Abstract

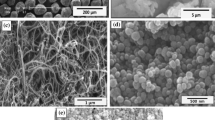

Cold spraying was first used for the purpose of preparing nickel-based high-temperature lubrication coatings. High-quality In625-Cr2O3-Ag composite coatings were deposited by a high-pressure cold-spray system, and their tribological properties were evaluated at 20 and 1000 °C by a high-temperature tribometer. The microstructure, composition, and wear mechanisms of the coatings were analyzed by x-ray diffraction, scanning electron microscopy, and Raman spectroscopy. The measurements showed that the cold-sprayed In625-Cr2O3-Ag composite coatings have a very dense structure, good bonding strength to substrate, low friction coefficient, and excellent wear resistance. The friction coefficients of the In625-Cr2O3-Ag coatings were around 0.3 and the wear rates of the coating were maintained at about 10−5 mm3/N m at 20 and 1000 °C. The experimental observation of the wear tracks revealed that the silver provided lubrication at 20 °C. As the temperature increased up to 1000 °C, a lubrication layer with low shear strength made up of Ag2MoO4 and Cr2O3 was formed on the wear track.

Similar content being viewed by others

References

I.M. Allam, Solid Lubricants for Applications at Elevated-Temperatures—A Review, J. Mater. Sci., 1991, 26, p 3977-3984

S. Zhu, J. Cheng, Z. Qiao, and J. Yang, High Temperature Solid-Lubricating Materials: A Review, Tribol. Int., 2019, 133, p 206-233

H. Torres, M.R. Ripoll, and B. Prakash, Tribological Behaviour of Self-lubricating Materials at High Temperatures, Int. Mater. Rev., 2018, 63, p 309-340

H. Torres, T. Vuchkov, S. Slawik, C. Gachot, B. Prakash, and M. Rodríguez Ripoll, Self-lubricating Laser Claddings for Reducing Friction and Wear from Room Temperature to 600 °C, Wear, 2018, 408-409, p 22-23

A.A. Voevodin, C. Muratore, and S.M. Aouadi, Hard Coatings with High Temperature Adaptive Lubrication and Contact Thermal Management: Review, Surf. Coat. Technol., 2014, 257, p 247-265

C. Dellacorte, Experimental Evaluation of Chromium-Carbide-Based Solid Lubricant Coatings for Use to 760 °C, NASA CR, 1987, 180808

H. Heshmat, P. Hryniewicz, J.F. Walton Ii, J.P. Willis, S. Jahanmir, and C. DellaCorte, Low-Friction Wear-Resistant Coatings for High-Temperature Foil Bearings, Tribol. Int., 2005, 38, p 1059-1075

K. Radil and C. DellaCorte, The Performance of PS400 Subjected to Sliding Contact at Temperatures from 260 to 927 °C, Tribol. Trans., 2017, 60, p 957-964

L. Du, W. Zhang, W. Zhang, T. Zhang, H. Lan, and C. Huang, Tribological and Oxidation Behaviors of the Plasma Sprayed NiCoCrAlY-Cr2O3-AgVO3 Coating, Surf. Coat. Technol., 2016, 298, p 7-14

J.H. Ouyang, S. Sasaki, and K. Umeda, Low-Pressure Plasma-Sprayed ZrO2-CaF2 Composite Coating for High Temperature Tribological Applications, Surf. Coat. Technol., 2001, 137(1), p 21-30

L. Du, C. Huang, W. Zhang, T. Li, and W. Liu, Preparation and Wear Performance of NiCr/Cr3C2–NiCr/hBN Plasma Sprayed Composite Coating, Surf. Coat. Technol., 2011, 205(12), p 3722-3728

J. Chen, X. Zhao, H. Zhou, J. Chen, Y. An, and F. Yan, HVOF-Sprayed Adaptive Low Friction NiMoAl-Ag Coating for Tribological Application from 20 to 800 °C, Tribol. Lett., 2014, 56(1), p 55-66

J. Chen, X. Zhao, H. Zhou, J. Chen, Y. An, and F. Yan, Microstructure and Tribological Property of HVOF-Sprayed Adaptive NiMoAl–Cr3C2–Ag Composite Coating from 20 °C to 800 °C, Surf. Coat. Technol., 2014, 258, p 1183-1190

W. Ma, Y. Xie, C. Chen, H. Fukanuma, J. Wang, Z. Ren, and R. Huang, Microstructural and Mechanical Properties of High-Performance Inconel 718 Alloy by Cold Spraying, J. Alloys Compd., 2019, 792, p 456-467

D. Srinivasan, V. Chandrasekhar, R. Amuthan, Y.C. Lau, and E. Calla, Characterization of Cold-Sprayed IN625 and NiCr Coatings, J. Therm. Spray Technol., 2016, 25(4), p 725-744

P. Poza, C.J. Múnez, M.A. Garrido-Maneiro, S. Vezzù, S. Rech, and A. Trentin, Mechanical Properties of Inconel 625 Cold-Sprayed Coatings After Laser Remelting. Depth Sensing Indentation Analysis, Surf. Coat. Technol., 2014, 243, p 51-57

C. Huang, L. Du, and W. Zhang, Friction and Wear Characteristics of Plasma-Sprayed Self-lubrication Coating with Clad Powder at Elevated Temperatures up to 800 °C, J. Therm. Spray Technol., 2014, 23(3), p 463-469

R.K.S. Gautam, U.S. Rao, and R. Tyagi, High Temperature Tribological Properties of Ni-Based Self-lubricating Coatings Deposited by Atmospheric Plasma Spray, Surf. Coat. Technol., 2019, 372, p 390-398

A.V. Bondarev, P.V. Kiryukhantsev-Korneev, D.A. Sidorenko, and D.V. Shtansky, A New Insight into Hard Low Friction MoCN–Ag Coatings Intended for Applications in Wide Temperature Range, Mater. Des., 2016, 93, p 63-72

C. Muratore and A.A. Voevodin, Molybdenum Disulfide as a Lubricant and Catalyst in Adaptive Nanocomposite Coatings, Surf. Coat. Technol., 2006, 201(7), p 4125-4130

Acknowledgments

The authors are grateful to the National Natural Science Foundation of China (Grant Nos. 51705481 and 51705482), Foundation of State Key Laboratory of Solid lubrication (LSL-1912) and Ningbo City (2018B10047) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, J., Song, H., Liu, G. et al. Cold Spraying: A New Alternative Preparation Method for Nickel-Based High-Temperature Solid-Lubrication Coating. J Therm Spray Tech 29, 1892–1901 (2020). https://doi.org/10.1007/s11666-020-01088-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01088-5