Abstract

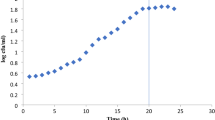

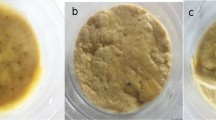

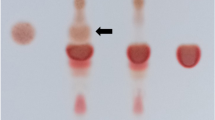

This study investigated the viability of encapsulated and un-encapsulated (free cell) Lactobacillus rhamnosus GG (LGG) in bread baked at different baking conditions (180 °C for 30 min, 220 °C for 20 min, and 250 °C for 15 min) and in simulated gastrointestinal conditions. The cell was encapsulated either with sodium alginate, singly or in combination with chitosan, cassava starch, and hi-maize resistant starch. There was complete loss of viability of un-encapsulated LGG after baking. Significantly (P < 0.05) higher viability was recorded for LGG encapsulated with sodium alginate + cassava starch + chitosan beads (SCCB) and sodium alginate + hi-maize resistant starch + chitosan beads (SHCB) compared to sodium alginate beads (SAB) and sodium alginate + cassava starch beads (SSB). Lactobacillus rhamnosus GG encapsulated with SHCB gave the highest viability (P < 0.05) after subjection to simulated gastric and intestinal juices. The incorporation of LGG did not have significant (P < 0.05) influence on volume, specific volume, moisture, ash, fat, and fiber contents of bread. The lowest moisture content was obtained at baking condition of 180 °C for 30 min, while the highest value was at 250 °C for 15 min. Baking condition did not cause significant (P > 0.05) change in fat, ash, and carbohydrate content of bread. The encapsulation of LGG with multiple layers of encapsulating materials significantly preserved its viability during baking and in simulated gastrointestinal conditions.

Similar content being viewed by others

References

Gorbach S, Doron S, Magro F (2017) Lactobacillus rhamnosus GG. In: Floch MH, Ringel Y, Walker WA (eds) The microbiota in gastrointestinal pathophysiology. Elsevier Inc., Amsterdam, pp 79–88

Hojsak I, Snovak N, Abdovic S (2015) Lactobacillus GG in the prevention of gastrointestinal and respiratory tract infections in children who attend day care centers: a randomized, double-blind, placebocontrolled trial. Clin Nutr 29:312–316

Giuseppe B, Torino F, Marletta F, Santagati M, Salemi R, Cannarozzo E, Falzone L, Ferrau F, Libra M (2017) Lactobacillus rhamnosus GG: an overview to explore the rationale of its use in cancer. Front Pharmacol. https://doi.org/10.3389/fphar.2017.00603

Seyedain-Ardabili M, Sharifan A, Tarzi B (2016) The production of synbiotic bread by microencapsulation. Food Technol Biotechnol 54:52–59

Jantarathin S, Borompichaichartkul C, Sanguandeekul R (2017) Microencapsulation of probiotic and prebiotic in alginate-chitosan capsules and its effect on viability under heat process in shrimp feeding. Mater Today Proc 4:6166–6172

Martin MJ, Lara-Villoslada F, Ruiz MA, Morales M (2013) Effect of unmodified starch on viability of alginate-encapsulated Lactobacillus fermentum CECT5716. LWT Food Sci Technol 53:480–486

Chavárri M, Marañón I, Ares R, Ibáñez FC, Marzo F, Villarán MC (2010) Microencapsulation of a probiotic and prebiotic in alginate-chitosan capsules improves survival in simulated gastro-intestinal conditions. Int J Food Microbiol 142:185–189

Chavárri M, Izaskun M, María CV (2012) Encapsulation technology to protect probiotic bacteria, probiotics. Intech Open, London. https://doi.org/10.5772/50046

Malmo C, La Storia A, Mauriello G (2013) Microencapsulation of Lactobacillus reuteri DSM 17938 cells coated in alginate beads with chitosan by spray drying to use as a probiotic cell in a chocolate soufflé. Food Bioprocess Technol 6:795–805

Ashwani K, Dinesh K (2016) Development of antioxidant rich fruit supplemented probiotic yogurts using free and microencapsulated Lactobacillus rhamnosus culture. J Food Sci Technol 53:667–675

Annunziata A, Vecchio R (2011) Functional foods development in the European market: a consumer perspective. J Funct Foods 3:223–228

Vitaglione P, Troise AD, De Prisco AC, Mauriello GL, Gokmen V, Fogliano V (2015) Use of microencapsulated ingredients in 634 bakery products: technological and nutritional aspects. Microencapsulation 635 and microspheres for food applications. Elsevier Inc., Amsterdam. https://doi.org/10.1016/B978-0-12-800350-3.00020-0

Wahyono A, Tifania AZ, Kurniawat E, Kang WW, Chung SK (2018) Physical properties and cellular structure of bread enriched with pumpkin flour. IOP Conf Series Earth Environ Sci 207:012054

Longoria-García S, Cruz-Hernández MA, Flores-Verástegui IMM, Contreras-Esquivel J, Montañez-Sáenz C, Belmares JR (2018) Potential functional bakery products as delivery systems for prebiotics and probiotics health enhancers. J Food Sci Technol 55(3):833–845

Soukoulis C, Yonekura L, Gan H, Behboudi-Jobbehdar S, Parmenter C, Fisk I (2014) Probiotic edible films as a new strategy for developing functional bakery products: the case of pan bread. Food Hydrocoll 39:231–242

Pitigraisorn P, Srichaisupakit K, Wongpadungkiat N, Wongsasulak S (2017) Encapsulation of Lactobacillus acidophilus in moist-heat-resistant multilayered 597 microcapsules. J Food Eng 192:11–18

Zhang L, Taal MA, Boom RM, Chen XD, Schutyser MA (2018) Effect of baking conditions aand storage on the viability of Lactobacillus plantarum supplemented to bread. LWT Food Sci Technol 87:318–325

Zhang L, Putranto A, Zhou W, Boom RM, Schutyser MAI, Chen XD (2016) Miniature bread baking as a timesaving research approach and mathematical modeling of browning kinetics. Food Bioprod Process 100:401–411

Trabelsi I, Ayadi D, Bejar W, Bejar S, Chouayekh H, Salah RB (2014) Effects of Lactobacillus plantarum immobilization in alginate coated with chitosan and gelatin on antibacterial activity. Int J Biol macromol 64:84–89

Krasaekoopt W, Bhandari B, Deeth HC (2006) Survival of probiotics encapsulated in chitosan-coated alginate beads in yoghurt from UHT- and conventionally treated milk during storage. LWT Food Sci Technol 39:177–183

Soghomonyan D, Trchounian A (2017) The effects of different physicochemical factors on survival of human gut lactic acid bacteria. J Int Soc Microbiota 3:1–4

Sanchita M, Senthil KS, Krishnamoorthy B, Basu S (2010) Development and evaluation of calcium alginate beads prepared by sequential and simultaneous methods. Braz J Pharm Sci 46:785–793

Haynes IN, Playne MJ (2002) Survival of probiotic cultures in low fat ice cream. Aust J Dairy Technol 57:10–14

Sheu TY, Marshall RT (1993) Microentrapment of Lactobacilli in calcium alginate gels. J Food Sci 58:557–561

Joel N, James O, Simeon A (2013) Comparative evaluation of the nutritional and sensory quality of major commercial whole- wheat bread in Nigerian market. J Food Sci Technol 5:1600–1605

Association of Official Analytical Chemists International, AOAC (2005) Official methods of analysis. AOAC, Gaithersburg

Mokarram R, Mortazavi S, Najafi M, Shahidi F (2009) The influence of multi stage alginate coating on survivability of potential probiotic bacteria in simulated gastric and intestinal juice. Food Res Int 42:1040–1045

González-Cuello R, Colpas-Castillo F, Tarón-Dunoyer A (2017) Protection of Lactobacillus acidophilus under in vitro gastrointestinal conditions employing binary microcapsules containing inulin. Afr J Biotechnol 16(3):132–138

Ismail M, Lim SM, Mishra R, Ramasamy K (2014) Chitosan coated alginate–xanthan gum bead enhanced pH and thermotolerance of Lactobacillus plantarum LAB12. Int J Biol Macromol 72:1419–1428

Burgain J, Gaiani C, Francius G, Revol-Junelles AM, Cailliez-Grimal C, Lebeer S, Scher J (2013) In vitro interactions between probiotic bacteria and milk proteins probed by atomic force microscopy. Coll Surf B: Biointerfaces 104:153–162

Peres CM, Peres C, Hernandez-Mendoza A, Malcata FX (2012) Review on fermented plant materials as carriers and sources of potentially probiotic lactic acid bacteria—with an emphasis on table olives. Trends Food SciTechnol 26:31–42

Altamirano-Fortoul A, Moreno-Terrazas R, Quezada-Gallo A, Rosell CM (2012) Viability of some probiotic coatings in bread and its effect on the crust mechanical properties. Food Hydrocoll 29:166–174

Weinbreck F, Bodna’r I, Marco ML (2010) Can encapsulation lengthen the shelf-life of probiotic bacteria in dry products? Int J Food Microbiol 136:364–367

Yu WK, Yim TB, Lee KY, Heo TR (2001) Effect of skim milk alginate beads on survival rate of bifidobacteria. Biotechnol Bioprocess Eng 6:133–138

Raman M, Dinakaran A, Ravindran A, Vasunambisan T, Krishnaswamy ST, Gopal S (2019) Dietary supplementation of κ-carrageenan to improve the physio-chemical and functional properties of white bread. Food Nutr Sci 10:997–1010

Balarabe MM, Mohammed SSD, Orukota AA (2017) Physico-chemical analysis and sensory evaluation of bread produced using different indigenous yeast isolates. Sci World J 12:33–37

Almorale NM (2019) The effect of walnut flour on the physical and sensory characteristics of wheat bread. Int J Food Sci. https://doi.org/10.1155/2019/5676205

Author information

Authors and Affiliations

Contributions

OOE designed the research, supervised the study, and approved the final draft. IDO conducted laboratory experiments and statistical analysis. OEA designed the experiment, conducted statistical analysis, and prepared the draft manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ezekiel, O.O., Okehie, I.D. & Adedeji, O.E. Viability of Lactobacillus rhamnosus GG in Simulated Gastrointestinal Conditions and After Baking White Pan Bread at Different Temperature and Time Regimes. Curr Microbiol 77, 3869–3877 (2020). https://doi.org/10.1007/s00284-020-02203-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-020-02203-z