Abstract

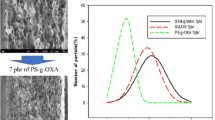

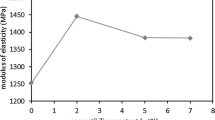

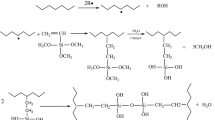

Properties of polyethylene terephthalate (PET) and polypropylene (PP) can be enhanced by blending both in a specific proportion to get combined superior properties. To make a homogeneous blend, maleic anhydride functionalized PP (PP-g-MAH) was used as a compatibilizer in 60% PET blends. In all blends, PET’s percentage crystallinity was reduced as compared to pure PET because there were hindrances in chains packing because of the presence of PP chains. The addition of compatibilizer in PET and PP blend enhanced interactions resulted in a homogeneous blend with fewer voids. 2.5% of PP-g-MAH was observed to be the optimum value of compatibilizer in the blend of PET and PP. The decrease in free space inside the blend hindered water molecules' passage through the sheets. Owing to this, water vapor permeability of the blend was less compared to pure PET. The addition of the nonpolar PP also influenced the water transmittance rate of blended sheets.

Similar content being viewed by others

References

Utracki LA (2000) Polymer Blends. vol v. 11. Rapra Technology Limited,

Citterio CSE, Testa G, Bonfatti AM, Seves A (1999) Physico-chemical characterization of compatibilized poly(propylene)/aromatic polyamide blends. Macromol Mater Eng 270(1):22–27

Bhatia A, Bhattacharya GR and Choi HS (2007) Compatibility of biodegradable poly (lactic acid) (PLA) and poly (butylene succinate) (PBS) blends for packaging application. KoreaAustralia Rheology Journal 19 (3):125-131

Faisant AAi-K JB, Bousmina M, and Deschenes L (18 June 1998) Morphology, thermomechanical and barrier properties of polypropylene-ethylene vinyl alcohol blends. Polymer 39 (3):533-545

Torradas JM ZD New laminar oxygen barrier technology for food packaging applications. In: conference proceedings of Society of Plastics Engineers Annual Technical Papers, Montreal, Canada, 1991.

Nalin Ploypetchara PS, Atong D, Pechyen C (2014) Blend of polypropylene/poly(lactic acid) for medical packaging application: physicochemical, thermal, mechanical, and barrier properties. Energy Procedia 56:201–210

Cristina Moniz MDCaMI (2007) Blends of poly(ethylene terephthalate) and low density polyethylene containing aluminium: A material obtained from packaging recycling. J Appl Polym Sci 106(4):2524–2535

Isayev AI (2010) Encyclopedia of Polymer Blends: Volume 1: Fundamentals. John Wiley & Sons,

Tice P (2002) Packaging materials: 3. Polypropylene as a packaging material for foods and beverages, International Life Sciences Institute Europe Belgium

Mangaraj S, Goswami TK, Mahajan P (2009) Applications of Plastic Films for Modified Atmosphere Packaging of Fruits and Vegetables: A Review. Food Engineering Reviews 1:133–158. https://doi.org/10.1007/s12393-009-9007-3

Shorten DW (1982) Polyolefins for food packaging. Food Chem 8(2):109–119

Faisant JBA-KA, Bousmina M, Deschenes L (1998) Morphology, thermomechanical and barrier properties of polypropylene – ethylene vinyl alcohol blends. Polymer 39(3):533–545

Subramanian PM (1985) Permeability barriers by controlled morphology of polymer blends. Polym Eng Sci 25(8):483–487

Dukjoon Kim SWK (2003) Barrier Property and Morphology of Polypropylene/Polyamide Blend Film. Korean J Chem Eng 20(4):776–782

Papadopoulou CP, Kalfoglou NK (2000) Comparison of compatibilizer effectiveness for PET/PP blends: their mechanical, thermal and morphology characterization. Polymer 41(7):2543–2555. https://doi.org/10.1016/S0032-3861(99)00442-5

Shi D, Yang J, Yao Z, Wang Y, Huang H, Jing W, Yin J, Costa G (2001) Functionalization of isotactic polypropylene with maleic anhydride by reactive extrusion: mechanism of melt grafting. Polymer 42(13):5549–5557. https://doi.org/10.1016/S0032-3861(01)00069-6

Sichina W (2000) DSC as problem solving tool: measurement of percent crystallinity of thermoplastics. Perkin Elmer Instruments, and PETech 40

Kong Y, Hay J (2002) The measurement of the crystallinity of polymers by DSC. Polymer 43(14):3873–3878

Oromiehie A, Ebadi-Dehaghani H, Mirbagheri S (2014) Chemical modification of polypropylene by maleic anhydride: Melt grafting, characterization and mechanism. International Journal of Chemical Engineering and Applications 5(2):117

Sichina WJ DSC as Problem Solving Tool: Measurement of Percent Crystallinity of Thermoplastics.

Testing ASf, Materials (2013) Standard test methods for water vapor transmission of materials. ASTM International,

Glaser TK, Plohl O, Vesel A, Ajdnik U, Ulrih NP, Hrnčič MK, Bren U, Fras Zemljič L (2019) Functionalization of polyethylene (PE) and polypropylene (PP) material using chitosan nanoparticles with incorporated resveratrol as potential active packaging. Materials 12(13):2118

Sanbhal N, Li Y, Khatri A, Peerzada M, Wang L (2019) Chitosan Cross-Linked Bio-based Antimicrobial Polypropylene Meshes for Hernia Repair Loaded with Levofloxacin HCl via Cold Oxygen Plasma. Coatings 9(3):168

Chiu H-T, Hsiao Y-K (2006) Compatibilization of Poly(ethylene terephthalate)/Polypropylene Blends with Maleic Anhydride Grafted Polyethylene-Octene Elastomer. J Polym Res 13(2):153–160. https://doi.org/10.1007/s10965-005-9020-z

Mecozzi M (2019) The differentiation of biodegradable and non-biodegradable polyethylene terephthalate (PET) samples by FTIR spectroscopy: A potential support for the structural differentiation of PET in environmental analysis. Infrared Physics & Technology 101. doi:https://doi.org/10.1016/j.infrared.2019.06.008

Espinoza-García K, Marcos-Fernández A, Navarro R, Ramírez-Hernández A, Báez-García JE, Rangel-Porras G (2019) Polymerization of ε-caprolactone with degraded PET for its functionalization. J Polym Res 26(8):180. https://doi.org/10.1007/s10965-019-1821-6

Seki Y (2019) Enhancement of Electrical Conductivity of Polyethylene Terephthalate (PET) Fabrics via Ionic Liquids. Polymer-Plastics Technology and Materials 58(1):70–76. https://doi.org/10.1080/03602559.2018.1466163

Song Q, Xia Y, Hu S, Zhao J, Zhang G (2016) Tuning the crystallinity and degradability of PCL by organocatalytic copolymerization with δ-hexalactone. Polymer 102:248–255

Guo C, Zhou L, Lv J (2013) Effects of expandable graphite and modified ammonium polyphosphate on the flame-retardant and mechanical properties of wood flour-polypropylene composites. Polym Polym Compos 21(7):449

Abdul Razak NC, Inuwa IM, Hassan A, Samsudin SA (2013) Effects of compatibilizers on mechanical properties of PET/PP blend. Compos Interfaces 20(7):507–515. https://doi.org/10.1080/15685543.2013.811176

Oyman ZO, Tinçer T (2003) Melt blending of poly(ethylene terephthalate) with polypropylene in the presence of silane coupling agent. J Appl Polym Sci 89(4):1039–1048. https://doi.org/10.1002/app.12228

Xanthos M, Young MW, Biesenberger JA (1990) Polypropylene/polyethylene terephthalate blends compatibilized through functionalization. Polym Eng Sci 30(6):355–365. https://doi.org/10.1002/pen.760300607

Akbari M, Zadhoush A, Haghighat M (2007) PET/PP blending by using PP-g-MA synthesized by solid phase. J Appl Polym Sci 104(6):3986–3993

Thirtha V, Lehman R, Nosker T (2006) Morphological effects on glass transition behavior in selected immiscible blends of amorphous and semicrystalline polymers. Polymer 47(15):5392–5401

Serhatkulu T, Erman B, Bahar I, Fakirov S, Evstatiev M, Sapundjieva D (1995) Dynamic mechanical study of amorphous phases in poly (ethylene terephthalate)/nylon-6 blends. Polymer

Zdrazilova N, Hausnerova B, Kitano T, Saha P. (2004). Rheological behaviour of PP/PET and modified PP/PET blends. II. Dynamic viscoelastic properties Polymers and Polymer Composites. 12(5):433–448

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tariq, A., Afzal, A., Rashid, I.A. et al. Study of thermal, morphological, barrier and viscoelastic properties of PP grafted with maleic anhydride (PP-g-MAH) and PET blends . J Polym Res 27, 309 (2020). https://doi.org/10.1007/s10965-020-02291-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02291-2