Abstract

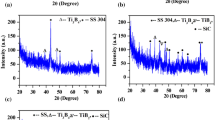

Owing to the desired mechanical and biomedical characteristics of TiN-based coatings and the encourage features of pulsed magnetron sputtering, the current study was conducted to deposit Ti-Al-N thin film on AISI 316 using DC pulsed magnetron sputtering. All processing parameters were constant excluding the pulsed magnetron power which was varied from 100 to 175 W. The effect of processing power on the structure, mechanical, electrochemical, and biocompatibility characteristics of Ti-Al-N thin films were inspected. X-ray outlines the formation of (Ti, Al)N solid solution with (111) preferred orientation at high-pulsed magnetron powers. The outcomes of this study demonstrated that the Vickers’s microhardness of Ti-Al-N coatings increased with increasing pulsed power to record a value of nearly 810 HV0.015 at 175 W. Moreover, the wear characteristics and the friction coefficient of the coated AISI 316 with Ti-Al-N were ascendant as compared with the uncoated substrate. The wear rate of Ti-Al-N films deposited at pulsed power of 175 W recorded a value of nearly 4.7 × 10−6 mm3/Nm which was very low compared with that of stainless steel substrate (3.2 × 10−4 mm3/Nm). The biological peculiarities of Ti-Al-N films were examined by exploring the proliferation rate of MC3T3-E1 osteoblast cells on the film surface. The results reflected that the proliferation rate of the osteoblast cells were enhanced on Ti-Al-N films deposited at pulsed powers of 150 and 175 W. The biological attitudes were discussed according to the results of surface roughness and surface energy besides the surface chemical compositions.

Similar content being viewed by others

References

Vladescu, A., Cotrut, C.M., Kiss, A., Balaceanu, M., Braic, V., Zamfir, S., Braic, M.: U.P.B. Sci. Bull. Series B. 68, 57 (2006)

Vardanyan, E.L., Budilov, V.V., Ramazanov, K.N., Ataullin, Z.R.: J. Phys. Conf. Ser. 872, 012026 (2017)

El-Hossary, F.M., Negm, N.Z., Abd El-Rahman, A.M., Raaif, M., Seleem, A.A., Abd El-Moula, A.A.: Surf. Coat. Technol. 276, 658 (2015)

Liang, F., Wang, H., Zou, C.: Japa J. Appl. Phys. 53, 075503 (2014)

El-Hossary, F.M., Abd El-Rahman, A.M., Raaif, M., Ghareeb, D.A.: Appl. Phys. A Mater. Sci. Process. 122 (2016)

Kim, G.S., Lee, S.Y., Hahn, J.H.: Surf. Coat. Technol. 193, 213 (2005)

Hasegawa, H., Kimura, A., Suzuki, T.: Surf. Coat. Technol. 132, 76 (2000)

Zhu, L., Hu, M., Ni, W., Liu, Y.: Vac. 86, 1795 (2012)

Ig, Z., Efim, O., Rosen, J.: J. Appl. Phys. 117, 213301 (2015)

Shieh, J., Hon, M.H.: Thin Solid Films. 391, 101 (2001)

Endle J. P., Sun Y. M, Silverman J., Nguyen N., Cowley A. H., White J. M. and Ekerdt J. G.2001 Thin Solid Films 385 66

Knotek, O., Munz, W.D., Leyendecker, T.: J. Vac. Sci. Technol. A. 5, 2173 (1987)

Anselme, K., Bigerelle, M.: Acta Biomater. 1, 211 (2005)

Ramana, J.V., Kumar, S., David, C., Raju, V.S.: Mater. Lett. 58, 2553 (2004)

Oliveira, J.C., Manaia, A., Cavaleiro, A., Vieira, M.T.: Surf. Coat. Technol. 201, 4073 (2006)

Oliveira, J.C., Manaia, A., Dias, J.P., Cavaleiro, A., Teer, D., Taylor, S.: Surf. Coat. Technol. 200, 6583 (2006)

Raaif, M.: J. Adv. Phys. 14, 5638 (2018)

El-Hossary, F.M., Abd El-Rahman, A.M., Raaif, M., Shuxin, Q., Zhao, J., Manfred, F.M., Abo, E.-K.M.: Appl. Phys. A Mater. Sci. Process. 124 (2018)

ASTM standard E384, 2011, ASTM International, West Conshohocken, PA 19428-2959, United States, https://doi.org/10.1520/E0384-11

Shetty, A.R., Karimi, A., Cantoni, M.: Thin Solid Films. 519, 4262 (2011)

PalDey, S., Deevi, S.C.: Mater. Sci. Eng. A. 342, 58 (2003)

Gredic´ T. and Zlatanovic´ M.: Surf. Coat. Technol. 48, 25 (1991)

Chinsakolthanakorn, S., Buranawong, A., Witit-anun, N., Chaiyakun, S., Limsuwan, P.: Process. Eng. 32, 571 (2012)

Lim, S.H.N., McCullogh, D.G., Bilek, M.M.M., McKenzie, D.R.: Surf. Coat. Technol. 174–175, 76 (2003)

Kim, D.-K., Lee, H., Kim, D., Kim, Y.K.: J. Cryst. Growth. 283, 404 (2005)

Escobar, D., Ospina, R., Gómez, A.G., Restrepo-Parra, E., Arango, P.J.: Mater. Charact. 88, 119 (2014)

Subramanian, B., Ashok, K., Kuppusami, P., Sanjeeviraja, C., Jayachandran, M.: Cryst. Res. Technol. 43, 1078 (2008)

Irudayaraj, A.A., Kuppusami, P., Thirumurugesan, R., Mohandas, E., Kalainathan, S., Raghunathan, V.S.: Surf. Eng. 23, 7 (2007)

Deviaa, D.M., Restrepo-Parraa, E., Arango, P.J., Tschiptschin, A.P., Velez, J.M.: Appl. Surf. Sci. 257, 6181 (2011)

Chang, Y.-Y., Wang, D.-Y., Hung, C.-Y.: Surf. Coat. Technol. 200, 1702 (2005)

Subramanian, Brindha, Makoto, Hiroshi and Akira 2011 Trans. JWRI 40 55

Aihua, L., Jianxin, D., Haibing, C., Yangyang, C., Jun, Z.: Int. J. Refra Metals Hard Mater. 31, 82 (2012)

Ipaz, L., Caicedo, J.C., Esteve, J., Espinoza-Beltran, F.J., Zambrano, G.: Appl. Surf. Sci. 258, 3805 (2012)

Milosev, I., Strehblow, H.-H., Navinsek, B.: Surf. Coat. Technol. 74–75, 897 (1995)

Alami, J., Sarakinos, K., Uslu, F., Wuttig, M.: J. Phys. D. Appl. Phys. 42, 015304 (2009)

Kelesoglu, E., Mitterer, C., Kazmanli, M.K., Ürgen, M.: Surf. Coat. Technol. 133, 116 (1999)

Olaya, J.J., Rodil, S.E., Muhl, S.: Thin Solid Films. 474, 119 (2005)

Hultman, L., Munz, W.D., Musil, J., Kadlec, S., Petrov, I., Greene, J.E.: J. Vac. Sci. Technol. A. 9, 434 (1992)

Ponsonnet, L., Reybier, K., Jaffrezic, N., Comte, V., Lagneau, C., Lissac, M., Martelet, C.: Mater. Sci. Eng. C. 23, 551 (2003)

Fenker, M., Balzer, M., Kappl, H.: Surf. Coat. Technol. 257, 182 (2014)

Cunha, L., Andritschky, M., Rebouta, L., Pischow, K.: Surf. Coat. Technol. 116-119, 1152 (1999)

Aromaa, J., Ronkainen, H., Mahiout, A., Hannula, S.-P.: Surf. Coat. Technol. 49, 353 (1991)

Webb, K., Hlady, V., Tresco, P.: J. Biomed. Mater. Res. 41, 422 (1998)

Chien, C.-C., Liu, K.-T., Duh, J.-G., Chang, K.-W., Chung, K.-H.: Dent. Mater. 24, 986 (2008)

Hallab, N.J., Bundy, K.J., O’Connor, K., Moses, R.L., Jacobs, J.J.: Tissue Eng. 7, 55 (2001)

Zhang, Y.M., Bataillon-Linez, P., Huang, P., Zhao, Y.M., Han, Y., Traisnel, M., Xu, K.W., Hidebrand, H.F.: J. Biomed. Mater. Res. 68A, 383 (2004)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El-Hossary, F.M., El-Rahman, A.M.A., Raaif, M. et al. Physical, electrochemical, and biocompatibility characteristics of Ti-Al-N thin film synthesized by DC pulsed magnetron sputtering. J Aust Ceram Soc 56, 1155–1165 (2020). https://doi.org/10.1007/s41779-020-00449-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-020-00449-1