Abstract

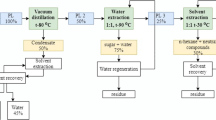

This article presents the results of the investigation of the properties of phenol-formaldehyde resin, obtained using the phenol-replacing fraction. A two-step method was developed for phenol-replacing fraction separation from liquid pyrolysis products with a yield up to 15%, and this fraction was used in the phenol-formaldehyde resin synthesis. Then, a work was conducted for the removal of neutrals from the modified phenol-formaldehyde resin with organic solvents, n-hexane and benzene. As a result, benzene was defined as a more efficient solvent because it removed more aromatics, like ethers and substituted phenols, that cannot react and worsen the glue line water resistance. Benzene dissolved 3.2% weight of the resin, and n-hexane dissolved 2.5% weight. The removal of neutrals increased the water resistance coefficient by more than 60%, so neutrals have a considerable effect on the resin properties. The results can be used for production of resin from renewable feedstock with the similar properties with the traditional resin.

Similar content being viewed by others

References

Doronin YG, Svitkina MM, Miroshnichenko SN (1979) Synthetic resins in wood processing: a guide. Lesnaya promyshlennost’. 208 p. (in Russian)

Weber M, Weber M, Kleine-Boymann M (2004) Phenol/Ullmann’s Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCN. doi:https://doi.org/10.1002/14356007.a19_299.pub2

Grachev AN, Zabelkin SA, Iakovleva AY, Fayzrahmanova GM, Bashkirov VN (2014) Resole phenol-formaldehyde resin glue line strength when modified by wood pyrolysis piqued products. Vestnik Kazanskogo Technologicheskogo Universiteta 16:27–29 (In Russian)

Bridgwater AV, Peacocke GVC (2000) Fast pyrolysis processes for biomass. Renew Sust Energ Rev 4(1):1–73. https://doi.org/10.1016/S1364-0321(99)00007-6

Stücker A, Schütt F, Saake B, Lehnen R (2016) Lignins from enzymatic hydrolysis and alkaline extraction of steam refined poplar wood: utilization in lignin-phenol-formaldehyde resins. Ind Crop Prod 85:300–308

Varfolomeev MA, Emel'yanenko VN, Musin TR, Gerasimov AV, Nurgaliev DK, Grachev AN, Makarov AA, Zabelkin SA (2015) Thermal analysis and calorimetric study of the combustion of hydrolytic wood lignin and products of its pyrolysis. Chem Technol Fuels Oils 51(1):140–145

Fayzrakhmanova GM, Zabelkin SA, Grachev AN, Bashkirov VN (2016) A study of the properties of a composite asphalt binder using liquid products of wood fast pyrolysis. Polymer Science, Series D: Glues and Sealing Materials 9(2):181–184

Amen-Chen C, Pakdel H, Roy C (2001) Production of monomeric phenols by thermochemical conversion of biomass: a review. Bioresour Technol 79:277–299

Fardhyanti DS, Triwibowo B, Prasetiawan H, Chafidz A, Andriyani S, Cahyani NN (2019) Improving the quality of bio-oil produced from rice husk pyrolysis by extraction of its phenolic compounds. Jurnal Bahan Alam Terbarukan JBAT 8(2):90–100

La Ifa, Setiawati Yani, Mandasini, Zakir Sabara, Nurjannah Nurjannah, & Andi Rusnaenah. Production of phenol from liquid smoke resulted by the pyrolysis of cashew nut shells. IOP Conf. Series: Earth and Environmental Science 2018 IOP Conf. Ser.: Earth Environ. Sci. 175 012033.

Awasthia A, Dhyania V, Biswasa B, Kumara J, Bhaskar T (2019) Production of phenolic compounds using waste coir pith: estimation of kinetic and thermodynamic parameters. Bioresour Technol 274:173–179

Zabelkin SA, Grachev AN, Bikbulatova GM, Yakovleva AE, Makarov AA, Bashkirov VN (2018) Resole-type phenol–formaldehyde resin with neutralized liquid products of fast pyrolysis of birch wood. Polymer Science, Series D 11:131–134

Zhang W, Ma Y, Wang C, Li S, Zhang M, Chu F (2013) Preparation and properties of lignin–phenol–formaldehyde resins based on different biorefinery residues of agricultural biomass. Ind Crop Prod 43:326–333

Zabelkin S, Grachev A, Fayzrakhmanova G, Makarov A, Bashkirov V (2016) Application of the water-insoluble pyrolysis oil fraction as an organic binder. Constr Build Mater 102:59–64

Grachev AN, Varfolomeev MA, Emel’yanov DA, Zabelkin SA, Gilfanov MF, Nuriyakhmetov RA (2017) Joint thermal treatment of heavy oil and liquid products of fast wood pyrolysis for producing fuels and chemicals. Chem Technol Fuels Oils 53:638–645

Lee JH, Jeon J, Kim SJ (2011) Green adhesives using tannin and cashew nut shell liquid for environment-friendly furniture materials. Korean Furniture Soc 22:219–229

Bisanda ETN, Ogola WO, Tesha JV (2003) Characterisation of tannin adhesive blends for particle board applications. Cem Concr Res 25:593–598

Vazquez G, Antorrena G, Gonzalez J et al (1996) Tannin based adhesives for bonding high moisture eucalyptus veneers: influence of tannin extraction and press conditions. Holz Roh Werkst 54:93–97

Uvarov IP, Gordon LV (1962) Wood resins (synthetic products based on wood chemical phenols). Moscow: Goslesbumizdat. 84 p. (In Russian)

Nakos P, Tsiantzi S, Athanassiadou E. (2001) Wood adhesives made with pyrolysis oils. In: Proceedings of 3rd European Wood-based Panel Symposium, Sep 12–14; European Panel Federation & Wilhelm Klauditz Institute, Hannover, pp. 1–8

Chaouch M, Diouf PN, Laghdir A, Yin S (2014) Bio-oil from whole-tree feedstock in resol-type phenolic resins. Journal of Applied Polymer Science. 10.1002/app.40014

Cui Y, Chang J, Wang W (2016) Fabrication of glass fiber reinforced composited based on bio-oil phenol formaldehyde resin. Materials 9:886. https://doi.org/10.3390/ma9110886

Lee W, Tseng I, Kao Y, Lee Y, Hu M (2014) Synthesis of alcohol-soluble resins from pyrolysis oil of Cunninghamia lanceolate wood and properties of molding plates made of resin-impregnated materials. Holzforschung. 68(2):217–222. https://doi.org/10.1515/hf-2013-0068

Sukhbaatar B, Steele PH, Kim MG (2009) Use of lignin separated from bio-oil in oriented strand board binder phenol-formaldehyde adhesives. BioResources. 4:789–804

Aslan M, Özbay G, Ayrilmis N (2015) Adhesive characteristics and bonding performance of phenol formaldehyde modified with phenol-rich fraction of crude bio-oil. J Adhes Sci Technol 29:2679–2691. https://doi.org/10.1080/01694243.2015.1080474

Guzelciftci B, Park K, Kim J(2020) Production of phenol-rich bio-oil via a two-stage pyrolysis of wood. Energy 200. doi: https://doi.org/10.1016/j.energy.2020.117536

Kim J (2014) Production, separation and applications of phenolic-rich bio-oil – A review. Bioresour Technol 178:90–98. https://doi.org/10.1016/j.biortech.2014.08.121

Chum HL, Black SK (1990) Process for fractionating fast-pyrolysis oils and products derived from, USA patent 4, 942, 269. July 17

Suzuki T, Hiroshi N, Yamada T, Homma T (1992) Preparation of wood tar-based phenol-resin adhesives. Mokuzai Gak 38:321–324

Cheng S, Yuan Z, Anderson M, Leitch M, Xu C (2012) Synthesis of biobased phenolic resins/adhesives with methylolated wood-derived bio-oil. J Appl Polym Sci 126:E431–E441. https://doi.org/10.1002/app.35655

Choi G, Oh S, Lee S, Kim J (2015) Production of bio-based phenolic resin and activated carbon from bio-oil and biochar derived from fast pyrolysis of palm kernel shells. Bioresour Technol 178:99–107

Farag S, Chaouki J (2014) Economics evaluation for on-site pyrolysis of kraft lignin to value-added chemicals. Bioresour Technol 175:254–261. https://doi.org/10.1016/j.biortech.2014.10.096

Vithanage AE, Chowdhury E, Alejo LD, Pomeroy PC, DeSisto WJ, Frederick BG, Gramlich WM (2017) Renewably sourced phenolic resins from lignin bio-oil. J Appl Polym Sci, DOI: 10.1002/APP.44827

Effendi A, Gerhauser H, Bridgwater AV (2007) Production of renewable phenolic resins by thermochemical conversion of biomass: a review. Renew Sustain Energy Rev. doi: 10.1016/j.rser.2007.04.008

Zhang W, Ma Y, Xu Y, Wang C, Chu F (2013) Lignocellulosic ethanol residue-based lignin–phenol–formaldehyde resin adhesive. Int J Adhes Adhes 40:11–18

Feghali E. et al. (2020) Thermosetting polymers from lignin model compounds and depolymerized lignins. In: Serrano L., Luque R., Sels B. (eds) Lignin chemistry. Topics in Current Chemistry Collections. Springer, Cham

Valeeva AR, Grachev AN, Zabelkin SA, Bashkirov VN, Sabirzyanova AI (2020) Determination of phenol substitution level influence by wood pyrolysis liquid products on phenol-formaldehyde resin strength. Derevoobrabatyvayuschaya Promyshlennost 16:88–95 (In Russian)

Grachev AN et al. A fast ablative pyrolysis plant for decentralized processing of biomass into biochar and biooil. EUBCE 2019; 27TH European Biomass Conference and Exhibition. Lisbon – Portugal: 164

ASTM E 203-16 Standard test method for water using volumetric Karl Fischer titration.

ASTM D5266-13 Standard practice for estimating the percentage of wood failure in adhesive bonded joints

Dahiya A (2015) Bioenergy. Biomass to biofuels. 1st Edition. Academic Press

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zabelkin, S., Valeeva, A., Sabirzyanova, A. et al. Neutrals influence on the water resistance coefficient of phenol-formaldehyde resin modified by wood pyrolysis liquid products. Biomass Conv. Bioref. 12, 5563–5570 (2022). https://doi.org/10.1007/s13399-020-01025-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01025-0