Abstract

Systemic insecticides such as neonicotinoids are widely used in seed coating practices for pest control in many crops, e.g., corn. Their success is due to their ability to protect the whole plant, from the roots to the upper leaves, but their use at high amounts is causing possible adverse effects on non-target animals exposed to contaminated pollen, nectar, leaves, and dust emitted during sowing. In 2018, the European Union banned some neonicotinoids and fipronil as seed coating insecticides in open fields. Consequently, the methylcarbamate methiocarb and less-toxic neonicotinoids, e.g., thiacloprid, have been authorized and largely used as alternative pesticides for corn seed coating. Here, an analytical protocol based on QuEChERS extraction/purification procedure and analysis by liquid chromatography-mass spectrometry has been optimized for the identification and the quantification of methiocarb, thiamethoxam, thiacloprid, and their metabolites in guttation drops, the xylem fluid excreted at leaf margins, and in leaves of corn plants grown from coated seeds. Although methiocarb is a non-systemic pesticide, we unexpectedly found high concentrations of its metabolites in both guttations and leaves, whereas methiocarb itself was below detection limits in most of the samples. The methiocarb main metabolite, methiocarb sulfoxide, was found at a mean concentration of 0.61 ± 1.12 µg mL−1 in guttation drops and 4.4 ± 2.1 µg g−1 in leaves. Conversely, parent compounds of neonicotinoids (thiamethoxam, thiacloprid) are systemically distributed in corn seedlings. This result raises safety concerns given that methiocarb sulfoxide is more toxic than the parent compound for some non-target species.

Similar content being viewed by others

Introduction

Large-scale worldwide use of neonicotinoid insecticides in recent decades (Bonmatin et al. 2015; Giorio et al. 2017) was found to impact the health of honeybees and wild pollinators (Tapparo et al. 2012, 2013; Wood and Goulson 2017; Pisa et al. 2017), aquatic species (Gibbons et al. 2015; Pisa et al. 2015), birds, and mammals (Gibbons et al. 2015) including humans (Ichikawa et al. 2019). Despite being introduced as a safe and more environmentally friendly approach, the seed coating application of these systemic insecticides did not prevent their release into soil, ground and surface waters, in guttation drops, and into the air (through dust emitted during sowing) (Tapparo et al. 2012; Bonmatin et al. 2015; Giorio et al. 2017; Hitaj et al. 2020). In 2018, after a first restriction in 2013, the use of seeds coated with the neonicotinoid insecticides imidacloprid, thiamethoxam, and clothianidin was definitively banned in the EU (their use is now only permitted in greenhouses) (EU Commission 2020). Other insecticides have been introduced and used as replacements. Among these, methiocarb (a methylcarbamate) and thiacloprid (a less toxic neonicotinoid) were authorized in the EU up to 2020. Although methiocarb and thiacloprid are currently no longer authorized in the EU (European Commission 2019, 2020), they are used for seed coating applications worldwide. While thiacloprid is a systemic insecticide, methiocarb is considered a non-systemic insecticide and bird repellent (EFSA 2018). For these insecticides, information on their residue levels within the plant, and on the presence and the environmental fate of their metabolites, is scarcely available (Böhme et al. 2018; Erban et al. 2019; Martinello et al. 2019; Lentola et al. 2020).

In the present work, we analyzed guttations and leaves of corn plants grown from seeds coated with methiocarb to assess residue levels and the possible presence of metabolites of the active ingredient. A suspect screening approach was used starting from the metabolic pathways available in the literature (Kuhr 1970; Ford and Casida 2006; Simon-Delso et al. 2015). It is worth noticing that guttations, a natural phenomenon forming drops of xylem sap at the leaf margins of many vascular plants (Goatley et al. 1966), may represent a renewable matrix in which soluble species (i.e., systemic insecticides and their metabolites (Harris et al. 1999; Girolami et al. 2009)) can be studied without compromising the whole plant. For guttation samples, direct injection is proposed as a simple analytical procedure by using ultra-high performance liquid chromatography with high-resolution mass spectrometry (UHPLC-HRMS). For leaf samples, we optimized an analytical method based on Quick, Easy, Cheap, Effective, Rugged, and Safe (QuEChERS) extraction/purification procedure (Plácido et al. 2013; Rejczak and Tuzimski 2015; Rahman et al. 2017) before UHPLC-HRMS analysis in order to identify and quantify the degradation products of methiocarb in corn plants. Samples collected from plants treated with the well-known systemic pesticides thiacloprid and thiamethoxam were also analyzed to compare residue levels in both leaves and guttation drops.

Materials and methods

Seeds

Corn seeds coated with different pesticides, Cruiser® 350 FS (thiamethoxam 1.0 mg/seed, Syngenta, Basel, Switzerland), Sonido® (thiacloprid, 1.0 mg/seed, Bayer Cropscience AG, Leverkusen, Germany), and Mesurol® (methiocarb, 1.25 mg/seed, Bayer Cropscience), were from Pioneer HiBred Italia. All seeds have also been treated with the fungicide Celest XL® (Fludioxonil 2.4% and Metalaxyl-M 0.93%; Syngenta, Basel, Switzerland). Seeds coated with fludioxonil and metalxyl-M (Celest®, Syngenta International, 2.4% and 0.93%, respectively) fungicides were used as controls.

Plant growth conditions and collection of guttations and leaves

Seven corn seeds coated for each of methiocarb, thiamethoxam and thiacloprid were sown in pots (Ø 12 cm, h 12 cm) and grown in the laboratory. To obtain samples replicates, nine pots were prepared for methiocarb and six pots for thiamethoxam and thiacloprid. Sterilized garden soil was used and plants were watered regularly once a day. Leaf samples from the same pot were collected on different days, and each corn leaf sample consisted of one corn seedling manually gathered. In view of the observed differences in the growth of seedlings from the different seeds (for example, not all the seedlings grew enough to obtain an adequate leaf sample or produced guttation drops in the same period), the sampling procedures were adapted daily to sample availability. For methiocarb, a total of 30 samples were collected between 9 and 16 days after sowing. Instead, 19 and 23 samples were collected for thiamethoxam and thiacloprid, respectively, between 19 and 42 days after sowing. Samples were placed in plastic bags, and they were stored at − 20 °C until analysis.

Guttation samples were collected for two weeks starting a few days after plant emergence. Micropipettes were used to collect guttation drops twice-daily from the same plants used for leaf sample collection. For methiocarb, a total of 21 samples were collected between 7 and 15 days after sowing. For thiamethoxam and thiacloprid, 7 and 4 samples were collected, respectively, between 17 and 21 days after sowing. In addition, for corn plants grown from seeds coated with methiocarb, guttation samples were collected from plants sown in an open field (Agripolis University Campus, Legnaro, Padova, IT). In this case, five different plants were sampled in the morning (between 9 and 11 am) for three non-consecutive days. All guttation samples were collected in 1.5 mL plastic tubes with caps, and they were stored at − 20 °C until analysis.

Sample preparation

Guttations

Guttation samples were filtered through 0.2 μm syringe filters (Phenomenex, RC), diluted 1:1 with a methanol solution of the internal standards (final internal standard concentration was 0.10 µg mL−1 and directly injected into the UHPLC-HRMS system; the analytical procedure is reported in details in the ESM).

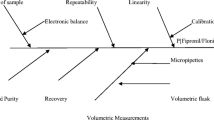

Insecticide extraction from leaves by QuEChERS procedure

Before extraction, leaves were ground with liquid nitrogen followed by manual homogenization using a micro-spatula. An aliquot of 100 ± 5 mg of ground sample was weighed in an Eppendorf test tube. 500 µL of acetonitrile with 1% acetic acid was added and the sample vortexed for 1 min. After that, 400 µL of water and 250 mg of a salt mixture (magnesium sulfate and sodium acetate; 4:1) were added. The solution was quickly shaken for 30 s and then placed in an ultrasonic bath for 10 min. After centrifugation, the upper organic phase was transferred into an Eppendorf containing 30 mg of the dispersive solid-phase extraction (d-SPE) PSA sorbent. The sample was extracted again with another 500 µL of solvent, and the combined extracts were mixed and placed in an ultrasonic bath for 5 min. After centrifugation, the supernatant was transferred into another Eppendorf and evaporated to dryness under a nitrogen stream at 30 °C. Finally, the extract was recovered with 300 µL of a water/methanol (80:20) solution, filtered through a 0.2 μm syringe filter (Phenomenex, RC), and diluted 1:1 with a water/methanol (80:20) solution of the internal standards (150 µg L−1), before analysis.

UHPLC-HRMS analysis

Analyses were carried out using an UltiMate 3000 UHPLC system coupled to an electrospray (ESI)-QExactive Hybrid Quadrupole-Orbitrap™ Mass Spectrometer (Thermo Scientific™). Analyte separation was achieved using a reverse-phase Luna® Omega C18 polar column (1.6 µm, 2.1 × 100 mm, Phenomenex), maintained at 30 °C. The injection volume was 20 µL, and mobile phases were water with ammonium acetate 5 mM (A) and acetonitrile with ammonium acetate 5 mM (B). The flow rate was 0.2 mL min−1 with the following elution gradient: 0–3 min 100% A, 3–20 min linear gradient from 100 to 30% A, 20–22 min linear gradient from 30% A to 0% A, 22–25 min 0% A, 25–26 min to 100% A and 3 min of equilibration time before the next injection.

Tandem MS acquisition was performed in both polarities using the parallel reaction monitoring (PRM) mode with the multiplex option (MSX, Table S1 in the Electronic Supplementary Material for details). The normalized collision energy (NCE) was optimized for each analyte (Table S1), and other parameters were as follows: spray voltage 3.3 kV in positive ionization and 2.8 kV in negative ionization, capillary temperature 320 °C, probe heather temperature 340 °C, sheath gas 40 arbitrary units (a.u.), auxiliary gas nitrogen 20 a.u., S-lens RF 60 V, resolution 35,000 in MS and 17,500 in MS/MS, Automatic Gain Control (AGC) target 3·106 in MS and 2·105 in MS/MS, max injection time 50 ms, scan range 50–750 m/z, isolation window 3.0 m/z and isolation offset 1.0 m/z, collision gas nitrogen. Data were acquired using Thermo Xcalibur 3.0.63, and quantification was carried out by internal standard calibration.

Individual pesticide stock solutions (100 mg L−1) were prepared in methanol. Standard solutions for instrumental calibration, including the deuterated internal standards, were prepared weekly by diluting stock solutions in water/methanol (80:20). All solutions were stored at − 20 °C in darkness. Details about chemicals, reagents, method optimization, and validation are reported in the Electronic Supplementary Material.

Results and discussion

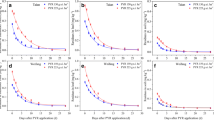

Methiocarb and its metabolites in corn plants grown in pots and in open field

Twenty-one guttation samples were collected from plants treated with methiocarb. Concerning the active ingredient (AI), its concentration in guttation drops was lower than the method detection limit (MDL, 8.7 ng mL−1) in 17 of the 21 analyzed samples. In one sample its concentration was 31 ng mL−1, and in three samples its concentration was between the method quantification limit (MQL, 26 ng mL−1) and MDL. Unexpectedly, four methiocarb metabolites were identified in guttation drops: methiocarb sulfoxide (0.61 ± 1.12 µg mL−1), methiocarb sulfoxide phenol (0.54 ± 0.42 µg mL−1), methiocarb sulfoxide hydroxy (0.068 ± 0.138 µg mL−1), and methiocarb sulfone phenol (0.018 ± 0.025 µg mL−1), while methiocarb phenol and methiocarb sulfone were below the MDL in all samples (Table 1). This is the first study in which the absence of the insecticide in the guttations is evidenced together with the significant presence of its metabolites, so that the metabolites may have systemic properties that are different from that of their parent active ingredient. The main methiocarb modification is the oxidation of the sulfur atom, which leads to higher water solubility of the compound. In fact, methiocarb sulfoxide is more soluble in water than the parent compound methiocarb. Such modification seems to affect the systemic properties of the compounds. Methiocarb is known to be oxidized to sulfoxide both in soil and plants (EFSA 2018; Kuhr 1970). Therefore, in our case it is difficult to assess where the oxidation actually takes place. However, due to the high amount of methiocarb sulfoxide detected compared to the parent compound, it is likely that the oxidation takes place in soil before uptake by the roots.

Methiocarb sulfoxide maintains a relevant toxicity (Buronfosse et al. 1995; EPA 1987) and it is known to be more toxic than the parent compound for mice (Oonnithan and Casida 1968), so its impact against non-target small mammals needs to be considered in risk assessment studies, including supporting documents for pesticide registration (EU Commission, 2012,Sgolastra et al. 2020; Hitaj et al. 2020). The metabolization of methiocarb in humans has been reported to proceed through both oxidation and hydrolyzation mechanisms and that some of the methiocarb metabolites showed nuclear receptor activities equivalent to those of their parent compound (Fujino et al. 2016). Possible human exposure routes reported are through accumulation on surfaces after household applications and through dusts emitted during sowing for workers (Fujino et al. 2016; Lentola et al. 2020). The European Food Safety Authority, in a recent report (EFSA 2018), highlighted significant knowledge gaps concerning mammal toxicology and worker exposure to methiocarb, as well as genotoxic potential of methiocarb sulfoxide.

In corn leaves, the active ingredient was detected in 7 out of 30 samples analyzed, but its concentration was below the MQL (79 ng g−1). Conversely, some methiocarb metabolites were detected at high concentrations. Methiocarb sulfoxide had the highest mean concentration of 4.4 ± 2.1 µg g−1, followed by methiocarb sulfoxide hydroxy with a mean concentration of 3.0 ± 1.6 µg g−1 and methiocarb sulfoxide phenol with a mean concentration of 1.4 ± 1.0 µg g−1. All other metabolites were also detected in leaf samples albeit at lower concentrations (Table 1). This result is consistent with the results obtained for guttation drops and proves that methiocarb metabolites have systemic properties. In addition, the approach of measuring the presence of the active ingredients and their metabolites both in guttations and leaves highlighted that guttation analysis can be an effective and innovative tool for the study of systemic properties of the insecticides, as well as their metabolic pathways, in plants grown from coated seeds. Compared with analyses of leaves or other vegetative tissues, guttation drop analysis has many advantages: (1) guttation drops are easy to collect, (2) their sampling does not affect the plant, (3) no sample extraction is required before analysis because guttations are characterized by a relatively clean matrix. Furthermore, systemic insecticides are highly concentrated in guttation drops and their detection is therefore relatively easy compared with other plant tissues. However, concentrations measured in guttation samples are not only analyte-dependent but are related to plant physiology or drop-evaporation processes prior to collection. In fact, the main challenge with guttation is to obtain a regular production by the plant while guttation drops may roll off, evaporate, or may be sucked back into the leaf (Chen and Chen 2005), causing a variable analyte concentration. To limit these drawbacks, it is advisable where possible to cover the plant to obtain a suitable air humidity saturation. This precaution improves the production of guttations and reduces the evaporation of the drops, which could reduce sample-to-sample variability.

Residue levels of methiocarb metabolites in guttations and leaves are in-line with residue levels of systemic insecticides and their metabolites in plants grown from seeds coated with thiamethoxam and thiacloprid. Noteworthy, for both these neonicotinoids the largely dominant species is the active compound and not its metabolites (see sections S4 and S5).

Analysis of guttation samples collected from corn plants grown in an open field gave similar results. Methiocarb and methiocarb phenol concentrations were below the MDL. Conversely, high concentrations of methiocarb sulfoxide and methiocarb sulfoxide phenol were observed (Fig. 1). Other metabolites were also detected: methiocarb sulfone phenol (0.163 ± 0.036 µg mL−1) and methiocarb sulfoxide hydroxy (0.139 ± 0.071 µg mL−1). Therefore, these metabolites and their systemic behavior must be considered in the risk assessment related to the use of methiocarb for seed coating.

Conclusion

This work demonstrates that the existence of methiocarb sulfoxide (together with other degradation products) in corn seedlings may indicate a systemic action of methiocarb through the presence of its metabolites, despite methiocarb being classified as a non-systemic pesticide. To the authors’ knowledge, this is the first study in which a non-systemic pesticide is found to produce systemically distributed metabolites throughout plants grown from coated seeds. Therefore, environmental behavior, exposure routes and toxic effects of the degradation products of active ingredients should be carefully considered in the risk assessment procedures for the authorization of new seed-coating insecticides or new formulations.

Notably, the approach of measuring the presence of active ingredients and their metabolites both in guttations and leaves highlighted that guttation analysis can be an effective and innovative tool for the study of systemic properties of the insecticides, as well as their metabolic pathways, in plants grown from coated seeds.

References

Böhme F, Bischoff G, Zebitz CPW et al (2018) Pesticide residue survey of pollen loads collected by honeybees (Apis mellifera) in daily intervals at three agricultural sites in South Germany. PLoS ONE 13:e0199995. https://doi.org/10.1371/journal.pone.0199995

Bonmatin J-M, Giorio C, Girolami V et al (2015) Environmental fate and exposure; neonicotinoids and fipronil. Environ Sci Pollut Res 22:35–67. https://doi.org/10.1007/s11356-014-3332-7

Buronfosse T, Moroni P, Benoĭt E, Rivière JL (1995) Stereoselective sulfoxidation of the pesticide methiocarb by flavin-containing monooxygenase and cytochrome P450-dependent monooxygenases of rat liver microsomes. Anticholinesterase activity of the two sulfoxide enantiomers. J Biochem Toxicol 10:179–189. https://doi.org/10.1002/jbt.2570100402

Chen CC, Chen YR (2005) Study on laminar hydathodes of Ficus formosana (Moraceae) III. Salt injury of guttation on hydathodes. Bot Stud 48:215–226

EFSA (2018) Peer review of the pesticide risk assessment of the active substance methiocarb. EFSA J. https://doi.org/10.2903/j.efsa.2018.5429

EPA (1987) Guidance for the Reregistration of Pesticide Products Containing Methiocarb (100501) as the Active Ingredient, Case Number 577, CAS 2032–65–7.

European Commission (2012) EU Regulation No 528/2012 of the European Parliament and of the Council of 22 May 2012. Official Journal of the European Union.

EU Commission (2018) Commission Implementing Regulation (EU) No 2018/783, No 2018/784 and No 2018/785 of 29 May 2018, Official Journal of the European Union.

European Commission (2019) Commission Implementing Regulation (EU) No 2019/1606 of 27 September 2019, Official Journal of the European Union.

European Commission (2020) Commission Implementing Regulation (EU) No 2020/23 of 13 January 2020, Official Journal of the European Union.

Erban T, Vaclavikova M, Tomesova D et al (2019) tau -Fluvalinate and other pesticide residues in honey bees before overwintering. Pest Manag Sci 75:3245–3251. https://doi.org/10.1002/ps.5446

Ford KA, Casida JE (2006) Chloropyridinyl neonicotinoid insecticides: diverse molecular substituents contribute to facile metabolism in mice. Chem Res Toxicol 19:944–951. https://doi.org/10.1021/tx0600696

Fujino C, Tamura Y, Tange S et al (2016) Metabolism of methiocarb and carbaryl by rat and human livers and plasma, and effect on their PXR, CAR and PPARα activities. J Toxicol Sci 41:677–691

Gibbons D, Morrissey C, Mineau P (2015) A review of the direct and indirect effects of neonicotinoids and fipronil on vertebrate wildlife. Environ Sci Pollut Res 22:103–118. https://doi.org/10.1007/s11356-014-3180-5

Giorio C, Safer A, Sánchez-Bayo F et al (2017) An update of the Worldwide Integrated Assessment (WIA) on systemic insecticides. Part 1: new molecules, metabolism, fate, and transport. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-017-0394-3

Girolami V, Mazzon L, Squartini, et al (2009) Translocation of neonicotinoid insecticides from coated seeds to seedling guttation drops: a novel way of intoxication for bees. J Econ Entomol 102:1808–1815. https://doi.org/10.1603/029.102.0511

Goatley JL, Lewis RW (1966) Composition of guttation fluid from rye, wheat, and barley seedlings. Plant Physiol 41:373–375

Harris RI (1999) Guttation: the basis of an assay for evaluating formulation behaviour in vivo. Pest Manag Sci 55:582–584

Hitaj C, Smith DJ, Code A et al (2020) Sowing uncertainty: what we do and don’t know about the planting of pesticide-treated seed. Bioscience 70:390–403. https://doi.org/10.1093/biosci/biaa019

Ichikawa G, Kuribayashi R, Ikenaka Y et al (2019) LC-ESI/MS/MS analysis of neonicotinoids in urine of very low birth weight infants at birth. PLoS ONE 14:e0219208. https://doi.org/10.1371/journal.pone.0219208

Kuhr RJ (1970) Metabolism of carbamate insecticide chemicals in plants and insects. J Agric Food Chem 18:1023–1030. https://doi.org/10.1021/jf60172a042

Lentola A, Giorio C, Petrucco Toffolo E et al (2020) A new method to assess the acute toxicity toward honeybees of the abrasion particles generated from seeds coated with insecticides. Environ Sci Eur 32:93. https://doi.org/10.1186/s12302-020-00372-z

Martinello M, Manzinello C, Borin A et al (2019) A survey from 2015 to 2019 to investigate the occurrence of pesticide residues in dead honeybees and other matrices related to honeybee mortality incidents in Italy. Diversity 12:15. https://doi.org/10.3390/d12010015

Oonnithan ES, Casida JE (1968) Oxidation of methyl- and dimethylcarbamate insecticide chemicals by microsomal enzymes and anticholinesterase activity of the metabolites. J Agric Food Chem 16:28–44. https://doi.org/10.1021/jf60155a022

Pisa L, Goulson D, Yang E-C et al (2017) An update of the Worldwide Integrated Assessment (WIA) on systemic insecticides Part 2: impacts on organisms and ecosystems. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-017-0341-3

Pisa LW, Amaral-Rogers V, Belzunces LP et al (2015) Effects of neonicotinoids and fipronil on non-target invertebrates. Environ Sci Pollut Res 22:68–102. https://doi.org/10.1007/s11356-014-3471-x

Plácido A, Paíga P, Lopes DH et al (2013) Determination of methiocarb and its degradation products, methiocarb sulfoxide and methiocarb sulfone, in bananas using QuEChERS extraction. J Agric Food Chem 61:325–331. https://doi.org/10.1021/jf304027s

Rahman MM, Abd El-Aty AM, Na T-W et al (2017) Simultaneous quantification of methiocarb and its metabolites, methiocarb sulfoxide and methiocarb sulfone, in five food products of animal origin using tandem mass spectrometry. J Chromatogr B 1060:387–394. https://doi.org/10.1016/j.jchromb.2017.06.025

Rejczak T, Tuzimski T (2015) A review of recent developments and trends in the QuEChERS sample preparation approach. Open Chem. https://doi.org/10.1515/chem-2015-0109

Sgolastra F, Medrzycki P, Bortolotti L et al (2020) Bees and pesticide regulation: lessons from the neonicotinoid experience. Biol Conserv 241:108356. https://doi.org/10.1016/j.biocon.2019.108356

Simon-Delso N, Amaral-Rogers V, Belzunces LP et al (2015) Systemic insecticides (neonicotinoids and fipronil): trends, uses, mode of action and metabolites. Environ Sci Pollut Res 22:5–34. https://doi.org/10.1007/s11356-014-3470-y

Tapparo A, Giorio C, Marzaro M et al (2013) UHPLC-DAD method for the determination of neonicotinoid insecticides in single bees and its relevance in honeybee colony loss investigations. Anal Bioanal Chem 405:1007–1014. https://doi.org/10.1007/s00216-012-6338-3

Tapparo A, Marton D, Giorio C et al (2012) Assessment of the environmental exposure of honeybees to particulate matter containing neonicotinoid insecticides coming from corn coated seeds. Environ Sci Technol 46:2592–2599. https://doi.org/10.1021/es2035152

Wood TJ, Goulson D (2017) The environmental risks of neonicotinoid pesticides: a review of the evidence post 2013. Environ Sci Pollut Res 24:17285–17325. https://doi.org/10.1007/s11356-017-9240-x

Acknowledgements

The seeds coated with thiamethoxam were supplied by A.I.S. (Italian seed association) courtesy of MiPAAF (Ministry of Agriculture, Food and Forestry) for the research project Apenet. We thank University of Padova and Aldo Gini Foundation that supported PhD activities of A.L.

Funding

Open access funding provided by Università degli Studi di Padova within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lentola, A., Giorio, C., Bogialli, S. et al. Methiocarb metabolites are systemically distributed throughout corn plants grown from coated seeds. Environ Chem Lett 19, 1887–1892 (2021). https://doi.org/10.1007/s10311-020-01098-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-020-01098-3