Abstract

Liquids obtained by fractional condensation of pyrolysis vapors from two types of lignocellulosic biomass, namely Jerusalem artichoke stalk (high cellulose and ash contents) and white birch bark (high lignin and extractive contents), were compared. Using two condensers connected in series, a dark oily fraction rich in phenolic compounds and sugar derivatives was obtained at 90 °C (respectively, 14% of total polyphenols and 11% of total carbohydrates for the oily fraction from the agricultural stalk) followed by aqueous fraction at 0 °C. Stalk yielded a homogeneous oily fraction whereas the bark oily liquid was heterogeneous, due possibly to lignin pyrolysis products. Both yielded clear orange aqueous fractions having a chemical composition close to wood vinegar, > 60% water, and high concentrations of acetic acid, with also a significant content of polyphenols, around 5%. This study showed that fractional condensation could be a vital tool in pyrolysis-based biorefinery producing an oily (application as an energy source or as a chemical feedstock) and an aqueous fraction (applications as biocide or biostimulation in agriculture) by pyrolysis of vastly different lignocellulosic biomasses.

Similar content being viewed by others

Data availability

Not applicable

References

Mohan D, Pittman CU Jr, Steele PH (2006) Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuel 20:848–889. https://doi.org/10.1021/ef0502397

Staš M, Kubička D, Chudoba J, Pospíšil M (2014) Overview of analytical methods used for chemical characterization of pyrolysis bio-oil. Energy Fuel 28:385–402. https://doi.org/10.1021/ef402047y

Pinheiro Pires AP, Arauzo J, Fonts I et al (2019) Challenges and opportunities for bio-oil refining: a review. Energy Fuels 0:null. https://doi.org/10.1021/acs.energyfuels.9b00039

Meier D (2019) Pyrolysis Oil Biorefinery. In: Wagemann K, Tippkötter N (eds) Biorefineries. Springer International Publishing, Cham, pp 301–337

Papari S, Hawboldt K (2018) A review on condensing system for biomass pyrolysis process. Fuel Process Technol 180:1–13. https://doi.org/10.1016/j.fuproc.2018.08.001

Oasmaa A, Fonts I, Pelaez-Samaniego MR et al (2016) Pyrolysis oil multiphase behavior and phase stability: a review. Energy Fuel 30:6179–6200. https://doi.org/10.1021/acs.energyfuels.6b01287

Lindfors C, Kuoppala E, Oasmaa A et al (2014) Fractionation of bio-oil. Energy Fuel 28:5785–5791. https://doi.org/10.1021/ef500754d

Chang C-C, Wu S-R, Lin C-C et al (2012) Fast pyrolysis of biomass in pyrolysis gas: fractionation of pyrolysis vapors using a spray of bio-oil. Energy Fuel 26:2962–2967. https://doi.org/10.1021/ef201858h

Sui H, Yang H, Shao J et al (2014) Fractional condensation of multicomponent vapors from pyrolysis of cotton stalk. Energy Fuel 28:5095–5102. https://doi.org/10.1021/ef5006012

Westerhof RJM, Brilman DWF, Garcia-Perez M et al (2011) Fractional condensation of biomass pyrolysis vapors. Energy Fuel 25:1817–1829. https://doi.org/10.1021/ef2000322

Pollard AS, Rover MR, Brown RC (2012) Characterization of bio-oil recovered as stage fractions with unique chemical and physical properties. J Anal Appl Pyrolysis 93:129–138. https://doi.org/10.1016/j.jaap.2011.10.007

Gooty AT, Li D, Berruti F, Briens C (2014) Kraft-lignin pyrolysis and fractional condensation of its bio-oil vapors. J Anal Appl Pyrolysis 106:33–40. https://doi.org/10.1016/j.jaap.2013.12.006

Gooty AT, Li D, Briens C, Berruti F (2014) Fractional condensation of bio-oil vapors produced from birch bark pyrolysis. Sep Purif Technol 124:81–88. https://doi.org/10.1016/j.seppur.2014.01.003

Scott DS, Piskorz J, Bergougnou MA et al (1988) The role of temperature in the fast pyrolysis of cellulose and wood. Ind Eng Chem Res 27:8–15. https://doi.org/10.1021/ie00073a003

Schulzke T, Conrad S, Westermeyer J (2016) Fractionation of flash pyrolysis condensates by staged condensation. Biomass Bioenergy 95:287–295. https://doi.org/10.1016/j.biombioe.2016.05.022

Adjalle K, Larose L-V, Bley J, Barnabé S (2017) The effect of organic nitrogenous compound content and different pretreatments on agricultural lignocellulosic biomass characterization methods. Cellulose 24:1395–1406. https://doi.org/10.1007/s10570-017-1199-8

Soest PJV, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

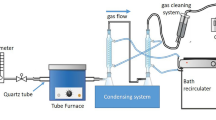

Verma M, Godbout S, Solomatnikova O et al System and process for thermochemical treatment of matter containing organic compounds. 30 pages, WO 2012/126096 A1, published 27/09/2012

Brassard P, Godbout S, Raghavan V et al (2017) The production of engineered biochars in a vertical auger pyrolysis reactor for carbon sequestration. Energies:10. https://doi.org/10.3390/en10030288

Schulzke T, Conrad S, Shumeiko B, Auersvald M, Kubička D, Raymakers LFJM (2020) Fuels from Reliable Bio-based Refinery Intermediates: BioMates. Waste Biomass Valorization 11:579–598. https://doi.org/10.1007/s12649-019-00625-w

Kim P, Weaver S, Noh K, Labbé N (2014) Characteristics of bio-oils produced by an intermediate semipilot scale pyrolysis auger reactor equipped with multistage condensers. Energy Fuel 28:6966–6973. https://doi.org/10.1021/ef5016186

Faix O, Fortmann I, Bremer J, Meier D (1991) Thermal-degradation products of wood—gas-chromatographic separation and mass-spectrometric characterization of polysaccharide derived products. Holz Roh Werkst 49:213–219. https://doi.org/10.1007/BF02613278

Faix O, Meier D, Fortmann I (1990) Thermal-degradation products of wood—gas-chromatographic separation and mass-spectrometric characterization of monomeric lignin derived products. Holz Roh Werkst 48:281–285. https://doi.org/10.1007/BF02626519

Faix O, Fortmann I, Bremer J, Meier D (1991) Thermal degradation products of wood: a collection of electron-impact (EI) mass spectra of polysaccharide derived products. Holz Roh Werkst 49:299–304. https://doi.org/10.1007/BF02663795

Faix O, Meier D, Fortmann I (1990) Thermal degradation products of wood: a collection of electron-impact (EI) mass spectra of monomeric lignin derived products. Holz Roh Werkst 48:351–354. https://doi.org/10.1007/BF02639897

Ralph J, Hatfield RD (1991) Pyrolysis-GC-MS characterization of forage materials. J Agric Food Chem 39:1426–1437. https://doi.org/10.1021/jf00008a014

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) [14] Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. In: Oxidants and Antioxidants Part A. Academic Press, pp 152–178

Rover MR, Brown RC (2013) Quantification of total phenols in bio-oil using the Folin–Ciocalteu method. J Anal Appl Pyrolysis 104:366–371. https://doi.org/10.1016/j.jaap.2013.06.011

Stankovikj F, McDonald AG, Helms GL et al (2017) Characterization of the water-soluble fraction of woody biomass pyrolysis oils. Energy Fuel 31:1650–1664. https://doi.org/10.1021/acs.energyfuels.6b02950

Albalasmeh AA, Berhe AA, Ghezzehei TA (2013) A new method for rapid determination of carbohydrate and total carbon concentrations using UV spectrophotometry. Carbohydr Polym 97:253–261. https://doi.org/10.1016/j.carbpol.2013.04.072

DuBois M, Gilles KA, Hamilton JK et al (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Rover MR, Johnston PA, Lamsal BP, Brown RC (2013) Total water-soluble sugars quantification in bio-oil using the phenol–sulfuric acid assay. J Anal Appl Pyrolysis 104:194–201. https://doi.org/10.1016/j.jaap.2013.08.004

Godin B, Ghysel F, Agneessens R et al (2010) Détermination de la cellulose, des hémicelluloses, de la lignine et des cendres dans diverses cultures lignocellulosiques dédiées à la production de bioéthanol de deuxième génération. Biotechnol Agron Soc Environ 14:549–560

Gunnarsson IB, Svensson S-E, Johansson E et al (2014) Potential of Jerusalem artichoke (Helianthus tuberosus L.) as a biorefinery crop. Ind Crop Prod 56:231–240. https://doi.org/10.1016/j.indcrop.2014.03.010

Stefanidis SD, Kalogiannis KG, Iliopoulou EF et al (2014) A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J Anal Appl Pyrolysis 105:143–150. https://doi.org/10.1016/j.jaap.2013.10.013

Vassilev SV, Baxter D, Andersen LK et al (2012) An overview of the organic and inorganic phase composition of biomass. Fuel 94:1–33. https://doi.org/10.1016/j.fuel.2011.09.030

Sun W-G, Zhao H, Yan H-X et al (2012) The pyrolysis characteristics and kinetics of Jerusalem artichoke stalk using thermogravimetric analysis. Energy Sources A Recover Utilization Environ Effects 34:626–635. https://doi.org/10.1080/15567036.2011.615006

Mullen CA, Boateng AA, Goldberg NM (2013) Production of deoxygenated biomass fast pyrolysis oils via product gas recycling. Energy Fuel 27:3867–3874. https://doi.org/10.1021/ef400739u

Pittman CU Jr, Mohan D, Eseyin A et al (2012) Characterization of bio-oils produced from fast pyrolysis of corn stalks in an auger reactor. Energy Fuel 26:3816–3825. https://doi.org/10.1021/ef3003922

Azargohar R, Jacobson KL, Powell EE, Dalai AK (2013) Evaluation of properties of fast pyrolysis products obtained, from Canadian waste biomass. J Anal Appl Pyrolysis 104:330–340. https://doi.org/10.1016/j.jaap.2013.06.016

Ingram L, Mohan D, Bricka M et al (2008) Pyrolysis of wood and bark in an auger reactor: physical properties and chemical analysis of the produced bio-oils. Energy Fuel 22:614–625. https://doi.org/10.1021/ef700335k

Jendoubi N, Broust F, Commandre JM et al (2011) Inorganics distribution in bio oils and char produced by biomass fast pyrolysis: the key role of aerosols. J Anal Appl Pyrolysis 92:59–67. https://doi.org/10.1016/j.jaap.2011.04.007

Liaw S-S, Wang Z, Ndegwa P et al (2012) Effect of pyrolysis temperature on the yield and properties of bio-oils obtained from the auger pyrolysis of Douglas Fir wood. J Anal Appl Pyrolysis 93:52–62. https://doi.org/10.1016/j.jaap.2011.09.011

Kanaujia PK, Sharma YK, Garg MO et al (2014) Review of analytical strategies in the production and upgrading of bio-oils derived from lignocellulosic biomass. J Anal Appl Pyrolysis 105:55–74. https://doi.org/10.1016/j.jaap.2013.10.004

O'Connell MM, Bentley MD, Campbell CS, Cole BJW (1988) Betulin and lupeol in bark from four white-barked birches. Phytochemistry 27:2175–2176. https://doi.org/10.1016/0031-9422(88)80120-1

Fagernas L, Kuoppala E, Tiilikkala K, Oasmaa A (2012) Chemical composition of birch wood slow pyrolysis products. Energy Fuel 26:1275–1283. https://doi.org/10.1021/ef2018836

Ohira T (2012) Functional substances obtained through biomass pyrolysis—functions of acid liquid, bamboo vinegar, etc. - http://www.biocharinternational.org/sites/default/files/Bamboo_Vinegar_Japan_2012.pdf. Accessed 28 Sept. 2019

Kim P, Weaver S, Labbe N (2016) Effect of sweeping gas flow rates on temperature-controlled multistage condensation of pyrolysis vapors in an auger intermediate pyrolysis system. J Anal Appl Pyrolysis 118:325–334. https://doi.org/10.1016/j.jaap.2016.02.017

Grewal A, Abbey L, Gunupuru LR (2018) Production, prospects and potential application of pyroligneous acid in agriculture. J Anal Appl Pyrolysis 135:152–159. https://doi.org/10.1016/j.jaap.2018.09.008

Mattos C, Veloso MCC, Romeiro GA, Folly E (2019) Biocidal applications trends of bio-oils from pyrolysis: characterization of several conditions and biomass, a review. J Anal Appl Pyrolysis 139:1–12. https://doi.org/10.1016/j.jaap.2018.12.029

Acknowledgments

Special thanks go to Cédric Morin for his technical assistance and to Olga Solomatnikova for her pyrolysis expertise.

Funding

This work was supported by funding from MITACS (IT07388).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Le Roux, É., Barnabé, S., Godbout, S. et al. Production and characterization of two fractions of pyrolysis liquid from agricultural and wood residues. Biomass Conv. Bioref. 12, 3333–3343 (2022). https://doi.org/10.1007/s13399-020-01015-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01015-2