Abstract

Silica aerogels have attracted significant interest in thermal insulation applications because of their low thermal conductivity and great thermal stability, however, their fragility has limited their application in every-day products. Herein, a self-reinforcing strategy to design silica nanofibrous aerogels (SNFAs) is proposed using electrospun SiO2 nanofibers as the matrix and a silica sol as a high-temperature nanoglue. Adopting this approach results in a strong and compatible interfacial interaction between the SiO2 fibers and the silica sol, which results in the SNFAs exhibiting high-temperature-resistant and tunable mechanical properties from elastic to rigid. Furthermore, additional properties such as low density, high thermal insulation performance, and fire-resistance are still retained. The self-reinforcing method described herein may be extended to numerous other new ceramic aerogels that require robust mechanical properties and high-temperature resistance.

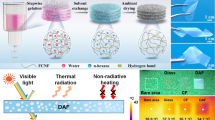

Graphic Abstract

Similar content being viewed by others

References

Soleimani Dorcheh A, Abbasi MH. Silica aerogel: synthesis, properties and characterization. J Mater Process Technol. 2008;199:10–26.

Yang S, Wang XQ, Dou LY, Yu JY, Ding B. Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity. Sci Adv. 2018;4:8925.

Alain CP, Gerard MP. Chemistry of aerogels and their applications. Chem Rev. 2002;102:4243–66.

Kistler SS. Coherent expanded aerogels and jellies. Nature. 1931;127:741.

Lee H, Lee D, Cho J, Kim YO, Lim S, Youn S, Jung YC, Kim SY, Seong DG. Super-insulating, flame-retardant, and flexible poly(dimethylsiloxane) composites based on silica aerogel. Compos Part A Appl Sci Manuf. 2019;123:108–13.

Lu Y, Li X, Yin X, Utomo HD, Tao NF, Huang H. Silica aerogel as super thermal and acoustic insulation materials. J Environ Prot (Irvine Calif). 2018;9:295–308.

Cuce E, Cuce PM, Wood CJ, Riffat SB. Toward aerogel based thermal superinsulation in buildings: a comprehensive review. Renew Sustain Energy Rev. 2014;34:273–99.

Hüsing N, Schubert U. Aerogels- airy materials: chemistry, structure, and properties. Angew Chem Int Ed. 2010;37:22–45.

Maleki H, Durães L, Portugal A. An overview on silica aerogels synthesis and different mechanical reinforcing strategies. J Non-Cryst Solids. 2014;385:55–74.

Ziegler C, Wolf A, Eacute, Liu W, Herrmann AK, Gaponik N, Eychmüller A. Modern inorganic aerogels. Angew Chem Int Ed Engl. 2017;56:13200–21.

Zu G, Kanamori K, Maeno A, Kaji H, Nakanishi K. Superflexible multifunctional polyvinylpolydimethylsiloxane-based aerogels as efficient absorbents, thermal superinsulators, and strain sensors. Angew Chem Int Ed Engl. 2018;57:9722–7.

Zu G, Shimizu T, Kanamori K, Zhu Y, Maeno A, Kaji H, Shen J, Nakanishi K. Transparent, superflexible doubly cross-linked polyvinylpolymethylsiloxane aerogel superinsulators via ambient pressure drying. ACS Nano. 2018;12:521–32.

Leventis N, Sotiriou-Leventis C, Zhang G, Rawashdeh AMM. Nanoengineering strong silica aerogels. Nano Lett. 2002;2:957–60.

Zhang G, Dass A, Rawashdeh AMM, Thomas J, Counsil JA, Sotiriou-Leventis C, Fabrizio EF, Ilhan F, Vassilaras P, Scheiman DA, McCorkle L, Palczer A, Johnston JC, Meador MA, Leventis N. Isocyanate-crosslinked silica aerogel monoliths: preparation and characterization. J Non-Cryst Solids. 2004;350:152–64.

Leventis N. Cross-linking amine-modified silica aerogels with epoxies: mechanically strong lightweight porous materials. Chem Mater. 2015;17:1085–98.

Li L, Yalcin B, Nguyen BN, Meador MA, Cakmak M. Flexible nanofiber-reinforced aerogel (xerogel) synthesis, manufacture, and characterization. ACS Appl Mater Inter. 2009;1:2491–501.

Xu LZ, Zhao XL, Xu CL, Kotov NA. Water-rich biomimetic composites with abiotic self-organizing nanofiber network. Adv Mater. 2018;30:1703343.

Liu GD, Ghosh R, Vaziri A, Hossieni A, Mousanezhad D, Nayeb-Hashemi H. Biomimetic composites inspired by venous leaf. J Compos Mater. 2018;52:361–72.

Chen SM, Gao HL, Zhu YB, Yao HB, Mao LB, Song YQ, Xia J, Pan Z, He Z, Wu HA, Yu SH. Biomimetic twisted plywood structural materials. Natl Sci Rev. 2018;5:703–14.

Mi HY, Jing X, Huang HX, Turng LS. Instantaneous self-assembly of three-dimensional silica fibers in electrospinning: Insights into fiber deposition behavior. Mater Lett. 2017;204:45–8.

Sun B, Long YZ, Zhang HD, Li MM, Duvail JL, Jiang XY, Yin HL. Advances in three-dimensional nanofibrous macrostructures via electrospinning. Prog Polym Sci. 2014;39:862–90.

Mi HY, Jing X, Napiwocki BN, Li ZT, Turng LS, Huang HX. Fabrication of fibrous silica sponges by self-assembly electrospinning and their application in tissue engineering for three-dimensional tissue regeneration. Chem Eng J. 2018;331:652–62.

Wang H, Zhang X, Wang N, Li Y, Feng X, Huang Y, Zhao C, Liu Z, Fang M, Ou G, Gao H, Li X, Wu H. Ultralight, scalable, and high-temperature–resilient ceramic nanofiber sponges. Sci Adv. 2017;3:1603170.

Alcock B, Peijs T. Technology and development of self-reinforced polymer composites. Berlin: Springer Berlin Heidelberg; 2013.

Capiati NJ, Porter RS. The concept of one polymer composites modelled with high density polyethylene. J Mater Sci. 1975;10:1671–7.

Yu F, White KW. Relationship between microstructure and mechanical performance of a 70% silicon nitride–30% barium aluminum silicate self in reinforced ceramic composite. J Am Ceram Soc. 2001;84:5–12.

Li J, Nawaz H, Wu J, Zhang J, Wan J, Mi Q, Yu J, Zhang J. All-cellulose composites based on the self-reinforced effect. Compos Commun. 2018;9:42–53.

Pyzik AJ, Beaman DR. Microstructure and properties of self-reinforced silicon nitride. J Am Ceram Soc. 1993;76:2737–44.

Tang X, Sun A, Chu C, Yu M, Ma S, Cheng Y, Guo J, Xu G. A novel silica nanowire-silica composite aerogels dried at ambient pressure. Mater Des. 2017;115:415–21.

Shao Z, He X, Niu Z, Huang T, Cheng X, Zhang Y. Ambient pressure dried shape-controllable sodium silicate based composite silica aerogel monoliths. Mater Chem Phys. 2015;162:346–53.

Qiu L, Liu JZ, Chang SL, Wu Y, Li D. Biomimetic superelastic graphene-based cellular monoliths. Nat Commun. 2012;3:1241.

Wang L, Wang J, Zheng L, Li Z, Wu L, Wang X. Superelastic, anticorrosive, and flame-resistant nitrogen-containing resorcinol formaldehyde/graphene oxide composite aerogels. ACS Sustain Chem Eng. 2019;7:10873–9.

Ren RP, Wang Z, Ren J, Lv KY. Highly compressible polyimide/graphene aerogel for efficient oil/water separation. J Mater Sci. 2018;54:5918–26.

Zhang X, Liu M, Wang H, Yan N, Cai Z, Yu Y. Ultralight, hydrophobic, anisotropic bamboo-derived cellulose nanofibrils aerogels with excellent shape recovery via freeze-casting. Carbohydr Polym. 2019;208:232–40.

Sun H, Xu Z, Gao C. Multifunctional. Ultra-flyweight, synergistically assembled carbon aerogels. Adv Mater. 2013;25:2554–60.

Schaedler TA, Jacobsen AJ, Torrents A, Sorensen AE, Lian J, Greer JR, Valdevit L, Carter WB. Ultralight metallic microlattices. Science. 2011;334:962.

Hu Y, Zhuo H, Luo Q, Wu Y, Wen R, Chen Z, Liu L, Zhong L, Peng X, Sun R. Biomass polymer-assisted fabrication of aerogels from MXenes with ultrahigh compression elasticity and pressure sensitivity. J Mater Chem A. 2019;7:10273–81.

Gibson LJ, Ashby MF. Cellular solids: structure and properties. 2nd ed. Cambridge: Cambridge University Press; 1997.

Wong JCH, Kaymak H, Brunner S, Koebel MM. Mechanical properties of monolithic silica aerogels made from polyethoxydisiloxanes. Micropor Mesopor Mater. 2014;183:23–9.

Yu ZL, Yang N, Apostolopoulou-Kalkavoura V, Qin B, Ma ZY, Xing WY, Qiao C, Bergstrom L, Antonietti M, Yu SH. Fire-rtardant and thermally insulating phenolic-silica aerogels. Angew Chem Int Ed Engl. 2018;57:4538–42.

Lee OJ, Lee KH, Yim TJ, Kim YS, Yoo KP. Determination of mesopore size of aerogels from thermal conductivity measurements. J Non-Cryst Solids. 2002;298:287–92.

Hrubesh LW, Pekala RW. Thermal properties of organic and inorganic aerogels. J Mater Res. 1994;9:731–8.

Acknowledgements

We gratefully acknowledge the joint financial support provided by the National Natural Science Foundation of China (No. 51703024), “Chenguang Program” supported by Shanghai Education Development Foundation and Shanghai Municipal Education Commission (18CG37), the Fundamental Research Funds for the Central Universities (No. 2232018D3-18), and the Program of Shanghai Academic Research Leader (18XD1400100).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing financial interest.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Supplementary Material 2 (MP4 2602 kb)

Supplementary Material (MP4 8483 kb)

Supplementary Material 2 (AVI 3519 kb)

Supplementary Material 5 (MP4 3643 kb)

Rights and permissions

About this article

Cite this article

Huang, T., Zhu, Y., Zhu, J. et al. Self-reinforcement of Light, Temperature-Resistant Silica Nanofibrous Aerogels with Tunable Mechanical Properties. Adv. Fiber Mater. 2, 338–347 (2020). https://doi.org/10.1007/s42765-020-00054-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-020-00054-8