Abstract

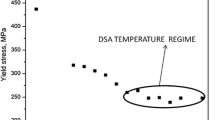

The present study aims at understanding the mechanisms of fatigue endurance through high-cycle fatigue (HCF) behavior of Alloy 617M at varying temperatures, ranging from 300 to 1023 K. Dynamic strain aging (DSA) was a key feature observed in this alloy at high temperatures (853-973 K), which also affects the cyclic life as well as the endurance limit. Furthermore, in situ precipitation of Cr23C6 and γ′ phase (Ni3(Al,Ti)) at 973 K during the course of HCF cycling is found to impart a beneficial effect on the HCF life of the alloy. At T > 973 K, effect of creep damage was found to be prominent, resulting in a deteriorating effect on HCF life. The role of DSA, precipitation and creep on the fatigue damage is assessed through in-depth microstructural characterization of the tested specimens, which is further utilized to develop a damage map across the temperatures 300-1023 K.

Similar content being viewed by others

References

A.D. Gianfrancisco, Materials for Ultra-super Critical Power Plants (USC) and Advanced-USC Power Plants, 1st ed., Wood Head Publication, Oxford, 2016, ISBN 9780081005521

Q. Wu, Microstructural Evolution in Advanced Boiler Materials for Ultra-supercritical Coal Power Plants, Ph.D thesis, Division of Research and Advanced Studies of the University of Cincinnati, July 2006

J.P. Strizak, C.R. Brinkman, M.K. Booker, and P.L. Rittenhouse, The Influence of Temperature, Environment, and Thermal Aging on the Continuous Cycle Fatigue Behavior of Hastelloy X and Inconel 617, HTGR Base Technology Program (FTP/A 01332), Oak Ridge National Laboratory, 1992

R.H. Hayes and W.C. Hayes, A Proposed Model for the Disappearance of Serrated Flow in Two Fe Alloys, Acta Metall., 1982, 30, p 1295

Y. Guo, B. Wang, and S. Hou, Aging Precipitation Behavior and Mechanical Properties of Inconel 617 Superalloy, Acta Metall. Sin., 2013, 26, p 307–312

A.N. Singh, A. Moitra, P. Bhaskar, G. Sasikala, A. Dasgupta, and A.K. Bhaduri, Effect of Thermal Aging on Microstructure, Hardness, Tensile and Impact Properties of Alloy 617, Mater. Sci. Eng. A, 2018, 710, p 47–56

V. Shankar, A. Kumar, K. Mariappan, R. Sandhya, K. Laha, A.K. Bhaduri, and N. Narasaiah, Occurrence of Dynamic Strain Aging in Alloy 617M under Low Cycle Fatigue Loading, Int. J. Fatigue, 2017, 100, p 12–20

S.J. Kim, P.H. Choia, R.T. Dewaa, W.G. Kim, and M.H. Kim, Low Cycle Fatigue Properties of Alloy 617 Base Metal and Weld Joint at Room Temperature, Proc. Mater. Sci., 2014, 3, p 2201–2206

X. Chen, Z. Yang, M.A. Sokolov, D.L. Erdman, K. Mo, and J.F. Stubbins, Effect of Creep and Oxidation on Reduced Fatigue Life of Ni-Based Alloy 617 at 850 °C, J. Nucl. Mater., 2014, 444, p 393–403

M. Schlesinger, T. Seifert, and J. Preussner, Experimental Investigation of the Time and Temperature Dependent Growth of Fatigue Cracks in Inconel 718 and Mechanism Based Lifetime Prediction, Int. J. Fatigue, 2017, 99, p 242–249

K. Gopinath, A.K. Gorgia, S.V. Kamat, R. Balamuralikrishnan, and U. Ramamurthy, Low Cycle Fatigue Behaviour of a Low Interstitial Ni-Base Superalloy, Acta Mater., 2009, 57(12), p 3450–3459

C. Cornet, K. Wackermann, C. Stöcker, H.-J. Christ, C. Lupton, M. Hardy, and J. Tong, Effects of Temperature and Hold Time on Dynamic Strain Aging in a Nickel Based Superalloy, Mater. High Temp., 2014, 31(3), p 226–232

A. Sarkar, A. Nagesha, R. Sandhya, K. Laha, and A.K. Bhaduri, Influence of Dynamic Strain Aging on High Cycle Fatigue Behavior of Alloy 617M, Trans. Indian Inst. Met., 2016, 69(2), p 399–402

A.K. Karnati, A. Sarkar, A. Nagesha, P. Parameswaran, R. Sandhya, and N. Narasaiah, Evaluation of High Cycle Fatigue Behaviour of Alloy 617M at 973 K: Haigh Diagram and Associated Mechanisms, Int. J. Press. Vessels Pip., 2019, 172, p 304–312

A. Sarkar and A. Nagesha, Elevated Temperature Fatigue Behaviour of Structural Materials for Advanced Ultra Supercritical Application, Mater. High Temp., 2019, 36(6), p 471–478

A. Kumar, A. Sarkar, A. Nagesha, and G.A. Harmain, Generation of HCF–Creep Interaction Diagram in Alloy 617M at 973 K, Int. J. Fatigue, 2020, 136, p 105612

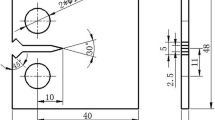

ASTM E-466-15, Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials, ASTM International, West Conshohocken, 2015

T. Nicholas, High Cycle Fatigue: A Mechanics of Materials Perspective, 1st ed., Elsevier Publications, Oxford, 2006, ISBN–13: 978-0-08-044691-2

G.E. Dieter, Mechanical Metallurgy, 3rd ed., McGraw-Hill Education Publications, New Delhi, 2001, ISBN–10: 1-25-906479

L. Kubin and Y. Estrin, Dynamic Strain Ageing and the Mechanical Response of Alloys, J. Phys. III, EDP Sci., 1991, 1(6), p 929–943

C. Visweswara Rao, N.C. Santhi Srinivas, G.V.S. Sastry, and V. Singh, Dynamic Strain Aging, Deformation and Fracture Behavior of the Nickel Base Superalloy Inconel 617, Mater. Sci. Eng. A, 2019, 742, p 44–60

I.M.W. Ekaputra, W.-G. Kim, J.-Y. Park, S.-J. Kim, and E.-S. Kim, Influence of Dynamic Strain Aging on Tensile Deformation Behavior of Alloy 617, Nucl. Eng. Technol., 2016, 48, p 1387–1395

D. Kaoumi and K. Hrutkay, Tensile Deformation Behavior and Microstructure Evolution of Ni-Based Superalloy 617, J. Nucl. Mater., 2014, 454, p 265–273

M.D.S. Rahman, G. Priyadarshan, K.S. Raja, C. Nesbitt, and M. Misra, Characterization of High Temperature Deformation Behavior of Inconel 617, Mech. Mater., 2009, 41, p 261–270

U. Martin, U. Muhle, and O. Heinrich, The Quantitative Measurement of Dislocation Density in the Transmission Electron Microscope, Parkt. Metallogr., 1995, 32, p 467

Q. Wu, H. Song, and R.W. Swindeman, Microstructure of Long-Term Aged IN617 Ni-Base Superalloy, Metall. Mater. Trans. A, 2008, 39, p 2569–2585

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarkar, A., Ghosh, C., Nagesha, A. et al. Mechanisms of Fatigue Endurance in Alloy 617M at Different Temperatures (300-1023 K). J. of Materi Eng and Perform 29, 5663–5671 (2020). https://doi.org/10.1007/s11665-020-05013-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05013-3