Abstract

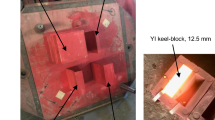

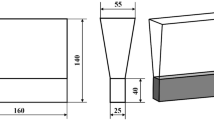

The ferrous industry keeps evolving, and the demand for castings with complex geometries is increasing. Due to this, some foundries are facing several challenges when it comes to producing highly complex parts with a specific microstructure. Normally, heat treatment is performed when a ferritic matrix is desired. However, distortion and cracking can become a problem too. Because of this, it is important to explore alternative methods that can potentially help with these problems. In ductile iron, cobalt additions are known to increase the nodule count, which favors higher ferrite fractions. Hence, the addition of cobalt was studied to investigate its effects on the microstructure and tensile properties of ductile iron. Five heats were produced and cast into ½ inch ASTM A536 Y-blocks: 0 wt%, 1 wt%, 2 wt%, 3 wt%, and 4 wt% Co. Metallography was performed to evaluate the percent nodularity, nodule count (N/mm2), and ferrite/pearlite percentages. Tensile testing was executed using sub-size round samples. Brinell hardness and micro-Vickers were conducted on each Y-block to assess the macro and microscopic behavior of the cobalt bearing ductile iron. The addition of 4 wt% Co was found to decrease the nodule size and increase the percent nodularity and nodule count resulting in higher ferrite contents. Cobalt did not have a statistically significant effect in tensile strength and percent elongation. However, cobalt was found to increase the yield strength due to the solid solution strengthening effect in ferrite.

Similar content being viewed by others

References

R. Salazar, M. Herrera-Trejo, M. Castro, J. Mendez, J. Torres, M. Mendez, Effect of nodule count and cooling rate on as-cast matrix of a Cu-Mo spheroidal graphite. J. Mater. Eng. Perform. 8, 325–329 (1999)

D.R. Askeland, S.S. Gupta, Effect of nodule count and cooling rate on the matrix of nodular cast iron. AFS Trans. 83, 313–320 (1975)

C.R. Loper Jr., Processing and control of ductile cast iron. AFS Trans. 55, 1–7 (1969)

G.F. Ruff, B.K. Doshi, Relation between mechanical properties and graphite structure in cast iron, part II. Mod. Cast. 70, 70–74 (1980)

R.A. Gonzaga, Influence of ferrite and pearlite content on mechanical properties of ductile cast irons. Mater. Sci. Eng., A 567, 1–8 (2013). https://doi.org/10.1016/j.msea.2012.12.089

M.M. Shea, Influence of cooling rate and manganese and copper content on hardness of as-cast ductile iron. AFS Trans. 86, 7–12 (1978)

Ductile Iron Handbook. American Foundry Society, pp. 79–83, 87–95, 1992

C. Labrecque, M. Gagné, Ductile iron: fifty years of continuous development. Can. Metall. Q. 37(5), 343–378 (1998). https://doi.org/10.1179/cmq.1998.37.5.343

J. R. Davis, Ed., Alloying: understanding the basics. ASM International, pp. 68–70, 2001

R.A. Gonzaga, P.M. Landa, A. Perez, P. Villanueva, Mechanical properties dependency of the pearlite content of ductile irons. J. Achiev. Mater. Manuf. Eng. 33(2), 9 (2009)

S.K. Yu, C.R. Loper, The effect of molybdenum, copper, and nickel on the microstructure, hardness, and hardenability of ductile cast irons. AFS Trans. 94, 557–576 (1986)

S.K. Yu, C.R. Loper Jr., The effect of molybdenum, copper, and nickel on the pearlitic, and martensitic hardenability of ductile cast irons. AFS Trans. 96, 811–822 (1988)

I.A. Franson, R.D. Schelleng, Nickel alloyed pearlitic ductile iron for heavy sections. AFS Trans. 64, 850–856 (1964)

Nickel as an alloy in cast iron, Modern Casting, 1977

J. Hernandez-Avila et al., The effect of molybdenum on the microstructure of nodular iron. Eur. Sci. J. 11(36), 377–388 (2015)

R. Smoluchowski, Diffusion rate of carbon in iron-cobalt alloys. Phys. Rev. 62(11–12), 539–544 (1942). https://doi.org/10.1103/PhysRev.62.539

B.F. Brown, M.F. Hawkes, Kinetics of graphitization in cast iron. AFS Trans. 59, 181–200 (1951)

A. S. Appleton, The Kinetics of first-stage graphitization in Fe-C and Fe-Co-C alloys, J. Iron Steel Inst., pp. 160–168, 1960

E. K. Modl, Effect of Cobalt Additions to Ductile Iron, Giesserei, vol. 10, 1968

V.P. Solov’ev, O. Kuragin, Evaluating the influence of different elements on iron graphitization. Sov. Cast. Technol. USA 7, 10–11 (1991)

X.P. Shen, S.J. Harris, B. Noble, Influence of small vanadium and cobalt additions on microstructure and properties of ductile iron. Mater. Sci. Technol. 11(9), 893–900 (1995). https://doi.org/10.1179/mst.1995.11.9.893

S. Yazdani, H. Bayati, R. Elliott, The influence of cobalt on the austempering reaction in ductile cast iron. Int. J. Cast Met. Res. 13(6), 317–326 (2001). https://doi.org/10.1080/13640461.2001.11819413

C.-H. Hsu, M.-L. Chen, C.-J. Hu, Microstructure and mechanical properties of 4% cobalt and nickel alloyed ductile irons. Mater. Sci. Eng., A 444, 339–346 (2007). https://doi.org/10.1016/j.msea.2006.09.027

J.H. Doubrava, S.F. Carter, J.F. Wallace, The influence of processing variables on the matrix structure and nodularity of ductile iron. AFS Trans. 89, 229–250 (1981)

M. Górny, E. Tyrała, Effect of cooling rate on microstructure and mechanical properties of thin-walled ductile iron castings. J. Mater. Eng. Perform. 22(1), 300–305 (2013). https://doi.org/10.1007/s11665-012-0233-0

Z. Glavas, The Influence of metallic charge on metallurgical quality and properties of ductile iron. Met. Mater. 50(02), 75–82 (2012). https://doi.org/10.4149/km_2012_2_75

S. Bockus, A. Dobrovolskis, Melting and modification by producing ductile iron castings. Proc Est. Acad Sci Eng 10, 10–17 (2004)

S. Bockus, A. Dobrovolskis, Effect of melting techniques on ductile iron casting properties. Metalurgija. 45, 13–16 (2006)

G.M. Goodrich, D.P. Jones, Factors affecting ductile iron nodule count: a literature review. AFS Trans. 101, 1031–1037 (1993)

J.M. Tartaglia, R.B. Gundlach, G.M. Goodrich, Optimizing structure-property relationships in ductile iron. Inter Metalcast 8, 7–38 (2014). https://doi.org/10.1007/BF03355592

Acknowledgements

Funding for the present work was provided by the Ductile Iron Society and the Materials Science & Engineering (MSE) department of Michigan Technological University. The authors acknowledge the Institute of Materials Processing and the MSE department for the use of processing equipment, characterization instruments, and staff assistance. Chemical analysis of all heats was performed by Neenah Foundry and Aarrowcast, Inc to confirm the chemical composition. Metallography for all heats was performed by Waupaca and Neenah Foundry to confirm the analysis done at Michigan Technological University. Technical assistance was offered throughout the project by Vadim Pikhovich who performed the simulation of the mold using Magma Software. Catherine Hartung, Lizeth Medina, Lyle Heberling, and Mathew Meyer who provided technical support at different stages of the project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Almanza, A., Dewald, D., Licavoli, J. et al. Influence of Cobalt in the Tensile Properties of ½ Inch Ductile Iron Y-blocks. Inter Metalcast 15, 433–446 (2021). https://doi.org/10.1007/s40962-020-00521-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00521-3