Abstract

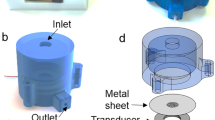

A biomimetic surface for water collection was successfully engineered using three-dimensional (3D) printing technology. The fused deposition modeling-type 3D printing was used to create a reusable mold. This was used to cast waveform microstructures on a hydrophobic polymer surface, which was induced by using stacked filaments. The etching was performed on the printed mold by using a chemical solvent to generate nano/micro pores, which enhanced the rolling-off motion of water droplets. To create a hydrophilic region on the hydrophobic surface, the metal deposition was achieved using a 3D-printed mask and the self-masking effect of the tilted tips of waveform microstructures. The metal array served as seeding points for the growth of water droplets in foggy conditions. As a result, the fabricated biomimetic surface exhibited the highest water-collecting performance (average 0.77 g for 10 min) compared with the other four different surfaces. This study demonstrates the use of 3D printing technology to rapidly and simply fabricate engineered (hybrid) surfaces for various applications involving facile control of wettability.

Similar content being viewed by others

References

Stratakis, E., Ranella, A., & Fotakis, C. (2011). Biomimetic micro/nanostructured functional surfaces for microfluidic and tissue engineering applications. Biomicrofluidics, 5, 013411.

Malshe, A., Rajurkar, K., Samant, A., Hansen, H. N., Bapat, S., & Jiang, W. (2013). Bio-inspired functional surfaces for advanced applications. CIRP Annals, 62, 607–628.

Yao, L., & He, J. (2014). Recent progress in antireflection and self-cleaning technology – from surface engineering to functional surfaces. Progress in Materials Science, 61, 94–143.

Müller, F., Kunz, C., & Gräf, S. (2016). Bio-inspired functional surfaces based on laser-induced periodic surface structures. Materials, 9, 476.

Myint, M. T. Z., Kumar, N. S., Hornyak, G. L., & Dutta, J. (2013). Hydrophobic/hydrophilic switching on zinc oxide micro-textured surface. Applied Surface Science, 264, 344–348.

Nagaoka, S., & Akashi, R. (1990). Low-friction hydrophilic surface for medical devices. Biomaterials, 11, 419–424.

Cole, D. J., Payne, M. C., Csányi, G., Mark Spearing, S., Colombi, L., & Ciacchi. (2007). Development of a classical force field for the oxidized Si surface: application to hydrophilic wafer bonding. The Journal of Chemical Physics, 127, 204704.

Dong, X., Fu, J., Xiong, X., & Chen, C. (2011). Preparation of hydrophilic mesoporous carbon and its application in dye adsorption. Materials Letters, 65, 2486–2488.

Somlo, B., & Gupta, V. (2001). A hydrophobic self-assembled monolayer with improved adhesion to aluminum for deicing application. Mechanics of Materials, 33, 471–480.

Li, J., Wei, Y., Huang, Z., Wang, F., Yan, X., & Wu, Z. (2017). Electrohydrodynamic behavior of water droplets on a horizontal super hydrophobic surface and its self-cleaning application. Applied Surface Science, 403, 133–140.

Min, T., & Kim, J. (2004). Effects of hydrophobic surface on skin-friction drag. Physics of Fluids, 16, L55–L58.

Barthwal, S., & Lim, S.-H. (2020). Robust and chemically stable superhydrophobic aluminum-alloy surface with enhanced corrosion-resistance properties. International Journal of Precision Engineering and Manufacturing - Green Technology, 7, 481–492.

Khayet, M., Mengual, J. I., & Matsuura, T. (2005). Porous hydrophobic/hydrophilic composite membranes: application in desalination using direct contact membrane distillation. Journal of Membrane Science, 252, 101–113.

Kobayashi, T., Shimizu, K., Kaizuma, Y., & Konishi, S. (2011). Novel combination of hydrophilic/hydrophobic surface for large wettability difference and its application to liquid manipulation. Lab on a Chip, 11, 639–644.

Troitsky, V., Berzina, T., Shchukin, D., Sukhorukov, G., Erokhin, V., & Fontana, M. P. (2004). Simple method of hydrophilic/hydrophobic patterning of solid surfaces and its application to self-assembling of nanoengineered polymeric capsules. Colloids and Surfaces A: Physicochemical and Engineering Aspects , 245, 163–168.

Lee, S. H., Lee, J. H., Park, C. W., Lee, C. Y., Kim, K., Tahk, D., & Kwak, M. K. (2014). Continuous fabrication of bio-inspired water collecting surface via roll-type photolithography. International Journal of Precision Engineering and Manufacturing - Green Technology, 1, 119–124.

Park, J., & Kim, S. (2019). Three-dimensionally structured flexible fog harvesting surfaces Inspired by Namib Desert Beetles. Micromachines, 10, 201.

Lee, A., Moon, M.-W., Lim, H., Kim, W.-D., & Kim, H.-Y. (2012). Water harvest via dewing. Langmuir, 28, 10183–10191.

Barron, V., Killion, J. A., Pilkington, L., Burke, G., Geever, L. M., Lyons, J. G., et al. (2016). Development of chemically cross-linked hydrophilic–hydrophobic hydrogels for drug delivery applications. European Polymer Journal, 75, 25–35.

Parker, A. R., & Lawrence, C. R. (2001). Water capture by a desert beetle. Nature, 414, 33–34.

White, B., Sarkar, A., & Kietzig, A.-M. (2013). Fog-harvesting inspired by the Stenocara beetle—an analysis of drop collection and removal from biomimetic samples with wetting contrast. Applied Surface Science, 284, 826–836.

Yin, K., Du, H., Dong, X., Wang, C., Duan, J.-A., & He, J. (2017). A simple way to achieve bioinspired hybrid wettability surface with micro/nanopatterns for efficient fog collection. Nanoscale, 9, 14620–14626.

Yu, Z., Yun, F. F., Wang, Y., Yao, L., Dou, S., Liu, K., et al. (2017). Desert beetle-inspired superwettable patterned surfaces for water harvesting. Small, 13, 1701403.

Zhang, L., Wu, J., Hedhili, M. N., Yang, X., & Wang, P. (2015). Inkjet printing for direct micropatterning of a superhydrophobic surface: toward biomimetic fog harvesting surfaces. Journal of Materials Chemistry A, 3, 2844–2852.

Khare, V., Sonkaria, S., Lee, G.-Y., Ahn, S.-H., & Chu, W.-S. (2017). From 3D to 4D printing – design, material and fabrication for multi-functional multi-materials. International Journal of Precision Engineering and Manufacturing - Green Technology, 4, 291–299.

Sabahi, N., Chen, W., Wang, C.-H., Kruzic, J. J., & Li, X. (2020). A review on additive manufacturing of shape-memory materials for biomedical applications. JOM, 72, 1229–1253.

Sharma, A., Mondal, S., Mondal, A. K., Baksi, S., Patel, R. K., & Chu, W.-S. (2017). Pandey, 3D printing: It’s microfluidic functions and environmental impacts. International Journal of Precision Engineering and Manufacturing - Green Technology, 4, 323–334.

Jasiuk, I., Abueidda, D. W., Kozuch, C., Pang, S., Su, F. Y., & McKittrick, J. (2018). An overview on additive manufacturing of polymers. JOM, 70, 275–283.

Kang, B., Hyeon, J., & So, H. (2020). Facile microfabrication of 3-dimensional (3D) hydrophobic polymer surfaces using 3D printing technology. Applied Surface Science, 499, 143733.

Dudek, P. (2013). FDM 3D printing technology in manufacturing composite elements. Archives of Metallurgy and Materials, 58, 1415–1418.

Bikas, H., Stavropoulos, P., & Chryssolouris, G. (2016). Additive manufacturing methods and modeling approaches: a critical review. International Journal of Advanced Manufacturing Technology, 83, 389–405.

Kang, B., Sung, J., & So, H. (2019). Realization of superhydrophobic surfaces based on three-dimensional printing technology. International Journal of Precision Engineering and Manufacturing - Green Technology. https://doi.org/10.1007/s40684-019-00163-9

Sato, S., Gondo, D., Wada, T., Kanehashi, S., & Nagai, K. (2013). Effects of various liquid organic solvents on solvent-induced crystallization of amorphous poly(lactic acid) film. Journal of Applied Polymer Science, 129, 1607–1617.

Lafuma, A., & Quéré, D. (2003). Superhydrophobic states. Nature Materials, 2, 457–460.

He, B., Lee, J., & Patankar, N. A. (2004). Contact angle hysteresis on rough hydrophobic surfaces. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 248, 101–104.

Miwa, M., Nakajima, A., Fujishima, A., Hashimoto, K., & Watanabe, T. (2000). Effects of the surface roughness on sliding angles of water droplets on superhydrophobic surfaces. Langmuir, 16, 5754–5760.

Mitra, S., Gunda, N. S. K., & Mitra, S. K. (2017). Wetting characteristics of underwater micro-patterned surfaces. RSC Advances, 7, 9064–9072.

Extrand, C. W. (2002). Model for contact angles and hysteresis on rough and ultraphobic surfaces. Langmuir, 18, 7991–7999.

Koishi, T., Yasuoka, K., Fujikawa, S., & Zeng, X. C. (2011). Measurement of contact-angle hysteresis for droplets on nanopillared surface and in the Cassie and Wenzel states: a molecular dynamics simulation study. ACS Nano, 5, 6834–6842.

Acknowledgements

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP), granted financial resource from the Ministry of Trade, Industry and Energy (MOTIE) of the Republic of Korea under Grant 20192010106680.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, S., Sung, J. & So, H. Simple Fabrication of Water Harvesting Surfaces Using Three-Dimensional Printing Technology. Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 1449–1459 (2021). https://doi.org/10.1007/s40684-020-00263-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-020-00263-x