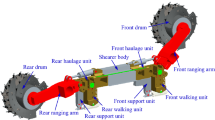

A method of cutting coal with three drums was advanced, a three-drum shearer was designed, and the free mode and restrained model under prestress of the third drum were analyzed in large mining with ANSYS Workbench 14.0 to solve the damage problem of the cutting blade in a large mining face. The vibration modes caused by its own structural characteristics are obtained, and the dynamic response of all parts of the shearer is studied with MATLAB R2016a software under given conditions and the change of the parameters. The overloads of the front drum give rise to larger vibration displacements that should be avoided in the operation of the shearer. The above approach is of importance to evolve the design concepts and improve cutting characteristics of the largeheight shearer, to provide theoretical backgrounds ensuring safe and reliable mining of superthick coal seams by the large-height shearer.

Similar content being viewed by others

References

X. L. Zhang, Y. L. Liu, and C. Chen, “Structural optimization design of shearer pick-shaped cutter based on workbench,” Coal Mine Machinery, 35, No. 10, 177–180 (2014).

L. Hou, J. L. Feng, Y. L. Wang, and Z. J. Yang, “Study on influence of installation angle of shearer to force,” Coal Technol., 36, No. 4, 277–230 (2017).

X. M. Qi, “Finite element analysis and optimization of cutting line distance of coal cutter drum,” Coal Mine Machinery, 35, No. 10, 231–232 (2014).

Y. J. Zhang, J. Y. Wang, L. Dong, et al., “Analysis of vibration characteristics of cutting arm of EML340 continuous miner,” Ind. Mine Automat., 42, No. 12, 63–67 (2016).

Q. H. Jia, “Research and development as well as industrial test of MG1100/ 2760-GWD electric-traction drum shearer for large mining height,” China Coal, 39, No. 2, 64–66 (2013).

X. K. Song, J. Hu, and X. P. Zhu, “Common faults and countermeasures of high power shearer walking system under complex geological conditions,” Coal Mine Machinery, 35, No. 11, 288–290 (2014).

Q. R. Li, L. Shen, and Y. B. Li, “Research and discussion of new pattern shearer travel wheel,” Coal Mine Machinery, 32, No. 12, 158–159 (2011).

L. Shen, Q. R. Li, Q. Lei, and H. Yan, “Structure improvement and finite element analysis of shearer guide skid shoe,” Coal Mine Machinery, 34, No. 10, 165–166 (2013).

X. W. Wang, Y. T. Zhang, Y. Li, et al., “Cause analysis and preventive measures of gear wear in walking part of shearer,” Coal Mine Machinery, 34, No. 3, 195–196 (2013).

Z. H. Huang, X. J. Zhang, and Y. J. Zhou, “Simulation of meshing collision force of involute gear,” J. Central South Univ.: Natural Sci. Edition, 42, No. 2, 379–383 (2011).

F. F. Cheng, Z. J. Yang, S. P. Wang, and X. W. Wang, “Simulation of meshing between shearer traction wheel and scraper conveyor tooth rail,” Coal Mine Machinery, 34, No. 7, 55–57 (2013).

J. W. Zhou, Y. Liu, S. Y. Liu, and C. L. Du, “Characteristic analysis of dynamic meshing for shearer walking mechanism,” Chinese J. Eng. Design, 20, No. 3, 230–235 (2013).

L. W. Shi and C. Y. Li, “FEA on walking unit of shearer based on virtual prototype technology,” Mining Process. Equip., 42, No. 6, 9–13 (2014).

Q. Zhang, Z. H. Liu, H. J. Wang, et al., “On-line monitoring of gear cutting wear degree based on BP Neural Network,” China Mech. Eng., No. 9, 1062–1068 (2017).

Q. Zhang, Z. G. Wu, Z. Y. Wu, and H. J. Wang, “On-line testing and analysis of shearer steering slide mechanics,” Chinese J. Eng. Design, 24, No. 6, 694–716 (2017).

Q. Zhang, H. J. Wang, Z. G. Wu, et al., “Study on mechanical characteristics and test system of coal and rock cutting of drum shearer,” Chinese J. Eng. Design, 24, No. 4, 459–479 (2017).

H. Wang, Q. Zhang, and F. Xie, “Dynamic tension test and intelligent coordinated control system of a heavy scraper conveyor,” IET Sci. Meas. Technol., 11, No. 7, 871–877 (2017).

Q. Zhang, J. M. Liu, Y. F. Liu, and L. Y. Li, “Study on high-strength ring chain dynamic characteristics under different launch parameters,” Strength Mater., 50, No. 2, 331–339 (2018).

Q. Zhang, M. J. Xu, and N. Hu, “Study on fatigue life of plow bit under different planning parameters,” Strength Mater., 46, No. 2, 262–269 (2014).

H. Wang and Q. Zhang, “Dynamic identification of coal-rock interface based on adaptive weight optimization and multi-sensor information fusion,” Inform. Fusion, 51, 114–128 (2018).

M. Akhtaruzzaman, R. Akmeliawati, and T. W. Yee, “Modeling and control of a multi degree of freedom flexible joint manipulator,” in: Proc. of the 2009 Second Int. Conf. on Computer and Electrical Engineering (Dec. 28–30, 2009, Dubai, United Arab Emirates), IEEE (2009), https://doi.org/10.1109/ICCEE.2009.100.

S. M. Sahebkar, M. R. Ghazavi, S. E. Khadem, and M. H. Ghayesh, “Nonlinear vibration analysis of an axially moving drillstring system with time dependent axial load and axial velocity in inclined well,” Mech. Mach. Theory, 46, 743–760 (2011).

Acknowledgments

This study was financially supported by the National Natural Science Foundation Fund of China (Projects Nos. U1810119, 51774161, and 51804151), Development of National Key Laboratory of Mineral Processing Science and Technology (BGRIMM-KJSKL-2017-20), the Youth Research Projects in Colleges and Universities of Liaoning Provincial Department of Education of China (LJ2017QL018), and Taishan Scholar Program of Shandong Province of China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 181 – 191, January – February, 2020.

Rights and permissions

About this article

Cite this article

Zhang, Q., Wang, Y., Li, B.Q. et al. Vibration Analysis of a Three-Drum Shearer for a Large Mining Height. Strength Mater 52, 160–170 (2020). https://doi.org/10.1007/s11223-020-00161-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-020-00161-2