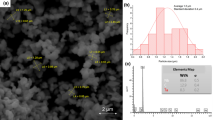

Composite materials based on aluminum are used in various fields of metallurgy and, in particular, for the production of high-strength products whose properties, such as low density, low coefficient of thermal expansion, and thermal stability, satisfy basic requirements imposed in the course of their operation. At present, we observe rapid development of the technologies of production of high-strength aluminum alloys with composite compounds characterized by the improved mechanical characteristics for a given level of plasticity. The existing technologies of modification of the alloys with ceramic materials, such as B4C, guarantee the required operating characteristics for cast and, especially, rolled billets. However, high levels of segregation of particles in the aluminum matrix, the heterogeneity of the surface of composite particles in the course of the rolling, and low wettability sharply worsen the quality of billets and, hence, lead to a decrease in the yield of useful products. Solid B4C particles form a rigid reinforcing frame in the aluminum matrix of the composite responsible for the unique properties of the aluminum alloy (such as stiffness, strength, thermal, and electric properties). On the basis of the aluminum matrix, we have produced a multicomponent Al–Cu–B4C composite material. The matrix material with a copper content of 5% was produced by introducing boron carbide particles (2.0–7.0%) in the stage of melting. It is shown that the technology of injection casting into a given mold decreases the level of porosity, which creates conditions for the production of high-quality composites of the Al– Cu–B4C system with high level of the mechanical properties.

Similar content being viewed by others

References

M. V. Gorshenkov, Highly Filled Aluminum Composites Strengthened by Boron-Containing Particles: Structure and Properties [in Russian], Candidate-Degree Thesis (Engineering), Moscow (2013).

I. E. Kalashnikov, Development of the Methods of Reinforcement and Modification of the Structure of Aluminum-Matrix Composites [in Russian], Author’s Abstract of the Doctoral-Degree Thesis (Engineering), Moscow (2011).

V. Yu. Bazhin, V. M. Sizyakov, A. A. Vlasov, and R. Yu. Feshchenko, “Surface defects of an ingotless foil billets made of highly doped aluminum alloys,” Metallurg, No. 11, 75–79 (2012).

M. R. Ghomashchi and A. Vikhrov, “Squeeze casting: An overview,” J. Mater. Proc. Tech., 101, 1–9 (2000).

M. Rosso, “Ceramic and metal matrix composites: Routes and properties,” J. Mater. Proc. Tech., 175, 364–375 (2006).

I. E. Kalashnikov, L. K. Bolotova, and T. A. Chernyshova, “Influence of nanosized refractory additives on the crystallization of aluminum-matrix composites produced in the in-situ process,” in: Abstr. of the Sixth Internat. Sci. Conf. “Kinetics and Mechanism of Crystallization. Self-Organization in the Course of Phase Formation” [in Russian], Ivanovo (2010), p. 182.

V. I. Napalkov and S. V. Makhov, Alloying and Modification of Aluminum and Magnesium [in Russian], MISiS, Moscow (2002).

A. V. Panfilov and E. S. Prusov, “On the production and properties of complex reinforced composites with aluminum matrix,” Litein. Proizvod., No. 8, 2–6 (2008).

E. S. Prusov, “Technology of production and properties of complexly reinforced aluminum-matrix composites,” Perspektiv. Mater., No. 5 (Spec. Issue), 93–95 (2008).

E. Hajjari and M. Divandari, “An investigation on the microstructure and tensile properties of direct squeeze cast and gravity die cast 2024 wrought Al alloy,” Mater. Design, 29, No. 9, 1685–1689 (2008).

M. V. Gorshenkov, Highly Filled Aluminum Composites Strengthened by Boron-Containing Particles: Structure and Properties [in Russian], Candidate-Degree Thesis (Engineering), Moscow (2013).

Yu. A. Abuzin, “Nonequilibrium structures in metallic composites,” Metallurg. Mashinostr., No. 6, 32–35 (2009).

W. A. Uju and I. N. A. Oguocha, “A study of thermal expansion of Al–Mg alloy composites containing fly ash,” Mater. Design, 33, 503–509 (2012).

C. Kannan and R. Ramanujam, “Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting,” J. Adv. Research, 8, 309–319 (2017).

I. E. Kalashnikov, V. V. Kovalevski, T. A. Chernyshova, and L. K. Bolotova, “Aluminum-matrix composite materials with shungite rock fillers,” Russian Metall. (Metally), No. 11, 1063–1071 (2010).

E. Hagеn, M. Еinarsrud, and T. Grandе, “Chеmical stability of cеramic sidе linings in Hall-Hеroult cеll,” in: J. L. Anjier (editor), Light Mеtals, TMS, Warrendale (2001), pp. 257–263.

K. Grjothеim and B. Wеlch, Aluminium Smеltеr Tеchnology, Dussеldorf Aluminium Verlag, Dussеldorf (1988).

R. Cavalla and V. Yu. Bazhin, “Control over the structure and properties of sheet billets made of magnesium alloys under the conditions of the ingotless rolling,” Zapis. Gorn. Inst. SPb, 2014, 33–39 (2015).

T. A. Chernyshova, L. I. Kobeleva, I. E. Kalashnikov, and L. K. Bolotova, “Modification of cast aluminum-matrix composite materials by refractory nanoparticles,” Rus. Metallurgy (Metally), No. 1, 71–77 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 5, pp. 65–70, June, 2020.

Rights and permissions

About this article

Cite this article

Alattar, A.L., Bazhin, V.Y. Al–Cu–B4C Composite Materials for the Production of High-Strength Billets. Metallurgist 64, 566–573 (2020). https://doi.org/10.1007/s11015-020-01028-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-01028-2