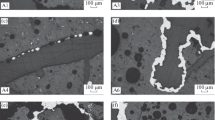

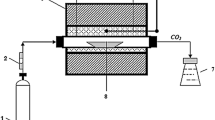

Brown iron ore constitutes about 13% of the global ore reserves and is widespread throughout the world. Brown iron ore is characterized by a significant content of harmful phosphorus (0.7 to 3.0%), which is typically present in the lattice of the main iron ore component in a chemically bound form. Based on the case study of the gravity-magnetic concentrate from the Lisakovsk field, OJSC “VNIIMT” has developed and lab-tested a pyro-hydrometallurgical dephosphorization technology, which can be applied while preparing the concentrate for agglomeration. As established earlier, phosphorus leaching proceeds successfully only after a high-temperature roasting of the gravity-magnetic concentrate, when the hydrated phosphorus-containing component decomposes. Free phosphorus then reacts with sulfuric acid. The main difference of the leaching process was that dephosphorization of the preliminary roasted concentrate with weak aqueous solution of sulfuric acid was performed without cooling it (hot leaching). A fixed-bed roasting was performed in a laboratory muffle furnace. After heating to a specific temperature and soaking for 60 minutes, a crucible containing the sample of the material was removed from the furnace. The roasted material was unloaded in hot condition into a previously prepared weak aqueous solution of sulfuric acid containing 5 wt.% of H2SO4 (solid-to-liquid phase ratio — 1:2). Such ratio prevents the solution from boiling during unloading of the hot concentrate. The pulp was mixed inside the ceramic crucible using an overhead stirrer. It has been established experimentally that hot leaching significantly reduces the duration of dephosphorization (by 3 times or more) compared to leaching under normal conditions. Another important advantage is the possibility of reducing the number of pieces of process equipment industry-wide, since cooling and leaching of the roasted gravity-magnetic concentrate from the Lisakovsk field can be implemented in one apparatus. In this case, reduced duration of the leaching process will enable an increase in productivity of the dephosphorization equipment by 3 times or more.

Similar content being viewed by others

References

B. L. Levintov, V. A. Mirko, M. D. Kantemirov, A. N. Klimushkin, V. A. Naydenov, and A. V. Bobir, “Structure of oolitic brown iron ores and their influence on the efficiency of thermochemical enrichment of Lisakovsk concentrates,” Stal’, No. 8, 8–11 (2007).

B. L. Levintov, V. A. Mirko, and O. A. Pchelintseva, “Status and prospects of solving the problem of dephosphorization of refractory iron ore raw materials of Kazakhstan,” in: Creation of Scientific Basics of Fundamentally New Chemical and Metallurgical Technologies Adapted to a Raw Material Base of Kazakhstan [in Russian], Kompleks, Almaty (2003), pp. 137–142.

V. V. Belikov, V. B. Ogorodov, A. O. Yadryshnikov, and N. A. Mikhailovina, “Dephosphorization of brown iron ores and concentrates,” Obogashcheniye Rud, No. 3, 8–12 (2003).

O. A. Pchelintseva, N. R. Mazhrenova, and B. L. Levintov, “On the possibility of radiation stimulation of dephosphorization of Lisakovsk concentrates,” KIMS, No. 3, 57 (2003).

B. L. Levintov, V. A. Mirko, M. D. Kantemirov, A. N. Klimushkin, V. A. Naydenov, and A. V. Bobir, “Structure of oolitic brown iron ores and their influence on the efficiency of thermochemical enrichment of Lisakovsk concentrates,” Stal’, No. 8, 8–11 (2007).

V. V. Belikov, V. B. Ogorodov, A. O. Yadryshnikov, et al., “Method for cleaning of iron ore concentrate from phosphorus contaminants,” RF Patent No. 2184158, Priority date: May 23, 2001.

I. G. Kovzun, Z. R. Ulberg, I. T. Protsenko, et al., “Procedure for purification of iron containing material from arsenic and phosphorus,” RF Patent No. 2413012, Priority date: November 16, 2009.

V. G. Karelin, D. A. Artov, S. L. Kalyuzhin, A. Yu. Yepishin, and V. A. Naydenov, “Industrial installation for roasting and cooling of Lisakovsk concentrate,” Izv. Vuzov, Chernaya Metallurgiya, No. 12, 65–67 (2009).

V. G. Karelin, L. A. Zainullin, D. A. Artov, A. Yu. Yepishin, and V. A. Naydenov, “Cooling of roasted fine-grained Lisakovsk concentrate in a rotating drum,” Stal’, No. 3, 6–7 (2010).

A. Yu. Yepishin, V. G. Karelin, and L. A. Zainullin, “Behavior of the phosphorus-containing component during high-temperature roasting of Lisakovsk iron ore concentrate,” Izv. Vuzov, Chernaya Metallurgiya, No. 12, 59–60 (2012).

A. Yu. Yepishin and L. A. Zainullin, “Enhancement of the industrial installation “Rotating furnace — drum cooler” for roasting of Lisakovsk iron ore concentrate,” Proc. 8th Int. Conf. Prior. Areas Develop. Sci. Techn., UGTU-UPI, Yekaterinburg (2009), pp. 70–72.

A. Yu. Yepishin, L. A. Zainullin, and V. G. Karelin, “On dephosphorization of brown iron ore by leaching with preliminary roasting,” Proc. 8th Congress of CIS Enrichers, Moscow (2011), pp. 83–86.

V. G. Karelin, L. A. Zainullin, A. Yu. Yepishin, and D. A. Artov, “Combined pyro-hydrometallurgical technology for dephosphorization of brown iron ore of the Lisakovsk field,” Chernaya Metallurgiya, Bull. Nauch. Tekh. Ekonom. Inf. (NTiEI), No. 2, 10–15 (2015).

V. G. Karelin, L. A. Zainullin, A. Yu. Yepishin, and D. A. Artov, “Specifics of pyro-hydrometallurgical technology of dephosphorization of brown iron ore of the Lisakovsk field,” Stal’, No. 3, 8–11 (2015).

V. G. Karelin, L. A. Zainullin, and A. Yu. Yepishin, “Kinetics of high-temperature dehydration of Lisakovsk iron ore concentrate,” Izv. Vuzov, Chernaya Metallurgiya, 60, 8, 656–661 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 6, pp. 32–35, June, 2020.

Rights and permissions

About this article

Cite this article

Zainullin, L.A., Karelin, V.G., Epishin, A.Y. et al. Enhancement of Pyro-Hydrometallurgical Technology of Dephosphorization of Brown Iron Ore of the Lisakovsk Field by Hot Leaching Method. Metallurgist 64, 522–525 (2020). https://doi.org/10.1007/s11015-020-01022-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-01022-8