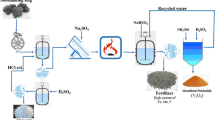

Research is conducted for creating technology for processing hydrometallurgical production of vanadium pentoxide slurries. The technology includes threestage counterflow leaching of vanadium from slurries and hydrolysis of a vanadiumcontaining solution. The V2O5 content is ≈ 70 wt.% in the resultant concentrate,

Similar content being viewed by others

References

Yu. P. Kudryavskii, Yu. F. Trapeznikov, V. V. Strelkov, et al., “Hydrometallurgical treatment of vanadium-containing waste,” Tsvet. Met., No. 1, 25–29 (2000).

I. V. Vygovskaya, “Development of physicochemical bases and technology for utilizing technogenic vanadium-containing waste in lime-sulfuric acid production of vanadium pentoxide” Diss. Cand. Techn. Sci., Tula (2002).

V. P. Zaiko, V.I. Zhuchkov, L. I. Leont’ev, et al., Vanadium-Containing Ferroalloy Technology [in Russian], Akademkniga, Moscow (2004).

V. G. Mizin, E. M. Rabinovich, and T. P. Sirina, Comprehensive Treatment of Vanadium Raw Material: Chemistry and Technology [in Russian], URO RAN, Ekaterinburg (2005).

U. A. Kologrieva, A. I. Volkov, A. C. Kirichenko, et al., “Development of a production scheme for utilizing hydrometallurgical waste of vanadium pentoxide production,” Metallurg, No. 4, 78–82 (2019).

I. A. Volkov, U. A. Kologrieva, A. I. Kovalev, and D. L. Vainshtein, “Effect of degree of oxidation and form of elements in vanadium slag in its treatment technology,” Metallurg, No. 8, 42–46 (2019).

E. M. Rabinovich, V. G. Mizin, and M. E. Rabinovich, Comprehensive Treatment of Vanadium Raw Material: Metallurgy [in Russian], URO RAN, Ekaterinburg (2005).

T. P. Sirina, V. G. Mizin, E. M. Rabinovich, et al., Extraction of Vanadium and Nickel from Thermal Power Station Waste [in Russian], URO RAN, Ekaterinburg (2001).

A. Amer, “Processing of Egyptian boilerash for extraction of vanadium and nickel,” Waste Management, 22, No. 5, 515–520 (2002).

S. Vitolo, M. Seggiani, S. Filippi, and C. Brocchini, “Recovery of vanadium from heavy oil and Orimulsion fly ashes,” Hydrometallurgy, 57, No. 2, 141–149 (2000).

S. Vitolo, M. Seggiani, S. Filippi, and C. Brocchini, “Recovery of vanadium from a previously burned heavy oil fly ash,” Hydrometallurgy, 62, No. 3, 145–150 (2001).

R. Navarro, J. Guzman, I. Saucedo, et al., “Vanadium recovery from oil fly ash by leaching, precipitation and solvent extraction processes,” Waste Management, 27, No. 3, 425–438 (2007).

J. Wen, T. Jiang, X. Zheng, et al., “Efficient separation of chromium and vanadium by calcification roasting–sodium carbonate leaching from high chromium vanadium slag and V2O5 preparation,” Separation and Purification Technology, 230 (2019); https://doi.org/10.1016/j.seppur.2019.115881.

G. Lu, T. Zhang, G. Zhang, et al., “Process and kinetic assessment of vanadium extraction from vanadium slag using calcification roasting and sodium carbonate leaching,” JOM, 71, 4600–4607 (2019).

H. Peng, “A literature review on leaching and recovery of vanadium,” J. Environ. Chem. Eng., 7, No. 5 (2019); https://doi.org/10.1016/j.jece.2019.103313.

Work was performed with RFFI financial support, project 18-29-24074 mk.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 5, pp. 48–51, June, 2020.

Rights and permissions

About this article

Cite this article

Kologrieva, U.A., Volkov, A.I., Stulov, P.E. et al. Counterflow Leaching Technology for Vanadium from Vanadium Pentoxide Hydrometallurgical Production Slurry. Metallurgist 64, 542–547 (2020). https://doi.org/10.1007/s11015-020-01025-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-01025-5