Abstract

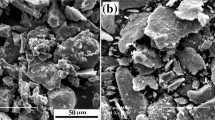

Multilayered Al sheets having alternative stacking of 2 N Al (99.21 wt.% purity, N is short for nine) and 4 N Al (99.993 wt.% purity, N is short for nine) with various layer thicknesses from 16 to 1 μm were fabricated by 6 to 10 accumulative roll bonding (ARB) cycles, followed by annealing. The effects of layer thickness and annealing treatment on mechanical properties were studied. In all samples, the grain sizes in the 4 N layers were larger than those in the 2 N layers due to the purity difference. The grain size and mechanical properties saturated after 6 ARB cycles, but the layer thickness gradually decreases with increasing cycles and accordingly, more homogeneous microstructures were obtained with higher cycles. After annealing, heterogeneous structures were retained in 6-cycle sample, while most homogenous structures were observed in 10-cycle sample. Yield-drop phenomenon widely observed in the homogeneous samples disappeared in the heterogeneous 6-cycle sample after annealing at 225 and 250 °C.

Similar content being viewed by others

References

M.A. Meyers, A. Mishra, and D.J. Benson, Mechanical Properties of Nanocrystalline Materials, Prog. Mater Sci., 2006, 51(4), p 427–556

B.L. Li, A. Godfrey, Q.C. Meng, Q. Liu, and N. Hansen, Microstructural Evolution of IF-Steel During Cold Rolling, Acta Mater., 2004, 52(4), p 1069–1081

N.N. Liang, Y.H. Zhao, Y. Li, T. Topping, Y.T. Zhu, R.Z. Valiev, and E.J. Lavernia, Influence of Microstructure on Thermal Stability of Ultrafine-Grained Cu Processed by Equal Channel Angular Pressing, J. Mater. Sci., 2018, 53(18), p 13173–13185

J. Čížek, M. Janeček, T. Krajňák, J. Stráská, P. Hruška, J. Gubicza, and H.S. Kim, Structural Characterization of Ultrafine-Grained Interstitial-Free Steel Prepared by Severe Plastic Deformation, Acta Mater., 2016, 105, p 258–272

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, and Y.T. Zhu, Microstructures and Mechanical Properties of Ultrafine Grained 7075 Al Alloy Processed by ECAP and Their Evolutions During Annealing, Acta Mater., 2004, 52(15), p 4589–4599

H. Miura, X. Yang, and T. Sakai, Evolution of Ultra-Fine Grains in AZ31 and AZ61 Mg Alloys During Multi Directional Forging and Their Properties, Mater. Trans., 2008, 49(5), p 1015–1020

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino, Strength and Ductility of Ultrafine Grained aluminum and Iron Produced by ARB and Annealing, Scr. Mater., 2002, 47(12), p 893–899

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong, Ultra-Fine Grained Bulk Aluminum Produced by Accumulative Roll-BONDIng (ARB) Process, Scr. Mater., 1998, 39(9), p 1221–1227

Q. Chen, D.Y. Shu, J. Lin, Y. Wu, X.S. Xia, S.H. Huang, Z.D. Zhao, O.V. Mishin, and G.L. Wu, Evolution of Microstructure and Texture in Copper During Repetitive Extrusion-Upsetting and Subsequent Annealing, J. Mater. Sci. Tech, 2017, 33(7), p 690–697

Y. Ito, N. Tsuji, Y. Saito, H. Utsunomiya, and T. Sakai, Change in Microstructure and Mechanical Properties of Ultra-Fine grained Aluminum During Annealing, J. Jpn. Inst. Met., 2000, 64(6), p 429–437

N. Kamikawa, N. Tsuji, and Y. Minamino, Microstructure and Texture Through Thickness of Ultralow Carbon IF Steel Sheet Severely Deformed by Accumulative Roll-Bonding, Sci. Tech. Adv. Mater., 2004, 5(1–2), p 163–172

L. Zhang, Z. Chen, Y. Wang, G. Ma, T. Huang, G. Wu, and D.J. Jensen, Fabricating Interstitial-Free Steel with Simultaneous High Strength and Good Ductility with Homogeneous Layer and Lamella Structure, Scr. Mater., 2017, 141, p 111–114

X. Jiang, L. Zhang, L. Zhang, T. Huang, G. Wu, X. Huang, and O.V. Mishin, Heterogeneous Microstructure and Enhanced Mechanical Properties in Annealed Multilayered IF Steel, Mater. Sci. Eng., A, 2019, 759, p 262–271

X. Luo, T.L. Huang, Y.H. Wang, Y.C. Xin and G.L. Wu, Strong and Ductile AZ31 Mg Alloy with a Layered Bimodal Structure, Sci. Rep., 2019, 9

K. Wu, H. Chang, E. Maawad, W.M. Gan, H.G. Brokmeier, and M.Y. Zheng, Microstructure and Mechanical Properties of the Mg/Al Laminated Composite Fabricated by Accumulative Roll Bonding (ARB), Mater. Sci. Eng. A, 2010, 527(13), p 3073–3078

M.Z. Quadir, N. Najafzadeh, and P.R. Munroe, Variations in Through-Thickness Recrystallization and Grain Growth Textures in the Al Layers in ARB-Processed Al/Al(03% Sc) Composite Sheets, Mater. Des., 2016, 93, p 467–473

X. Jiang, Y. Bai, L. Zhang, G. Wu, S. Gao, X. Huang, and N. Tsuji, Termination of local strain concentration led to better tensile ductility in multilayered 2 N/4 N Al sheet, Mater. Sci. Eng. A, 2020, 782, p 139240

P. Chekhonin, J. Scharnweber, M. Scharnweber, C.G. Oertel, T. Hausol, H. Hoppel, J. Jaschinski, T. Marr, and W. Skrotzki, Mechanical Properties of Aluminium Laminates Produced by Accumulative Roll Bonding, Cry. Res. Tech., 2013, 48(8), p 532–537

C.C. Hsieh, M.S. Shi, and W.T. Wu, Growth of Intermetallic Phases in Al/Cu Composites at Various Annealing Temperatures During the ARB Process, Met. Mater. Int., 2012, 18(1), p 1–6

O. Seri and S. Fukuchi, Improvement of Corrosion-Resistance of Anodized Oxide Film by Preferential Removing of FeAl3 System Intermetallic Compound on 1100 Aluminum, Journal of Japan Institute of Light Metals, 2007, 57(10), p 457–460

Tetsuya, MOTOI, Kiyoshi and FUKUOKA, Effect of intermetallic compounds on corrugation wave of double rolled commercial purity aluminum foils. Journal of Japan Institute of Light Metals, 2002.

K. Furumata, T. Suzuki, K. Yamada, and O. Seri, Effect of Fe/Si Ratio in Intermetallic Compound Particles on Pitting Attacks of 1100 Aluminum, Journal of Japan Institute of Light Metals, 1999, 49(2), p 62–66

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, Novel Ultra-High Straining Process for Bulk Materials—Development of the Accumulative Roll-Bonding (ARB) Process, Acta Mater., 1999, 47(2), p 579–583

S. Roy, B.R. Nataraj, S. Suwas, S. Kumar, and K. Chattopadhyay, Accumulative Roll Bonding of Aluminum Alloys 2219/5086 Laminates: Microstructural Evolution and Tensile Properties, Mater. Des., 2012, 36, p 529–539

M. Eizadjou, H.D. Manesh, and K. Janghorban, Microstructure and Mechanical Properties of Ultra-Fine Grains (UFGs) Aluminum Strips Produced by ARB Process, J. Alloys Compd., 2009, 474(1), p 406–415

M. Ruppert, C. Schunk, D. Hausmann, H.W. Höppel, and M. Göken, Global and Local Strain Rate Sensitivity of Bimodal Al-Laminates Produced by Accumulative Roll Bonding, Acta Mater., 2016, 103, p 643–650

F. Nowicke, A. Zavaliangos, and H.C. Rogers, The Effect of Roll and Clad Sheet Geometry on the Necking Instability During Rolling of Clad Sheet Metals, Int. J. Mech. Sci., 2006, 48(8), p 868–877

H.L. Yu, A.K. Tieu, C. Lu, X. Liu, A. Godbole, H.J. Li, C. Kong and Q.H. Qin, A Deformation Mechanism of Hard Metal Surrounded by Soft Metal During Roll Forming, Sci. Rep., 2014, 4

N. Kamikawa and N. Tsuji, Microstructure and Mechanical Properties of ARB Processed Aluminium with Different Purities, Mater. Trans., 2016, 57(10), p 1720–1728

C. Kwan and Z.R. Wang, Microstructure Evolution Upon Annealing of Accumulative Roll Bonding (ARB) 1100 Al Sheet Materials: Evolution of interface microstructures, J. Mater. Sci., 2008, 43(15), p 5045–5051

C. Kwan, Z. Wang, and S.-B. Kang, Mechanical Behavior and Microstructural Evolution Upon Annealing of the Accumulative Roll-Bonding (ARB) Processed Al Alloy 1100, Mater. Sci. Eng., A, 2008, 480(1), p 148–159

K. Kashihara, Y. Komi, D. Terada, and N. Tsuji, Improvement of Uniform Elongation by Low Temperature Annealing in Al-25% Mg Alloy Processed by Accumulative Roll Bonding, Mater. Trans., 2015, 56(6), p 803–807

S. Gao, M. Chen, S. Chen, N. Kamikawa, A. Shibata, and N. Tsuji, Yielding Behavior and Its Effect on Uniform Elongation of Fine Grained IF Steel, Mater. Trans., 2014, 55(1), p 73–77

S. Gao, M. Chen, M. Joshi, A. Shibata, and N. Tsuji, Yielding Behavior and Its Effect on Uniform Elongation in IF Steel with Various Grain Sizes, J. Mater. Sci., 2014, 49(19), p 6536–6542

G.T. Hahn, A Model for Yielding with Special Reference to the Yield-Point Phenomena of Iron and Related BCC Metals, Acta Metall., 1962, 10(8), p 727–738

X. Huang, N. Kamikawa, and N. Hansen, Strengthening Mechanisms in Nanostructured Aluminum, Mater. Sci. Eng. A, 2008, 483–484, p 102–104

N. Kamikawa, X. Huang, N. Tsuji, and N. Hansen, Strengthening Mechanisms in Nanostructured High-Purity Aluminium Deformed to High Strain and Annealed, Acta Mater., 2009, 57(14), p 4198–4208

D.J. Lloyd, S.A. Court, and K.M. Gatenby, Lüders Elongation in AI-Mg Alloy AA5182, Mater. Sci. Tech., 1997, 13(8), p 660–666

S.V. Noor, A.R. Eivani, H.R. Jafarian, and M. Mirzaei, Inhomogeneity in Microstructure and Mechanical Properties During twist Extrusion, Mater. Sci. Eng., A, 2016, 652, p 186–191

F.J. Kalahroudi, A.R. Eivani, H.R. Jafarian, A. Amouri, and R. Gholizadeh, Inhomogeneity in Strain, Microstructure and Mechanical Properties of AA1050 Alloy During Twist Extrusion, Mater. Sci. Eng., A, 2016, 667, p 349–357

Acknowledgments

The authors would like to thank the financial support by the Natural Science Foundation of China (NSFC, Grants No. 51671039) and National Key Research and Development Program of China (2016YFB0700403). SG and NT appreciate the support by JST CREST (Grant No. JPMJCR1994), Japan. Project No. 2020CDCGCL006 and 2020CDJDPT001 supported by the Fundamental Research Funds for the Central Universities of China was also appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jiang, X., Gao, S., Zhang, L. et al. Heterogeneity and Homogeneity in 2/4 N Multilayered Al Fabricated by Accumulative Roll Bonding and Annealing. J. of Materi Eng and Perform 29, 6147–6154 (2020). https://doi.org/10.1007/s11665-020-05081-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05081-5