Abstract

This work reveals a modified method for the preparation of activated carbon (P-ACA) using low-cost materials (mix natural asphalt: polypropylene waste). The P-ACA was prepared at 600 °C by assisting KOH and HF. The morphological variations and chemical species of the P-ACA were characterized using SEM–EDX and FTIR. The active surface area, density and ash content of the P-ACA were also investigated. Adsorption properties of P-ACA were used for the thermodynamic and kinetic study of 4-((2-hydroxy naphthalenyl) diazenyl) antipyrine (HNDA), which was prepared as a novel azo dye in this work. The optimal conditions (initial concentration, adsorbent dose, contact time and temperature) of the adsorption process were determined. Adsorption isotherms (Freundlich and Langmuir) were applied to the experimental data. These isothermal constants were used to describe the nature of the adsorption system, and the type of interaction between the dye and the P-ACA surface. The results have indicated that the mixture (Natural asphalt-polypropylene waste) is efficient for the synthesis of P-ACA. The synthesized P-ACA demonstrates the presence of pores on the surface with various diameter ranges (from 1.4 to 4.5 μm). Furthermore, P-ACA exhibits an active surface area of 1230 m2 g−1, and shows a high adsorption capacity for HNDA.

Similar content being viewed by others

1 Introduction

Pollution is a hazardous and difficult issue that currently confronts the world resulting from industrial revolutions. This has raised pollution to higher levels than the normal standard, thus creating an imbalance in the environment and increasing the risk level of pollution. This level of pollution has necessitated the need for substantial treatment and amelioration techniques [1,2,3]. Water pollution is the most hazardous type of pollution since it plays a crucial role in the lifecycle; hence, it is a fundamental component in a variety of related studies. Azo dyes are one of the largest groups of dyes which are extensively synthesized and utilized in numerous industries due to their high stability and several unique colors. However, most azo dyes are toxic and harmful to human health, which they should be treated before being released to the environment [4,5,6,7]. Several approaches have been employed for the removal of these dyes from wastewater, but they are negated by their high costs and toxic effects. Adsorption is a technique used conventionally to remove the dye. It is cost-effective and entails a simple procedure [8,9,10,11]. Activated carbon is extensively utilized as dyes sorbent, although its potential wide application is hindered by its high cost. Hence, there is a need to produce cost-effective activated carbon with accessible raw materials [12,13,14,15,16].

Asphalt is extracted industrially from the non-destructive distillation of crude oil; sometimes it emerges naturally as heavy oil on the surface of the earth [17]. Asphalt is a mixture of hydrocarbons (aliphatic and aromatic compounds) and has a small amount of heteroatoms in its backbone [18]. The addition of polymer to the high shear blender results in the dispersion of polymer pellets into the fine particles and, hence, the polymer surface is larger in the continuum asphalt process [19]. The most important polyolefin in asphalt modification is polypropylene [20]. The reaction of the polymer and the asphalt contributes to the swelling of the polymer by absorbing the light oily components found in asphalt [21, 22].

The natural asphalt used in this work is sourced from the deposition of asphalt materials in western Iraq, which is found in millions of tons of quantities. It is used for heat isolation and waterproof coating for the roofs of the houses because of its high abundance and low cost. Therefore, this work aims to synthesize efficiently activated carbon from a mixture of asphalt and waste polymers, which will be used as a cost-effective adsorbent to eliminate contaminants.

2 Experimental

2.1 Materials

The raw asphalt, (Penetration 28 mm), (Softening Point 60 °C), (Specific gravity 1.05), has been obtained from natural deposits asphalt western Iraq. Polypropylene was collected from the local waste dump in Hit, Iraq. The waste polypropylene has been washed with purified water several times to remove the adhered contaminants from its surface. It was dried, crushed and sieved by 75 μm mesh. All chemicals and solvents used in this work were supplied from Sigma Aldrich (Germany).

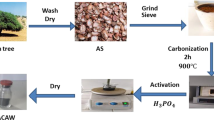

2.2 Modification of rheological properties of Asphalt using polypropylene

This involved the distillation of 1000 g of asphalt stones at low pressure (20 mmHg), followed by treatment of the resulting residue with 0.5% polypropylene. The mixing process was carried out at 180 °C for 30 min. The sample was then put in a microwave oven set at 360 W for 15 min.

2.3 Preparation and characterization of P-ACA

The modified asphalt was put in a pottery basin and mixed with KOH at a ratio of 1:1. The mixture was stored at 600 °C for 3 h. The alkaline and metallic contaminants of P-ACA were removed by washing with distilled water (DW). The carbon was refluxed with 10% HF for 5 h to eliminate the ions. Afterwards, the sample was directly filtered and washed with DW several times to achieve pH neutrality. The P-ACA was subsequently dried in an oven (set at 120 °C) for 24 h, then crushed and separated using molecular sieves of 75 μm mesh. The P-ACA was characterized (density and ash content) in line with ASTM standard procedure. Scanning electron microscopy–energy-dispersive (SEM–EDX) and Fourier-transform infrared spectroscopy (FTIR) were used to investigate morphological variations and chemical species in P-ACA and its components.

2.4 Preparation of HNDA

To prepare HNDA, a solution of 0.01 M 4-Aminoantipyrine (dissolved in concentrated HCl) mixed with 2 ml distilled water (DW) was continuously stirred at a constant temperature range (0–5 °C). This step was accompanied by the gradual addition of 0.015 M NaNO2 dissolved in 5 ml DW at a constant temperature range (0–5 °C) for the synthesis of dizonium salt [23, 24].

For the preparation of the β-naphthol solution, 9 ml of 10% NaOH solution was added to 0.015 mol β-naphthol at a constant temperature range (0–5 °C). The final step involved the dropwise addition of the dizonium salt to the β-naphthol solution. The resulting solution was continuously stirred until the desired dye crystal was formed. The mixture was then kept for 30 min in an ice bath to produce the dye, which was subsequently filtered and aerated at 80 °C for 2 days (Table 1).

2.5 Preparation of stock solution

A dye stock solution was prepared with a concentration of (4 × 10–4 M) in a mixed solution of 50% ethanol/water. This was achieved by dissolving a specific weight of dye in 50 ml ethanol, which was then diluted with distilled water to 100 ml. Subsequently, this solution was utilized to prepare other solutions of lower concentrations. The wavelength was measured for the maximum absorption (λmax) for the dye using the same ratio of ethanol/water mixture as blank.

2.6 Estimation of adsorbate

The amount of adsorbed dye was described using adsorption efficiency (%adsorption) and capacity (qe mg g−1) via the estimation of the remaining dye concentration in the solution after adsorption Eqs. (1 and 2). These parameters were derived from the calibration curve obtained at the maximum absorption (λmax) of the dye.

where Ci denotes the initial concentration of the dye (mg L−1), Ce represents the concentration of the residual dye in the solution at equilibrium, m is the weight of the P-ACA, and V is the volume of the dye solution utilized in the adsorption process.

2.7 Adsorption isotherms

The determination of the adsorbent dose involves the shaking of three different weights of P-ACA in a dye solution of 4 × 10–4 M concentration at 20 °C and neutral pH for 70 min. The effect of concentration was investigated by constant shaking of 20 ml of five different concentrations of the dye solution (2 × 10–4–6 × 10–4 M) containing 0.01 g of P-ACA for 70 min. On the other hand, the effect of temperature was examined by shaking the mixture of 0.01 g P-ACA in 6 × 10–4 M dye solution for 70 min over a temperature range of 20–60 °C. The solutions were then subjected to filtration, followed by the measurement of adsorption efficiency and capacity.

2.8 Determination of the thermodynamic functions

The adsorption equilibrium constant (K) was calculated for different temperatures at equilibrium from the ratio between the concentrations of adsorbed in solution. The adsorption enthalpy was calculated using Vant Hoff equation (Eq. 3), which articulates the relationship between the equilibrium constant and temperature.

where ∆H denotes adsorption enthalpy. K and Ko represent adsorption equilibrium and constant value, respectively.

The value of ∆H is derived from the slope of the linear relation between (lnK) and (1/T). The other thermodynamic functions (∆S°, ∆G°) are calculated using the following equations:

3 Results and discussion

3.1 Characterization of P-ACA

The asphalt components were modified using polypropylene to increase the bond between the polymer and the condensed aromatic rings in asphalt molecules. This could increase the alkyl fraction in asphalt molecules and change its chemical structure. The reaction of functional groups in waste polypropylene with asphalt increases its molecular weight, which can be attributed to the binding of the high-molecular-weight polymeric molecules with asphaltic compounds. The presence of polymers also enhances the quality of inner and external pores of activated carbon, thereby improving the porous structure [25, 26].

At high temperature, hydroxide ion (KOH) plays a key role in the activation process, which involves the expansion of the minute pore structure of the precursor material utilized in the production of activated carbon. The carbonization process necessitates slow heating to 350 °C for an hour to enable the KOH to reach its melting point so it can mix completely with the residual material from the vacuum distillation. The heating temperature is then increased to 600 °C for 2 h. The yield of P-ACA is 81% (Table 2), which confirms the industrial and commercial preference for the use of mixed asphalt polymers in the production P-ACA. The height surface area of P-CAC is 1230 m2 g−1. The effectiveness of activated carbon in adsorbing gas is directly related to its pores and internal surface area. Therefore, the large pores and active area of P-CAC (Fig. 1b) support its potential use to actively control the gas pollutants that are hazardous to the environment. Also, it is observed the lower density (0.554 g cm−3) and ash content (1.20%) of P-CAC compared with commercial activated carbon (B.D.H). Therefore, the results confirm that the methodology can be selected to synthesize high-quality activated carbon capable of adsorbing small particles.

The natural asphalt used in this study is a homogeneous mass of hydrocarbons with no significant variations in the surface morphology (Fig. 1a). Figure 1b indicates the presence of large pores with various diameters on the outer surface of the P-ACA. The pores’ diameter ranges between 1.4 and 4.5 μm. The random distribution of pores led up to high and rapid adsorption of HNDA.

The asphalt comprises a mixture of organic components (carbon and sulfur atoms) and small amounts of trace elements (Al, Ba, Ca, Cl, Na, Mg, Si), as shown in Fig. 2a. The low ash content (Table 2) is attributable to the use of the reflux process with 10% HF solution, which aids the elimination of bulk of the metallic components (trace elements) either present in the starting material (Fig. 2b). Other minor occurrences in the residue include fluorine ions (0.4%), which denotes the HF used in the activation process, and calcium (2.45%) and sulfur (1.32%), both from the raw materials. This shows that both physical and chemical adsorptions can occur concurrently on P-ACA because of their chemical composition.

The FTIR spectrum of natural asphalt is presented in Fig. 3a. The absorption peak at 815 cm−1 denotes the presence of the covalent Si–C bond. The peak at 1154 cm−1 is assigned to the Si–O bond. There are absorption peaks at 1030, 1373, 1454, 2851 and 2920 cm−1 that are attributed to a homogeneous and heterogeneous bending vibration of methyl groups in the raw material. The absorption band at 1610 cm−1 signifies the successive double bonds in the aromatic loops of C=C stretching vibration. The peak at 3090 cm−1 may be assigned to stretching vibration of the (=CH) group, indicating the presence of aromatic compounds in the asphalt [27, 28]. The absorption pack at 720 cm−1 is related to C–S stretching vibration, which affirms the presence of sulfur compounds, whilst the absorption peak at 1130 cm−1 specifies the attachment of chlorine ions to carbon atoms (C–Cl group). The chlorine is sourced from salts and by heat and light, where some hydrogen atoms are substituted with chlorine atoms [29,30,31,32]. The broad absorption band at 3414 cm−1 confirms the presence of oxygen as the hydroxyl (–OH) group [29] in the carboxylic acid (salicylic acid) present in the asphalt. The peaks at 450, 550 and 610 cm−1 can be due to the empty orbitals of Al, Ba, Ca, Mg and Na ions in the form of silicates coupled with sulfur and oxygen atoms in the raw material, as is confirmed by the SEM–EDX spectrum (Fig. 1a).

The FT-IR spectrum for P-ACA is shown in Fig. 3b. The characteristic peaks for silica and its compounds are absent due to the use of HF. The presence of a peak at 1250 cm−1 denotes a weak CF stretching vibration, which is attributed to the small quantities of residual HF during the activation process of P-ACA (Fig. 2b). The disappearance of the typical peaks of (C–O) and (C–Cl) groups can be ascribed to the loss of hydrogen atoms from high-electron negative atoms by the heating process. The very weak peak at 750 cm−1 is related to the stretching vibration of the CS group, which confirms the presence of a small quantity of sulfur compounds.

3.2 Characterization of HNDA

The azo dye was synthesized using 4-aminoantipyrine as a base. The diazotization process starts with the conversion of aromatic amine to dizonium salt at low temperatures in the presence of NaNO2 and HCl, which is followed by the reaction of the produced dizonum compound with the coupling agent (phenol) to form the dye [33]. HNDA was examined using a variety of spectroscopic measurements.

The FTIR spectrum (Fig. 4) displays a distinct peak at the range of 1676–1598 cm−1, which can be assigned to the stretching vibrations of carbonyl groups. The adsorption signal discernible at the range of 1593–1481 cm−1 signifies the –N=N– stretching vibrations of the azo compound, while the ultraviolet spectrum shows a higher absorption band at 454 nm wavelength.

The mass spectrometry (Fig. 5) shows signs of fragmented molecular masses. Each molecular mass is indicative of the potential breakdown in the chemical composition of the prepared dye. The relative abundance of the fractured formula is 100% at a signal of 56 m/z, which is assigned to the (N–N–C=O) group broken from the pentagonal ring. The presence of HNDA within the fractured structures is confirmed by the presence of the 28 m/z molecular mass due to the nitrogen molecule (N2) released after the fracture. The other fragments are shown in Table 3 and Fig. 5.

The 1H-NMR proton of HNDA (Fig. 6) shows a singlet signal at 2.64 ppm, which is assigned to the three protons of (N–CH3) group, while the singlet signal at 3.28 ppm signifies the three protons of (=C–CH3) group. Also, the multiplet signals in the region of 7.70–7.06 ppm are assigned to aromatic protons (11H) for rings within the dye structure. There is a singlet signal at 8.70 ppm, which denotes the hydroxyl group (OH).

The 13C-NMR spectrum of dye (Fig. 7) shows a singlet at 11.79 ppm which confirms the presence of carbon (N–CH3) group, while the singlet at 34.77 ppm specifies the presence of carbon group (=C–CH3). The multiplet signals in the range of 134.01–113.58 ppm are assigned to aromatic carbon rings, while the singlet at 147.26 ppm indicates the presence of (=C–CH3) carbon group. The singlet at 155.32 ppm and 172.48 ppm are assigned to (–N=N–C=) and (C=O) carbon groups, respectively.

3.3 Thermodynamic study of HNDA adsorption on P-ACA

The conditions of the adsorption system have been optimized to achieve the objectives of this study. The conditions include contact time, initial concentration, adsorbent dose and temperature. This method involves the derivation of a calibration curve at its maximum wavelength (454 nm) by the preparation of the dye solution within the range of concentration of (1 × 10−4–1 × 10–5) M that is compatible with the color intensity of the dye. The calibration curve was generated according to Lambert Beer’s law.

The effect of adsorbent dose was investigated to determine the optimum amount of the adsorbent material required by the system to attain equilibrium without the overall removal of the dye color. Figure 8a indicates that the adsorption capacity decreases with an increase in the amount of adsorbent at a fixed volume, which is followed by an increase in adsorption efficiency. This phenomenon is possibly due to an increase in the active sites on the solid surface as the amount of activated carbon increases. 0.5 g of P-ACA is the optimum dose selected for further studies [34].

The effect of contact time was also studied to determine the period required to attain an equilibrium, which is needed to calculate the thermodynamic functions as well as in the application of adsorption isotherm equations. In addition, the change in the adsorption rate with time (till equilibrium is attained) is considered a key parameter in the adsorption kinetics. The effect of time was studied over different durations (10–70 min) under a constant concentration (3 × 10–4 M), neutral pH, the temperature of 20 °C, and 20 ml of dye solution containing 0.01 g of the activated carbon that is agitated at a speed of 100 rpm.

Figure 8b shows that the adsorption process was initially fast, and then started to slow down until equilibrium was gradually attained [35]. This implies that the adsorption rate of the adsorbate bounded to the adsorbent surface is equal to the desorption rate of molecules from the adsorbent surface into the solution. The studied dye attained equilibrium in approximately 60–70 min. Hence, this study time of 70 min was chosen for further studies.

The effect of initial concentration was also investigated using 0.01 g of P-ACA in the range of (2 × 10–4–6 × 10–4) M at constant temperature and pH. With increasing concentration, the adsorption capacity increased, but the adsorption efficiency decreased (Fig. 8c). This can be explained as follows: at the start of the process, the increase of the concentration leads to increase the number of available molecules for adsorption, as well as the availability/increase of adsorption locations on the solid surface. Over time, the dye molecules compete to be connected to the rest as the active location on the surface increases. The increase in concentration results in a higher displacement of the dye molecules in solution after equilibrium. This will lower the adsorption efficiency calculated from the ratio between the initial concentration of the adsorbate and the residual quantity in solution, as expressed by Eqs. (5) and (6) [12].

Based on the above results, the concentration of 3 × 10–4 M was chosen for the subsequent studies since it has an intermediate effect on the adsorption efficiency and capacity. In addition, the color is retained in an acceptable range for this concentration.

The effect of temperature was studied over a range of 20–60 °C at a concentration range of 4 × 10–4–6 × 10−4 M, neutral pH, and 20 ml of dye solution containing 0.01 g of the activated carbon. The solutions were shaken for 70 min at a velocity of 100 rpm.

In general, at a constant concentration, the adsorption efficiency and capacity decreased with increase in temperature from 20 to 60 °C (Table 4). The temperature increase causes the displacement of the dye molecules from the adsorbent into the solution (desorption) [36]. This phenomenon arises from the disruption of the binding force between dye molecules and adsorbent surface, which confirms the physical nature of the adsorption process. The effect of temperature was investigated over different concentrations to calculate thermodynamic functions, which will then be applied to the data of adsorption isotherms to determine the changes in the driving force of adsorption process.

3.4 Calculation of thermodynamic functions for adsorption process

The thermodynamic analysis defines the nature of the system under investigation, as well as the type of the driving force controlling the adsorption process. In addition, it conceptualizes the kind of molecule interactions that arise in the course of the adsorption. It also serves an important role in determining the efficiency of the adsorption process. Adsorption enthalpy (∆H) is a parameter that directly measures the intermolecular force between the adsorbate molecules and the adsorbent surface [37]. The thermodynamic analysis was performed based on the change in adsorption capacity with temperature. The calculation of the thermodynamic functions was performed over a temperature range of 293–333 K, initial concentration of 3 × 10–4 M and neutral pH using 0.01 g of prepared activated carbon. The sample was shaken for 70 min at a speed of 100 rpm. This procedure was repeated several times under similar conditions using different initial concentrations ranging from 4 × 10–4 to 6 × 10−4 M. The linear relationship between ln K versus 1/T derived from the application of the Vant Hoff equation is utilized to calculate changes in adsorption enthalpy of the dye. The thermodynamic functions (K, ΔG°, ΔH, ΔS°, ΔS) are presented in Table 5.

Table 5 shows that the adsorption system is exothermic, implying that the adsorption is a chemical reaction that releases energy through the heating process. The van der Waal force is the driving force that controls the adsorption process. The exothermic nature of the adsorption is indicated by the negative sign of ∆H. This also indicates that the adsorption process occurs simultaneously in the direction of adsorption, which is similarly indicated by the negative sign of ΔG. The values of ΔS denote a reduction in the randomness of the system.

3.5 Adsorption isotherms

Freundlich isotherm was used to fit the experimental results of the studied dye, according to Eq. 13 [38, 39]. The relationship between log qe versus log Ce was plotted. Freundlich constants (Kf, n) were derived from the slope and intercept, respectively. Table 6 shows the experimental data that follow the Freundlich isotherm equation, as specified by the correlation coefficient values (0.966–0.996). The n values range from 1 to 10, meaning that the adsorption system being investigated is positive and can be controlled by physical forces.

Langmuir isotherm is valuable for describing the adsorption systems. For the mono-layer adsorption, the isotherm suggests that the energy is homogeneously distributed on the adsorbent surface at a constant temperature. It also gives information about the adsorbent presuming maximum capacity for adsorption (Qmax) [40, 41].

The relationship between Ce/qe and Ce gives a straight-line plot with slope (1/Qmax) and intercept (1/b Qmax). The constants b, Qmax could then be calculated,

where b denotes a factor related to the connection force between dye and adsorbent surface, and Qmax represents the maximum theoretical adsorbent capacity (mg g−1).

Table 6 shows that the application of Langmuir isotherm provides an excellent linear relationship for the studied dye. Thus, it has more applicability on the experimental data compared to the Frendlich isotherm, which is evident from the correlation coefficients (R). The Langmuir constant (b) values are related to the binding force between the dye and activated carbon surface. The Langmuir constant values decrease with increase in temperature. The results support the physical nature of the investigated system, as well as the theory that Langmuir isotherm is effective for deciphering adsorption systems. It can also be observed that the Qmax values are unaffected by the variation in temperature. Langmuir isotherm has a special character that can be expressed as dimensionless constant separation factor (RL), which is presented in the underlying Eq. (9) [40, 41].

Table 6 presents the calculated RL values at all initial concentrations and at a temperature range of 20–60 °C. The values fall within the range of (0 < RL < 1), which indicates that the adsorption occurs within the studied range. Furthermore, the RL values decreased with an increase in initial concentration. However, RL values are oscillating with temperature variation, with the values moving toward an undesirable shape. This implies the interactive force between the dye and activated carbon was weakened with temperature and desorption occurred, resulting in an increase in RL value. This is indicative of the physical nature of the adsorption system. As RL values decrease with increased concentration, the system investigated in this study becomes closer to the irreversible shape. This offers an indication of the effectiveness of the adsorption process when the research is conducted at low concentrations.

3.6 Adsorption kinetics

Pseudo first-order, pseudo second-order, Elovich and intraparticle diffusion kinetic models were applied to the adsorption kinetic data to decipher the behavior of HNDA during the adsorption on P-ACA.

The pseudo first-order kinetic model expressed as:

where qe and qt are the adsorption capacities (mg g−1) at equilibrium and t, k1 is the rate constant (min−1).

The relationship between ln(qe − qt) versus t gives a straight line. The rate constant k1 is derived from the slope of the straight line. Table 7 shows that the adsorption system does not adhere to the pseudo first-order, as indicated by the R2 value and the incongruity between qe (cal) and qe (exp) values.

The pseudo second-order kinetic model is articulated by Eq. 11 [42].

Table 7 indicates a linear relationship between t/qt and t, as indicated by the R2 value and the incompatibility between the qe (cal) and qe (exp) values. The results also indicate that the adsorption system follows the pseudo second-order kinetic model.

The Elovich model is expressed by Eq. 12.

A linear relationship was obtained between qt and ln t with a slope β/1 and an intercept of β/1 ln (αβ). From Table 7, the α (initial adsorption rate (mol g−1 min−1)), β (adsorption constant (g mol−1)) and R2 (correlation coefficients) values indicate that the Elovich Kinetic model is inconsistent with the experimental data.

The Intra-particle diffusion model is expressed by the following equation:

where Kdiff (mol g−1 min−1/2) denotes the diffusion rate constant, C (mol g−1) represents a value that is proportional to boundary layer thickness, and t1/2 is the intercept (mol g−1).

The Kdiff values are derived from the slopes of qt versus t1/2 plots. Generally, the applicability of the intraparticle diffusion model suggests it is a rate-determining step. However, the application of this model in this study provides a linear relationship, although the line does not pass through the origin. This indicates that intraparticle diffusion is not the sole mechanism to control the adsorption process of the systems under consideration.

The study of intraparticle diffusion (Fig. 9) indicates that the adsorption process comprises two steps. The first step is a rapid attachment of dye onto the external surface of activated carbon at the onset of adsorption. The second step is a slower process that involves the diffusion of the molecules of the dye into the existing pores on the carbon surface. Thus, the intraparticle diffusion is not a rate-limiting step, and the adsorption surface is produced simultaneously in the course of the dye–carbon interaction.

4 Conclusion

Asphalt stones (available in huge amount in Iraq) are modified using waste polypropylene rich with elemental carbon to synthesize activated carbon. The adsorption properties of P-ACA have been used for thermodynamic and kinetic study of novel azo dyes HNDA. The yield and active surface area of P-ACA are 81% and 1230 m2 g−1, respectively, which confirms the industrial and commercial preference of using mix asphalt polymers to produce P-ACA. The application of Langmuir isotherm provides an excellent linear relationship for the studied dye. Thus, it has more applicability on the experimental data compared to the Frendlich isotherm, which is evident from the correlation coefficients (R), and these results support the physical nature of the system under investigation. Adsorption kinetics shows that the adsorption system follows the pseudo second-order kinetic model.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Min J, Kim Y, Lee S, Jang T, Kim I, Song J (2019) The fourth industrial revolution and its impact on occupational health and safety, worker's compensation and labor conditions. Saf Health Work. https://doi.org/10.1016/j.shaw.2019.09.005

Mohammed MI, Yousif SW, Rabeea MA (2018) Physiological and biochemical changes analysis to labors blood samples in plastics recycling factory in Mosul-Iraq. J Global Pharma Technol 10(06):281–288

Bayan MH, Muwafaq AR, Marwan MF (2020) Characterization and behavior of hydrogen sulfide plumes released from active sulfide-tarsprings, Hit-Iraq. Atmos Pollut Res 11:894–902. https://doi.org/10.1016/j.apr.2020.02.001

Ribeiro AR, Umbuzeiro GA (2014) Effects of a textile azo dye on mortality, regeneration, and reproductive performance of the planarian, Girardia tigrina. Environ Sci Eur 26(1):22

Wu F-C, Tseng R-L (2008) High adsorption capacity NaOH-activated carbon for dye removal from aqueous solution. J Hazard Mater 152:1256. https://doi.org/10.1016/j.jhazmat.2007.07.109

de Campos Ventura-Camargo B, Marin-Morales MA (2013) Azo dyes: characterization and toxicity—a review. Text Light Ind Sci Technol 2(2):85–103

Hernández-Zamora M, Martínez-Jerónimo F (2019) Congo red dye diversely affects organisms of different trophic levels: a comparative study with microalgae, cladocerans, and zebrafish embryos. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-019-04589-1

Katheresan V, Kansedo J, Lau SY (2018) Efficiency of various recent wastewater dye removal methods: a review. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2018.06.060

Rabeea MA, Owaid MN, Aziz AA, Jameel MS, Dheyab MA (2020) Mycosynthesis of gold nanoparticles using the extract of Flammulina velutipes, Physalacriaceae, and their efficacy for decolorization of methylene blue. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2020.103841

Krasnova TA, Belyaeva OV, Gorelkina AK et al (2020) Trichloroethylene adsorption from aqueous solutions by activated carbons. Carbon Lett 30:281–287. https://doi.org/10.1007/s42823-019-00096-y

Al-Kdasi A, Idris A, Saed K, Guan CT (2005) Treatment of textile wastewater by advanced oxidation processes—a review. Glob Nest Int J 6:222–230

Bal Altuntaş D, Nevruzoğlu V, Dokumaci M et al (2020) Synthesis and characterization of activated carbon produced from waste human hair mass using chemical activation. Carbon Lett 30:307–313. https://doi.org/10.1007/s42823-019-00099-9

Muwafaq AR, Rasim FM, Atyaf AY (2017) Preparation activated carbon from Biji refnery asphalt treated with sulfur and waste polymers. Int J Appl Eng Res 12:14783

Muslim RF, Rabeea MA, Zaidan TA (2019) Properties improvement of activated carbon prepared from Hit natural asphalt by phenol formaldehyde polymer waste. Res J Pharm Technol. https://doi.org/10.5958/0974-360X.2019.00497.9

Rabeea MA, Zaidan TA, Ayfan AH et al (2019) High porosity activated carbon synthesis using asphaltene particles. Carbon Lett. https://doi.org/10.1007/s42823-019-00086-0

Kosheleva RI, Mitropoulos AC, Kyzas GZ (2019) Synthesis of activated carbon from food waste. Environ Chem Lett 17:429. https://doi.org/10.1007/s10311-018-0817-5

Simon IA, James GS (2001) Petroleum resins: separation, character, and role in petroleum. Pet Sci Technol 19:1–2. https://doi.org/10.1081/LFT-100001223

James GS (2004) Petroleum asphaltenes—part 1: asphaltenes, resins and the structure of petroleum. Oil Gas Sci Technol 59:467

Jasso M (2016) The mechanism of modification and properties of polymer modified asphalts (unpublished doctoral thesis). University of Calgary, Calgary, AB. https://doi.org/10.11575/PRISM/28244m

Tayfur S, Ozen H, Aksoy A (2007) Investigation of rutting performance of asphalt mixtures containing polymer modifiers. Constr Build Mater 21(2):328–337

Speight JG, Yen TF, Chilingarian GV (1994) Asphaltenes and asphalts, 1. Dev Pet Sci 40:7–8

Upadhyay S, Mallikarjunan V, Subbaraj VK, Varughese S (2008) Swelling and diffusion characteristics of polar and nonpolar polymers in asphalt. J Appl Polym Sci 109(1):135–143

Prabhat KB, Pooja J, Chauhan RS, Goswami AK (2011) Synthesis, characterization and activity prediction of some new class of hydroxytriazenes. Int J Chem Sci and Tech 1:1–4

Vogel I (1964) A Textbook of practical organic chemistry, 3rd edn. Longmans, Green and Co. Ltd., London, pp 622–623

Makomaski G (2018) Porous structure and thermal properties of carbon adsorbents from pitch–polymer compositions. J Therm Anal Calorim 133:1345. https://doi.org/10.1007/s10973-018-7209-8

Makomaski G (2016) The preparation of porous materials from waste polymers-modified carbon bitumens. Przem Chem 95:1378–1380. https://doi.org/10.15199/62.2016.7.19

Mistry B (2009) Handbook of spectroscopic data CHEMISTRY (UV, JR, PMR, JJCNMR and mass spectroscopy). Oxford Book Company, Oxford, pp 26–56

Lee SM, Bae BS, Park HW, Ahn NG, Cho BG, Cho YL, Kwak YS (2015) Characterization of Korean Red Ginseng (Panax ginseng Meyer): history, preparation method, and chemical composition. J Ginseng Res 39(4):384–391. https://doi.org/10.1016/j.jgr.2015.04.009

Silverstein R, Webster F, Kiemle D (2005) Spectrometric identification of organic compounds, 7th edn. Wiley, Hoboken, pp 72–126

Nakamoto K (2009) Infrared and raman spectra of inorganic and coordination compounds part A: theory and applications in inorganic chemistry, 6th edn. Wiley, Hoboken

Field L, Stern S, Kalman J (2008) Organic structures from spectra, 4th edn. Wiley, Hoboken, pp 15–20

Simek J (2013) Organic chemistry, 8th edn. Pearson Education Inc, London, pp 412–414

JA Al-Meamary (2017) Synthesis of some 4-amine antipyrine derivatives and their biological activity. Ph.D. Thesis, University of Mosul, Iraq

Al-Hyali E, Al-Abady R (2013) Kinetic and equilibrium study of adsorption of di-azo dyes on commercial activated carbon. Pak J Sci Ind Res Ser A Phys Sci 56:70–85

Dima AA (2008) Adsorptive removal of reactive azo dyes using industrial residue. M. Sc. Thesis, University of Addis Ababa

Aksu Z, Tezer S (2000) Equilibrium and kinetic modelling of biosorption of Remazol Black B by Rhizopus arrhizus in a batch system: effect of temperature. Process Biochem 36:431–439. https://doi.org/10.1016/S0032-9592(00)00233-8

Peláez-Cid AA, Hernández VR, González AMH, Bautista-Hernández A, Coreño-Alonso O (2019) Synthesis of activated carbons from black sapote seeds, characterization and application in the elimination of heavy metals and textile dyes. Chin J Chem Eng. https://doi.org/10.1016/j.cjche.2019.04.021

Freundlich H (1906) Uber die adsorption Isoungen. Z Phys Chem 57:385

Knaebel KS (2003) Adsorbent selection, Adsorption research. Inc, Dubiln, pp 1–23

Theivarasu C, Mylsamy S, Sivakumar N (2011) Coca shell as adsorbent for the removal of methylene blue from aqueous solution kinetic and equilibrium study. Univers J Environ Res Technol 1:70–78

Keskinkan O, Balci B (2013) Adsorptive removal of dyes using crude tree barks: equilibrium isotherm and kinetics. Asian J Chem 25:4693–4698

El Ashtoukhy ESZ (2009) Loofa Egyptiaca as a novel dye from aqueous solution. J Environ Manage 90:2755–2761. https://doi.org/10.1016/j.jenvman.2009.03.005

Funding

This research received no grant from any funding agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None declared.

Ethical approval

Not required.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Toohi, H.T.S.AS., Rabeea, M.A., Abdullah, J.A. et al. Synthesis and characterization activated carbon using a mix (asphalt-polypropylene waste) for novel azo dye (HNDA) adsorption. Carbon Lett. 31, 837–849 (2021). https://doi.org/10.1007/s42823-020-00185-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-020-00185-3