Abstract

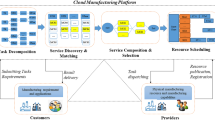

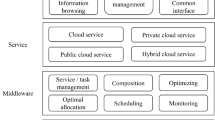

Cloud manufacturing is a new kind of networked manufacturing model. In this model, manufacturing resources are organized and used on demand as market-oriented services. These services are highly uncertain and focus on users. The information between service demanders and service providers is usually incomplete. These challenges make the resource scheduling more difficult. In this study, an iterative double auction mechanism is proposed based on game theory to balance the individual benefits. Resource demanders and providers act as buyers and sellers in the auction. Resource demanders offer a price according to the budget, the delivery time, preference, and the process of auction. Meanwhile, resource providers ask for a price according to the cost, maximum expected profit, optimal reservation price, and the process of auction. A honest quotation strategy is dominant for a participant in the auction. The mechanism is capable of guaranteeing the economic benefits among different participants in the market with incomplete information. Furthermore, the mechanism is helpful for preventing harmful market behaviors such as speculation, cheating, etc. Based on the iterative double auction mechanism, manufacturing resources are optimally allocated to users with consideration of multiple objectives. The auction mechanism is also incentive compatibility.

Similar content being viewed by others

Abbreviations

- a :

-

Asked price

- B :

-

Bidding price set

- b :

-

Bidding price

- C :

-

Execution cost

- c, c r :

-

Number of iteration

- d :

-

Distance

- e :

-

Exponential function

- F :

-

Distribution function

- f :

-

Density function

- i :

-

Index of demander

- j :

-

Index of provider

- k :

-

Index of task submitted by a demander

- l :

-

Index of resource provided by a provider

- l 1 :

-

Logistics time

- l 2 :

-

Logistics cost

- l 3 :

-

Logistics load

- O 1 :

-

Occupied cost

- O 2 :

-

Occupied time

- P :

-

Relationship vector

- p :

-

Partnership between demander and provider

- Q :

-

Comprehensive quality

- q :

-

Probability of a demander adopting the strategy greater than valuation

- r :

-

Reservation price

- S :

-

Strategy space

- T :

-

Execution time

- \(\bar{t}\) :

-

Average period of each iteration

- \(\hat{t}\) :

-

Ready time

- t 0 :

-

Initial moment

- t c :

-

Moment of the bidding

- u :

-

Net benefit of demander

- u 0 :

-

Expected net benefit of a demander with bidding price b0

- u b :

-

Expected net benefit of a demander with bidding price b

- û :

-

Net benefit of provider

- û 0 :

-

Expected net benefit of a provider with asked price a0

- û s :

-

Expected net benefit of a provider with asked price a

- v :

-

Transaction value

- x, y :

-

Index of subtask

- Y :

-

Maximum expected profit margin

- α, γ :

-

Subjective factor

- β :

-

Zoom factor

- Φ :

-

Finance budget

- Φ res :

-

Set of subtasks that have not been matched with resources

- \(\hat{\varPhi }\) :

-

Cost of resource

- Γ :

-

Game participants

- ∆ :

-

Influence of delivery time

- δ :

-

Priority vector of task

- η :

-

Quantity of candidate resources

- Θ :

-

Delivery time

- Θ res :

-

Set of subtasks after a subtask along the longest past to the end subtask

- θ :

-

Delivery time of subtask

- Ω :

-

Circumference

- π :

-

Expected payment

- ϑ :

-

Resource

- ρ :

-

Influence of demander preference

- τ :

-

Probability of an event

- υ :

-

Subtask

- ω :

-

Workload of subtask

- Ζ :

-

Execution time of resource

References

Li BH, Zhang L, Wang SL et al (2010) Cloud manufacturing: a new service-oriented networked manufacturing model. Comput Integr Manufac Syst 16(1):1–7

Li BH, Zhang L, Ren L et al (2011) Further discussion on cloud manufacturing. Comput Integr Manufac Syst 17(3):449–457

Xu X (2012) From cloud computing to cloud manufacturing. Robot Comput Integr Manuf 28(1):75–86

Voinov N, Chernorutsky I, Drobintsev P et al (2017) An approach to net-centric control automation of technological processes within industrial IoT systems. Adv Manuf 5(4):388–393

Tao F, Cheng Y, Li DX et al (2014) CCIoT-CMfg: cloud computing and internet of things-based cloud manufacturing service system. IEEE T Ind Inform 10(2):1435–1442

Ren L, Zhang L, Tao F et al (2015) Cloud manufacturing: from concept to practice. Enterp Inf Syst 9(2):186–209

Wang Y, Ma HS, Yang JH et al (2017) Industry 4.0: a way from mass customization to mass personalization production. Adv Manuf 5(4):311–320

Zhang L, Luo Y, Tao F et al (2014) Cloud manufacturing: a new manufacturing paradigm. Enterp Inf Syst 8(2):167–187

Wang T, Guo S, Lee CG (2014) Manufacturing task semantic modeling and description in cloud manufacturing system. Int J Adv Manuf Tech 71(9/12):2017–2031

Mazar AM, Yazdian N, Kovacevic R (2018) Hybrid laser/arc welding of thick high-strength steel in different configurations. Adv Manuf 6(2):176–188

Yamato S, Yamada Y, Nakanishi K et al (2018) Integrated in-process chatter monitoring and automatic suppression with adaptive pitch control in parallel turning. Adv Manuf 6(3):291–300

Liu Y, Xu X, Zhang L et al (2017) Workload-based multitask scheduling in cloud manufacturing. Robot Comput Integr Manuf 45:3–20

Zhou L, Zhang L, Zhao C et al (2018) Diverse task scheduling for individualized requirements in cloud manufacturing. Enterp Inf Syst 12(3):300–318

Tunc LT, Ozsahin O (2018) Use of inverse stability solutions for identification of uncertainties in the dynamics of machining processes. Adv Manuf 6(3):308–318

Laili YJ, Tao F, Zhang L et al (2012) A study of optimal allocation of computing resources in cloud manufacturing systems. Int J Adv Manuf Tech 63(5/8):671–690

Jian CF, Wang Y (2014) Batch task scheduling oriented optimization modelling and simulation in cloud manufacturing. Int J Simul Model 13(1):93–101

Li W, Zhu C, Yang LT et al (2017) Subtask scheduling for distributed robots in cloud manufacturing. IEEE Syst J 11(2):941–950

Wang SL, Zhu ZQ, Kang L (2016) Resource allocation model in cloud manufacturing. Proc Inst Mech Eng Part C-J Mech Eng Sci 230(10):1726–1741

Zhou J, Yao X (2017) A hybrid artificial bee colony algorithm for optimal selection of QoS-based cloud manufacturing service composition. Int J Adv Manuf Tech 88(9/12):3371–3387

Cao Y, Wang S, Kang L et al (2016) A TQCS-based service selection and scheduling strategy in cloud manufacturing. Int J Adv Manuf Tech 82(1/4):235–251

Cheng Z, Zhan D, Zhao X et al (2014) Multitask oriented virtual resource integration and optimal scheduling in cloud manufacturing. J Appl Mat 2014(7):1–9

Lin YK, Chong CS (2017) Fast GA-based project scheduling for computing resources allocation in a cloud manufacturing system. J Intell Manuf 28(5):1189–1201

Jiang H, Yi J, Chen S et al (2016) A multi-objective algorithm for task scheduling and resource allocation in cloudbased disassembly. J Manuf Syst 41:239–255

Wang J, Gong B, Liu H et al (2015) Multidisciplinary approaches to artificial swarm intelligence for heterogeneous computing and cloud scheduling. Appl Intell 43(3):662–675

Ren L, Cui J, Wei Y et al (2016) Research on the impact of service provider cooperative relationship on cloud manufacturing platform. Int J Adv Manuf Tech 86(5/8):2279–2290

Nielsen I, Dang QV, Bocewicz G et al (2017) A methodology for implementation of mobile robot in adaptive manufacturing environments. J Intell Manuf 28(5):1171–1188

Wang L, Cai JC, Li M (2016) An adaptive multi-population genetic algorithm for job-shop scheduling problem. Adv Manuf 4(2):142–149

Yuan MH, Deng K, Chaovalitwongse WA et al (2017) Multi-objective optimal scheduling of reconfigurable assembly line for cloud manufacturing. Optim Methods Softw 32(3):581–593

Wang L, Guo S, Li X et al (2018) Distributed manufacturing resource selection strategy in cloud manufacturing. Int J Adv Manuf Tech 94(9/12):3375–3388

Romp G (1997) Game theory: introduction and applications. Oxford University Press, Oxford

Zhang Y, Wang J, Liu S et al (2017) Game theory based real-time shop floor scheduling strategy and method for cloud manufacturing. Int J Intell Syst 32(4):437–463

Erdman AG, Sandor GN (1997) Mechanism design: analysis and synthesis. Prentice Hall, Englewood

Vickrey W (1961) Counter speculation, auctions, and competitive sealed tenders. J Financ 16(1):8–37

Riley JG, Samuelson WF (1981) Optimal auctions. Am Econ Rev 71(3):381–392

McAfee RP (1992) A dominant strategy double auction. J Econ Theory 56(2):434–450

Nezarat A, Dastghaibifard GH (2015) Efficient nash equilibrium resource allocation based on game theory mechanism in cloud computing by using auction. PLoS ONE 10(10):e0138424

Fard HM, Prodan R, Fahringer T (2013) A truthful dynamic workflow scheduling mechanism for commercial multicloud environments. IEEE T Parall Distr 24(6):1203–1212

Samimi P, Teimouri Y, Mukhtar M (2016) A combinatorial double auction resource allocation model in cloud computing. Inf Sci 357:201–216

Peng W, Guo W, Shao HY (2017) Price formation mechanism in cloud manufacturing system for small and medium enterprices. Comput Integr Manufac Syst 23(3):650–660

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, ZH., Wang, ZJ. & Yang, C. Multi-objective resource optimization scheduling based on iterative double auction in cloud manufacturing. Adv. Manuf. 7, 374–388 (2019). https://doi.org/10.1007/s40436-019-00281-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-019-00281-2