Abstract

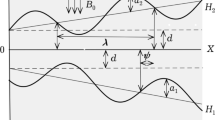

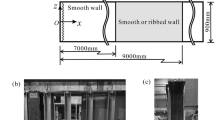

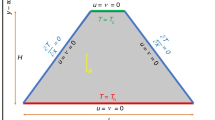

Air curtains are produced by thin vertical planar air jets and are used to prevent exchange flows between two fluids with a horizontal density gradient. They have been shown to work effectively provided the deflection modulus (DM) is greater than a critical value (DM = 0.14). Herein, results are presented from an experimental and modeling study of the initial transient development of the buoyancy distribution within an enclosure containing a round buoyant turbulent plume that is segmented by a co-flowing planar turbulent jet. A theoretical model based on filling box theory is developed to predict the leakage of buoyant fluid across the planar jet and the time at which the planar jet is no longer able to contain the buoyant plume outflow. Results from a series of analog salt-bath experiments are also presented that show that the model accurately predicts the rate of transport of buoyant fluid across the planar jet up until DM falls below the critical value of 0.14. The experiments show that, following the breakdown of the model there is a transition period after which the horizontal distribution of buoyant fluid throughout the enclosure is the same as it would be in the absence of the planar jet.

Similar content being viewed by others

Availability of data and materials

Please contact the corresponding author for enquires about accessing the data used in this study.

Code availability

Please contact the corresponding author for enquires about accessing the computer codes used in this study.

References

Baines WD, Turner JS (1969) Turbulent buoyant convection from a source in a confined region. J Fluid Mech 37:51–80

Germeles AE (1975) Forced plumes and mixing of liquids in tanks. J Fluid Mech 71:601–623

Linden PF, Lane-Serff GF, Smeed DA (1990) Emptying filling boxes, the fluid mechanics of natural ventilation. J Fluid Mech 212:309–335

Field BS, Loth E (2006) Entrainment of refrigerated air curtains down a wall. Exp Therm Fluid Sci 30:175–184

Bhattacharjee P, Loth E (2004) Entrainment by a refrigerated air curtain down a wall. ASME J Fluids Eng 126:871–879

Frank D, Linden PF (2015) The effects of an opposing buoyancy force on the performance of an air curtain in the doorway of a building. Energy Build 96:20–29

Gonçalves J, Costa J, Figueiredo A, Lopes A (2010) CFD modelling of aerodynamic sealing by vertical and horizontal air curtains. Energy Build 52:153–160

Foster A, Swain M, Barrett R, D’Agaro P, James S (2006) Effectiveness and optimum jet velocity for a plane jet air curtain used to restrict cold room air infiltration. Int J Refrig 29:692–699

Foster AM, Swain MJ, Barrett R, D’Agaro P, Ketteringham LP, James SJ (2007) Three-dimensional effects of an air curtain used to restrict cold room infiltration. Appl Math Model 31(6):1109–1123

Hayes FC, Stoecker WF (1969) Heat transfer characteristics of the air curtains. Trans ASHRAE 2120:153–167

Hayes FC, Stoecker WF (1969) Design data for air curtains. Trans ASHRAE 2121:168–180

Mowrer FW (2002) Enclosure smoke filling and management with mechanical ventilation. Fire Technol 38:33–56

Mowrer FW (1999) Enclosure smoke filling revisited. Fire Saf J 33:93–114

Guyonnaud L, Solliec C, Dufresne de Virel M, Rey C (2000) Design of air curtains used for area confinement in tunnels. Exp Fluids 28(4):377–384

Viegas JC (2016) Saltwater experiments with air curtains for smoke control in the event of fire. J Build Eng 8:243–248

Hu L, Zhou J, Huo R, Peng W, Wang H (2008) Confinement of fire-induced smoke and carbon monoxide transportation by air curtain in channels. J Hazard Mater 156:327–334

Felis F, Pavageau M, Elicer-Cortés J, Dassonville T (2010) Simultaneous measurements of temperature and velocity fluctuations in a double stream-twin jet air curtain for heat confinement in case of tunnel fire. Int Commun Heat Mass Transf 37:1191–1196

Gupta S, Pavageau M, Elicer-Cortés JC (2007) Cellular confinement of tunnel sections between two air curtains. Build Environ 42:3352–3365

Shih Y-C, Yang A-S, Lu C-W (2011) Using air curtain to control pollutant spreading for emergency management in a cleanroom. Build Environ 46:1104–1114

Liu Q, Nie W, Hua Y, Peng H, Liu C, Wei C (2019) Research on tunnel ventilation systems: dust diffusion and pollution behaviour by air curtains based on CFD technology and field measurement. Build Environ 147:444–460

Kaye NB, Hunt GR (2004) Time-dependent flows in an emptying filling box. J Fluid Mech 520:135–156

Flynn M, Caulfield C (2006) Natural ventilation in interconnected chambers. J Fluid Mech 564:139–158. https://doi.org/10.1017/S0022112006001261

Hunt GR, Cooper P, Linden PF (2001) Thermal stratification produced by plumes and jets in enclosed spaces. Build Environ 36:871–882

Lee JHW, Chu VH (2003) Turbulent jets and plumes a Lagrangian approach. Kluwer, Dodrecht

Allgayer D, Hunt GR (2010) On the application of the light-attenuation technique as a tool for non-intrusive buoyancy measurements. Exp Therm Fluid Sci 38:257–261

Batchelor GK (1954) Heat convection and buoyancy effects in fluids. Q J R Meterol Soc 80:339–358

Acknowledgements

The authors would like to thank Isabelle Whittaker and Sarah Young for their assistance with the experiments.

Funding

This work was not funded by any external funding agencies.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest/competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kaye, N., Williamson, N., Huang, D. et al. Buoyancy distribution in a filling box segmented by a planar jet. Environ Fluid Mech 21, 239–261 (2021). https://doi.org/10.1007/s10652-020-09768-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10652-020-09768-0