Abstract

Japan has promoted a policy to use lumber in various types of buildings since 2010. As cross-laminated timber (CLT) is one of the engineered timber products, an amount of CLT production has been increasing in Japan under this policy. The purpose of this study is to produce generic life cycle assessment data for CLT production in Japan and to propose measures for reducing environmental impacts of CLT production. The system boundary includes from material production to CLT production (cradle-to-gate). The operational data at three major Japanese companies are collected in the fiscal year of 2018. The evaluated environmental impact categories are climate change, ozone layer depletion, eutrophication, acidification, photochemical oxidant, land occupation, and land transformation. The results show that electricity used in wood laminae production had the largest impact to climate change and the roundwood production had the second largest. The sensitivity analysis clarified that the use of fossil fuels during the drying process greatly increased CLT’s environmental impacts. The policies to promote the introduction of biomass boilers for sawmills are appropriate for reducing environmental impacts. If CLT is used for more than 30 years, greenhouse gas reduction due to temporary carbon storage will be greater than that of the CLT production. It is also recommended to extend the life of buildings using CLT and/or to use CLT for a long time through the reuse of CLT panels to avoid releasing biogenic carbon to the atmosphere.

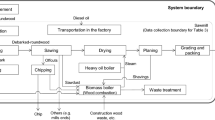

Graphic abstract

Similar content being viewed by others

Availability of data and materials

The datasets generated during and/or analyzed during the current study are not publicly available due to an inclusion of individual companies’ confidential data but are available from the corresponding author on reasonable request.

Abbreviations

- CLT:

-

Cross-laminated timber

- EPD:

-

Environmental product declarations

- GHG:

-

Greenhouse gas

- HB:

-

Hard board

- IB:

-

Insulation board

- LCA:

-

Life cycle assessment

- MAFF:

-

Ministry of agriculture, forestry and fisheries of Japan

- MDF:

-

Medium density fiberboard

- PB:

-

Particle board

References

Anand CK, Amor B (2017) Recent developments, future challenges and new research directions in LCA of buildings: a critical review. Renew Sustain Energy Rev 67:408–416. https://doi.org/10.1016/j.rser.2016.09.058

Artuso Legnami S.r.l (2018) Dichiarazione ambientale di prodotto (EPD) del pannello in legno

Athena Sustainable Materials Institute; (2013) A life cycle assessment of cross-laminated timber produced in Canada

Bergman RD, Kaestner D, Taylor AM (2016) Life cycle impacts of North American wood panel manufacturing. Wood Fiber Sci 48:40–53

Brandner R, Flatscher G, Ringhofer A et al (2016) Cross laminated timber (CLT): overview and development. Eur J Wood Wood Prod 74:331–351. https://doi.org/10.1007/s00107-015-0999-5

Cabinet Secretariat of Japan (2019) Government contact point to promote the use of CLT (in Japanese). https://www.cas.go.jp/jp/seisaku/cltmadoguchi/. Accessed 18 Mar 2020

Chen CX, Pierobon F, Ganguly I (2019) Life cycle assessment (LCA) of cross-laminated timber (CLT) produced in Western Washington: the role of logistics and wood species mix. Sustain. https://doi.org/10.3390/su11051278

Corradini G, Pierobon F, Zanetti M (2019) Product environmental footprint of a cross-laminated timber system: a case study in Italy. Int J Life Cycle Assess 24:975–988. https://doi.org/10.1007/s11367-018-1541-x

Egoin, (2018) EGO-CLT cross laminated timber wood panel EPD. Natxitua, Spain

Fujiwara T, Yamashita K, Hirakawa Y (2004) Mean basic density and density variation within individual trees in major plantation species. Bull FFPRI 3:341–348

Hitoe K, Habuto M, Nishimura Y et al (2009) on the trial allocation in life cycle inventory of structural domestic lumber. J Life Cycle Assess Japan 5:456–461. https://doi.org/10.3370/lca.5.456

Horn R, Maier S (2018) LANCA®-characterization factors for life cycle impact assessment, Version 2.5

Hussain M, Naseem Malik R, Taylor A (2017) Carbon footprint as an environmental sustainability indicator for the particleboard produced in Pakistan. Environ Res 155:385–393. https://doi.org/10.1016/j.envres.2017.02.024

ISO (2017) ISO 21930:2017-Sustainability in buildings and civil engineering works—core rules for environmental product declarations of construction products and services

ISO (2018) ISO 14067:2018 Greenhouse gases — Carbon footprint of products — Requirements and guidelines for quantification

Itsubo N, Inaba A (2012) LIME2: life-cycle impact assessment method based on endpoint modeling: summary. life cycle assess forum Japan 1–20

Jia L, Chu J, Ma L et al (2019) Life cycle assessment of plywood manufacturing process in China. Int J Environ Res Public Health. https://doi.org/10.3390/ijerph16112037

JRC (2010) International reference life cycle data system (ilcd) handbook: general guide for life cycle assessment—detailed guidance, 1st edn. Isppra, Italy

Kouchaki-Penchah H, Sharifi M, Mousazadeh H, Zarea-Hosseinabadi H (2015a) Gate to gate life cycle assessment of flat pressed particleboard production in I. R Iran J Clean Prod. https://doi.org/10.1016/j.jclepro.2015.07.056

Kouchaki-Penchah H, Sharifi M, Mousazadeh H, Zarea-Hosseinabadi H (2015b) Life cycle assessment of medium-density fiberboard manufacturing process in I R Iran. J Clean Prod 112:351–358. https://doi.org/10.1016/j.jclepro.2015.07.049

Levasseur A, Lesage P, Margni M, Samson R (2013) Biogenic carbon and temporary storage addressed with dynamic life cycle assessment. J Ind Ecol 17:117–128. https://doi.org/10.1111/j.1530-9290.2012.00503.x

MAFF (2019a) JAS3079: japanese agricultural standard of cross-laminated-timber (in Japanese). MAFF, Tokyo, Japan

MAFF (2019b) MOKUZAI TOUKEI (Wood statistics) in Japanese. https://www.maff.go.jp/j/tokei/kekka_gaiyou/mokuzai/toukei/h30/index.html. Accessed 26 Dec 2019

McDevitt JE, Grigsby WJ (2014) Life cycle assessment of bio- and petro-chemical adhesives used in fiberboard production. J Polym Environ 22:537–544. https://doi.org/10.1007/s10924-014-0677-4

Myhre G, Shindell D, Bréon F-M, et al (2013) Anthropogenic and natural radiative forcing: In: Climate change 2013: the physical science basis. contribution of working group I to the fifth assessment report of the intergovernmental pa nel on climate change

Nakano K, Ando K, Takigawa M, Hattori N (2018) Life cycle assessment of wood-based boards produced in Japan and impact of formaldehyde emissions during the use stage. Int J Life Cycle Assess 23:957–969. https://doi.org/10.1007/s11367-017-1343-6

Nakano K, Karube M, Hattori N (2020) Environmental impacts of building construction using cross-laminated timber panel construction method: a case of the research building in. Sustainability 12:2220. https://doi.org/10.3390/su12062220

Nakano K, Shibahara N, Nakai T et al (2018) Greenhouse gas emissions from round wood production in Japan. J Clean Prod 170:1654–1664. https://doi.org/10.1016/j.jclepro.2016.10.024

National Institute of Advanced Industrial Science and Technology;Sustainable Management Promotion Organization (2016) LCA database IDEA version 2. Tsukuba and Tokyo, Japan

NIES (2020) National Greenhouse Gas Inventory Report of JAPAN 2020

Ohno H (2012) Development of laminated lumber composed of sugi (Cryptomeria japonica D. Don) and other softwood species. Bull Utsunomiya Univ For 48:35–70

Passarelli RN, Koshihara M (2017) CLT panels in Japan from cradle to construction site gate: global warming potential and freight costs impact of three supply options. Int Wood Prod J 8:127–136. https://doi.org/10.1080/20426445.2017.1317471

Pommier R, Grimaud G, Prinçaud M et al (2016) LCA (life cycle assessment) of EVP-engineering veneer product: plywood glued using a vacuum moulding technology from green veneers. J Clean Prod 124:383–394. https://doi.org/10.1016/j.jclepro.2016.02.130

Puettmann M, Sinha A, Ganguly I (2019) Life cycle assessment of Katerra’s cross-laminated timber and catalyst building: summary document. J Green Build 14:17–33. https://doi.org/10.3992/1943-4618.14.4.17

Ramsay J, Macdonald E (2013) Timber properties of minor conifer species: a report to the forestry commission

Röck M, Saade MRM, Balouktsi M et al (2020) Embodied GHG emissions of buildings—the hidden challenge for effective climate change mitigation. Appl Energy 258:114107. https://doi.org/10.1016/j.apenergy.2019.114107

Sahoo K, Bergman R, Alanya-Rosenbaum S et al (2019) Life cycle assessment of forest-based products: a review. Sustain 11:1–30

Sawada Y, Ando K, Hattori N, Tamura Y (2006) Inventory analysis of adhesives used for wood based materials. Mokuzai Gakkaishi 52:235–240

Silva DAL, Lahr FAR, Garcia RP et al (2013) Life cycle assessment of medium density particleboard (MDP) produced in Brazil. Int J Life Cycle Assess 18:1404–1411. https://doi.org/10.1007/s11367-013-0583-3

Silva DAL, Lahr FAR, Pavan ALR et al (2014) Do wood-based panels made with agro-industrial residues provide environmentally benign alternatives? an LCA case study of sugarcane bagasse addition to particle board manufacturing. Int J Life Cycle Assess 19:1767–1778. https://doi.org/10.1007/s11367-014-0776-4

The Carbon Leadership Forum, CINTRAFOR (2020) Life cycle assessment of Katerra’s CLT and catalyst building: summary document

Thomas SC, Martin AR (2012) Carbon content of tree tissues: a synthesis. Forests 3:332–352. https://doi.org/10.3390/f3020332

Vogtländer JG, Van Der Velden NM, Van Der Lugt P (2014) Carbon sequestration in LCA, a proposal for a new approach based on the global carbon cycle; cases on wood and on bamboo. Int J Life Cycle Assess 19:13–23. https://doi.org/10.1007/s11367-013-0629-6

Wang S, Wang W, Yang H (2018) Comparison of product carbon footprint protocols: case study on medium-density fiberboard in China. Int J Environ Res Public Health 15:1–14. https://doi.org/10.3390/ijerph15102060

WMO (1999) Scientific assessment of ozone depletion, WMO global ozone research and monitoring Project: Report No. 44

Acknowledgements

The authors thank the three companies that provided factory data for this study. We also thank Katsuji Ebisu in the Sustainable Management Promotion Organization who supported data reduction.

Funding

This research was partly supported by grants from the Project of the NARO Bio-oriented Technology Research Advancement Institution (the special project on vitalizing management entities of agriculture, forestry and fisheries).

Author information

Authors and Affiliations

Contributions

NH helped in conceptualization; KN contributed to methodology and formal analysis; WK and KY helped in investigation; KN contributed to writing—original draft preparation; NH helped in writing—review and editing and funding acquisition and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nakano, K., Koike, W., Yamagishi, K. et al. Environmental impacts of cross-laminated timber production in Japan. Clean Techn Environ Policy 22, 2193–2205 (2020). https://doi.org/10.1007/s10098-020-01948-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-020-01948-2