Abstract

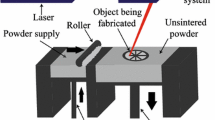

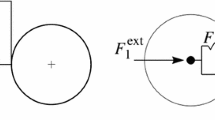

A fundamental numerical model at the powder particle scale based on the material point method (MPM) is developed for selective laser sintering (SLS). In order to describe the thermo-mechanical phenomena, a laser heat source model with a Gaussian energy distribution and the Perzyna viscoplastic model with a return mapping algorithm are employed. The principal process conditions, such as the laser power and radius, and the scanning speed are systematically varied. Based on the obtained temperature distribution generated by laser irradiation under these conditions, elastic–viscoplastic stresses were calculated to evaluate the deformation of powder particle pairs under the driving force of surface tension via a simple two-dimensional test case. The developed MPM model can capture minute changes of the deformation behavior and the temperature distribution history during melting and consolidation at the particle scale. Melting and consolidation of particle pairs during SLS are basic nature in determining the final product quality. The model can help to evaluate variations in the fusion of microscopic areas, melted by a laser, resulting from variations in the process conditions.

Similar content being viewed by others

References

Abdul-Hameed H, Messager T, Ayoub G, Zaïri F, Naït-Abdelaziz M, Qu Z, Zaïri F (2014) A two-phase hyperelastic-viscoplastic constitutive model for semi-crystalline polymers: application to polyethylene materials with a variable range of crystal fractions. J Mech Behav Biomed Mater 37:323–332. https://doi.org/10.1016/j.jmbbm.2014.04.016

Abu Al-Rub R, Tehrani A, Darabi M (2015) Application of a large deformation nonlinear-viscoelastic viscoplastic viscodamage constitutive model to polymers and their composites. Int J Damage Mech 24:198–244. https://doi.org/10.1177/1056789514527020

Aleksy N, Kermuche G, Vautrin A, Bergheau JM (2010) Numerical study of scratch velocity effect on recovery of viscoelastic-viscopkastic solides. Int J Mech Sci 52:455–463

Ammer R, Markl M, Ljungblad U, Körner C, Rüde U (2014) Simulating fast electron beam melting with a parallel thermal free surface lattice boltzmann method. Comput Math Appl 67(2):318–330. https://doi.org/10.1016/j.camwa.2013.10.001 Mesoscopic Methods for Engineering and Science (Proceedings of ICMMES-2012, Taipei, Taiwan, 23–27 July 2012)

Arruda EM, Boyce MC, Jayachandran R (1995) Effects of strain rate, temperature and thermomechanical coupling on the finite strain deformation of glassy polymers. Mech Mater 19(2):193–212. https://doi.org/10.1016/0167-6636(94)00034-E

Balemans C, Jaensson N, Hulsen M, Anderson P (2018) Temperature-dependent sintering of two viscous particles. Add Manuf 24:528–542. https://doi.org/10.1016/j.addma.2018.09.005

Bardenhagen SG, Kober EM (2004) The generalized interpolation material point method. Comput Model Eng Sci 5(6):477–496. https://doi.org/10.3970/cmes.2004.005.477

Bierwisch C, Mohseni-mofidi S, Dietemann B, Rudloff J, Baumann S, Popp K, Lang M (2019) Particle-based simulations and dimensional analysis of selective laser sintering of PA12 powder. In: Auricchio F, Rank E, Steinmann P, Kollmannsberger S, Morganti S (eds) Sim-AM 2019. CIMNE, Barcelona, pp 316–327

Brackbill J, Kothe D, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100(2):335–354. https://doi.org/10.1016/0021-9991(92)90240-Y

Chen Z, Brannon RM (2002) An evaluation of the material point method. SAND report SAND2002-0482

Chen L, Lee J, Chen Cf (2012) On the modeling of surface tension and its applications by the generalized interpolation material point method. Comput Model Eng Sci 86:199–224. https://doi.org/10.3970/cmes.2012.086.199

Dong Y, Grabe J (2018) Large scale parallelisation of the material point method with multiple GPUS. Comput Geotech 101:149–158. https://doi.org/10.1016/j.compgeo.2018.04.001

Drozdov A, Christiansen J (2003) Model for the viscoelastic and viscoplastic responses of semicrystalline polymers. J Appl Polym Sci 88:1438–1450. https://doi.org/10.1002/app.11797

Du Y, You X, Qiao F, Guo L, Liu Z (2019) A model for predicting the temperature field during selective laser melting. Results Phys 12:52–60. https://doi.org/10.1016/j.rinp.2018.11.031

Fincan M (2015) Assessing viscoelastic properties of polydimethylsibxane (PDMS) using loading and unloading of the macroscopic compression test. PhD thesis, University of South Florida

Fürstenau JP, Wessels H, Weißenfels C, Wriggers P (2020) Generating virtual process maps of SLM using powder scale SPH simulations. Comput Part Mech 7:655–677. https://doi.org/10.1007/s40571-019-00296-3

Ganeriwala R, Zohdi T (2016) A coupled discrete element-finite difference model of selective laser sintering. Granul Matter 18:21. https://doi.org/10.1007/s10035-016-0626-0

Inoue T, Wang ZG (1988) Thermal and mechanical fields in continuous casting slab—a steady state analysis incorporating solidification. Arch Appl Mech 58(4):265–275. https://doi.org/10.1007/BF00535936

Kermouche G, Aleksy N, Bergheau JM (2013) Viscoelastic-viscoplastic modelling of the scratch response of PMMA. Adv Mater Sci Eng. https://doi.org/10.1155/2013/289698

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45. https://doi.org/10.1016/j.actamat.2016.02.014

Kinstlinger IS, Bastian AA, Paulsen SJ, Hwang DH, Ta AH, Yalacki DR, Schmidt T, Miller JS (2016) Open-source selective laser sintering (opensls) of nylon and biocompatible polycaprolactone. PLoS One 11:e0147399

Kruth JP, Levy G, Schindel R, Craeghs T, Yasa E (2008) Consolidation of polymer powders by selective laser sintering. In: Proceedings of the 3rd international conference on polymers and moulds innovations, pp 15–30

Majewski C, Zarringhalam H, Hopkinson N (2008) Effect of the degree of particle melt on mechanical properties in selective laser-sintered Nylon-12 parts. Proc Inst Mech Eng, Part B: J Eng Manuf 222:1055–1064. https://doi.org/10.1243/09544054JEM1122

Perzyna P (1971) Thermodynamic theory of viscoplasticity. Adv Appl Mech 11:313–354

Peyre P, Rouchausse Y, Defauchy D, Regnier G (2015) Experimental and numerical analysis of the selective laser sintering (SLS) of PA12 and PEKK semi-crystalline polymers. J Mater Process Technol 225:326–336. https://doi.org/10.1016/j.jmatprotec.2015.04.030

Russell M, Souto-Iglesias A, Zohdi T (2018) Numerical simulation of laser fusion additive manufacturing processes using the SPH method. Comput Methods Appl Mech Eng 341:163–187. https://doi.org/10.1016/j.cma.2018.06.033

Simo JC, Hughes TJR (1998) Computational inelasticity. Springer, New York

Steffen M, Wallstedt P, Guilkey J, Kirby R, Berzins M (2008) Examination and analysis of implementation choices within the material point method (MPM). Comput Model Eng Sci 31(2):107–127

Stomakhin A, Schroeder C, Jiang C, Chai L, Teran J, Selle A (2014) Augmented MPM for phase-change and varied materials. ACM Trans Graph 33(4):1–11. https://doi.org/10.1145/2601097.2601176

Sulsky D, Chen Z, Schreyer H (1994) A particle method for history-dependent materials. Comput Methods Appl Mech Eng 118(1):179–196. https://doi.org/10.1016/0045-7825(94)90112-0

Sulsky D, Zhou SJ, Schreyer HL (1995) Application of a particle-in-cell method to solid mechanics. Comput Phys Commun 87(1–2):236–252. https://doi.org/10.1016/0010-4655(94)00170-7

Voller V, Swaminathan C (1991) General source-based method for solidification phase change. Numer Heat Trans, Part B: Fundam 19(2):175–189. https://doi.org/10.1080/10407799108944962

Wang X, Qiu Y, Slattery SR, Fang Y, Li M, Zhu SC, Zhu Y, Tang M, Manocha D, Jiang C (2020) A massively parallel and scalable multi-cpu material point method. ACM Trans Graph 39(4). https://doi.org/10.1145/3386569.3392442

Wessels H, Weißenfels C, Wriggers P (2018) Metal particle fusion analysis for additive manufacturing using the stabilized optimal transportation meshfree method. Comput Methods Appl Mech Eng 339:91–114. https://doi.org/10.1016/j.cma.2018.04.042

Yan W, Ge W, Qian Y, Lin S, Zhou B, Liu WK, Lin F, Wagner GJ (2017) Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater 134:324–333. https://doi.org/10.1016/j.actamat.2017.05.061

Yang WC, Arduino P, Miller GR, Mackenzie-Helnwein P (2018) Smoothing algorithm for stabilization of the material point method for fluid solid interaction problems. Comput Methods Appl Mech Eng 342:177–199. https://doi.org/10.1016/j.cma.2018.04.041

Zhang F, Zhang X, Sze KY, Lian Y, Liu Y (2017) Incompressible material point method for free surface flow. J Comput Phys 330:92–110

Zhao M, Drummer D, Wudy K, Drexler M (2015) Sintering study of polyamide 12 particles for selective laser melting. Int J Recent Contrib Eng Sci IT 3:28–33

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest of any type during the production of this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

T. Maeshima and Y. Kim authors are contributed equally to this work.

Rights and permissions

About this article

Cite this article

Maeshima, T., Kim, Y. & Zohdi, T.I. Particle-scale numerical modeling of thermo-mechanical phenomena for additive manufacturing using the material point method. Comp. Part. Mech. 8, 613–623 (2021). https://doi.org/10.1007/s40571-020-00358-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-020-00358-x