Abstract

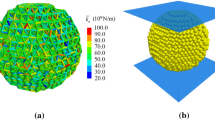

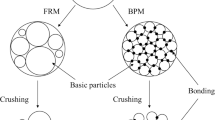

This paper uses the discrete element method to model the size and cushion effects during single-particle crushing tests. We propose simplified numerical modeling to examine the effects of particle size and coordination number on particle breakage behavior. We validate the proposed modeling by comparing the numerical results with the experimental data reported in the literature, in terms of the variability of particle tensile strength and axial force–displacement responses. Based on the numerical results, it is clear that a larger particle size entails a higher tensile strength with a larger discreteness. In addition, the characteristic tensile strength increases linearly with an increasing coordination number. Moreover, smaller particles are more susceptible to the cushion effect than larger particles. The numerical results also indicate that an increasing coordination number induces a more ductile mode of failure. Based on these results, we propose an empirical equation for calculating tensile strength, incorporating both the cushion effect and the size effect.

Similar content being viewed by others

References

Wang JF, Yan HB. On the role of particle breakage in the shear failure behavior of granular soils by DEM. Int J Numer Anal Meth Geomech. 2013;37(8):832–54.

Zhao T, Crosta GB, Utili S, De Blasio FV. Investigation of rock fragmentation during rockfalls and rock avalanches via 3-D discrete element analyses. J Geophys Res Earth Surf. 2017;122(98):678–95.

Shen WG, Zhao T, Crosta GB, Dai F. Analysis of impact-induced rock fragmentation using a discrete element approach. Int J Rock Mech Min Sci. 2017;98:33–8.

Liu Y, Li XZ, Wang CL. Discrete element simulation of rock crushing considering different shape. Appl Mech Mater. 2013;353–356:715–8.

McDowell GR, Bolton MD. On the micromechanics of crushable aggregates. Géotechnique. 1998;48(5):667–79.

Zhou W, Yang L, Ma G, Chang XL, Lai ZQ, Xu Q. DEM analysis of the size effects on the behavior of crushable granular materials. Granul Matter. 2016;18(3):1–11.

Saeidi F, Yahyaei M, Powell M, Tavares LM. Investigating the effect of applied strain rate in a single breakage event. Miner Eng. 2017;100:211–22.

Cheshomi A, Sheshde EA. Determination of uniaxial compressive strength of microcrystalline limestone using single particles load test. J Petrol Sci Eng. 2013;111:121–6.

Zhong S, Baitalow F, Nikrityuk P, Gutte H, Meyer B. The effect of particle size on the strength parameters of German brown coal and its chars. Fuel. 2014;125:200–5.

Wang C, Cheng Y, He X, Yi MH, Wang ZY. Size effect on uniaxial compressive strength of single coal particle under different failure conditions. Powder Technol. 2019;345:169–81.

McDowell GR, Amon A. The application of Weibull statistics to the fracture of soil particles. Soils Found. 2000;40(5):133–41.

Sukumaran B, Einav I, Dyskin A. Qualitative assessment of the influence of coordination number on crushing strength using DEM. In: Proceedings of the fifth world congress particle technology. 2006, pp 23–7.

Cheng Z, Wang J. Quantification of particle crushing in consideration of grading evolution of granular soils in biaxial shearing: a probability-based model. Int J Numer Anal Meth Geomech. 2017;42:488–515.

Huang J, Xu S, Hu S. Effects of grain size and gradation on the dynamic responses of quartz sands. Int J Impact Eng. 2013;59:1–10.

Das SK, Das A. Influence of quasi-static loading rates on crushable granular materials: a DEM analysis. Powder Technol. 2019;344:393–403.

Tsoungui O, Vallet D, Charmet JC. Numerical model of crushing of grains inside two-dimensional granular materials. Powder Technol. 1999;105(1–3):190–8.

Einav I. Breakage mechanics—part I: theory. J Mech Phys Solids. 2007;55(6):1274–97.

Wei H, Zhao T, Meng QS, Wang XZ, He JQ. Experimental evaluation of the shear behavior of fiber-reinforced calcareous sands. Int J Geomech. 2018;18(12):1–10.

Wang P, Arson C. Discrete element modeling of shielding and size effects during single particle crushing. Comput Geotech. 2016;78:227–36.

Voivret C. Cushioning effect in highly polydisperse granular media. In: Proceedings of AIP conference. 2013, pp 405–8.

Liakas S, O’Sullivan C, Saroglou C. Influence of heterogeneity on rock strength and stiffness using DEM and the parallel bond model. J Rock Mech Geotech Eng. 2017;9(4):575–84.

Shi DD, Zheng L, Xue JF, Sun J. DEM modeling of particle breakage in silica sands under one-dimensional compression. Acta Mech Solida Sin. 2016;29(1):78–94.

Li H, McDowell G, Lowndes I. Discrete element modelling of a rock cone crusher. Powder Technol. 2014;263:151–8.

Ma G, Zhou W, Chang XL. Modeling the particle breakage of rockfill materials with the cohesive crack model. Comput Geotech. 2014;61:132–43.

Lim WL, McDowell GR. The importance of coordination number in using agglomerates to simulate crushable particles in the discrete element method. Géotechnique. 2007;57(8):701–5.

Nakata AFL, Hyde M, Hyodo H, Murata H. A probabilistic approach to sand particle crushing in the triaxial test. Géotechnique. 1999;49(4):567–83.

Weibull W. A statistical distribution function of wide applicability. J Appl Mech. 1951;18(2):293–7.

Ma L, Li Z, Wang MY, Wei HZ, Fan PX. Effects of size and loading rate on the mechanical properties of single coral particles. Powder Technol. 2018;342:961–71.

Huang J, Xu S, Yi H, Hu S. Size effect on the compression breakage strengths of glass particles. Powder Technol. 2014;268:86–94.

Jaeger JC. Failure of rocks under tensile conditions. Int J Rock Mech Min Sci. 1967;4(2):219–27.

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant Nos. 51971188 and 51071134), the Science and Technology Major Project of Hunan Province (Grant No. 2019GK1012), Huxiang High-Level Talent Gathering Program of Hunan Province-Innovative team (Grant No. 2019RS1059), and the Degree and Postgraduate Education Reform Project of Hunan Province (Grant No. CX20190493). All of this support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Rights and permissions

About this article

Cite this article

Kuang, Dm., Long, Zl., Guo, Rq. et al. Numerical Investigation of the Cushion and Size Effects During Single-Particle Crushing via DEM. Acta Mech. Solida Sin. 33, 851–863 (2020). https://doi.org/10.1007/s10338-020-00191-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-020-00191-y