Abstract

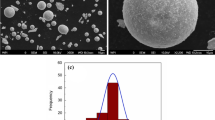

Prior work has demonstrated greater antipathogenic efficacy concerning the nanostructured copper cold spray coatings versus conventional copper cold spray coatings, while both the nanostructured and conventional cold spray coatings maintain greater contact killing/inactivation rates relative to other thermal spray deposition methods. Recent work has more heavily focused upon the nanostructured cold spray coatings greater efficacy. However, the antimicrobial efficacy of conventional copper cold spray coatings may be improved upon by way of identifying processing parameters that yield microstructures with the greatest concentration of atomic copper ion diffusion pathways. Since ideal processing parameters for a given application can be computed in silico via finite element analysis methods, the fundamental computational frameworks for doing so using the Johnson–Cook and Preston–Tonks–Wallace plasticity models. Modeled single-particle impact morphology outputs were compared with experimental microstructures using scanning electron microscopy and optical microscopy. The computed von Mises flow stresses associated with the two plasticity models were compared with traditionally static nanoindentation data as well as dynamic spherical nanoindentation stress–strain curves. Continued work with the finite element analysis framework developed herein will enable the best cold spray parameters to be identified for optimized antimicrobial properties as a function of deformation-mediated microstructures while still maintaining the structural integrity of the deposited material. Subsequent work will extend the finite element analysis models to multi-particle impacts when spray-dried and gas-atomized copper powder particles have been appropriately meshed.

Similar content being viewed by others

References

V.K. Champagne and D.J. Helfritch, A Demonstration of the Antimicrobial Effectiveness of Various Copper Surfaces, J. Biol. Eng., 2013, 7(1), p 8

C. Massar, K. Tsaknopoulos, B.C. Sousa, J. Grubbs, and D.L. Cote, Heat Treatment of Recycled Battlefield Stainless-Steel Scrap for Cold Spray Applications, JOM, 2020, 72, p 3080-3089

B.C. Sousa, C.E. Walde, V.K. Champagne, and D.L. Cote, Initial Observation of Grain Orientation Dependent Nanoindentation Hardness of Al 6061 Gas-Atomized Powder, Int. J. Metall. Met. Phys., 2020, 5(1), p 050

K. Sundberg and V. Champagne, Effectiveness of Nanomaterial Copper Cold Spray Surfaces on Inactivation of Influenza A Virus, J. Biotechnol. Biomater., 2015, 05(04), p 1

B. Sousa, K. Sundberg, C. Massar, V. Champagne, and D. Cote, Spherical Nanomechanical Characterization of Novel Nanocrystalline Cu Cold Spray Manufactured Materials, Vol 2019, 2019

B.C. Sousa, K.L. Sundberg, M.A. Gleason, and D.L. Cote, Understanding the Antipathogenic Performance of Nanostructured and Conventional Copper Cold Spray Material Consolidations and Coated Surfaces, Crystals, 2020, 10(6), p 504

K. Sundberg, Application of Materials Characterization, Efficacy Testing, and Modeling Methods on Copper Cold Spray Coatings for Optimized Antimicrobial Properties, Worcester Polytechnic Institute, Worcester, 2019

K. Sundberg, The Effect of Corrosion on Conventional and Nanomaterial Copper Cold Spray Surfaces for Antimicrobial Applications, Biomed. J. Sci. Tech. Res., 2019, 22(3), p 16753-16763

K. Sundberg, M. Gleason, B. Haddad, V.K. Champagne, C. Brown, R.D. Sisson, and D. Cote, The Effect of Nano-Scale Surface Roughness on Copper Cold Spray Inactivation of Influenza A Virus, Int. J. Nanotechnol. Med. Eng., 2019, 4, p 33-40

O. Mishchenko, V. Filatova, M. Vasylyev, V. Deineka, and M. Pogorielov, Chemical and Structural Characterization of Sandlasted Surface of Dental Implant Using ZrO2 Particle with Different Shape, Coatings, 2019, 9(4), p 223

F.-P. Lee, D.-J. Wang, L.-K. Chen, C.-M. Kung, Y.-C. Wu, K.-L. Ou, and C.-H. Yu, Antibacterial Nanostructured Composite Films for Biomedical Applications: Microstructural Characteristics, Biocompatibility, and Antibacterial Mechanisms, Biofouling, 2013, 29(3), p 295-305

J.O. Noyce, H. Michels, and C.W. Keevil, Inactivation of Influenza A Virus on Copper versus Stainless Steel Surfaces, Appl. Environ. Microbiol., 2007, 73(8), p 2748-2750

C.E. Santo, N. Taudte, D.H. Nies, and G. Grass, Contribution of Copper Ion Resistance to Survival of Escherichia Coli on Metallic Copper Surfaces, Appl. Environ. Microbiol., 2008, 74(4), p 977-986

J.M. Schreiber, Finite Element Implementation of the Preston–Tonks–Wallace Plasticity Model and Energy Based Bonding Parameter for the Cold Spray Process, Pennsylvania State University, State College, 2016

G.R. Johnson and W.H. Cook, Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures, Eng. Fract. Mech., 1985, 21(1), p 31-48

D.L. Preston, D.L. Tonks, and D.C. Wallace, Model of Plastic Deformation for Extreme Loading Conditions, J. Appl. Phys., 2003, 93(1), p 211-220

S. Kardes and C. Choi, Determining the Flow Stress Curve with Yield and Ultimate Tensile Strengths. Pt.I: Important Data from the Tensile Test, Stamp. J., 2011, Retrieved from https://www.thefabricator.com/stampingjournal/article/metalsmaterials/

S. Kardes and C. Choi, Determining the Flow Stress Curve with Yield and Ultimate Tensile Strengths. Pt.II: Using the Curve for FE Simulation, Stamp. J., 2011, Retrieved from https://www.thefabricator.com/stampingjournal/article/metalsmaterials/

M. Grujicic, J.R. Saylor, D.E. Beasley, W.S. DeRosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process, Appl. Surf. Sci., 2003, 219(3–4), p 211-227

P.C. King, G. Bae, S.H. Zahiri, M. Jahedi, and C. Lee, An Experimental and Finite Element Study of Cold Spray Copper Impact onto Two Aluminum Substrates, J. Therm. Spray Technol., 2010, 19(3), p 620-634

E. Broitman, Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview, Tribol. Lett., 2017, 65(1), p 23

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564-1583

J. Hay, Introduction to Instrumented Indentation Testing, Exp. Tech., 2009, 33(6), p 66-72

S.C. Krishna, N.K. Gangwar, A.K. Jha, and B. Pant, On the Prediction of Strength from Hardness for Copper Alloys, J. Mater., 2013, 2013, p 1-6

W.D. Nix and H. Gao, Indentation Size Effects in Crystalline Materials: A Law for Strain Gradient Plasticity, J. Mech. Phys. Solids, 1998, 46(3), p 411-425

S.J. Vachhani, R.D. Doherty, and S.R. Kalidindi, Effect of the Continuous Stiffness Measurement on the Mechanical Properties Extracted Using Spherical Nanoindentation, Acta Mater., 2013, 61(10), p 3744-3751

J.K. Engels, S. Gao, W. Amin, A. Biswas, A. Kostka, N. Vajragupta, and A. Hartmaier, Indentation Size Effects in Spherical Nanoindentation Analyzed by Experiment and Non-Local Crystal Plasticity, Materialia, 2018, 3, p 21-30

S.R. Kalidindi and S. Pathak, Determination of the Effective Zero-Point and the Extraction of Spherical Nanoindentation Stress-Strain Curves, Acta Mater., 2008, 56(14), p 3523-3532

S. Pathak, J. Shaffer, and S. Kalidindi, Determination of an Effective Zero-Point and Extraction of Indentation Stress-Strain Curves without the Continuous Stiffness Measurement Signal, Scr. Mater., 2009, 60(6), p 439-442

A.J. Moseson, S. Basu, and M.W. Barsoum, Determination of the Effective Zero Point of Contact for Spherical Nanoindentation, J. Mater. Res., 2008, 23(1), p 204-209

S. Pathak, Development and Validation of a Novel Data Analysis Procedure for Spherical Nanoindentation, PhD. thesis, Drexel University, (2009)

S. Pathak and S.R. Kalidindi, Spherical Nanoindentation Stress–Strain Curves, Mater. Sci. Eng. R Rep., 2015, 91, p 1-36

A. Leitner, V. Maier-Kiener, and D. Kiener, Essential Refinements of Spherical Nanoindentation Protocols for the Reliable Determination of Mechanical Flow Curves, Mater. Des., 2018, 146, p 69-80

P. Chivavibul, M. Watanabe, S. Kuroda, J. Kawakita, M. Komatsu, K. Sato, and J. Kitamura, Effects of Particle Strength of Feedstock Powders on Properties of Warm-Sprayed WC-Co Coatings, J. Therm. Spray Technol., 2011, 20(5), p 1098-1109

L.H. He and M.V. Swain, Nanoindentation Derived Stress–Strain Properties of Dental Materials, Dent. Mater., 2007, 23(7), p 814-821

J. Dean, J.M. Wheeler, and T.W. Clyne, Use of Quasi-Static Nanoindentation Data to Obtain Stress–Strain Characteristics for Metallic Materials, Acta Mater., 2010, 58(10), p 3613-3623

S. Basu, A. Moseson, and M.W. Barsoum, On the Determination of Spherical Nanoindentation Stress–Strain Curves, J. Mater. Res., 2006, 21(10), p 2628-2637

G.R. Johnson and W.H. Cook, A Constitutive Model and Data from Metals Subjected to Large Strains, High Strain Rates and High Temperatures, in Proceedings of 7th International Symposium on Ballistics, The Hague, Netherlands (1983)

H. Assadi, I. Irkhin, H. Gutzmann, F. Gärtner, M. Schulze, M. Villa Vidaller, and T. Klassen, Determination of Plastic Constitutive Properties of Microparticles through Single Particle Compression, Adv. Powder Technol., 2015, 26(6), p 1544-1554

W. Li, K. Yang, D. Zhang, and X. Zhou, Residual Stress Analysis of Cold-Sprayed Copper Coatings by Numerical Simulation, J. Therm. Spray Technol., 2016, 25(1–2), p 131-142

L. Venkatesh, N.M. Chavan, and G. Sundararajan, The Influence of Powder Particle Velocity and Microstructure on the Properties of Cold Sprayed Copper Coatings, J. Therm. Spray Technol., 2011, 20(5), p 1009-1021

P. Chivavibul, M. Watanabe, S. Kuroda, J. Kawakita, M. Komatsu, K. Sato, and J. Kitamura, Effects of Particle Strength of Feedstock Powders on Properties of Warm-Sprayed WC-Co Coatings, J. Therm. Spray Technol. (2011)

V.Y. Gertsman, M. Hoffmann, H. Gleiter, and R. Birringer, The Study of Grain Size Dependence of Yield Stress of Copper for a Wide Grain Size Range, Acta Metall. Mater., 1994, 42(10), p 3539-3544

W. Yan, C.L. Pun, and G.P. Simon, Conditions of Applying Oliver–Pharr Method to the Nanoindentation of Particles in Composites, Compos. Sci. Technol., 2012, 72(10), p 1147-1152

G. Antipas, Gas Atomization of Aluminium Melts: Comparison of Analytical Models, Metals (Basel), 2012, 2(2), p 202-210

A. Ünal, Effect of Processing Variables on Particle Size in Gas Atomization of Rapidly Solidified Aluminium Powders, Mater. Sci. Technol., 1987, 3(12), p 1029-1039

J. Villafuerte, Modern Cold Spray, Modern Cold Spray: Materials, Process, and Applications, J. Villafuerte, Ed., Springer, Cham, 2015,

M.R. Rokni, C.A. Widener, and V.R. Champagne, Microstructural Evolution of 6061 Aluminum Gas-Atomized Powder and High-Pressure Cold-Sprayed Deposition, J. Therm. Spray Technol., 2014, 23(3), p 514-524

S. Yin, X. Wang, X. Suo, H. Liao, Z. Guo, W. Li, and C. Coddet, Deposition Behavior of Thermally Softened Copper Particles in Cold Spraying, Acta Mater., 2013, 61(14), p 5105-5118

C. Borchers, F. Gärtner, T. Stoltenhoff, H. Assadi, and H. Kreye, Microstructural and Macroscopic Properties of Cold Sprayed Copper Coatings, J. Appl. Phys., 2003, 93(12), p 10064-10070

R. Jenkins, S. Yin, B. Aldwell, M. Meyer, and R. Lupoi, New Insights into the In-Process Densification Mechanism of Cold Spray Al Coatings: Low Deposition Efficiency Induced Densification, J. Mater. Sci. Technol., 2019, 35(3), p 427-431

A. Leitner, V. Maier-Kiener, and D. Kiener, Dynamic Nanoindentation Testing: Is There an Influence on a Material’s Hardness?, Mater. Res. Lett., 2017, 5(7), p 486-493

N. Hansen, Hall-Petch Relation and Boundary Strengthening, Scr. Mater., 2004, 51(8), p 801-806

Y.-K. Kim, K.-S. Kim, H.-J. Kim, C.-H. Park, and K.-A. Lee, Microstructure and Room Temperature Compressive Deformation Behavior of Cold-Sprayed High-Strength Cu Bulk Material, J. Therm. Spray Technol., 2017, 26(7), p 1498-1508

M.P. Schmitt, J.M. Schreiber, A.K. Rai, T.J. Eden, and D.E. Wolfe, Development and Optimization of Tailored Composite TBC Design Architectures for Improved Erosion Durability, J. Therm. Spray Technol., 2017, 26(6), p 1062-1075

Acknowledgments

We are grateful to Christopher J. Massar of Worcester Polytechnic Institute for his insightful comments and feedback on an earlier draft of the paper. This research was funded by U.S. Army Research Laboratory, Grant Number W911NF-10-2-0098.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sundberg, K., Sousa, B.C., Schreiber, J. et al. Finite Element Modeling of Single-Particle Impacts for the Optimization of Antimicrobial Copper Cold Spray Coatings. J Therm Spray Tech 29, 1847–1862 (2020). https://doi.org/10.1007/s11666-020-01093-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01093-8