Abstract

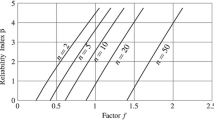

This article investigates the dependence between the method of statistical data processing and the necessary amount of experimental studies required for empirical determination with a given level of reliability of the impact surface dent visual detectability threshold in composite aeronautical structures. Two methods for determining the minimum detectable damage size are considered, one of which is based on using a binomial distribution, and the other, on bootstrap modeling. A comparative analysis of the effectiveness of the two methods is carried out. As a result, it is shown that the bootstrap method gives significantly less scatter of the estimates and allows reducing the number of experts involved by more than by half with the same accuracy of the estimates.

Similar content being viewed by others

REFERENCES

Advisory Circular 20-107B, Sept. 2009, Change 1, Washington, D.C.: Fed. Aviat. Administr., 2010.

Nesterenko G.I., Resource and survivability of aircraft structures, Probl. Mashinostr. Nadezhnosti Mash., 2005, no. 1, p. 106.

Nesterenko G.I., Dubinskii V.S., and Senik V.Ya., Requirements for safe operation of transport aircraft structures, J. Mach. Manuf. Reliab., 2012, vol. 41, no. 1, pp. 83–90.

Dubinskii S. Senik V. Feygenbaum Yu., Field-survey-based evaluation of realistic and remote wing impact energy levels, J. Aircraft, 2018, vol. 55, no. 6, p. 2307.

Sergeichev, I.V., Antonov, F.K., Safonov, A.A., and Ushakov, A.E., Estimation of residual strength of components of composite constructions after low-speed impact, J. Mach. Manuf. Reliab., 2013, vol. 42, no. 1, pp. 29–35.

Kan H.P., Cordero R., and Whitehead R.S., Advanced certification methodology for composite structures, Report, DOT/FAA/AR-96/111, Patuxent River, MD: Naval Air Warfare Center-Aircraft Div. Dep. of the Navy, 1997.

Tropis, A., Thomas, M., Bounie, J., and Lafon, P., Certification of the composite outer wing of the ATR72, Proc. Inst. Mech. Eng., Part G: J. Aerospace Eng., 1995, vol. 209, no. 4, p. 327.

Fawcett, A.J. and Oaks, G.D., Boeing composite airframe damage tolerance and service experience, in Proceedings of the Workshop for Composite Damage Tolerance and Maintenance, Chicago, IL: Natl. Inst. Aviat. Res., 2006.

Morteau, E. and Fualdes, C., Composites at Airbus. Damage tolerance methodology, in Proceedings of the Workshop for Composite Damage Tolerance and Maintenance, Chicago, IL: Natl. Inst. Aviat. Res., 2006.

Spencer F.W., Visual inspection research project report on benchmark inspections, Tech. Rep., DOT/FAA/AR-96/65, Washington, D.C.: U.S. Dep. of Transportation, Fed. Aviat. Administration, 1996.

Erhart, D., Ostrom L.T., and Wilhelmsen, C.A., Visual detectability of dents on a composite aircraft inspection specimen: an initial study, Int. J. Appl. Aviat. Studies, 2004, vol. 4, no. 2.

Baaran J., Visual inspection of composite structures, EASA-Research Project/2007/3 Final Report, Braunschweig, Germany: EASA, 2009.

Boulic, C.L., Harris A., Bellamy D., and Irving, P., Reliability of damage detection in advanced composite aircraft structures, CAA Paper no. 2013/03, West Sussex, UK: CAA 2013.

Feigenbaum, Yu.M., Metelkin, E.S., Mikolaichuk, Yu.A., Senik, V.Ya., Dubinskii, S.V., Gvozdev, S.A., and Khlebnikova, I.G., Experience and principal results of analytical and experimental studies focused on evaluation of composite skin defect visual detection reliability, Nauch. Vestn. GosNII GA, 2016, no. 14, p. 75.

Feigenbaum, Yu.M., Dubinskii, S.V., Bozhevalov, D.G., Sokolov, Yu.S., Metelkin, E.S., Mikolaichuk, Yu.A., and Shapkin, V.S., Obespechenie prochnosti kompozitnykh aviatsionnykh konstruktsii s uchetom sluchainykh ekspluatatsionnykh udarnykh vozdeistvii (Ensuring the Strength of Composite Aircraft Structures, Taking into Account Random Operational Impact), Moscow: Tekhnosfera, 2018.

Dubinskii, S.V. and Safonov, A.A., Composite-friendly approach to certification of advanced materials and fabrication methods used in aviation industry, J. Mach. Manuf. Reliab., 2017, vol. 46, no. 5, pp. 501–506.

Kendall, M.G. and Stuart, A., The Advanced Theory of Statistics, Vol. 1: Distribution Theory, London: Griffin, 1963.

Senik, V.Ya., Khlebnikova, I.G., Feigenbaum, B.M., and Metelkin, E.S., Methodology of statistical processing of experimetnal data to assess the detectrability of impact damage of composite material structure by visual inspection, Nauch. Vestn. GosNII GA, 2016, no. 14, p. 19.

Draper, N. and Smith, H., Applied Regression Analysis, New York: Wiley, 1998.

Efron B., Bootstrap methods: another look at the Jackknife, Ann. Stat., 1979, vol. 7, no. 1, pp. 1–26.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Additional information

Translated by A. Kolemesin

About this article

Cite this article

Dubinskii, S.V., Senik, V.Y., Sidorov, I.S. et al. Determination of the Minimum Number of Inspections Necessary for Establishing of the Barely Visible Impact Damage Size in Composite Aeronautical Structures. J. Mach. Manuf. Reliab. 49, 51–56 (2020). https://doi.org/10.3103/S1052618820010057

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618820010057