Abstract

Background

Persistent organic pollutants (POPs) such as dioxins, dioxin-like chemicals and non-dioxin-like PCBs causing adverse effects to human health bio-accumulate through the food web due to their affinity for adipose tissues. Foods of animal origin are therefore the main contributors to human dietary exposure. The European Union’s (EU) food safety policy requires checking of a wide range of samples for compliance with legal limits on a regular basis. Several methods of varying efficiency are applied by official control laboratories for extraction of the different classes of lipids and associated POPs, bound to animal tissue and animal products in varying degrees, sometimes leading to discrepancies especially in fresh weight based analytical results.

Results

Starting from Smedes’ lipid extraction from marine tissue, we optimized the extraction efficiency for both lipids and lipophilic pollutants, abandoning the time-consuming centrifugation step. The resulting modified Smedes extraction (MSE) method was validated based on multiple analyses of a large number of real-world samples, matrix calibration and performance assessment in proficiency testing utilizing both instrumental and bioanalytical methodologies. Intermediate precision in 12 different foods was below 3% in chicken eggs, egg powder, animal fat, fish, fish oil, poultry, whole milk, milk fat and milk powder, and below 5% in bovine meat, liver, and infant food. In comparison to Twisselmann hot extraction, results presented here show an increased efficiency of MSE by + 25% for bovine liver, + 14% for chicken eggs, + 13% for poultry meat, + 12% for fish, 8% for bovine meat, and 6% for infant food.

Conclusions

For the first time, a fast and reliable routine method is available that enables the analyst to reproducibly extract "total" lipids from any EU-regulated food sample of animal origin within 6 to 8 min. Increased efficiency translates into a considerable increase in both lipid and wet weight-based analytical results measured for associated POPs, reducing the risk of false non-compliant results. Compared to a 4 h Twisselmann extraction, the extraction of 1000 samples using MSE would result in annual savings of about 250 h or 32 working days. Our MSE procedure contributes to the European Commission's objective of harmonizing analytical results across the EU generated according to Commission Regulation (EU) 2017/644.

Similar content being viewed by others

Background

Persistent organic pollutants (POPs) include a wide range of anthropogenic toxic compounds, including industrial chemicals such as pesticides (e.g. endrin, heptachlor, mirex, toxaphene), polychlorinated biphenyls (PCBs), hexachlorobenzene (HCB), brominated flame retardants, perfluorinated compounds, and by-products of industrial processes such as polychlorinated dibenzo-p-dioxins (PCDDs) and dibenzofurans (PCDFs). Because of chlorine, bromine, or fluoride groups on the hydrocarbon rings or chains, these chemicals persist both in the environment and in the human and animal body. They exponentially bio-accumulate through the food web due to their affinity for adipose tissues, posing a risk of causing adverse effects to human and animal health. For example, the main contributors to exposure, accounting for more than 90% of the current average dietary exposure of the European population to dioxins, dioxin-like chemicals (PCDFs and DL-PCBs) and non-dioxin-like PCBs (NDL-PCBs), are milk, eggs, meat, fish, poultry and derived products, followed—due to high consumption—by the main group vegetables [1].

Due to their lipophilic nature, these POPs are usually found adhering to or dissolved in fatty tissue or milk fat. Therefore, methods of analysis for official control of the levels of lipophilic toxic compounds in EU-regulated foods of animal origin include an initial lipid extraction step, which isolates the lipids from potentially interfering compounds such as proteins, carbohydrates and other polar molecules. Especially in trace and ultra-trace analysis, lipid extraction requires proper validation towards its efficiency [2] in order not to significantly underestimate the level of contamination determined by the analytical procedure.

Lipids in farmed animal tissues, eggs, milk and fish

Lipids are a group of organic compounds with a considerable structural and functional diversity, often loosely defined as being hydrophobic or amphipathic (i.e. possessing both hydrophilic and lipophilic properties), and soluble in organic solvents. These physico-chemical features are present in a broad range of molecules such as fatty acids, phospholipids, glycolipids, sterols, sphingolipids, sulfolipids, amino lipids, steroids, terpenes and others [3]. Lipids are not found evenly distributed throughout the mammalian and nonmammalian (e.g. fish, bird, etc.) organism. Triacylglycerols and phospholipids featuring both polar and non-polar regions are common in mammalian cell membranes. Sphingomyelins, a type of sphingolipid, are important components of the membranes of nerve axons that promote nerve conduction [4]. Other fatty acids are stored as non-polar triacylglycerols and sterol esters in intracellular lipid droplets that function as long-term energy reservoirs and as a stockpile of fatty acids and sterols needed for membrane biosynthesis [5].

Tissue lipids may also be classified by the degree to which they are integrated into more complex lipids, or even tightly linked to proteins forming particular lipid-protein-complexes [6]. “Free” fatty acids with little or no binding include the fat of adipose tissue or distinct phospholipids functioning as important regulators of cell signalling. Lipids showing weak to moderately strong binding to other tissue components are found in myelin sheaths, blood cells (erythrocytes, eosinophils and neutrophils), mycobacteria, the isotropic disks of skeletal muscle, lipofuscins, and the cytoplasm of many cells. Structural lipids such as phospholipids, glycolipids and cholesterol are assembled in bilayer membranes and found covalently bound to proteins in cell nuclei, reticulin, and epithelial brush-borders, carrying out important functions in tissue metabolism and structure [7].

Adipose tissue is the main site for lipid storage and synthesis of fatty acids in mammals. Fat has been reported to comprise about 76% of wet adipose tissue from cattle and between 73 to 86% of wet adipose tissue from mature sheep [8]. As to its lipid composition, triacylglycerols are by far the major components of both bovine (81%) and ovine (92%) adipose tissue, accompanied by small amounts of mono- and diacylglycerols, cholesterol, free fatty acids and phospholipids which account for roughly 1% of lipids in bovine adipose tissue, and for 3% in that of sheep [8].

Lipids in the skeletal muscle of cattle are an integral part of the membranes, in adipocytes and as intracellular free lipid droplets. For example, intramuscular total lipids in the latissimus dorsi back muscle of 3-year-old cattle was determined to be 3.7% of wet tissue weight, while phospholipids were present at levels between 0.4 and 1.0%; phospholipids were 1.2% of the wet weight of sheep back muscle [8]. Pig meat, however, is lean once the visible fat is removed, compared to bovine and sheep meats. Intramuscular lipids in pig back muscle were 1.3% of wet tissue weight and comprised 67% triacylglycerols and 33% phospholipids, while the lipid content in chicken’s back muscle was 1.0% and consisted of approximately equal amounts of triacylglycerols and phospholipids [9].

Liver of ruminant animals often contains lipids mainly as phospholipids and cholesterol in the tissue’s membranous structures, and triacylglycerols as storage lipids. Lipid contents have been reported as 2.2% of calf liver wet weight (22% triacylglycerols, 4.6% mono- and diacylglycerols, 63% phospholipids), 3.3 to 6.2% of mature bovine liver wet weight (46% triacylglycerols, 49% phospholipids), and mature sheep liver contained 4.5% fat (49% triacylglycerols, 10% free fatty acids, 34% phospholipids) [8]. Phosphatidylcholine and phosphatidylethanolamine were the main phospholipid components. Pikul et al. [10] found that chicken liver was 5.6% total lipids, which was composed of 51% triacylglycerols, 42% phospholipids, and 6% total cholesterol.

A large chicken egg of 60 g contains a total of ~ 6 g of lipids, which are found almost exclusively in the egg yolk, a complex system containing a variety of particles suspended in a protein solution. Lipids make up one third of the yolk and consist of 62% triacylglycerols, 33% phospholipids (mainly phosphatidylcholine and phosphatidylethanolamine) and less than 5% cholesterol [11]. Together with protein and free cholesterol, phospholipids surround micelle-like particles (lipoproteins) with a non-polar core of triacylglycerides and cholesterol esters [12].

Most of the lipids in cows milk exist as an oil-in-water emulsion of small globules from 0.1 to 20 µm in diameter stabilized by the milk fat globule membrane (MFGM) enveloping each fat globule which prevents its enzymatic degradation by lipases. The MFGM is a phospholipid structure comprising a polar lipids bilayer, proteins, enzymes, neutral lipids and trace components, separating the triacylglycerol core of the fat droplet from the surrounding aqueous environment [8, 13]. However, this MFGM can be ruptured by external stresses (agitation, homogenization). Cow’s milk contains a total of 3.3 to 4.7% lipids, which are composed of 96–98% triacylglycerols, 0.25–0.5% diacylglycerols, 0.2–1% phospholipids (about 30% each of phosphatidylethanolamine, phosphatidylcholine, sphingomyelin [14]), 0.2–0.4% cholesterol and 0.1–0.4% free fatty acids [8, 15].

In fish tissue, the main lipid constituents are triacylglycerol and phosphoglycerides, both containing long chain fatty acids. Lean fish such as cod and haddock, which are active deep-water feeders, have their reserve lipids stored as triacylglycerols primarily in the liver [14, 16], while muscle mainly contains phospholipids. For example, haddock flesh contains a total of about 1% lipids, of which 0.1–0.2% are “free” lipids, the rest being “bound” to protein [6]. In contrast, fatty fish like herring, mackerel or rainbow trout are surface feeders with substantial amounts of lipids stored as triacylglycerols in the flesh [14, 16]. The CALIPSO study [17], conducted between 2003 and 2006 in four French coastal regions, showed that the fishes containing most total lipids were eel, salmon, swordfish and halibut, with respective average lipid levels of 20.4, 13.5, 12.4 and 11.7% wet weight (based on whole fish). Mackerel and sardine are also rich in lipids (7.1 and 5.7% wet weight), while anglerfish, pout and cod display the lowest fat levels of 0.2 to 0.3% wet weight. In another study [18] including migratory, coastal and reef dwelling fishes from around Japan and the Northern Pacific region, total lipid contents in most muscle tissues were found to range from 0.9 to 7.4% wet weight, with a strongly varying proportion of phospholipids in the total muscular lipids between 9 and 81%. However, with a range from 0.47 to 0.92% wet weight, the muscle phospholipid content showed a significantly smaller variation.

Tissue distribution of lipophilic POPs

Uptake of organic pollutants into the mammalian organism occurs by passive diffusion across the skin (e.g. from contaminated surfaces) the membranes lining the gut (contaminated food, or water) and lungs (contaminated vapour, droplets, or particles). Lipophilic organic molecules are absorbed from the gut often in association with fat, passing through the membrane barriers due to their affinity for the lipophilic properties of the membranes themselves. Subsequently, they are transported to the liver by the hepatic portal system [19]. Following absorption via lungs or skin, lipophilic POPs associated with lipoproteins and membranes of the blood cells will first travel to tissues other than the liver, resulting in a different initial pattern of distribution. Organic pollutants will be distributed within blood and lymph among various tissue compartments and eventually be stored in lipophilic environments such as fat depots, lipoproteins and cell membranes. Interestingly, Yu et al. [20] found inconsistent distributions of 10 PCB congeners and 22 chlorinated pesticides in various lipid compartments in humans. They concluded that lipophilic xenobiotic levels in serum or even subcutaneous fat are not necessarily indicative of concentrations and patterns in other kinds of adipose tissue such as visceral, retroperitoneal, and pelvic fat. To some degree, lipid composition of the various adipose tissues may be reflected in different solubility of individual POPs in different depots in the same individual. Thus, the common assumption that POP serum concentrations and patterns are indicative of those in adipose tissues throughout the body is questionable [20].

Based on their solubility, lipophilic properties, and the enthalpic and entropic forces that govern ligand affinity and selectivity, organic pollutants associate with the different lipid classes present within each tissue. Some lipophilic pollutants incorporate even spontaneously into lipoproteins, their oily core providing an ideal domain. POPs have the potential for long-term disruption of metabolic and endocrine processes, and they may alter systemic metabolic, endocrine, and immune system functions. With the exception of the liver, stored lipophilic pollutants be subjected to metabolism only to a limited extent [19]. Over time, however, accumulated POPs are slowly released into the bloodstream, and more so during weight loss. In female mammals, lipophilic pollutants are secreted into the mammalian milk and may cross the placenta into a developing embryo. In chicken, lipophilic POPs are transported together with lipids into the egg and subsequently into the developing embryo [19].

In farmed animals including poultry, liver and adipose tissue are the major storage organs for POPs such as hexachlorocyclohexane (HCH) isomers, HCB, dioxins and PCBs, and dichlorodiphenyltrichloroethane (DDT) and its principal metabolites [dichlorodiphenyldichloroethane (DDD) and dichlorodiphenyldichloroethylene (DDE)]. Hepatic sequestration may result in relatively high lipid-based concentrations compared to adipose tissue or meat [21,22,23,24,25,26]. Species-, chemical- and congener-specific differences in the accumulation in liver lead to differences between the relative chemical and/or congener composition in liver and body fat [26]. Shen et al. [27] found, for instance, that in pigs, liver has a much higher potential to accumulate PCDD/Fs and dioxin-like chemicals (e.g. PCB 126) than lung, kidney, subcutaneous fat, mesentery and muscle. On the other hand, they found that liver did not specifically concentrate polybrominated diphenyl ether congeners as compared to the other tissues examined. Jandacek et al. [28] demonstrated that weight loss redistributed HCB from adipose tissue to brain and kidneys, while HCB in the liver increased after weight regain. These findings suggest that changes in weight affect the concentration of POPs in adipose tissue and critical organs [29]. Further studies investigating transfer and resulting tissue levels of dioxins and PCBs in cattle, sheep, goats, pigs and poultry, reported high ratios of lipid-based levels for liver to adipose tissue demonstrated hepatic sequestration and have been recognized by the EFSA Panel on Contaminants in the Food Chain (CONTAM) [26].

Fish are directly exposed to pollutants dissolved or suspended in water. Therefore, the uptake via the respiratory organs and the skin as well as ingestion of contaminated food, particles and sediments is equally important [19]. Distributions of POPs in fish meat and liver tissue correlate with lipid content and metabolic activity [30]. For example, lean fish with less than 5% lipids, such as cod and seabream, accumulate higher concentrations of PCDD/Fs and DL-PCBs in their liver, while oily or fatty fish such as salmon and trout store these POPs to a greater extent in muscle [26]. In addition to lipid content, lipid composition seems to have a significant effect on the storage and bioaccumulation potential in fish. Neutral storage lipids are most important for the bioaccumulation of nonpolar residues (e.g. HCH), while slightly polar pollutants are mainly stored in membrane lipids mainly consisting of polar glycerolipids [31]. PCBs were detected in both the membrane-bound and the “free” lipid fraction in fish [32, 33]. In fact, significant interspecies as well as tissue-specific differences in the lipid-based levels of NDL-PCBs (congeners most prevalent in technical mixtures) in fish have reported described by Brázová et al. [34]. Total PCB concentrations corresponded to the trophic position of individual fish species within the food chain and were found to be highest in liver, followed by adipose tissue > muscles > hard roe > bones > brain. Again, individual congeners were not distributed homogeneously within liver and adipose tissue, leading to differences in their relative composition [34]. These findings were confirmed by Kampire et al. [35] based on analysis of 236 organ samples of fish from the North End Lake in Port Elizabeth, South Africa, for lipid-based levels of 6 NDL-PCB congeners (PCB 28, 52, 101, 138, 153 and 180) and levels were the highest in liver, followed by gonads > gills > muscle. PCBs 153 and 138 showed higher concentrations than other congeners in all samples.

Lipid extraction methods

In principle, “free lipids” can be extracted relatively easily using solvents in which they are normally readily soluble without being denatured, such as, for example, hexane, toluene, cyclohexane and ethyl ether, and moderately polar solvents such as diethyl ether and chloroform. Unless solubilized by the presence of other lipids, polar lipids are removed only after treatment with a polar solvent such as methanol, ethanol or propan-2-ol. The latter solvent may also pick up a considerable portion of “bound lipids” which originally are tightly linked to proteins forming particular lipid-protein-complexes where van der Waals forces, hydrogen bonds and ionic bonds are involved [36].

Phospholipids of cell membranes are arranged in a lipid bilayer with their polar hydrophilic phosphate heads directed outwards and non-polar hydrophobic tails inwards. They require solvents of similar characteristics to perturb both the hydrophilic and non-polar interactions simultaneously. For this purpose, a combination of a non-polar and a polar solvent should be chosen. The former should make the mixture non-polar enough for interacting with the hydrophobic tails and extracting non-polar fats, while the latter makes it polar enough to interact with the hydrophilic regions, disturbing and eventually destroying the highly organized structure of the cell membrane. Using the non-polar solvent component in some excess will always maintain enough of the mixture’s non-polar characteristic to extract fat properly. For extracting “trapped lipids” (e.g. in protein aggregates of cell membranes), the sample should be ground prior to the extraction procedure in order to break up the cell membranes and other structures that would make extraction difficult [37].

Numerous techniques for lipid extraction from samples of animal origin (e.g. fish, mammalian tissues, eggs) have evolved during the past 70 years [6, 38]. These methods vary considerably with tissue properties, binding modes of target lipids and the information required from the sample (e.g. lipid composition, residues of lipid-associated POPs, analytical results based on fat or on wet weight). Diethyl ether, petrol ether, chloroform, methanol, ethanol, and various mixtures thereof were used as lipid extractants mainly from fish tissue during the early 1950s [6]. Several decades later, increasing awareness of the potential toxicity of solvents to analysts became another driving factor that facilitated change in solvent usage [36].

In 1957, Folch, Lees and Stanley [39] published their much-noticed paper on fat extraction from liver, muscle and brain tissue. In brief, samples are homogenized for several minutes with water and chloroform–methanol (2:1, v/v) using a Potter–Elvehjem homogenizer for sample amounts up to 1 g and a blender for larger amounts. The ability of chloroform to associate with water molecules, probably by weak hydrogen bonds, is a key property making chloroform–methanol such a good lipid solvent [40]. More recently, Castro-Gómez et al. [41] used what became known as the classic “Folch-method” for extraction of total fat from raw whole milk from cows, sheep, and goats. However, it was the least efficient among several other procedures tested providing total milk fat yields of 47%, 84% and 77%, respectively.

Bligh and Dyer [42] developed the “Folch-method” further in 1959, into a 3-step extraction of large amounts of wet tissue, especially frozen fish: (1) methanol–chloroform (2:1, v/v), (2) chloroform and (3) water are added to fish muscle tissue. Each solvent addition follows homogenization using a waring blender. After evaporation of the solvent, total extracted lipids are determined in the (lower) chloroform phase. A modification of this rather laborious procedure by Carlson [43] uses dichloromethane–methanol (2:1, v/v) in the extraction of serum and liver tissue giving results identical to chloroform–methanol, an advantage being the lower toxicity of dichloromethane.

Over the past decades, hexane–propan-2-ol (3:2, v/v) mixtures have frequently and effectively been used for lipid extraction from animal tissues, due to their lower toxicity and reduced costs compared to chloroform and methanol, as described by Hara and Radin [44]. According to Furusawa et al. [45] total lipids are efficiently extracted from egg yolk with n-hexane–acetonitrile (2:1, v/v) for the determination of organochlorine pesticides (OCPs) HCH, aldrin, dieldrin, DDT, DDD and DDE.

Another prominent method is the 3-step procedure developed in 1999 by Smedes [46] after restrictions on the use of chlorinated solvents such as chloroform or dichloromethane under the 1987 Montreal Protocol [47] required an alternative. Following similar principles as Bligh and Dyer [42], Smedes replaced chloroform with the apolar solvent cyclohexane and extracted lipids from marine tissues using a propan-2-ol:cyclohexane:water (8:10:11, v/v/v) mixture. To 10 g of sample containing 8 g water, 16 mL of 2-propanol and 20 mL cyclohexane are added, and the mixture dispersed with an Ultra-Turrax disperser for 2 min. After adding 14 g of water the mixture is dispersed for 1 min, followed by centrifugation. Due to its lower density, the cyclohexane separates at the top of the extraction mixture and can therefore be easily recovered. Extraction is repeated one more time and supernatants are combined and reduced to dryness. When compared with the Bligh and Dyer [42] method, lipid extraction efficiency was found to be 6% higher for herring, but 8 and 4% lower for plaice and mussel, respectively.

It should be noted that “classical” methods for lipid extraction as developed by Lovern [6], Christie [36], Folch [39], Bligh and Dyer [42], Hara and Radin [44], or Smedes [46] predominantly focused on determination of the lipid composition in tissue of fish and vertebrates, rather than on quantification of lipophilic contaminants.

The Jensen extraction method [48] for total lipids and lipophilic pollutants in aquatic organisms such as fat or lean fish yields recoveries that are not significantly different from the Folch and Bligh and Dyer methods. The 3-step procedure involves (1) propan-2-ol-diethyl ether (DEE), (2) n-hexane/DEE and propan-2-ol, and (3) n-hexane/DEE.

Löfgren’s “BUME method” [49, 50] extracts lipids from small amounts of plasma (10–100 μL) and from pulverized freeze-dried heart or liver samples (15–150 mg) using butanol:methanol (3:1, v/v) in an automated homogenization procedure, followed by a second extraction step with the same solvent mixture. Extraction efficiency was determined by the addition internal standards prior to extraction. When compared to the Folch procedure, this method yields comparable or slightly better results for most tested lipids, but significantly improved results for a number of phospholipids.

Speer and co-workers [51] extracted 205 pesticides with cyclohexane:ethyl acetate (1:1, v/v) from egg and milk samples using an Ultra-Turrax tube drive. After cooling to − 20 °C, adding a mixture of NaCl, sodium citrate-dihydrate, disodium hydrogen citrate-sesquihydrate and magnesium sulphate, followed by shaking and centrifugation, target analytes were quantified with GC/MS–MS and LC/MS–MS. Recoveries were found to be generally higher than that achieved with the “QuEChERS” multi-method [52].

The Soxhlet apparatus, designed in 1879 by the agricultural chemist Franz Ritter von Soxhlet, allows for continuous solid–liquid extraction of lipids from (marine) animal tissues with various solvent systems. These include: toluene–hexane [53], acetone–petroleum [54], MTBE [55, 56], cyclohexane–acetone–petroleum ether [57], methylene chloride–hexane [58], hexane–acetone [59, 60], n-hexane [61, 62] and acetone–dichloromethane [63]. However, extraction results of the same sample often vary between laboratories due to the use of different solvent mixtures, numbers of cycles and/or boiling periods (6–24 h). The amount of time needed, large solvent volumes required (120–400 mL per sample) and subsequent losses of volatile and semivolatile species during concentration of extracts (for instance, up to 20% for highly chlorinated benzenes, depending on the evaporation method used), are among the main disadvantages of Soxhlet extraction [64]. Although boiling, rinsing and solvent recovery were eventually automated and optimized, efficiency is generally lower than that of the Bligh and Dyer [42] and Smedes [46] methods, because a considerable fraction of “bound lipids” are not extracted, and results are not considered as total lipids but as “extractable” lipids [46]. While Soxhlet extraction for 24 h using acetone:hexane (1:3, v/v), when compared to Smedes’ method, showed reduced extraction efficiency for plaice (− 30%) and mussel (− 20%), results with herring were comparable [46].

Twisselmann’s continuous hot extraction [65] overcomes this drawback, providing increased extraction temperature by hot solvent vapour flowing through the extraction thimble from below. This not only improves lipid solubility and extraction efficiency also for “bound lipids”, but reduces extraction time by up to 50%. The solvent is collected separately during the process, eliminating the evaporation step. These features make the Twisselmann technique, especially when integrated in an automated extraction device, more resource-efficient [66]. As an example, this method has been used to extract lipids from freeze-dried (marine) animal tissue, egg or milk samples with ethanol:toluene (70:30, v/v) during a boiling period of 6–8 h [67], while another study [68] used ethyl acetate:cyclohexane (1:1, v/v) for extraction of lipids from fish tissue (extraction time not given). As an alternative to freeze-drying, samples may be treated with a drying agent (e.g. super absorbent polymer, SAP) prior to extraction.

Accelerated solvent extraction (ASE) [69], or pressurized liquid extraction (PLE), combines elevated pressures and temperatures above the boiling point with smaller amounts (10–50 mL per sample [64]) of the same solvents or mixtures that are commonly used for standard liquid extraction techniques (Soxhlet or Twisselmann), such as dichloromethane–hexane [70], dichloromethane–cyclohexane [71], or methanol [72]. In an automated process, the solvent is pumped into a sealed tube with sample and support material. After a suitable time, it is pumped out and collected, then the procedure is repeated several times. The total extraction time is just 10–40 min [64]. However, the apparatus and equipment are rather expensive and solvent mixtures, temperatures and pressures must be adjusted for each sample type to ensure extraction of all free fat, while bound lipids may still not be extracted sufficiently [38]. The wash procedure of the extraction cells is also quite complicated and results in a significant increase in solvent consumption [73]. ASE was originally developed and tested for solid and semi-solid samples. Recoveries of polycyclic aromatic hydrocarbons (PAHs) from urban dust and marine sediment samples and of PCBs from sewage sludge and oyster tissue are reported as quantitative [69]. ASE may further be applied for lipid extraction from (marine) animal tissue [74,75,76,77], egg containing foods [78] or dairy products [79]. Chloroform–methanol, hexane–propane-2-ol, or methylene chloride have been used to extract fish tissue [74], egg yolk can be extracted with propan-2-ol:hexane (2:3, v/v) [75], egg-containing foods with chloroform:methanol (2:1, v/v) and hexane:propan-2-ol (3:2, v/v) [76], and poultry tissue with chloroform:methanol (2:1, v/v) [75, 76]. For ASE of various dairy products, Richardson [79] used mixtures of two or three of the following solvents: hexane, petroleum ether, dichloromethane, methanol, ethanol, propan-2-ol and acetone. Castro-Gómez et al. [41] performed ASE with dichloromethane–methanol (2:1, v/v) as solvent mixture at 60 °C, a pressure of 10.3 MPa and two cycles of 5 min each to extract total lipids from raw whole milk from cows, sheep and goats. While extraction efficiency was significantly higher than with the “Folch-method”, it was identical for cow’s milk, 5% less for sheep’s milk and 8% less for goat's milk than what was achieved with the rather laborious reference methods according to ISO 14156/IDF 172 [80] or Röse-Gottlieb [81].

Based on Baron Charles Cagniard de la Tour’s discovery of the phenomenon of supercritical fluids in 1822, supercritical fluid extraction (SFE) generally uses supercritical carbon dioxide (sCO2), which is particularly suitable for the extraction of non-polar compounds. The critical temperature of CO2 (31.1 °C) is close to ambient making SFE convenient for heat-sensitive (biological) compounds, and its low critical pressure (7.39 MPa) allows operation with moderate pressures [82]. The density of the sCO2 at around 200 bar (20 MPa) is similar to that of n-hexane, as are the solvation properties that allow it to act as a non-polar solvent [83]. Near the supercritical region, CO2 can dissolve triacylglycerols at concentrations up to 1% mass [83]. Extraction is complete within 15 min up to several hours, depending on sample type and target compounds. The solvent is easily removed by making them sub-critical through pressure reduction and/or temperature adjustment. A co-solvent, such as ethanol or methanol, may be added as a modifier. For example, Tanaka et al. [84] demonstrated that at 33 °C and 17.7 MPa only 65% of triacylglycerols and no phospholipids were extracted from freeze-dried fish roe when using pure CO2, while 100% of triacylglycerols and more than 80% of phospholipids were obtained by adding 20% ethanol to the solvent. In general, SFE seems to provide a significantly higher extraction efficiency than Bligh and Dyer's extraction method, while an increase in proportion of modifier in the solvent composition enhances extraction efficiency for phospholipids [85]. In SFE of lipids and cholesterol from fish muscle, extraction efficiency was not significantly enhanced by increasing CO2 pressure and/or temperature, but primarily by prolonging the extraction period from 3 to 9 h [86]. However, ethanol as an entrainer significantly enhanced lipid extraction at each pressure applied. sCO2, and sCO2 plus ethanol, removed 78% and 97% of the lipids, and 97% and 99% of the cholesterol, respectively, from trout muscle [86]. Sánchez-Camargo et al. [87] reported similar findings in SFE of lipids from shrimp. Snyder et al. [88] extracted lipids together with heptachlor, dieldrin and endrin from pre-dried peritoneal fat, breast, leg and thigh tissue, and liver from chickens by SFE, and by solvent extraction using petroleum ether. Recoveries of organochlorine pesticides by SFE extraction were equivalent to those obtained by conventional extraction with petroleum ether except for liver, for which recoveries from SFE extraction were significantly higher. The main advantage of SFE is the easy manipulation of fluid density and thus its solvating power, which results in improved fractionation capability. With CO2 being non-flammable, inexpensive, nontoxic and readily available, SFE has helped to eliminate the use of solvents such as n-hexane, chloroform or methylene chloride. Drawbacks of SFE include the complex phase equilibrium of the solvent/solute system and, through addition of co-solvents for the extraction of polar compounds, complication of further downstream sample processing. Capital costs and costs for running the multipart equipment process are high [82], so SFE is likely to be used only where there are significant advantages.

Implications for European official food control

This brief review suggests that depending on (1) sample matrix properties, (2) the nature of lipids to be extracted, (3) the type and extent of lipid binding, (4) the degree of association of lipophilic POPs to different classes of tissue lipids, (5) solvent properties and composition, and (6) the efficiency of the selected technology, both the extracted fractions of different lipid classes and the results for lipid-associated environmental POPs may vary considerably. Frequently observed unsatisfactory extraction efficiency due to insufficient and inconsistent release of POPs tightly associated with various covalently bound lipids cannot always be compensated by adding internal standards (IS) to the sample prior to the preparation and extraction steps. The basic assumption with internal standardization that any losses should affect the IS and target analyte proportionally, so the ratio of analyte to IS stays constant, proves most likely inapplicable in such cases and the approach not effective at improving method performance and data quality. Consequently, suchlike losses translate more or less directly into a significant bias and/or imprecision of the analytical results, affecting both intra- and inter-laboratory reproducibility and accuracy.

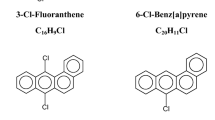

For instance, target compounds within European official control of dioxins and PCBs in various foods of animal origin are the 29 most toxicologically relevant PCDD/F and PCB congeners. After uptake and distribution among different tissue compartments, they associate with the various types of lipids present within each tissue, depending on their respective physico-chemical properties. However, besides free lipids, and lipids with weak or moderately strong affinity, lipids reversibly and non-covalently associated with specific intracellular lipid-binding proteins, tissue fat in the liver of farmed animals, fish meat and fish liver contains considerable fractions of covalently bound phospholipids (up to 90% of total lipids) varying with age and between species. The outcome of bioanalytical, enzyme inhibition or enzyme-linked immunosorbent assay methods or of the rather complex and cost-intensive physico-chemical multi-residue analysis may therefore fail to reflect the actual relative composition (congener-pattern or “fingerprint”) of toxic organic pollutants present in the tissue or sample. The illustrated scenario could also pose a substantial risk of generating results in official food control that underestimate the actual levels of lipid-associated POPs to which the consumer to be protected is in reality exposed.

False-compliant (false-negative) results could then be a consequence when checking compliance of samples with specific legal limits such as EU action levels [89] (ALs), serving as warning levels, and maximum levels [90, 91] (MLs) for PCDD/Fs and PCBs (Table 1), or maximum residue levels [92] (MRLs) for fat-soluble OCPs. This potential threat to consumer’s health is of significance especially where EU legislation has established ALs and MLs on wet weight basis requiring laboratories performing official control of the levels of contaminants such as PCDD/Fs and PCBs in food to report results on wet weight basis. In dioxin and PCB analysis, this is the case for liver of terrestrial animals including sheep [91], and for meat and liver of farmed fish and farmed fishery products [89, 90] (Table 1). Only if the result, expressed on wet weight basis, is above the respective wet weight-based ML (MLww) beyond a reasonable doubt, the sample is declared “non-compliant” with EU food legislation [2]. As a direct consequence, products of concern are withdrawn from the market, a measure with potentially significant (financial) implications. Table 1 shows, however, that in most cases, MLs and ALs for dioxins, PCBs and/or for the sum of dioxins and PCBs are based on the fat content because dioxins accumulate in the fatty tissue of the animals, and in egg and milk fat [89,90,91]. Only when samples contain less than 2% fat does EU food legislation require that a ML based on wet weight (MLww) must be calculated from the respective fat-based ML (MLfat), being MLww = MLfat × 0.02 [91].

Efficiency of lipid extraction from animal tissue may often be subject to strong variations difficult to control with internal standards and significantly affecting the reproducibility of lipid-based analytical results, both between and even within laboratories. Randall et al. [93] observed variations of up to a factor of 3.5 for the results of extracted lipids during a collaborative study evaluating different solvents and methods for lipid extraction. An explanation for such rather dramatic scatter seems that certain types of lipids get “trapped” in small domains or are covalently bound to proteins, as is the case, e.g. for phospholipids. The latter are present in substantial but varying species-, sex- and age-specific proportions in terrestrial animal liver, as well as in meat and liver of fish. Lipid-associated contaminants seem to be more easily extractable than these trapped or bound lipids, the extraction of which may—depending on the procedure applied—not only be deficient but of unsatisfactory reproducibility, as well. A one-to-one relationship between extracted lipids and the lipophilic contaminants, which may not be as evenly distributed within the sample tissue to be analysed as the analyst would like them to be, should therefore not be anticipated. Consequently, environmental lipophilic POPs may show considerable variability in fat-based results, generally expressed as relative standard deviation (RSD) under within-lab (RSDRw) and between-lab reproducibility conditions (RSDR). It is also not entirely surprising that the same results obtained from the same samples but based on wet weight appear more homogeneous with significantly lower RSDRw and RSDR values [94].

Recognizing these observations, the European Commission in accordance with the opinion of the Standing Committee on the Food Chain and Animal Health (SCoFCAH) changed in Regulation (EU) No 1067/2013 [91] the reference base of MLs, and ALs (only for meat of farmed fish and products thereof), from “fat” to “wet weight”. Paragraphs (8) and (9) state that “in order to ensure comparable results and an uniform enforcement approach across the Union as regards to dioxins and PCBs in liver of terrestrial animals, it is appropriate to establish the maximum levels on a wet weight basis as was already established for fish liver and derived products thereof.” In line with this modification, the respective MLs for PCDD/Fs and for the sum of PCDD/Fs and DL-PCBs in terrestrial animal liver were changed from 4.5 pg WHO-PCDD/F-TEQ/g fat and 10.0 pg WHO-PCDD/F-PCB-TEQ/g fat [90], to 0.30 pg WHO-PCDD/F-TEQ/g ww and 0.50 pg WHO-PCDD/F-PCB-TEQ/g ww [91], respectively. Although the nominal values of the MLs are now smaller by a factor of 15, and 20, respectively, this change actually represents an increase in both MLs for any farmed animal's liver (except sheep) containing less than 6.7%, and 5% lipids, respectively, by up to a factor of 5, as stated by the German Federal Institute for Risk Assessment (BfR). For the first time, individual MLs were introduced for dioxins and PCBs in sheep's liver and derived products, exceeding by a factor of 4 the MLs set for liver of terrestrial animals (Table 1). Having assessed the health implications of the new MLs, the BfR concluded that even the consumption of 250 g of sheep liver containing dioxins and DL-PCBs in the range of the new MLs on a single occasion may lead to the tolerable weekly intake (TWI) being exceeded [95]. The BfR further recommends that consumers in Germany generally avoid the consumption of sheep liver [95]. In summary, insufficient reproducibility of fat-based results from methods for extraction of lipids and lipophilic pollutants applied within official control lead to a significant increase in MLs and considerable consequences for the affected population’s diet.

In the case of fish, however, other reasons for choosing wet weight as reference base were pivotal. The European Commission’s Scientific Committee on Food (SCF) assessed in 2000 the dietary exposure of the general population of EU member states [96, 97]. This assessment was based on the “Final Report of Scientific Cooperation” (EU SCOOP) [98] containing a large set of PCDD, PCDF, and DL-PCB concentrations in many foods of 10 participating countries. Frequency distributions of the contamination levels based on extracted lipids across 1995–1999 showed, that ranges in fish span over two (for DL-PCBs) to three (for PCDD/Fs) orders of magnitude, which is readily explained by the large variety of species taken into account. Severely skewed distributions of PCDD/Fs (xmin = 0.125, \(\overline{x}\) = 9.80, 95%ile = 79.0, 99%ile = 188 pg I-TEQ/g fat) and DL-PCBs (xmin = 1.61, \(\overline{x}\) = 30.7, 95%ile = 148, 99%ile = 285 pg PCB-TEQ/g fat), respectively, reflect the remarkable dispersion of lipid-based concentrations in fish, which are between one and two orders of magnitude larger than those in other foods [96]. For example, the 95th percentile value serving as cut-off point for risk management, which would keep on the market 95% of the samples, is 37 times higher for PCDD/Fs in fish (79.0 pg I-TEQ/g fat) compared to terrestrial animals (2.11 pg I-TEQ/g fat). As levels of lipophilic POPs in fish depend on species, fat content, the extent of migration of wild fish, the number of spawning cycles, age, site, and feeding habits [99], the SCF concluded that for better comparability, maximum levels should preferably be expressed on wet weight basis [96].

Within the scope of our tasks as European Union Reference Laboratory (EU-RL) for Dioxins and PCBs in Feed and Food (2006–2017), following Article 32 of Council Regulation (EC) 882/2004 [100], we organized bi-annual proficiency testing (PT) studies aiming to ensure high-quality, uniform testing throughout the EU. The above described measures to improve reproducibility of results from analysis of dioxins and PCBs in fish meat was for the first time put to the test in 2011, when National Reference Laboratories (NRLs) and official laboratories of EU member states were requested to participate in a PT study on determination of PCDD/Fs and PCBs in salmon filet. 28 NRLs representing 25 EU member states and 63 official laboratories (OFLs) from 10 EU member states participated. Salmon filet samples were prepared from salmon from the Luleå archipelago in the Baltic Sea, kindly provided by the Swedish NRL. Participants used their own reference standards and the bioanalytical and/or physico-chemical (GC/HRMS) confirmatory methods of their choice. Applied extraction procedures included, but were not limited to, Bligh and Dyer and Smedes methods, Soxhlet and Twisselmann hot extraction, ASE (PLE) and SFE, with or without modifications in solvents and solvent combinations. Consensus values were calculated according to the IUPAC protocol [101] after excluding extreme outliers as Huber’s robust means [102], and they were used as assigned values. For extracted lipids (“lipid content”), the assigned value was 6.2%, however, we found large differences between laboratories (RSDR = 34%). Although 80% of extracted lipid results were within the ± 20% range of the assigned value, 8% were beyond the ± 20% range yet within ± 30% range, while 12% of the lipid results were more than 30% below the assigned value (of which 7.5% were more than 50% below the assigned value).

Participants’ lipid-based results for 17 individual 2,3,7,8-substituted PCDD/Fs, 12 DL-PCBs and 6 marker PCBs were clearly dependent on the amount of extracted fat and thus on the extraction method and/or solvents applied. Almost expectedly, the levels of PCDD/Fs and PCBs expressed on wet weight basis were more comparable. Assigned values for sum-parameters were 3.68 pg WHO-PCDD/F-TEQ/g ww, 6.03 pg WHO-PCB-TEQ/g ww, 9.76 pg WHO-PCDD/F-PCB-TEQ/g ww, and 35.3 ng/g ww for the sum of marker PCBs. For PCDD/Fs, DL-PCBs, the sum of PCDD/Fs and DL-PCBs, and the sum of marker PCBs, 83–90% of reported wet weight-based results were within a range of ± 20% of the assigned value (z-scores within the ± 2 range). Consequently, 10–17% were beyond the ± 20% range, some z-scores even outside of the ± 5 range (beyond ± 50% of the assigned value). This distribution of wet weight-based analytical results obviously reflects that described for the extracted lipids. To our surprise, a tendency to underestimate the sum of DL-PCBs, the sum of PCDD/Fs and DL-PCBs, and the sum of marker PCBs in salmon filet was noticeable in results submitted from NRLs. For results submitted for PCDD/Fs, the performance of NRLs and official laboratories was comparable. Taking into account the respective expanded measurement uncertainties (U), 43% of participating laboratories reported exceedance of the ML for the sum of PCDD/Fs and DL-PCBs (in 2011, this ML was set to 8.0 pg WHO-PCDD/F-PCB-TEQ/g ww [90]) and 57% reported no exceedance. While 56% of participating laboratories reported exceedance of the PCDD/F-AL (in 2011, the AL was set to 3.0 WHO-PCDD/F-TEQ/g ww [103]), and 44% of participants reported no exceedance. This clearly shows that assigned concentrations about 20% above the respective ML, or AL, may lead to about 50% of NRLs and official control laboratories assessing their analytical results as “exceeding the ML”, or “exceeding the AL”, while the remaining 50% of laboratories declare the same sample “compliant”.

We conclude that expression of results for lipophilic pollutants in fish meat on wet weight basis does not necessarily ensure acceptable inter-laboratory variability of lipid contents and concentrations of target analytes, and consistent assessment of compliance with EU maximum and action levels. Based on the extraction procedures applied during the PT, certain POPs conceivably closely associated with covalently bound or “trapped” lipids can be removed from the sample matrix only to a limited and varying extent. Whether analytical results are expressed on wet weight or on lipid basis, foods of animal origin generally require complete, reproducible extraction of both the lipids and the lipophilic analytes of interest.

Present study

Within the scope of establishing strong EU-wide analytical standards, the Bioassay Research Unit at the European Union Reference Laboratory (EU-RL) for Dioxins and PCBs in Feed and Food (Freiburg, Germany) has, in co-operation with the Department of Environmental Toxicology, University of California Davis (Davis, USA), evaluated and optimized the performance of bioanalytical screening methods for suitability within European official food control [104,105,106]. As a result of new developments in sample preparation, we present a rapid, efficient and selective procedure for removal of “total” lipids and lipophilic organic pollutants from any EU-regulated [89,90,91] food of animal origin. Starting out from Smedes’ method [64] for determination of lipids in fish and vertebrates, Ultra-Turrax assisted matrix dispersion was modified to facilitate desorption of “total” lipids and lipophilic POPs such as dioxins and PCBs from adipose tissue, fish, fish oil, liver, meat, chicken eggs, egg powder, whole milk, milk powder, milk products and infant food. Optimization and validation of this method was performed using a combination of instrumental and aryl hydrocarbon receptor (AhR)-based cell bioassay analysis.

Methods

Chemicals

Cyclohexane, n-hexane (for rinsing of glassware) and propan-2-ol, each of grade 'Dioxins, Pesti-S, Furans, PCBs analysis' used for lipid extraction were from Biosolve (Valkenswaard, Netherlands), double-distilled water (ddH2O) was from Roth (Karlsruhe, Germany).

Glassware

When dioxins and PCBs were analysed after determination of lipids, cleaned laboratory glassware was baked at 435 °C for 18 h (overnight), and after cooling to ambient temperature the glassware was kept covered or stored in a suitable container. Shortly before use, the glassware was rinsed three times with n-hexane and briefly allowed to dry. All glassware was loosely covered with aluminium foil throughout sample processing.

Samples

Samples in this study were obtained from regular market food, contamination incidents and PT studies, and included: adipose tissue (bovine, pig), liver (bovine, sheep), meat (bovine, pig, sheep, poultry), fish, fish oil, cow’s milk, milk powder, milk fat, butter, and chicken eggs. Lipids were extracted from freeze-dried sample material using Twisselmann hot extraction [65] at the Chemical and Veterinary Investigation Office (CVUA) Freiburg’s physico-chemical routine lab for dioxin analysis, part of which functioned as EU-RL for Dioxins and PCBs in Feed and Food. PCDD/F and DL-PCB levels were determined by GC/HRMS confirmatory analysis and results expressed as WHO-PCDD/F-TEQ, WHO-PCB-TEQ and WHO-PCDD/F-PCB-TEQ. TEQ results obtained for adipose tissue, liver, meat, fish, fish oil and chicken eggs ranged from slightly below the respective limit of quantification (LOQ) up to twice the ML and/or the AL set by EU legislation [89,90,91] (Table 1). These samples were used as reference materials in validation and QC studies as required by Commission Regulation (EU) 2017/644 [2] involving comparison of the individual TEQ values with cell bioassay-based bioanalytical screening results of the same sample, expressed in bioanalytical equivalents (BEQ) [2]. Further included in this study were human milk samples obtained from 8 countries (Australia, Brazil, China, Spain, Fiji, Ireland, Philippines and USA) during the third WHO Global Survey on POPs (2000–2003) [107] and pre-analysed at CVUA’s routine dioxin laboratory also functioning as WHO Reference Laboratory. Solid samples were homogenized in a waring blender to ensure representative subsamples and stored in a freezer below – 25 °C prior to extraction.

Modified Smedes extraction (MSE) of “total” lipids

Frozen (pre-homogenized) samples were thawed to ambient temperature and re-homogenized before weighing in a glass bottle (Duran glass bottle, 100 mL or 250 mL, Schott, Mainz, Germany). The analytical sample weight should be chosen according to requirements, such as certain amounts of lipids to be extracted, or expected concentrations of POPs to be quantified. See Table 2 for exemplary sample weights and corresponding solvent volumes, which need to be adjusted if other sample weights are chosen. Dry egg powder was soaked in an aliquot of ddH2O (for 76% water content) prior to extraction. Lipids were also extracted from fats and oils of animals and fish before clean-up, as this often results in reduced background signals. With the exception of fat, oil and dry matrices (e.g. egg or milk powder), for sample weights below 5 g the corresponding solvent volumes should not be further reduced. All solvents were dispensed from bottle-top dispensers.

An aliquot propan-2-ol was added and the mixture briefly swirled to avoid sample material sticking to the glass wall, or clumping. Then cyclohexane was added and the mixture was briefly homogenized using an Ultra-Turrax® disperser (IKA T25, IKA, Staufen, Germany) with an 18 mm dispersing element (IKA S25N-18G) at 10.000 rpm; dispersing times are presented in Table 2. After addition of ddH2O, the ternary solvent—matrix mixture was dispersed for 15 s (30 s for meat and fat). Table 3 shows fresh sample weight, average lipid and water contents, and the individual propan-2-ol–cyclohexane–water ratios for each sample, taking into account its average water content, prior to “Ultra-Turrax B” dispersion (Table 2).

With 5–10 mL propan-2-ol, sample remains adhering to the dispersing element were rinsed into the upper solvent layer. If necessary, horizontal circular swirling of the vessel on a flat surface by hand for a few seconds (Table 2) supported phase separation while re-mixing of already separated phase volumes was avoided. The lower aqueous phase, or remnants of an emulsion that may remain suspended between aqueous and organic layers, should not be allowed to re-mix with the upper cyclohexane layer. We observed spontaneous phase separations within less than 30 s for chicken eggs (Fig. 1), re-constituted egg powder, fats, meat (ruminants, poultry), fish oil, whole milk, milk powder, milk fat, butter and commercial infant foods. The upper phase was transferred into an evaporation glass tube using an accu-jet® pro pipette controller with adjustable speed (Brand, Wertheim, Germany) equipped with a glass pipette.

Modified Smedes extraction (MSE) of “total” lipids. Left: 15 s dispersion of 10 g chicken egg with 32 mL propan-2-ol, 40 mL cyclohexane and 24 mL water (“Ultra-Turrax B” in Table 2); right: 30 s after rinsing the rotor–stator with 5–10 mL propan-2-ol and brief circular swirling on a flat work surface. The clear upper organic phase was collected with a glass pipette connected to a pipette controller

For fish and liver tissue, a sufficiently large cyclohexane phase equal or greater than 25% of the added volume of cyclohexane did not always separate during the first extraction, even with prolonged swirling. Depending on lipid content, nature and composition, only a few mL of a clear upper phase may have formed, while a distinct cloudy mixed phase (emulsion) remained suspended between the aqueous and organic layers. In this instance, another 5–10 mL of propan-2-ol were carefully added to the emulsion. Swirling for a few seconds and let stand for 2–3 min resulted in clearer solvent and separation, where 25% or more of previously added cyclohexane could be collected as described above.

Extraction was repeated twice with additional cyclohexane (Table 2), once only for fish oil, and three times for fish and liver tissue if phases did not separate properly during the first extraction. The mixture was dispersed for 10 s, or 15 s if fat or meat were extracted. Cyclohexane phases again separated spontaneously within less than 30 s during repetitions, while for fish and liver tissue this process required up to 2 min for complete separation. The collected organic phases were reduced to dryness in a TurboVap II concentrator workstation (Biotage, Uppsala, Sweden). An outline of the modified Smedes [46] extraction (MSE) procedure is shown in Fig. 2.

If the dried extract was to be submitted for clean-up to follow-up POPs analysis, mild conditions were chosen (water bath: 45–50 °C, nitrogen: 0.6 bar) to minimize evaporation losses particularly of the semi-volatile dioxin-like coplanar PCB 126. The extract was weighed, dried for 30 min, or overnight (the vessel loosely covered with alumina foil), weighed again and the drying repeated if necessary until the weight remained constant. Alternatively, last traces of solvent were removed by placing the evaporation glass tubes in a drying oven at 103 °C for 45 to 60 min until—after cooling to ambient temperature—the extract weight remained constant. The lipid content was calculated from the weight of the dry residue and the initial weight of the analytical sample.

Note: In routine analysis it is advisable to use an individual dispersing element for each sample, so that samples can be extracted in sequence within each extraction step while the time-consuming cleaning between individual sample/solvent-mixtures and the risk of cross-contamination can be avoided. Then the time required for the entire extraction process will not exceed 8 min per sample for fish and liver and 6 min for all other matrices. It is time saving to initially subject all samples of a series in sequence to the first extraction. Solvent evaporation in the concentrator should commence for all extracts simultaneously after completion of the first extraction. The use of two concentrator workstations simultaneously for 12 sample extracts allows the entire evaporation process to be completed within 60 to 90 min. The time required for total lipid extraction from 12 samples of animal origin from weigh-in to the dried extract is 3.0 h for fish and liver, and 2.5 h for all other matrices.

Propan-2-ol:cyclohexane:water ratios (v/v/v), fresh sample weight (w) and lipid (w) ratios normalized to 10 parts by volume cyclohexane (v = 10) for all sample matrices of interest are depicted in Fig. 3.

Propan-2-ol:cyclohexane:water ratios (v/v/v), fresh sample weight (w) and lipid (w) ratios. Data normalized to 10 parts by volume cyclohexane (v = 10) for all matrices included; egg powder: sample weight parts refer to dry powder reconstituted with ddH2O prior to extraction (Table 3)

Clean-up of extracts

Purification of the crude extract represents an important step in removing unwanted co-extractives that can potentially interfere with GC/HRMS measurement or alter the response in the AhR-based cell bioassays used in this study. For example, the clean-up procedure for screening analysis of PCDD/Fs and DL-PCBs is briefly described: Up to 2 g of dry lipid extract were re-dissolved in 15 mL n-hexane. The solution was freed of lipids on 33% sulphuric acid activated silica (1:2, w/w), followed by fractionated elution of the target compounds from an 1% activated carbon/celite (1:99, w/w) mixture. PCDD/F and DL-PCB eluates were reduced and transferred to conical 1.2 mL vials. The volume was carefully reduced to 2–3 µL. In a final step, the remaining solvent was exchanged for 7 µL of DMSO in the case of the PCB-fraction, and for 14 µL of DMSO in the case of the dioxin-fraction, following a well-established procedure keeping vial-to-vial variability, expressed as relative standard deviation (RSD), below 5%. The smaller volume for the final extract containing DL-PCBs was chosen due to a reduced relative potency (REP), or response of the cell bioassay to PCB 126, the most abundant DL-PCB, being approximately 40% relative to the assay’s response to the most potent compound, 2,3,7,8-tetrachlorodibenzo-p-dioxin (2,3,7,8-TCDD) [105, 109,110,111].

Bioanalytical screening for PCDD/Fs and DL-PCBs

Relative quantitation of 2,3,7,8-TCDD and related dioxin-like chemicals (PCDDs, PCDFs and PCBs) in sample extracts was performed using the Chemically Activated LUciferase eXpression (CALUX) recombinant cell bioassay, which is based on the molecular mechanism by which the AhR mediates the toxic and biological effects of these compounds [112, 113]. First described in 1996 by Denison and coworkers [114, 115], the CALUX bioassay typically utilizes recombinant mouse (H1L6.1c3) and rat (H4L1.1c4) cell lines that contain a stably integrated AhR-responsive firefly luciferase gene plasmid as the detection system [112]. Exposure of these cells to standard solutions or extracts containing 2,3,7,8-TCDD and/or other AhR-active compounds results in a time-, dose- and chemical-specific and AhR-dependent induction of luciferase expression, which can be readily measured by light output in an enzymatic reaction [112, 114, 116, 117]. More recently, an amplified third generation CALUX rat cell line (H4L7.5c2) was developed and the firefly luciferase plasmid contains 20 dioxin-responsive elements (compared to the 4 contained in the plasmids in earlier CALUX lines) and these cells exhibit a significantly greater overall induction response and lower detection limit than previous cell lines [118]. Mouse (H1L6.1c3) and rat (H4L1.1c4 and H4L7.5c2) and other CALUX cell lines are freely available for non-profit research purposes and can be obtained from Prof. Denison, Department of Environmental Toxicology, University of California, Davis, CA 95616. These cells are also available for commercial and government screening purposes through a licensing agreement with the Hiyoshi Corporation, Omihachiman, Japan (www.calux-jp.com/english/).

Mouse (H1L6.1c3) or rat (H4L1.1c4 and H4L7.5c2) cells were seeded into 96-well culture plates and incubated at 37 °C in the presence of 5% CO2 for 24 h. Individual concentrations of a TCDD standard dilution series and sample extracts (all in DMSO) were added to incubation medium and the mixtures subsequently transferred to the cells in triplicate. After incubation at 33 °C in the presence of 5% CO2 for 24–48 h (depending on the cell line used), the cells were lysed, followed by addition of d-luciferin (Duchefa, Haarlem, The Netherlands), the substrate for the bioluminescence reaction of firefly luciferase. Incubations were carried out at 33 °C during the exposure period rather than at 37 °C because incubation at the lower temperature has been demonstrated to result in a significant increase in overall luciferase activity [119]. Luciferase activity was measured as emitted light (luminescence) from each well, expressed in relative light units (RLUs), in a Centro LB 960 microplate luminometer (Berthold, Bad Wildbad, Germany). The magnitude of induction of luciferase activity is directly related to the level of reporter gene expression and proportional to the total concentration of TCDD-like AhR activators in the standard solution or extract. This correspondence follows a classical ligand-receptor binding curve. When plotted in a semi-log graph, the concentration–response data adopt a sigmoidal shaped pattern to which most commonly a 4-parameter logistic (4PL) function is fit. Hill’s equation [120] being mathematically analogous to the logistic equation is frequently used for this purpose. Details on fitting concentration–response curves are described elsewhere [106]. The unknown concentration of the analyte(s) may now be determined by comparing the cell response measured in the assay to the fitted TCDD standard curve. Sample-based results (in BEQs) were calculated taking into account sample intake and final extract volume and subsequently corrected for the procedural blank and the apparent recovery of the positive control sample analysed with each sample series.

The bioanalytical method used within this study has been fully validated for all sample matrices of interest according to the requirements given in Commission Regulation (EU) 2017/644 [2] and applied under a strict GC/HRMS-backed quality control (QC) scheme [104,105,106].

Reporting bioanalytical results

The bioanalytical results presented are not shown with an associated measurement uncertainty (MU) expressed as expanded uncertainty (U) according to ISO/IEC Guide 98-3:2008, part 3 [121], and reported as an interval x ± U corresponding to a particular level of confidence, such as 95%. While Commission Regulation (EU) 2017/644 [2] requires reporting of TEQs obtained from confirmatory analysis together with the respective MU for decision over sample compliance with regulatory limits, BEQs from bioanalytical screening must be compared to pre-established cut-off values based on a normal distribution approach and acceptable α- and ß-errors [2, 106]. Ensuring a false-compliant rate below 5%, these cut-offs take into account the MU associated with results from confirmatory analysis, variability and apparent recovery of bioanalytical results at ML (or AL), and the sensitivity of the bioanalytical method [2, 106]. A sample with a BEQ-result above the cut-off is “suspected to be noncompliant” requiring follow-up confirmatory analysis to determine sample TEQs for final decision. Otherwise, the sample is declared "compliant" with immediate legally binding force. It follows that a "non-compliant" result can only be obtained by confirmatory analysis and the MU is therefore only required for that purpose.

This approach is in line with the IUPAC definition of “uncertainty of measurement” being “a parameter associated with the result of a measurement that characterizes the dispersion of the values that could reasonably be attributed to the measurand” [122], i.e. the quantity intended to be measured [123]. “The specification of a measurand requires knowledge of the kind of quantity, description of the state of the phenomenon, body, or substance carrying the quantity, including any relevant component, and the chemical entities involved” [123]. The analyst must therefore decide a priori on the compounds to be analysed. Once the “measurand” has been defined, it cannot be changed during the measurement process, since a goal for a measurement must not become a moving target in the course of that process [124].

The CALUX bioassay measures the overall response of the cell to chemical exposure and not individual chemical concentrations. Although highly selective [105], it is not 100% specific for the toxicologically relevant 29 PCDD/Fs and DL-PCBs of interest. Other AhR agonists, which despite all precautions may have made their way through the extraction and clean-up procedures into the final sample extract, and survived metabolism during cell incubation, may, in principle, contribute to the overall response [105]. Due to the possible cross-reactivity of the bioassay with unknown AhR active compounds, it is not possible to decide, before starting the analysis, what exactly will be measured. It follows that we cannot define the measurand and MU cannot be calculated for bioanalytical results, which are therefore—in line with the definition of “measurement result” [123]—expressed as a single measured value. Also based on the concept of a pre-defined measurand are the IUPAC definitions of “bias” and “random error” [125]. When presenting our validation results, we therefore chose the “method comparison bias” instead of the “systematic error” or “bias” as defined by IUPAC. It should be noted that the above considerations can apply to other screening assays as well.

Results and discussion

Reference methods, materials and database

Twisselmann hot extraction [65] combining extraction efficiency and moderate solvent consumption is one of the methods proposed in the recent UNEP Guidance Document on the Global Monitoring Plan for Persistent Organic Pollutants under the Stockholm Convention [126] to support comparability and consistency of monitoring results. Twisselmann extraction has also been selected as the method of choice by CVUA Freiburg’s routine dioxin lab running GC/HRMS confirmatory methods, being tightly linked to the EU-RL for Dioxins and PCBs in Feed and Food (since 08.02.2018 “EU-RL for Halogenated Persistent Organic Pollutants in Feed and Food”), and sharing analytical methods and infrastructure. Solvents used were cyclohexane:toluene (1:1, v/v) for adipose tissue, liver, meat, fish and chicken eggs, n-hexane for raw milk, and ethanol:toluene (70:30, v/v) for homogenized milk and milk products (e.g. butter, cheese). Boiling period was 6–8 h. Fat extracted from homogenized milk was further purified by re-dissolving in MTBE thus separating insoluble components. In all samples, CVUA’s dioxin routine lab had previously quantified extractable lipid contents and the levels of individual PCDD, PCDF and DL-PCB congeners using methods approved by the EU-RL for Dioxins and PCBs in Feed and Food, thus providing an excellent and comprehensive reference database for comparison with the amounts of lipids extracted by MSE (this work) and the bioanalytical results measured from the same samples in our Bioassay Research Lab.

Ultra-Turrax® assisted dispersion

Converting immiscible solvents such as water and cyclohexane together with a pre-homogenized food sample into a dispersion, thereby reducing particle sizes and disrupting cell membranes or the native macrostructure of milk fat globules is a crucial step in the extraction process. Ultra-Turrax assisted high-speed dispersion provides a fast and effective method for disintegration of animal tissue or foods of animal origin in a ternary solvent mixture, in which polar, medium-polar and non-polar solvents are equally distributed. Material suspended in the media is exposed to tearing, shear fluid forces and cavitation [127], the interaction of which rapidly disperses, homogenizes, emulsifies, cuts, crushes and disintegrates. Resulting particle size distributions between 4 and 10 µm [128] considerably increase the overall solvent-accessible surface area. The rotor of the dispersing element acts as a centrifugal pump to recirculate the liquid and suspended solids by drawing them axially into the dispersion head and then forcing them radially through the ports of the stationary stator into the surrounding mixture. A decline of the low pressure near the rotor’s inlet below the saturated vapour pressure of the liquid results in the formation of small vapour-filled cavities. The dispersion carries these “cavitation bubbles” to the surrounding high-pressure area in front of the blades, where they rapidly and violently collapse. This process may result in very high energy densities and in very high local temperatures and local pressures at the surface of the bubbles for a very short time [129]. Rapidly imploding bubbles send out shock waves and form tiny but powerful high-pressure micro-jets of fluid holding a tremendous amount of kinetic energy. When these micro-jets and shock waves hit mammalian cells, they damage and disrupt the cell walls and membranes resulting in an enhanced solvent penetration into the cells and an intensification of mass transfer. The destructive effect of cavitation on mammalian tissue cells down to the subcellular level has been described elsewhere [130]. "Free" lipids and lipids moderately attached or covalently bound and associated lipophilic POPs are released and are now easily available for transition to the organic phase. Ultra-Turrax dispersion of whole milk induces damage and break-up of the MFGMs enveloping the milk fat globules, releasing the di- and triacylglycerols as the main components from their core.

Solvent mixture composition

Our goal was an extensive removal of all lipid classes from each EU-regulated [89,90,91] food sample of animal origin—mainly phospho- and glycolipids, fatty acids, sterols, acylglycerols, etc. A low polarity solvent such as cyclohexane will remove most of non-polar lipids (sterols, acylglycerols), while polar lipids are removed with a medium polar solvent such as propan-2-ol which will also assist in disrupting van der Waals forces or hydrogen bonds between lipid head groups of “bound lipids” and proteins (chapter 1.3). Smedes [46] successfully introduced this approach for lipid extraction from marine tissues, in which a ternary solvent mixture with relative polarities of its components ranging from 0.006 (cyclohexane) to 0.546 (propan-2-ol) to 1.000 (water) was applied. In the liquid–liquid extraction procedure, propan-2-ol being mixable with water and to some extent soluble in cyclohexane will decrease the polarity of water and increase the polarity of unipolar solvent.

In an initial study, for which we selected fish, bovine liver, bovine meat, chicken eggs and whole milk, the method was to be extended and optimized for the extraction of other samples of animal origin. Following Smedes’ approach, a mixture of 16 mL propan-2-ol, 20 mL cyclohexane, 14.5 mL water and 10 g of homogenized sample (assuming a general sample water content of 7.5 mL) was dispersed with an Ultra-Turrax at 10,000 rpm. The ratio of cyclohexane to fresh sample weight being 2:1 (v/w), the overall solvent ratio was 8:10:11 (v/v/v). The presence of considerable amounts of surfactant-like compounds such as triglycerides, free fatty acids, phospholipids, proteins, etc., lowering the surface tension between water, water-soluble matrix compounds and the organic solvents, often led to the formation of rather stable emulsions above a clear water phase. Such emulsions are particularly common in samples where the diet of the source animal is high in fat [131], which is why we included high-fat bovine meat in our studies. Emulsions not only make quantitative collection of the phase of interest difficult, they can also trap some of the target analyte(s). The classical method for disrupting emulsions by adding salt(s) or salt water to increase the ionic strength of the aqueous phase with subsequent shaking and several minutes of standing time appeared too time consuming for a high-throughput routine laboratory. Centrifugation as employed by Smedes [46] can easily take up to 20 min to complete and should therefore also be avoided if possible. Freezing the water layer to cause phase separation is both time-consuming and less effective here, since the emulsion to be separated is already located above a clear layer of water consisting mainly of cyclohexane, propan-2-ol and disintegrated sample material. Unfortunately, the straightforward approach of increasing the volume of one solvent or another to achieve separation was not successful.

We therefore changed the ratio of cyclohexane to the fresh sample mass to 4:1 (v/w) for fish, bovine liver, bovine meat and chicken eggs and 32 mL propan-2-ol, 40 mL cyclohexane and 44 mL water (including 7.5 mL water in the sample) were used, while the overall solvent ratio remained 8:10:11 (v/v/v). First propan-2-ol, then cyclohexane and, after brief homogenization of the mixture, finally the water should be added to the weighed sample. This prevents the sample material from sticking to the glass wall of the vessel, or clumping. For meat and milk, the sample size was eventually increased to 15 g, and 30 g, respectively (Table 2) to ensure that the extracted lipid amounts were sufficient (> 0.2 g) for the subsequent analysis of POPs, even in samples with lower fat content. While keeping the cyclohexane volume constant, the volumes of the propan-2-ol and water fractions were systematically varied and phase separation and lipid extraction efficiency for fish, bovine liver, bovine meat and chicken eggs proved best when using an 8:10:8 (v/v/v) propan-2-ol:cyclohexane:water mixture with a significantly reduced water fraction (Table 3). For milk, however, the optimal solvent ratio was found to be 8:10:12 (v/v/v). After dispersion of each matrix, phase separation was facilitated by rinsing the rotor–stator device with 7–8 mL propan-2-ol, which we let carefully pass into the organic layer, followed by gentle circular swirling of the vessel on the worktop to complete phase separation. The additional amount of propan-2-ol changes the overall propan-2-ol–cyclohexane–water ratio effective at phase separation (Table 3).

Following this procedure, distinct phase separation spontaneously occurred with meat, egg and milk dispersions within less than 30 s and lipid extraction was complete after two repetitions (Table 2). In liver and most frequently in fish, dispersions phase separation required up to three minutes and even then was incomplete. In such cases, a few more mL propan-2-ol were added directly to the emulsion formed between the aqueous and organic layers with a pipette. This small amount of propan-2-ol appeared to adjust the solvent properties for separation, causing surfactant-like compounds to dissolve more readily in either the organic or aqueous layer, which helped break up the emulsion. Repeated circular swirling generally allowed 25–30% of the previously added cyclohexane volume to be collected while three repetitions were required for complete extraction of the "total" lipids and lipophilic POPs from liver or fish tissue, during which phases separated spontaneously. An increase of the propane-2-ol volume by the same 7–8 mL already before sample dispersion, however, had no supporting effect on the separation of the cyclohexane layer. If, in rare cases, still less than 25% of the previously added cyclohexane can be removed in the first extraction, the analyst may, as is routinely required in Smedes’ method [46], resort to the rather time-consuming centrifugation of the mixture at 450–480×g.

The method was extended to fat, fish oil, milk fat, butter and similar sample matrices, reducing the water fraction to a solvent ratio of 8:10:6 (v/v/v), and to various commercial infant foods, for which the solvent ratio of 8:10:8 (v/v/v) exhibited optimal performance.

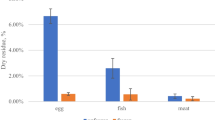

Extraction efficiency

We evaluated the efficiency of each consecutive extraction by applying the enhanced procedure described in this paper to five basic types of foods of animal origin considered analytically challenging in terms of texture, complexity, lipid and protein composition, release of lipids and targeted POPs, emulsion formation or co-extraction of interfering compounds. For sample amounts, solvent volumes and composition see Tables 2 and 3. Lipid extraction profiles were established in duplicate under within-lab reproducibility conditions for pre-homogenized chicken eggs, fish (brown trout), bovine liver, bovine meat (beef neck), and for cow’s whole milk (Fig. 4). The results presented are only examples and may vary depending on the width of the extraction vessel affecting the layer thickness of the formed phases, the extent of emulsion formation, if any, and the pipetting technique. Total extracted lipids are compared in Fig. 5 with the results of Twisselmann’s hot extraction [65] serving as a “reference” method within this study.

Lipid extraction profiles (in duplicate) from applying the modified Smedes [46] extraction (MSE, this work) under within-lab reproducibility conditions for chicken eggs, fish meat (brown trout), bovine liver, bovine meat (beef neck) and cow’s whole milk. Amounts are given in % of total extracted lipids

Cow’s whole milk Within just 15 s of dispersion of 30 g milk with an 8:10:12 (v/v/v) propane-2-ol:cyclohexane:water mixture at 10,000 rpm, more than 90% of the "total" lipids entered the cyclohexane phase. The subsequent two extractions yielded 6–8%, and below 2%, respectively. The cyclohexane separated spontaneously on top of the mixture following each dispersion. Total extracted lipids (4.2% of the fresh sample weight) corresponded well with results from the Twisselmann extraction (4.3%). The high efficiency and precision of our modified Smedes extraction (MSE) was confirmed within the scope of verifying the authenticity of organic milk using stable isotope analysis [132]. The results are in good agreement with those obtained from the Röse-Gottlieb reference method [81] but are available much faster.