference, IWTC (Vol. 15)

Girdhar P, Moniz O (2011) Practical centrifugal pumps. Elsevier, New York

González J, Parrondo J, Santolaria C, Blanco E (2006) Steady and unsteady radial forces for a centrifugal pump with impeller to tongue gap variation

Karassik IJ (1998) Centrifugal pumps, 2nd edn. Springer, Berlin

Kaupert KA, Staubli T (1999) The unsteady pressure field in a high specific speed centrifugal pump impeller—Part II: Transient hysteresis in the characteristic

Li WY, Zhang XY, Shuai ZJ, Jiang CX, Li FC (2014) CFD numerical simulation of the complex turbulent flow field in an axial-flow water pump. Adv Mech Eng 6:521706

Meng F, Yuan S, Li Y (2018) Fluid–structure coupling analysis of impeller in unstable region for a reversible axial-flow pump device. Adv Mech Eng 10(3):1687814017751762

Miyazoe Y, Sawairi T, Ito K, Konishi Y, Yamane T, Nishida M, Asztalos B, Masuzawa T, Tsukiya T, Endo S, Taenaka Y (1999) Computational fluid dynamics analysis to establish the design process of a centrifugal blood pump: second report. Artif Organs 23(8):762–768

Mostafa NH, Mohamed A (2012) Effect of blade angle on cavitation phenomenon in axial pump. JAppl Mech Eng 3(1):1–6

Nelik L (1999) Centrifugal & rotary pumps: fundamentals with applications. CRC Press, Boca Raton

Shi L, Tang F, Xie R, Zhang W (2017) Numerical and experimental investigation of tank-type axial-flow pump device. Adv Mech Eng 9(3):1687814017695681

Sinnott MD, Cleary PW (2010) Effect of rotor blade angle and clearance on blood flow through a non-pulsatile, axial, heart pump. Prog Comput Fluid Dyn Int J 10(5–6):300–306

Soe AK, Win ZE, Soe MM (2015) Numerical flow analysis of an axial flow pump. Int J Eng Appl Sci 2(7) ISSN: 2394-3661,

Song XJ, Liu C (2018) Numerical analysis of the influence of vortex on the pressure pulsation in axial flow pump system based on the CFD. In: IOP conference series: earth and environmental science (Vol. 163, No. 1, p. 012106). IOP Publishing

Srivastava S, Roy AK, Kumar K (2014) Design of a mixed flow pump impeller and its validation using FEM analysis. Procedia Technol 14:181–187

Takano T, Schulte-Eisturp S, Kawahito S et al (2002) Inlet port positioning for a miniaturized centrifugal blood pump. Artif Organs 26:45–48

Tao R, Xiao R, Yang W, Wang F, Wu Y (2013) Investigation of the hydrodynamics of sweep blade in hi-speed axial fuel pump impeller. Adv Mech Eng 5:174017

Tsukamoto Y, Ito K, Sawairi T et al (2000) Computational fluid dynamics analysis of a centrifugal blood pump with washout holes. Artif Organs 24:648–652

Varchola M, Bielik T, Hlbocan P (2013) Methodology of 3D hydraulic design of a impeller of axial turbo machine. Eng Mech 20(2):107–118

Yang F, Liu C (2013) Numerical and experimental investigation of slanted axial-flow pumping system. J Eng Sci Technol Rev 6(2):62–68

Yang F, Liu C, Tang FP (2015) Hydraulic interaction of flow conduits and pump in an axial-flow pump system. Rev Téc Ing Univ Zulia 38(1):25–33

Zhang D, Tsuneda T, Katayama Y, Watanabe S, Tsuda SI, Furukawa A (2018) Backflow vortex behaviours in contra-rotating axial flow pump at low flow rates. In: IOP conference series: earth and environmental science (Vol. 163, No. 1, p. 012036). IOP Publishing

Acknowledgments

The author in the present computational investigation would like to thank the Mustansiriyah University (www.uomustansiriyah.edu.iq) in Iraq – Baghdad.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Obaidi, A.R. Analysis of the Effect of Various Impeller Blade Angles on Characteristic of the Axial Pump with Pressure Fluctuations Based on Time- and Frequency-Domain Investigations. Iran J Sci Technol Trans Mech Eng 45, 441–459 (2021). https://doi.org/10.1007/s40997-020-00392-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-020-00392-3