Abstract

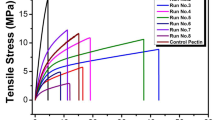

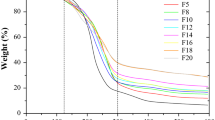

The properties of the mixtures of fatty acids obtained by adding different concentrations of cocoa butter (CB) to a pectin matrix (PEC) were studied. The influence of the CB concentration on the optical properties, mechanical properties, barrier properties, surface properties, microstructure and thermal stability of pectin polysaccharide films were determined. The addition of the CB affected the main properties of the films, with the mechanical strength, transparency and water absorption being reduced. The addition of CB led to opaque films with a heterogeneous microstructure, resulting in an increase in the film opacity. The surface hydrophilicity of the PEC films was reduced following the addition of the CB. The degree of the PEC crystallinity increased with the addition of the butter, making the PEC/CB films more thermally stable and shiny. The new materials obtained present great potential to produce edible films or coatings for moisture-sensitive food applications.

Similar content being viewed by others

References

Thakhiew W, Devahastin S, Soponronnarit S (2010) Effects of drying methods and plasticizer concentration on some physical and mechanical properties of edible chitosan films. J Food Eng 99:216–224. https://doi.org/10.1016/j.jfoodeng.2010.02.025

Jiménez A, Fabra MJ, Talens P, Chiralt A (2010) Effect of lipid self-association on the microstructure and physical properties of hydroxypropyl-methylcellulose edible films containing fatty acids. Carbohydr Polym 82:585–593. https://doi.org/10.1016/j.carbpol.2010.05.014

Dash KK, Ali NA, Das D, Mohanta D (2019) Thorough evaluation of sweet potato starch and lemon-waste pectin based-edible films with nano-titania inclusions for food packaging applications. Int J Biol Macromol 139:449–458. https://doi.org/10.1016/j.ijbiomac.2019.07.193

Liu P, Sun S, Hou H, Dong H (2016) Effects of fatty acids with different degree of unsaturation on properties of sweet potato starch-based films. Food Hydrocoll 61:351–357. https://doi.org/10.1016/j.foodhyd.2016.05.033

Yang L, Paulson A (2000) Effects of lipids on mechanical and moisture barrier properties of edible gellan film. Food Res Int 33:571–578. https://doi.org/10.1016/S0963-9969(00)00093-4

Gahruie HH, Mostaghimi M, Ghiasi F et al (2020) The effects of fatty acids chain length on the techno-functional properties of basil seed gum-based edible films. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2020.05.136

Ma Q, Hu D, Wang H, Wang L (2016) Tara gum edible film incorporated with oleic acid. Food Hydrocoll 56:127–133. https://doi.org/10.1016/j.foodhyd.2015.11.033

Fernández L, de Apodaca ED, Cebrián M et al (2007) Effect of the unsaturation degree and concentration of fatty acids on the properties of WPI-based edible films. Eur Food Res Technol 224:415–420. https://doi.org/10.1007/s00217-006-0305-1

Batista JA, Tanada-Palmu PS, Grosso CRF (2005) Efeito da adição de ácidos graxos em filmes à base de pectina. Ciência e Tecnol Aliment 25:781–788. https://doi.org/10.1590/S0101-20612005000400025

Ayranci E, Tunc S (2001) The effect of fatty acid content on water vapour and carbon dioxide transmissions of cellulose-based edible films. Food Chem 72:231–236. https://doi.org/10.1016/S0308-8146(00)00227-2

Péroval C, Debeaufort F, Despré D, Voilley A (2002) Edible arabinoxylan-based films. 1. Effects of lipid type on water vapor permeability, film structure, and other physical characteristics. J Agric Food Chem 50:3977–3983. https://doi.org/10.1021/jf0116449

Battegazzore D, Bocchini S, Alongi J, Frache A (2014) Plasticizers, antioxidants and reinforcement fillers from hazelnut skin and cocoa by-products: extraction and use in PLA and PP. Polym Degrad Stab 108:297–306. https://doi.org/10.1016/j.polymdegradstab.2014.03.003

Wang H, Maleky F (2018) Effects of cocoa butter triacylglycerides and minor compounds on oil migration. Food Res Int 106:213–224. https://doi.org/10.1016/j.foodres.2017.12.057

Huntrakul K, Harnkarnsujarit N (2020) Effects of plasticizers on water sorption and aging stability of whey protein/carboxy methyl cellulose films. J Food Eng 272:109809. https://doi.org/10.1016/j.jfoodeng.2019.109809

Karbowiak T, Hervet H, Léger L et al (2006) Effect of plasticizers (water and glycerol) on the diffusion of a small molecule in iota-carrageenan biopolymer films for edible coating application. Biomacromol 7:2011–2019. https://doi.org/10.1021/bm060179r

Espitia PJP, Du W-X, de Avena-Bustillos RJ et al (2014) Edible films from pectin: physical-mechanical and antimicrobial properties—a review. Food Hydrocoll 35:287–296. https://doi.org/10.1016/j.foodhyd.2013.06.005

McHUGH TH, Avena-Bustillos R, Krochta JM (1993) Hydrophilic edible films: modified procedure for water vapor permeability and explanation of thickness effects. J Food Sci 58:899–903. https://doi.org/10.1111/j.1365-2621.1993.tb09387.x

Lo Y-L, Lin Y, Lin H-R (2013) Evaluation of epirubicin in thermogelling and bioadhesive liquid and solid suppository formulations for rectal administration. Int J Mol Sci 15:342–360. https://doi.org/10.3390/ijms15010342

Nisar T, Wang Z-C, Yang X et al (2018) Characterization of citrus pectin films integrated with clove bud essential oil: physical, thermal, barrier, antioxidant and antibacterial properties. Int J Biol Macromol 106:670–680. https://doi.org/10.1016/j.ijbiomac.2017.08.068

Manrich A, Moreira FKV, Otoni CG et al (2017) Hydrophobic edible films made up of tomato cutin and pectin. Carbohydr Polym 164:83–91. https://doi.org/10.1016/j.carbpol.2017.01.075

Fadini AL, Rocha FS, Alvim ID et al (2013) Mechanical properties and water vapour permeability of hydrolysed collagen–cocoa butter edible films plasticised with sucrose. Food Hydrocoll 30:625–631. https://doi.org/10.1016/j.foodhyd.2012.08.011

Mendes JF, Norcino LB, Manrich A et al (2020) Development, physical-chemical properties, and photodegradation of pectin film reinforced with malt bagasse fibers by continuous casting. J Appl Polym Sci. https://doi.org/10.1002/app.49178

Aloui H, Baraket K, Sendon R et al (2019) Development and characterization of novel composite glycerol-plasticized films based on sodium caseinate and lipid fraction of tomato pomace by-product. Int J Biol Macromol 139:128–138. https://doi.org/10.1016/j.ijbiomac.2019.07.156

Farhan A, Hani NM (2017) Characterization of edible packaging films based on semi-refined kappa-carrageenan plasticized with glycerol and sorbitol. Food Hydrocoll 64:48–58. https://doi.org/10.1016/j.foodhyd.2016.10.034

Viana RM, Sá NMSM, Barros MO et al (2018) Nanofibrillated bacterial cellulose and pectin edible films added with fruit purees. Carbohydr Polym 196:27–32. https://doi.org/10.1016/j.carbpol.2018.05.017

Lorevice MV, Otoni CG, de Moura MR, Mattoso LHC (2016) Chitosan nanoparticles on the improvement of thermal, barrier, and mechanical properties of high- and low-methyl pectin films. Food Hydrocoll 52:732–740. https://doi.org/10.1016/j.foodhyd.2015.08.003

Otoni CG, de Moura MR, Aouada FA et al (2014) Antimicrobial and physical-mechanical properties of pectin/papaya puree/cinnamaldehyde nanoemulsion edible composite films. Food Hydrocoll 41:188–194. https://doi.org/10.1016/j.foodhyd.2014.04.013

Lara-Espinoza C, Carvajal-Millán E, Balandrán-Quintana R et al (2018) Pectin and pectin-based composite materials: beyond food texture. Molecules 23:942. https://doi.org/10.3390/molecules23040942

Peretto G, Du W-X, Avena-Bustillos RJ et al (2014) Increasing strawberry shelf-life with carvacrol and methyl cinnamate antimicrobial vapors released from edible films. Postharvest Biol Technol 89:11–18. https://doi.org/10.1016/j.postharvbio.2013.11.003

Ravishankar S, Zhu L, Olsen CW et al (2009) Edible apple film wraps containing plant antimicrobials inactivate foodborne pathogens on meat and poultry products. J Food Sci 74:M440–M445. https://doi.org/10.1111/j.1750-3841.2009.01320.x

Rojas-Graü MA, Avena-Bustillos RJ, Friedman M et al (2006) Mechanical, barrier, and antimicrobial properties of apple puree edible films containing plant essential oils. J Agric Food Chem 54:9262–9267. https://doi.org/10.1021/jf061717u

Munhoz DR, Moreira FKV, Bresolin JD et al (2018) Sustainable production and in vitro biodegradability of edible films from yellow passion fruit coproducts via continuous casting. ACS Sustain Chem Eng 6:9883–9892. https://doi.org/10.1021/acssuschemeng.8b01101

Otoni CG, Lodi BD, Lorevice MV et al (2018) Optimized and scaled-up production of cellulose-reinforced biodegradable composite films made up of carrot processing waste. Ind Crops Prod 121:66–72. https://doi.org/10.1016/j.indcrop.2018.05.003

Mendes JF, Norcino LB, Martins HHA et al (2020) Correlating emulsion characteristics with the properties of active starch films loaded with lemongrass essential oil. Food Hydrocoll 100:105428. https://doi.org/10.1016/j.foodhyd.2019.105428

Müller CMO, Laurindo JB, Yamashita F (2009) Effect of cellulose fibers addition on the mechanical properties and water vapor barrier of starch-based films. Food Hydrocoll 23:1328–1333. https://doi.org/10.1016/j.foodhyd.2008.09.002

ASTM D882-09 (2009) Standard test method for tensile properties of thin plastic sheeting

ASTM E96 (2016) Standard test methods for water vapor transmission of materials

ASTM (2008) ASTM D5725-99(2008), Standard test method for surface wettability and absorbency of sheeted materials using an automated contact angle tester (Withdrawn 2010)

Laboulfie F, Hémati M, Lamure A, Diguet S (2013) Effect of the plasticizer on permeability, mechanical resistance and thermal behaviour of composite coating films. Powder Technol 238:14–19. https://doi.org/10.1016/j.powtec.2012.07.035

Gouveia TIA, Biernacki K, Castro MCR et al (2019) A new approach to develop biodegradable films based on thermoplastic pectin. Food Hydrocoll 97:105175. https://doi.org/10.1016/j.foodhyd.2019.105175

Goodacre R, Anklam E (2001) Fourier transform infrared spectroscopy and chemometrics as a tool for the rapid detection of other vegetable fats mixed in cocoa butter. J Am Oil Chem Soc 78:993–1000. https://doi.org/10.1007/s11746-001-0377-x

Sri Rahayu W, Sundhani E, Dwi Saputri S (2015) The use of Fourier Transform Infrared Spectroscopy (FTIR) and gas chromatography mass spectroscopy (GCMS) for halal authentication in imported chocolate with various variants. J Food PharmSci 2:6–11

Pasini Cabello SD, Takara EA, Marchese J, Ochoa NA (2015) Influence of plasticizers in pectin films: microstructural changes. Mater Chem Phys 162:491–497. https://doi.org/10.1016/j.matchemphys.2015.06.019

Chaichi M, Hashemi M, Badii F, Mohammadi A (2017) Preparation and characterization of a novel bionanocomposite edible film based on pectin and crystalline nanocellulose. Carbohydr Polym 157:167–175. https://doi.org/10.1016/j.carbpol.2016.09.062

Tomé LC, Gonçalves CMB, Boaventura M et al (2011) Preparation and evaluation of the barrier properties of cellophane membranes modified with fatty acids. Carbohydr Polym 83:836–842. https://doi.org/10.1016/j.carbpol.2010.08.060

Nobrega MM, Olivato JB, Müller CMO, Yamashita F (2013) Addition of saturated fatty acids to biodegradable films: effect on the crystallinity and viscoelastic characteristics. J Polym Environ 21:166–171. https://doi.org/10.1007/s10924-012-0477-7

Jiménez A, Fabra MJ, Talens P, Chiralt A (2012) Effect of re-crystallization on tensile, optical and water vapour barrier properties of corn starch films containing fatty acids. Food Hydrocoll 26:302–310. https://doi.org/10.1016/j.foodhyd.2011.06.009

Gurram R, Souza Filho PF, Taherzadeh MJ, Zamani A (2018) A solvent-free approach for production of films from pectin and fungal biomass. J Polym Environ 26:4282–4292. https://doi.org/10.1007/s10924-018-1300-x

Das P, Borah PP, Badwaik LS (2018) Transformation of chicken feather keratin and pomelo peel pectin into biodegradable composite film. J Polym Environ 26:2120–2129. https://doi.org/10.1007/s10924-017-1109-z

Vargas M, Albors A, Chiralt A, González-Martínez C (2009) Characterization of chitosan–oleic acid composite films. Food Hydrocoll 23:536–547. https://doi.org/10.1016/j.foodhyd.2008.02.009

Tedeschi G, Benitez JJ, Ceseracciu L et al (2018) Sustainable fabrication of plant cuticle-like packaging films from tomato pomace agro-waste, beeswax, and alginate. ACS Sustain Chem Eng 6:14955–14966. https://doi.org/10.1021/acssuschemeng.8b03450

Bodin A, Ahrenstedt L, Fink H et al (2007) Modification of nanocellulose with a Xyloglucan–RGD conjugate enhances adhesion and proliferation of endothelial cells: implications for tissue engineering. Biomacromol 8:3697–3704. https://doi.org/10.1021/bm070343q

Bertan LC, Tanada-Palmu PS, Siani AC, Grosso CRF (2005) Effect of fatty acids and “Brazilian elemi” on composite films based on gelatin. Food Hydrocoll 19:73–82. https://doi.org/10.1016/j.foodhyd.2004.04.017

Heinämäki J, Halenius A, Paavo M et al (2015) Suberin fatty acids isolated from outer birch bark improve moisture barrier properties of cellulose ether films intended for tablet coatings. Int J Pharm 489:91–99. https://doi.org/10.1016/j.ijpharm.2015.04.066

Dangaran KL, Krochta JM (2007) Preventing the loss of tensile, barrier and appearance properties caused by plasticiser crystallisation in whey protein films. Int J Food Sci Technol 42:1094–1100. https://doi.org/10.1111/j.1365-2621.2006.01355.x

Al-Hassan AA, Norziah MH (2012) Starch–gelatin edible films: water vapor permeability and mechanical properties as affected by plasticizers. Food Hydrocoll 26:108–117. https://doi.org/10.1016/j.foodhyd.2011.04.015

Kaya M, Ravikumar P, Ilk S et al (2018) Production and characterization of chitosan based edible films from Berberis crataegina’s fruit extract and seed oil. Innov Food Sci Emerg Technol 45:287–297. https://doi.org/10.1016/j.ifset.2017.11.013

Fakhouri FM, Martelli SM, Caon T et al (2018) The effect of fatty acids on the physicochemical properties of edible films composed of gelatin and gluten proteins. LWT Food Sci Technol 87:293–300. https://doi.org/10.1016/j.lwt.2017.08.056

Andreuccetti C, Carvalho RA, Grosso CRF (2009) Effect of hydrophobic plasticizers on functional properties of gelatin-based films. Food Res Int 42:1113–1121. https://doi.org/10.1016/j.foodres.2009.05.010

Al Naim A, Alnaim N, Ibrahim SS, Metwally SM (2017) Effect of gamma irradiation on the mechanical properties of PVC/ZnO polymer nanocomposite. J Radiat Res Appl Sci 10:165–171. https://doi.org/10.1016/j.jrras.2017.03.004

Zhang X, Zhao Y, Li Y et al (2020) Physicochemical, mechanical and structural properties of composite edible films based on whey protein isolate/psyllium seed gum. Int J Biol Macromol 153:892–901. https://doi.org/10.1016/j.ijbiomac.2020.03.018

Otoni CG, Lorevice MV, de Moura MR, Mattoso LHC (2018) On the effects of hydroxyl substitution degree and molecular weight on mechanical and water barrier properties of hydroxypropyl methylcellulose films. Carbohydr Polym 185:105–111. https://doi.org/10.1016/j.carbpol.2018.01.016

Otoni CG, Avena-Bustillos RJ, Olsen CW et al (2016) Mechanical and water barrier properties of isolated soy protein composite edible films as affected by carvacrol and cinnamaldehyde micro and nanoemulsions. Food Hydrocoll 57:72–79. https://doi.org/10.1016/j.foodhyd.2016.01.012

Rezvani E, Schleining G, Sümen G, Taherian AR (2013) Assessment of physical and mechanical properties of sodium caseinate and stearic acid based film-forming emulsions and edible films. J Food Eng 116:598–605. https://doi.org/10.1016/j.jfoodeng.2012.12.039

Jouki M, Khazaei N, Ghasemlou M, HadiNezhad M (2013) Effect of glycerol concentration on edible film production from cress seed carbohydrate gum. Carbohydr Polym 96:39–46. https://doi.org/10.1016/j.carbpol.2013.03.077

Jafari SM, Khanzadi M, Mirzaei H et al (2015) Hydrophobicity, thermal and micro-structural properties of whey protein concentrate–pullulan–beeswax films. Int J Biol Macromol 80:506–511. https://doi.org/10.1016/j.ijbiomac.2015.07.017

Vogler EA (1998) Structure and reactivity of water at biomaterial surfaces. Adv Colloid Interface Sci 74:69–117. https://doi.org/10.1016/S0001-8686(97)00040-7

Shankar S, Tanomrod N, Rawdkuen S, Rhim J-W (2016) Preparation of pectin/silver nanoparticles composite films with UV-light barrier and properties. Int J Biol Macromol 92:842–849. https://doi.org/10.1016/j.ijbiomac.2016.07.107

Ferreira AS, Nunes C, Castro A et al (2014) Influence of grape pomace extract incorporation on chitosan films properties. Carbohydr Polym 113:490–499. https://doi.org/10.1016/j.carbpol.2014.07.032

Pereda M, Amica G, Marcovich NE (2012) Development and characterization of edible chitosan/olive oil emulsion films. Carbohydr Polym 87:1318–1325. https://doi.org/10.1016/j.carbpol.2011.09.019

Ojagh SM, Rezaei M, Razavi SH, Hosseini SMH (2010) Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem 122:161–166. https://doi.org/10.1016/j.foodchem.2010.02.033

Silva KS, Fonseca TMR, Amado LR, Mauro MA (2018) Physicochemical and microstructural properties of whey protein isolate-based films with addition of pectin. Food Packag Shelf Life 16:122–128. https://doi.org/10.1016/j.fpsl.2018.03.005

Gontard Nathalie Guilbert, Stéphane Cuq J-L (1992) Edible wheat gluten films: influence of the main process variables on film properties using response surface methodology. J Food Sci 57:190–195. https://doi.org/10.1111/j.1365-2621.1992.tb05453.x

Souza MP, Vaz AFM, Silva HD et al (2015) Development and characterization of an active chitosan-based film containing quercetin. Food Bioprocess Technol 8:2183–2191. https://doi.org/10.1007/s11947-015-1580-2

Acknowledgements

The authors acknowledge the National Council for Scientific and Technological Development—CNPq (grants 141823/2017-8) and Empresa Brasileira de Pesquisa Agropecuária (EMBRAPA).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mendes, J.F., Norcino, L.B., Manrich, A. et al. Characterization of Pectin Films Integrated with Cocoa Butter by Continuous Casting: Physical, Thermal and Barrier Properties. J Polym Environ 28, 2905–2917 (2020). https://doi.org/10.1007/s10924-020-01829-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01829-1