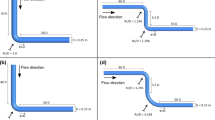

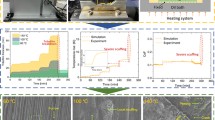

A subsea oil and gas pipeline repair clamp and circumferential sealing structure are designed. Based on the principle of equal contact pressure on the contact surface and the thick-walled cylinder calculation, a formula for the contact pressure between the sealing ring and the outer wall of the pipeline is derived. An axisymmetric finite element model is constructed for circumferential sealing with an ABAQUS software suite. The model is used to calculate the contact pressure necessary for the sealing structure, which requires different sealing pressures, and to determine the respective bolt preload for a ∅219-mm clamp. The model also defines a maximum effective contact pressure and average effective contact pressure between the sealing ring and the outer wall of the pipeline. The prediction of the contact force caused by the deformation of a sealing ring due to the geometry restriction was experimentally verified. The finite element and experimental results confirm the validity of grounding in theory and derived formula. The calculations can provide the guidelines for the design of the seal structure of a clamp and the overall structure, as well as future engineering applications.

Similar content being viewed by others

References

B. J. Zhao, H. W. Zhu, D. Y. Tang, et al., “The clamp repair technology of subsea oil and gas pipeline,” Ocean Eng., 31, No. 3, 95–100 (2013).

A. Rebello and R. R. Ayers, “Deep water pipeline emergencies, managing risk and cost: the co-ownership solution,” in: Proc. of the 6th Int. Offshore Pipeline Forum (Oct. 19–20, 2011, Houston, Texas, USA), IOPF2011-6003 (2011).

R. R. Ayers, S. Hoysan, A. Rebello, et al., “DW RUPE: A new deepwater pipeline repair capability for the gulf of Mexico and other deepwater regions,” in: Offshore Technology Conference (May 5–8, 2008, Houston, Texas, USA), OTC-19207-MS (2008), https://doi.org/10.4043/19207-MS.

C. S. Cai, F. Gao, and Y. T. Zhang, “Application of clamp installation method in the leak point repair of subsea pipeline,” Mech. Engineer, No. 4, 9–11 (2013).

C. Ma, K. Sun, Y. Z. Huang, et al., “Study on repair methods for deepwater pipeline,” Ocean Eng. Equip. Technol., 2, No. 3, 168–174 (2015).

S. M. Zhang, X. T. Mei, G. C. Wang, et al., “Oil/gas pipeline maintenance and emergency repair method and its progress,” Oil Gas Stor. Transport., 33, No. 11, 1180–1186 (2014).

Research on Maintenance Technology of Long Distance Oil & Gas Pipeline Storage and Transportation System [in Chinese], China Petroleum Pipeline Bureau, Langfang (2011).

C. T. Zhang, J. L. Tian, Z. Fang, et al., “Clamping apparatus mechanics analysis and structure optimization design,” Oil Field Equip., 42, No. 10, 28–32 (2013).

L. Gao and Z. Liang, “Optimized design of clamps for rush-repair of high-pressure pipeline,” Oil Gas Stor. Transport., 32, No. 7, 740–744 (2013).

G. C. Wang, Z. F. Jia, T. R. Wang, et al., The Sealing Structure of One Pipeline Repair Clamp [in Chinese], ZL200720149602.9 (2008).

H. T. Li, S. M. Zhang, L. S. Zhao, et al., “The sealing performance analysis of underwater tap clamp,” Oil Field Equip., 43, No. 1, 11–13 (2014).

B. J. Zhao, H. W. Zhu, S. L. Zhang, et al., “Design of subsea oil and gas pipeline repair clamp,” in: Proc. of the ASME 2015 Pressure Vessels and Piping Conference (July 19–23, 2015, Boston, MA, USA) (2015), https://doi.org/10.1115/PVP2015-45004.

B. J. Zhao, H. W. Zhu, S. L. Zhang, et al., “Research of sealing property to subsea oil and gas pipeline repair clamp,” in: Proc. of the ASME 2015 Pressure Vessels and Piping Conference (July 19–23, 2015, Boston, MA, USA) (2015), https://doi.org/10.1115/PVP2015-45049.

B. J. Zhao, H. W. Zhu, Y. J. Zhang, et al., “Research of sealing structure to subsea oil and gas pipeline repair clamp,” China Petrol. Machin., 44, No. 5, 50–54 (2016).

J. Chuan, and Y. C. Ma, “The design of high pressure clamp for plugging pipeline under water,” Jiangsu Ship, 32, No. 2, 11–14 (2015).

Pipeline Subsea Repair: DNV Recommended Practice DNV-RP-F113, Det Norske Veritas (2007).

Theoretical Basis and Application of Packer [in Chinese], Oil Production Technology Research Institute of Jianghan Petroleum Administration Bureau, Petroleum Industry Press, Beijing (1983).

X. R. Zhu, L. Z. Wu, and L. Z. Dai, Design Basis of Packer [in Chinese], China Petrochemical Press, Beijing (2012).

S. D. Ju, R. Q. Ma, X. M. Hong, et al., “Design and sealing performance analysis of the offshore completion packer rubber sleeve,” China Petrol. Machin., 43, No. 6, 46–49 (2015).

S. K. Tong, “Mechanical Properties analysis of compressed packing rubber during axial compressing,” Oil Field Equip., 41, No. 12, 1–7 (2012).

G. T. Yang, Introduction to Elasticity and Plasticity [in Chinese], Tsinghua University Press, Beijing (2004).

M. J. Mooney, “A theory of large elastic deformation,” J. Appl. Phys., 11, No. 6, 582–592 (1940).

R. S. Rivlin, “Large elastic deformations of elastic material: IV: Further developments of the general theory,” Philos. T. R. Soc. S-A, 241, No. 835, 379–397 (1948).

J. Zhang and G. Jin, “Finite element analysis of contact pressure on O-ring,” Lubr. Eng., 35, No. 2, 80–83 (2010).

X. J. Yang and H. L. Yang, “Numerical analysis of sealing process of hydraulic packer rubber,” J. Univ. Petrol., 27, No. 5, 84–87 (2003).

Y. P. Shi and Y. R. Zhou, The ABAQUS Finite Element Analysis Detailed Examples [in Chinese], China Machine Press, Beijing (2006).

W. J. Guan, Q. G. Du, and P. Q. Liu, “Finite element analysis of the sealing performance of rubber O-ring,” Lubr. Eng., 37, No. 6, 60–64 (2012).

Pressure Vessels, Standards Press of China, Beijing (2011).

Acknowledgments

This project was supported by the PetroChina Innovation Foundation, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 70 – 82, January – February, 2020.

Rights and permissions

About this article

Cite this article

Zhao, B.J., Zhu, H.W., Zhang, J.Y. et al. Circumferential Sealing Structure of a Subsea Oil and Gas Pipeline Repair Clamp. Strength Mater 52, 59–70 (2020). https://doi.org/10.1007/s11223-020-00150-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-020-00150-5