Abstract

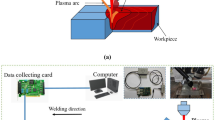

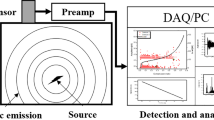

A procedure is proposed for rejecting girth welds based on an analysis of the main parameters of acoustic emission (AE) signals recorded during multiple-pass welding. The accuracy of locating AE signals recorded from defects and their filtering from noise and interference were ensured by the use of a modified tabular method and rejection grid. Normalized coefficients were calculated from the energy and amplitude of localized AE signals and used for in-process assessment of weld quality. Threshold values were determined for the normalized coefficients above which the weld is rejected. Defects in girth welds were identified using this procedure, and the possibility of determining defect hazardousness in real time was demonstrated.

Similar content being viewed by others

REFERENCES

Nedoseka, A.Ya., Osnovy rascheta i diagnostiki svarnykh kjonstruktsii (Fundamentals of Design and Diagnostics of Welded Structures) Paton, B.E., Ed., Kiev: INDPROM, 2008.

Gumenyuk, V.A., Kazakov, N.A., and Sul’zhenko, V.A., Acoustic emission testing of the process of welding marine equipment, V Mire NK, 2010, no. 4, pp. 20–25.

Nosov, V.V., Yamilova, A.R., Zelenskii, N.A., and Matviyan, I.V., Evaluating the strength and resource of welded structures based on the micromechanical model of acoustic emission under static loading, Deform. Razrushenie Mater., 2016, no. 11, pp. 38–45.

Nosov, V.V. and Zelenskii, N.A., Estimating the strength of welded hull elements of a submersible based on the micromechanical model of temporal dependences of acoustic-emission parameters, Russ. J. Nondestr. Test., 2017, vol. 53, no. 2, pp. 89–95.

Nosov, V.V., Yamilova, A.R., Zelenskii, N.A., and Matviyan, I.V., Optimization of acoustic emission testing of the strength of welded joints, Vestn. MEI, 2017, no. 2, pp. 96–101.

Nosov, V.V. and Zelenskii, N.A., Monitoring and diagnostics of the ring elements of the underwater vehicle’s welded hull based on the micromechanical model of the time dependences of acoustic emission parameters, Kontrol’ Diagn., 2016, no. 12, pp. 30–39.

Bigus, G.A. and Sabrekov, M.A., Investigation of the least durable sections of metal structures using the acoustic emission method, Svarka Diagn., 2013, no. 4, pp. 36–40.

Chentsov, V.P., Akusticheskaya emissiya pri uprugoplasticheskom deformirovanii konstruktsionnykh materialov i opyt ee primeneniya v nerazrushayushchem kontrole (Acoustic Emission during Elastoplastic Deformation of Structural Materials and the Experience of Its Usage in Nondestructive Testing), Khabarovsk–Tomsk: Tomsk Politekh. Univ., 2014.

Chernyaeva, E.V., Galkin, D.I., Bigus, G.A., and Merson, D.L., The use of the acoustic emission method for nondestructive testing of the state of the base metal and welded joints of pipelines operating in conditions of low-cycle fatigue, Svarka Diagn., 2010, no. 2, pp. 50–57.

Boström, E.Y., Patent of Sweden no 376084, MCP 4G 1N29/04. Anordning för bedömning av mateerialfel vid ultraljdundersökning, Motala Verkstad AB [SE], decl. October 5, 1972, publ. May 5, 1975.

Ser’eznov, A.N., Stepanova, L.N., and Kabanov, S.I., Diagnostic module of a distributed acoustic emission system, Datchiki Sist., 2016, no. 5, pp. 37–43.

Stepanova, L.N., Kabanov, S.I., Ramazanov, I.S., and Kanifadin, K.V., Analysis of errors in location of flaws in multipass welds using different clustering methods, Russ. J. Nondestr. Test., 2017, vol. 53, no. 2, pp. 96–103.

Stepanova, L.N., Chernova, V.V., and Ramazanov, I.S., The use of clustering methods for processing acoustic emission information, Kontrol’ Diagn., 2019, no 8, pp. 12–21.

Ser’eznov, A.N., Stepanova, L.N., Kabanov, S.I., et al., Akustiko-emissionnyi kontrol’ defektov svarki (Acoustic Emission Testing of Welding Defects) Novosibirsk: Nauka, 2018.

Stepanova, L.N., Kabanov, S.I., Ramazanov, I.S., and Kanifadin, K.V., RF Patent 2 572 067, MPK G 01 N 29/14. The method of acoustic emission control of the quality of the weld in the process of multi-pass welding and a device for its implementation, appl. patent holder Sib. Transp. Univ. no. 2014132494/28, claimed August 6, 2014, Byull. Izobret., 2015, no. 36.

Gomera, V.P., Smirnov, A.D., Nefed’ev, E.Yu., Potapov, A.I., and Zotov, K.V., Acoustic emission detection of cracks in a weld during welding, Kontrol’ Diagn., 2016, no. 7, pp. 25–32.

Stepanova, L.N., Ramazanov, I.S., and Kireenko, V.V., The development of a defect-rejection procedure for multiple-pass welding by the distribution of the principal parameters of acoustic-emission signals, Russ. J. Nondestr. Test., 2014, vol. 50, no. 11, pp. 667–678.

Barinov, A.V., Fedorov, A.V., Kinzhagulov, I.Yu., Sergeev, D.S., and Dorenskaya, A.V., Quality control of welded joints in the welding process using the acoustic emission method, Nauchn.-Tekh. Vestn. ITMO, 2013, no. 5(87), pp.144–148.S

Real-Time Weld Process Monitoring, Zang, Y.M., Cambrige: Woodhead Publ., 2008.

Meng, X., Papaelias, M., Huang, Z., and Melton, G., Welding quality monitoring using acoustic emission techniques, in Conf: First World Congr. Cond. Monit. WCCM 2017, London, June 2017.

Zhang, L., Carmen Basantes-Defaz, A., and Ozevin, D., Real-time monitoring of welding process using aircoupled ultrasonics and acoustic emission. Int. J. Adv. Manuf. Technol., 2019, vol. 101, nos. 5–8, pp. 1623–1634.

Brunner, A., Tannert, T., and Tallée, T., Waveform analysis of acoustic emission monitoring of tensile tests on welded wood-joints, J. Acoust. Emiss., 2010, vol. 28, pp. 59–67.

Poopat, B. and Jirarungsatean, C., Feasibility study of acoustic emission monitoring of hot cracking in GTAW weld, Key Eng. Mater., 2013, vol. 545, pp. 236–240.

Gumenyuk, V.A. and Nesmashnyi, E.V., Optimization of the acoustic emission defect location algorithm in the annular seams of welded structures, Kontrol’ Diagn., 2007, no. 9, pp. 34–42.

Stepanova, L.N., Kabanov, S.I., Lebedev, E.Yu., Kireenko, V.V., Vonsovskii, A.V., and Ramazanov, I.S., Acoustic emission testing for defects during multipass welding of samples from shipbuilding steel, Kontrol’ Diagn., 2013, no. 12, pp. 74–80.

Stepanova, L.N., Ramazanov, I.S., and Kireenko, V.V., Acoustic-emission location of flaws during multiple-run welding of contours with complex shapes, Russ. J. Nondestr. Test., 2016, vol. 52, no. 5, pp. 261–268.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Potapchouck

Rights and permissions

About this article

Cite this article

Stepanova, L.N., Kabanov, S.I., Ramazanov, I.S. et al. Acoustic-Emission Procedure for Rejecting Defects in Multiple-Pass Girth Welds. Russ J Nondestruct Test 55, 898–908 (2019). https://doi.org/10.1134/S106183091912012X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S106183091912012X