Abstract

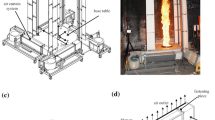

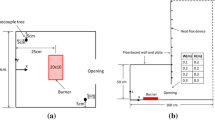

The present study examines the flare tip of a gas refinery. The practical solution was proposed for the destruction of the flare tip because of the flame downwash in the windy condition. CFD modelling was carried out for the flare tip in a 3-dimensional, steady state condition and non-premixed combustion model by the Fluent commercial software. In order to validate the computational results, and compare with the operational data, the flare flame was taken photographed by a thermography camera. The photos were analyzed by ICI-Reporter software. The CFD results of temperature distribution in the symmetry line are compared with the actual results of the photography. Then, the effect of the windshield is investigated on the flare performance. Without a windshield, closed plate, closed mesh, open plate and open mesh windshields are the five different type of windshields which were used in the simulations. Results show that a closed windshield prevents the flame entrance to the space between the flare tip and windshield. This reduced the flare tip body temperature. A closed mesh windshield has the best performance and can eliminate the flame downwash.

Similar content being viewed by others

Abbreviations

- \( D_{i} \) :

-

Diffusion coefficient of species i

- h:

-

Enthalpy

- \( g \) :

-

Gravitational acceleration

- \( \overrightarrow {{j_{i} }} \) :

-

Diffusion flux of i

- \( K_{eff} \) :

-

Effective thermal conductivity

- \( Y_{\mathrm{i}} \) :

-

Mass fraction of species i

- \( p \) :

-

Pressure

- \( R_{\mathrm{i}} \) :

-

Mass flow produced by the chemical reaction

- \( S_{\mathrm{i}} \) :

-

Other sources of component production

- \( {\mathrm{S}}_{\mathrm{h}} \) :

-

Source of production or energy consumption

- \( U^{\prime } \) :

-

Fluctuating velocity vector

- \( \overline{U} \) :

-

Average velocity vector

- \( \rho \) :

-

Fluid density

- \( \mu \) :

-

Dynamic viscosity

References

Abedini E, Zarei T, Rajabnia H, Kalbasi R, Afrand M (2017) Numerical investigation of vapor volume fraction in subcooled flow boiling of a nanofluid. J Mol Liq 238:281–289

Al-Fadhli FM, Kimura Y, McDonald-Buller EC, Allen DT (2012a) Impact of flare destruction efficiency and products of incomplete combustion on ozone formation in Houston, Texas. Ind Eng Chem Res 51:12663–12673

Al-Fadhli FM, Torres VM, Allen DT (2012b) Impacts of air-assist flare blower configurations on flaring emissions. Ind Eng Chem Res 51:12606–12610

Castineira D, Edgar TF (2006) CFD for simulation of steam-assisted and air-assisted flare combustion systems. Energy Fuels 20:1044–1056

Castiñeira D, Edgar TF (2008a) CFD for simulation of crosswind on the efficiency of high momentum jet turbulent combustion flames. J Environ Eng 134:561–571

Castiñeira D, Edgar TF (2008b) Computational fluid dynamics for simulation of wind-tunnel experiments on flare combustion systems. Energy Fuels 22:1698–1706

Fawole OG, Cai XM, MacKenzie AR (2016) Gas flaring and resultant air pollution: a review focusing on black carbon. Environ Pollut 216:182–197

Fortner E, Brooks W, Onasch T, Canagaratna M, Massoli P, Jayne J, Franklin J, Knighton W, Wormhoudt J, Worsnop D (2012) Particulate emissions measured during the TCEQ comprehensive flare emission study. Ind Eng Chem Res 51:12586–12592

Herndon SC, Nelson DD, Wood EC, Knighton WB, Kolb CE, Kodesh Z, Torres VM, Allen DT (2012) Application of the carbon balance method to flare emissions characteristics. Ind Eng Chem Res 51:12577–12585

Hosseini S, Fattahi M, Ahmadi G (2017) Investigation of hydrodynamics and heat transfer in pseudo 2D spouted beds with and without draft plates. Braz J Chem Eng 34:997–1009

Ishisone M (2004) Gas flaring in the Niger Delta: the potential benefits of its reduction on the local economy and environment. Retrieved on December 10:13

Knighton WB, Herndon SC, Franklin JF, Wood EC, Wormhoudt J, Brooks W, Fortner EC, Allen DT (2012) Direct measurement of volatile organic compound emissions from industrial flares using real-time online techniques: Proton Transfer Reaction Mass Spectrometry and Tunable Infrared Laser Differential Absorption Spectroscopy. Ind Eng Chem Res 51:12674–12684

Oliveira F, Martignoni W, Souza E, Pereira L, Santos L, Prata D, Monteiro L (2017) Convective recirculation effect on the selective non-catalytic reduction behavior in an industrial furnace. Braz J Chem Eng 34:1011–1021

Pavlovic RT, Allen DT, McDonald-Buller EC (2011) Temporal variability in flaring emissions in the Houston–Galveston Area. Ind Eng Chem Res 51:12653–12662

Soltanieh M, Zohrabian A, Gholipour MJ, Kalnay E (2016) A review of global gas flaring and venting and impact on the environment: case study of Iran. Int J Greenh Gas Control 49:488–509

Torres VM, Herndon S, Allen DT (2012a) Industrial flare performance at low flow conditions. 2. Steam-and air-assisted flares. Ind Eng Chem Res 51:12569–12576

Torres VM, Herndon S, Kodesh Z, Allen DT (2012b) Industrial flare performance at low flow conditions. 1. Study overview. Ind Eng Chem Res 51:12559–12568

Torres VM, Herndon S, Wood E, Al-Fadhli FM, Allen DT (2012c) Emissions of nitrogen oxides from flares operating at low flow conditions. Ind Eng Chem Res 51:12600–12605

Umukoro GE, Ismail OS (2017) Modelling emissions from natural gas flaring. J King Saud Univ Eng Sci 29:178–182

Zarei T, Abedini E, Rahimi R, Khorshidi J (2017a) Computational fluid dynamics on the hydrodynamic characteristics of the conical cap tray. Korean J Chem Eng 34:969–976

Zarei T, Farsiani M, Khorshidi J (2017b) Hydrodynamic characteristics of valve tray: computational fluid dynamic simulation and experimental studies. Korean J Chem Eng 34:150–159

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zarei, T., Ezadi, A.A. Study on the flare tip of a gas refinery with various designs of windshields using CFD simulations. Braz. J. Chem. Eng. 37, 227–236 (2020). https://doi.org/10.1007/s43153-020-00017-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43153-020-00017-x